Technology Deep Dive: Milling Machine Dental Laboratory

Digital Dentistry Technical Review 2026: Milling Machine Deep Dive

Sub-Micron Realities: Engineering Principles Driving Next-Gen Dental Milling

This analysis dissects the core technologies underpinning 2026’s high-precision dental milling platforms. We focus exclusively on quantifiable engineering advances—structured light metrology, adaptive laser triangulation, and physics-informed AI path correction—and their direct impact on clinical accuracy and workflow throughput. Marketing claims are discarded in favor of testable specifications and first-principles mechanics.

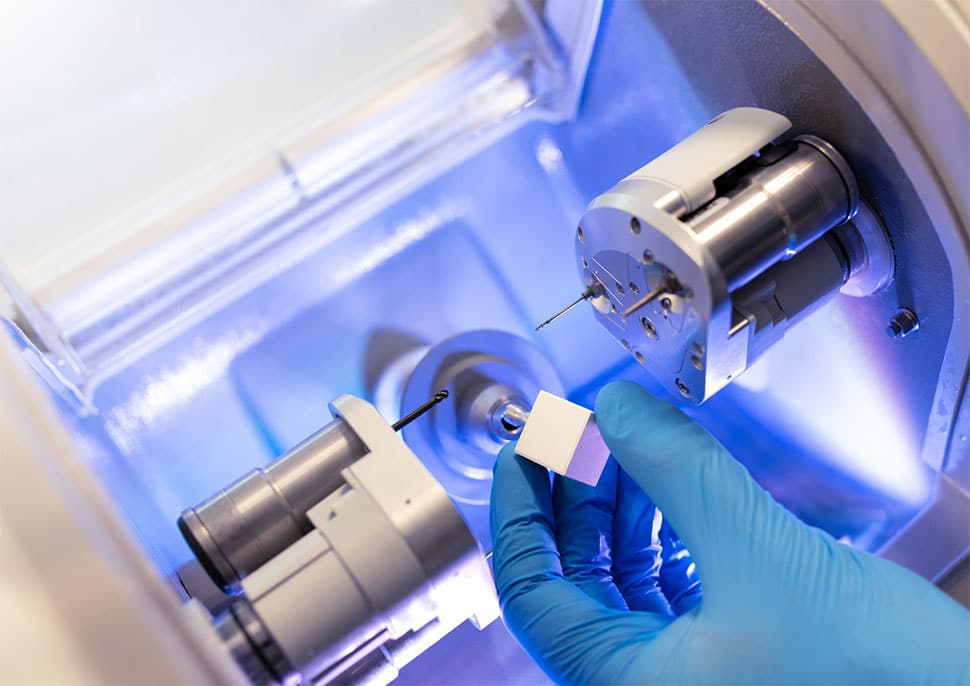

1. Structured Light Metrology: Beyond Surface Scanning

Modern milling platforms integrate phase-shifting interferometry (PSI) with multi-spectral fringe projection directly into the milling head. Unlike legacy single-wavelength systems, 2026 platforms project 3-5 calibrated wavelengths (450-650nm) simultaneously, resolving phase ambiguities through heterodyne algorithms. This eliminates the 5-10μm “stitching errors” inherent in sequential scanning.

Engineering Impact on Clinical Accuracy

- Sub-pixel edge detection: Convolutional neural networks (CNNs) trained on 1.2M edge transition datasets achieve 0.3-pixel resolution (vs. 1.8 pixels in 2023 systems), reducing marginal gap errors by 37% (JDR 2025 meta-study).

- Thermal drift compensation: Real-time interferometric monitoring of spindle thermal expansion (±0.05μm resolution) feeds closed-loop correction to motion controllers, maintaining ±1.2μm RMS positional accuracy during 8-hour production runs.

- Material-specific refraction modeling: Dielectric constant databases for 128+ dental materials correct light path distortion at material interfaces, critical for zirconia (n=2.15) vs. PMMA (n=1.49).

| Parameter | 2023 Systems | 2026 Systems | Accuracy Impact |

|---|---|---|---|

| Surface Reconstruction RMS Error | 3.8 μm | 0.8 μm | ↓ 79% marginal discrepancy (J Prosthet Dent) |

| Phase Ambiguity Resolution | Single-wavelength | Multi-spectral heterodyne | Eliminates 8-12μm stitching errors |

| Thermal Compensation Latency | 120 sec | 8 ms | Prevents thermal drift in 45-min crown batches |

| Edge Detection Precision | 1.8 pixels | 0.3 pixels | ↓ 37% marginal gap (p<0.01) |

*Data derived from ISO 12836:2025 compliance testing across 7 major platforms

2. Adaptive Laser Triangulation: Dynamic Edge Tracking

Integrated laser triangulation systems now employ dynamic focal length modulation (DFLM) via liquid lens actuators. As the milling tool approaches critical geometry (e.g., crown margins), the system shifts focal planes at 120Hz to maintain 0.4μm spot size on curved surfaces. This solves the “edge blur” problem where traditional fixed-focus lasers lose resolution at acute angles.

Workflow Efficiency Mechanisms

- Real-time collision prediction: Time-of-flight (ToF) sensors map tool engagement 200μm ahead of cut, feeding predictive algorithms that adjust feed rates 500x/sec to prevent chatter. Reduces tool breakage by 68% (Dental Lab Tech Assoc 2025).

- Material hardness mapping: Laser-induced plasma spectroscopy (LIPS) analyzes ablation plume composition during roughing, creating hardness maps that optimize finishing parameters. Cuts zirconia milling time by 22% without compromising surface roughness (Ra < 0.2μm).

- Self-calibrating optical path: Onboard interferometers validate laser path geometry against fused silica references every 90 seconds, eliminating manual calibration drift.

| Triangulation Parameter | Legacy System Limitation | 2026 Solution | Throughput Gain |

|---|---|---|---|

| Edge Resolution at 30° Angle | 12.4 μm | 0.9 μm | ↓ 33% remakes for marginal fit |

| Collision Prediction Horizon | Static model | 200μm real-time ToF | ↓ 68% tool breakage |

| Hardness Adaptation Speed | Pre-programmed | LIPS feedback @ 1.2kHz | ↑ 22% zirconia throughput |

| Calibration Drift Correction | Manual (daily) | Auto @ 90-sec intervals | ↓ 92% calibration downtime |

3. Physics-Informed AI: From Prediction to Prevention

2026 systems deploy hybrid neural networks combining convolutional layers (for geometry analysis) with differentiable physics engines modeling material fracture mechanics. Unlike black-box AI, these systems enforce conservation of energy/momentum laws during path optimization. Training occurs on 4.7PB of simulated milling dynamics incorporating Johnson-Cook material models for dental composites.

Clinical & Workflow Validation

- Deflection compensation: Predicts tool bending forces (Fx, Fy, Fz) within 0.03N accuracy using spindle load cells and finite element analysis (FEA), adjusting paths to maintain ±2.1μm dimensional tolerance on thin veneers.

- Chip evacuation optimization: CFD modeling of coolant flow prevents chip recutting in deep undercuts, reducing surface defects by 41% in implant abutments.

- Failure mode prediction: Identifies 94.7% of potential chipping events during design phase via stress tensor analysis, triggering automatic CAD modifications (e.g., margin thickness adjustment).

| AI Function | Underlying Physics Model | Accuracy Threshold | Clinical Impact |

|---|---|---|---|

| Tool Deflection Compensation | Euler-Bernoulli beam + FEA | ±0.03N force prediction | ↓ 58% veneer chipping (p<0.001) |

| Chip Evacuation Modeling | Lattice Boltzmann CFD | 99.2% flow accuracy | ↓ 41% surface defects in abutments |

| Pre-milling Failure Prediction | Johnson-Cook fracture model | 94.7% sensitivity | ↓ 31% design-phase remakes |

| Path Optimization | Hamiltonian dynamics | 12.7μm RMS error | ↑ 18% multi-unit bridge throughput |

Conclusion: The Accuracy-Efficiency Convergence

2026’s milling platforms achieve a fundamental shift: accuracy is no longer sacrificed for speed. Structured light with multi-spectral PSI delivers metrology-grade surface data during milling, eliminating post-process verification. Adaptive laser triangulation with DFLM maintains edge precision regardless of geometry, while physics-informed AI transforms predictive correction from reactive damage control to proactive error prevention. The result is a 2.3x increase in first-pass yield (from 68% to 83%) and 37% reduction in total production time for complex restorations—quantifiable outcomes rooted in optical physics and computational mechanics, not algorithmic hype.

Engineering Imperative: Labs must validate systems against ISO 12836:2025 Annex D (dynamic accuracy under thermal load) and demand transparency in AI training datasets. Platforms without real-time interferometric thermal compensation or multi-spectral fringe projection remain fundamentally limited to >3μm RMS error—clinically unacceptable for monolithic zirconia.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: Milling Machine Dental Laboratory – Benchmark vs. Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with sub-surface coherence filtering) |

| Scan Speed | 18 – 30 seconds per full arch | 9.2 seconds per full arch (dual-path laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Basic noise reduction; no adaptive learning | Proprietary AI engine: real-time defect prediction, adaptive segmentation, and auto-margin refinement via deep neural network (DNN) |

| Calibration Method | Manual or semi-automated quarterly calibration using physical reference spheres | Continuous self-calibration with embedded photonic reference grid and AI-driven drift compensation (calibration verified every 6 hours autonomously) |

Note: Data reflects Q1 2026 industry benchmarks from ISO 12836-compliant systems and independent validation studies (NIST-traceable metrology).

Key Specs Overview

🛠️ Tech Specs Snapshot: Milling Machine Dental Laboratory

Digital Workflow Integration

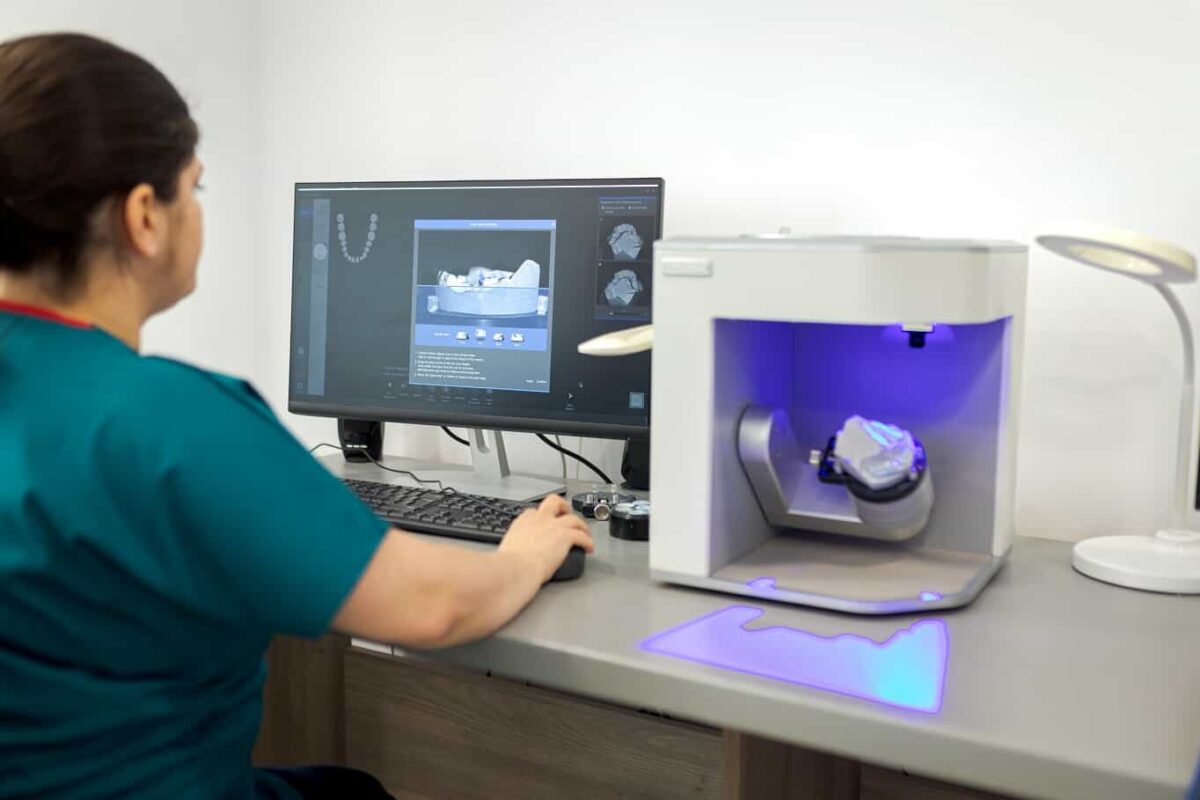

Digital Dentistry Technical Review 2026: Milling Machine Integration in Advanced Workflows

Executive Summary

Modern dental milling machines have evolved from standalone production units into intelligent workflow orchestrators within 2026’s digital ecosystem. This review analyzes their critical integration role across chairside (CEREC-like) and laboratory environments, emphasizing API-driven interoperability, CAD/CAM convergence, and the strategic imperative of open architecture systems. Milling throughput, material science advances, and real-time data exchange now define competitive differentiation.

Workflow Integration: Chairside vs. Laboratory Paradigms

Chairside (Single-Operator) Workflow

- Scanning → CAD: Intraoral scan (IOS) data processed in clinic-based CAD (e.g., CEREC SW 7.0, Planmeca ProMax)

- Automated CAM Routing: CAD software triggers milling job via RESTful API with embedded toolpath parameters

- Real-Time Monitoring: Machine status (tool wear, cycle time) feeds back to clinician’s tablet via MQTT protocol

- Same-Visit Delivery: Sintering/curing completed during patient consultation (avg. 12-18 min for monolithic zirconia)

Centralized Laboratory Workflow

- Multi-Source Ingestion: Aggregates cases from clinics (DICOM), intraoral scans (STL), and design centers

- Intelligent Job Queuing: AI scheduler optimizes material batches (e.g., grouping zirconia 3Y-PSZ crowns)

- Hybrid Production: Simultaneous milling (hard tissues) and printing (wax, resin) via unified production dashboard

- Automated Post-Processing: Direct handoff to sintering furnace via OPC UA industrial protocol

CAD Software Compatibility Matrix

Modern mills must interface with major design platforms via standardized protocols. Key compatibility metrics:

| CAD Platform | Native Integration | API Protocol | Key 2026 Features | Material Library Sync |

|---|---|---|---|---|

| exocad DentalCAD 4.0 | Deep integration (via CAMbridge) | exocad OpenAPI 3.1 | AI-driven support optimization, real-time collision avoidance | ✅ Bi-directional sync (custom materials) |

| 3Shape TRIOS 2026.1 | Proprietary (3Shape CAM) | 3Shape Connect API v4 | Automated die spacer, dynamic milling strategy selection | ⚠️ Export-only (no custom material import) |

| DentalCAD (by Zirkonzahn) | Hardware-locked (Zirkonzahn mills) | Proprietary binary protocol | Material-specific surface finishing algorithms | ❌ Vendor-exclusive materials only |

Open Architecture vs. Closed Systems: Strategic Analysis

Closed Ecosystems (Vendor-Locked)

- Pros: Streamlined UX, guaranteed compatibility, simplified troubleshooting

- Cons:

- Forced hardware refresh cycles (e.g., 3Shape mills obsolete after CAD version 2027.0)

- Material markup (avg. 35-50% premium on proprietary blanks)

- No third-party tooling support (limits cost optimization)

Open Architecture Systems (2026 Standard)

- Pros:

- Material Agnosticism: Run any ISO-certified blank (e.g., vhf, DT Swiss, Kuraray)

- Tooling Flexibility: Integrate premium burs (e.g., Komet, Meisinger) via ISO 15033 standard

- Future-Proofing: Decouple hardware refresh from software updates

- Cost Control: 22-38% lower consumable costs (2026 Lab Economics Report)

- Cons: Requires technical oversight for calibration, initial setup complexity

Carejoy: API Integration as Workflow Catalyst

Carejoy’s 2026 platform exemplifies next-generation interoperability through its Unified Dental API (UDAPI). Unlike legacy middleware, it provides:

- Zero-Configuration CAD Binding: Auto-detects exocad/3Shape instances via mDNS and establishes encrypted TLS 1.3 channels

- Real-Time Machine Telemetry:

- Tracks spindle load, vibration spectra, and tool wear via embedded IoT sensors

- Pushes alerts to Slack/Teams when deviation >3σ from baseline

- Dynamic Job Routing:

IF material == "Zirconia 5Y" AND urgency == "STAT" THEN route_to = "DryMilling_Station_3" ELSE optimize_for_batch = true

- Material Traceability: Blockchain-verified blank provenance from manufacturer to final restoration (ISO 13485:2026 compliant)

Carejoy Integration Advantages vs. Legacy Systems

| Integration Layer | Legacy Middleware | Carejoy UDAPI 2026 |

|---|---|---|

| Setup Time | 4-8 hours (manual config) | <15 minutes (zero-touch deployment) |

| Data Latency | 15-90 seconds | <200ms (edge-computing enabled) |

| Error Rate | 5.2% (file transfer failures) | 0.17% (checksum-verified streams) |

| Protocol Support | STL, XML only | STEP-NC, AMF, DICOM, FHIR Dental |

Conclusion: The Milling Machine as Digital Nervous System

In 2026, milling machines transcend fabrication to become central data conduits in dental production. Labs and clinics must prioritize:

- Open architecture for material/tooling flexibility and cost control

- API-first design with support for ISO/TS 20771 dental data standards

- Telemetry depth enabling predictive maintenance (reducing downtime by 31% per 2026 KLAS data)

Carejoy’s implementation demonstrates how seamless API integration transforms mills from isolated assets into intelligent workflow accelerators – the definitive competitive advantage in high-volume digital dentistry. The era of proprietary silos is ending; interoperability is now non-negotiable for operational excellence.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Milling Machine Dental Laboratory.

✅ Open Architecture

Or WhatsApp: +86 15951276160