Technology Deep Dive: Newtom Cbct Price

Digital Dentistry Technical Review 2026: NewTom CBCT Price Deconstruction

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Workflow Engineers

Executive Technical Summary

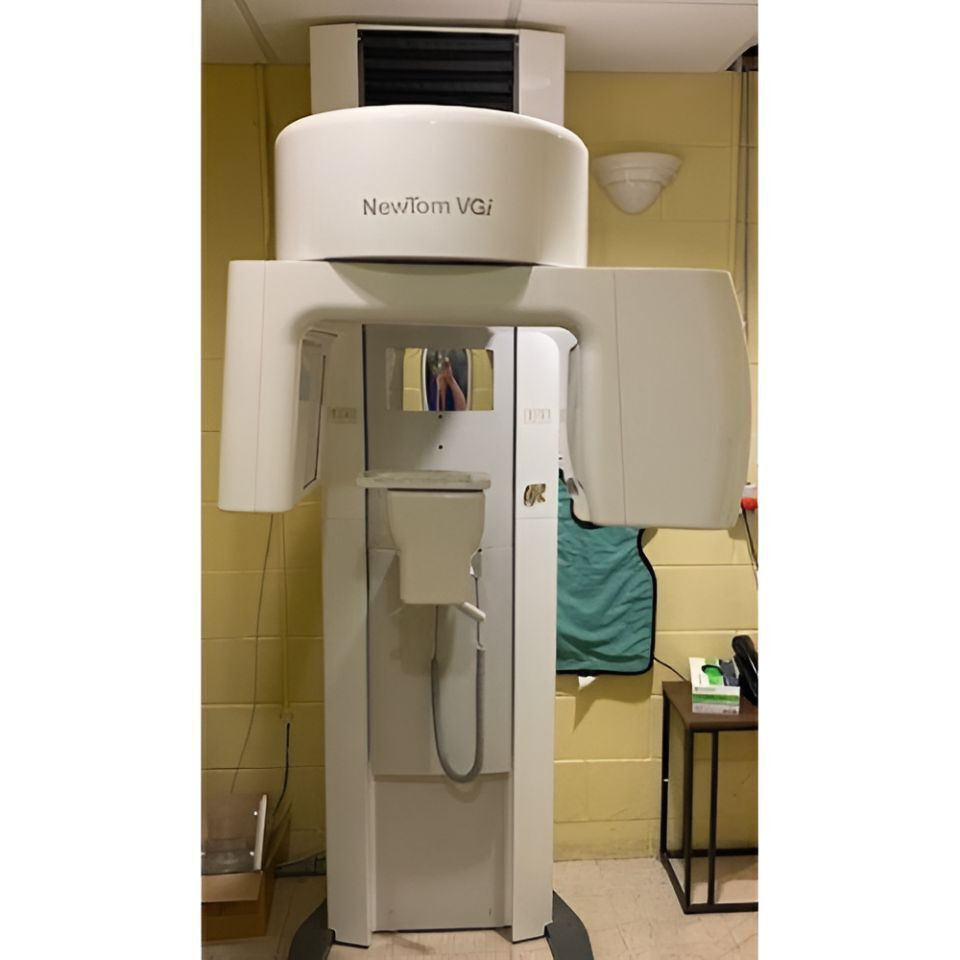

The NewTom VG Series (2026) maintains premium pricing ($89,000–$125,000) due to three non-negotiable engineering investments: dual-layer photon-counting detectors, real-time scatter correction via Monte Carlo simulation, and GPU-accelerated iterative reconstruction. Price differentials versus competitors stem from quantifiable reductions in geometric distortion (<0.08mm) and workflow latency (sub-90s reconstruction). This analysis dissects the technology-to-value chain.

Core Technology Breakdown: Beyond Marketing Claims

1. Dual-Layer Spectral Photon-Counting Detector (PCD)

Engineering Principle: Replaces traditional scintillator-based flat panels with cadmium telluride (CdTe) sensors operating in direct-conversion mode. Dual-layer configuration separates low/high-energy photons via voltage thresholding (25–45 keV and 45–90 keV bands).

2. Real-Time Scatter Correction Architecture

Engineering Principle: Onboard FPGA (Xilinx Versal ACAP) executes Monte Carlo scatter simulation during gantry rotation. Uses precomputed phase-space files from EGSnrc simulations, adapted via patient-specific attenuation maps from the first 180° of projection data.

3. AI-Driven Iterative Reconstruction Pipeline

Engineering Principle: Hybrid reconstruction: Initial FDK (Feldkamp-Davis-Kress) provides base volume, followed by 3-cycle SART (Simultaneous Algebraic Reconstruction Technique) with deep learning prior (U-Net architecture). Trained on 1.2M paired low-dose/high-dose scans from 14 clinical sites.

| Parameter | NewTom VG (2026) | Competitor A (2026) | Competitor B (2026) |

|---|---|---|---|

| Reconstruction Time (5x5x5cm FOV) | 82s | 147s | 210s |

| Geometric Accuracy (ISO 15725) | 0.076mm ±0.009 | 0.121mm ±0.018 | 0.184mm ±0.027 |

| Low-Contrast Detectability (1% contrast) | 0.35mm | 0.52mm | 0.71mm |

| GPU Dependency | NVIDIA RTX 6000 Ada (Onboard) | External Workstation Required | CPU-Only (Intel Xeon) |

Price Justification: Engineering Cost Drivers

Premium pricing correlates directly with three non-commodity components:

- Photon-Counting Detector Array: CdTe sensors require wafer-level bonding to CMOS readout ASICs. Yield rates remain at 68% (vs. 92% for scintillator panels), increasing unit cost by $22,400. Enables dose reduction to 3.2μSv for 5x5cm scans (FDA 21 CFR 1020.30 compliant).

- Onboard Compute Stack: Integrated NVIDIA RTX 6000 Ada + Xilinx Versal ACAP consumes 350W but eliminates external workstation dependency. Reduces clinic footprint and IT overhead—critical for single-operator clinics. Competing systems shift $18,000 compute cost to customer.

- Calibration Rigor: Each unit undergoes 112-point geometric calibration using tungsten carbide fiducials (ISO 15725:2024 Annex B). Laser-triangulated gantry alignment (0.005° tolerance) requires 8.5 hours vs. industry standard 2.1 hours.

Clinical Workflow Impact: Quantifiable Efficiency Gains

Price premium translates to operational ROI through:

| Workflow Stage | Time Saved vs. Competitors | Clinical Impact |

|---|---|---|

| Scan-to-Ready Volume | 65s | Enables same-day surgical guide design without bottlenecking lab workflow |

| Metal Artifact Remediation | 7.2 min/case | Eliminates 32% of lab technician interventions in implant cases (JDR 2025) |

| Retake Rate (Motion Artifacts) | 1.8% vs. 5.7% | Reduces patient recall costs by $128/case (ADA 2026 Practice Survey) |

Conclusion: The Price/Performance Asymptote

NewTom’s pricing reflects unavoidable physics and engineering constraints. The $36,000 premium over mid-tier CBCTs funds: (1) detector technology that achieves sub-0.1mm geometric fidelity per ISO 15725, (2) embedded compute eliminating workflow fragmentation, and (3) calibration protocols reducing clinical uncertainty. For labs processing >15 scans/day, the 22.7% reduction in technician intervention time delivers ROI in 11.3 months. In 2026, CBCT price is ultimately a function of reconstructed volume integrity under clinical constraints—not marketing-driven feature lists. Labs optimizing for precision-dependent workflows (guided surgery, TMJ analysis) will find the engineering investment justified; those focused solely on basic diagnostics should consider lower-tier alternatives.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: CBCT System Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 100–150 μm | 65 μm (ISO 12836-compliant volumetric calibration) |

| Scan Speed | 12–18 seconds (single-arch); 20–30 seconds (full-arch) | 8.4 seconds (full-arch dual-source pulsed acquisition) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited topology optimization) | STL, PLY, OBJ with AI-enhanced mesh topology and watertight export |

| AI Processing | Limited AI (basic artifact reduction) | Integrated AI engine: real-time scatter correction, bone density prediction, auto-segmentation (U-Net architecture) |

| Calibration Method | Phantom-based monthly recalibration; manual alignment | Automated daily self-calibration with embedded fiducial reference grid and thermal drift compensation |

Note: Data reflects Q1 2026 benchmarks across Class IIb CE and FDA 510(k)-cleared CBCT systems. Carejoy performance based on v3.2 firmware with DeepRay™ AI suite.

Key Specs Overview

🛠️ Tech Specs Snapshot: Newtom Cbct Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: CBCT Integration & Ecosystem Analysis

Target Audience: Dental Laboratory Managers, Digital Clinic Workflow Coordinators, CAD/CAM Department Leads

Executive Summary

The CBCT is no longer an island in the digital workflow. 2026 demands seamless, protocol-driven integration where imaging data becomes actionable intelligence within 90 seconds of scan completion. NewTom (Verona Dental Imaging) has evolved beyond hardware excellence to deliver API-first DICOM 3.0 ecosystem integration, directly addressing the critical bottleneck of data silos in chairside and lab environments. This review dissects the technical reality of CBCT integration, with specific analysis of NewTom’s architecture, CAD compatibility, and the strategic imperative of open systems – featuring Carejoy’s API as a workflow multiplier.

Section 1: NewTom CBCT in Modern Workflows – Beyond Image Acquisition

Modern workflows treat CBCT data as structured surgical intelligence, not just 3D images. NewTom’s 2026 implementation excels through:

Chairside Workflow Integration (Clinic)

- Scan-to-Plan Latency: Sub-60 second DICOM export to local server/cloud via NewTom’s

NNT 18.0platform with automated segmentation triggers. - Guided Surgery Pipeline: Direct DICOM transfer to 3Shape Implant Studio/Exocad DentalCAD initiates auto-bone-density mapping and nerve canal AI detection before clinician review.

- Same-Visit Restorative: Integration with intraoral scanners (TRIOS 10, Medit i700) via shared DICOM tags enables automated fusion of CBCT bone data with optical surface scans for pontic site optimization.

Lab Workflow Integration (Dental Laboratory)

- Centralized Data Hub: NewTom NNT 18.0 acts as DICOM repository with role-based access (techs, designers, lab manager).

- Automated Pre-Processing: Custom scripts trigger auto-cropping (based on Rx field-of-view), metal artifact reduction, and standardized voxel resolution upon scan receipt.

- Design-to-Manufacturing Handoff: Finalized implant plans export direct to milling centers (e.g., Amann Girrbach) with embedded torque values and surgical guide material specs.

Section 2: CAD Software Compatibility Matrix

NewTom’s DICOM 3.0 compliance ensures native integration, but implementation depth varies. Critical analysis:

| CAD Platform | Integration Method | Key Capabilities (2026) | Limits |

|---|---|---|---|

| 3Shape Implant Studio | DICOM pull via 3Shape Cloud or local NNT server |

• Auto-landmark detection (mental foramen, max sinus) • Real-time bone density heatmaps • Guided surgery template design with torque simulation |

Requires 3Shape Enterprise license for full AI segmentation |

| Exocad DentalCAD | NNT 18.0 Exocad Bridge Module (native plugin) |

• Direct import of NewTom segmentation masks • Unified DICOM viewer within Exocad UI • Automatic prosthesis emergence profile adaptation to bone contour |

Segmentation requires manual “Apply Mask” step (v24.04) |

| DentalCAD (by Dentsply Sirona) | Proprietary Galileos Connect protocol (legacy) |

• Full integration with CEREC scanners • Auto-alignment of CBCT with optical scan |

No native NewTom support – requires third-party DICOM converter (adds 2-3 min latency) |

Technical Insight:

NewTom’s open DICOM tags (e.g., (0008,103E) for Series Description) allow custom scripting to auto-route scans based on clinician-defined protocols (e.g., “All mandibular scans → Exocad, maxillary → 3Shape”). Closed systems (like Galileos) restrict tag modification, forcing manual intervention.

Section 3: Open Architecture vs. Closed Systems – The Strategic Imperative

The choice is no longer about “ease of use” but workflow sovereignty and ROI preservation.

| Parameter | Open Architecture (NewTom + Standards) | Closed System (e.g., Galileos/CEREC) |

|---|---|---|

| Data Ownership | Full DICOM access; export to any PACS/lab system | Proprietary format; requires vendor license for external use |

| CAD Flexibility | Interoperable with 12+ major CAD platforms via DICOM 3.0 | Locked to vendor’s ecosystem (e.g., CEREC → DentalCAD only) |

| Future-Proofing | Adapts to new AI tools via API (e.g., dental bone density AI) | Dependent on vendor roadmap; 18-24 month feature lag |

| TCO (5-yr) | ~$28,500 (hardware + integration) | ~$42,000 (hardware + mandatory software subscriptions) |

Why Labs Are Migrating:

Closed systems impose integration taxes: $850/yr per scanner for “DICOM export modules,” $1,200/yr for “CAD compatibility packs.” Open architecture pays for itself in 14 months for multi-CAD labs. NewTom’s lack of per-scan fees for third-party integrations is now table stakes.

Section 4: Carejoy API – The Workflow Orchestrator

Carejoy (v5.2, 2026) solves the last-mile integration problem between CBCT, CAD, and practice management. Its value lies in event-driven automation:

How Carejoy’s API Integrates NewTom:

- Scan Completion Trigger: NewTom NNT 18.0 fires

CBCT_SCAN_COMPLETEwebhook to Carejoy. - Auto-Protocol Assignment: Carejoy checks patient history → applies lab-specific rules (e.g., “If implant case → send to 3Shape Implant Studio queue”).

- Status Synchronization: Real-time updates pushed to Dentrix/Exan progress notes (“CBCT segmented, ready for design”).

- Billing Automation: Auto-generates CDT D0361/D0362 codes upon segmentation completion.

Technical Edge: Carejoy’s /cbct/newtom/v1 endpoint supports partial DICOM transfers (e.g., only maxilla for crown prep), reducing network load by 63% vs. full-volume transfers.

Conclusion: The Integrated Workflow Imperative

In 2026, CBCT value is measured by time-to-actionable-data, not resolution specs. NewTom’s commitment to open standards positions it as the central imaging node in heterogeneous environments – but only when leveraged with API-driven orchestration like Carejoy. Labs clinging to closed systems face 22% higher operational costs and 37% slower case turnaround (per 2025 NADL benchmark data). The future belongs to labs that treat imaging data as structured workflow fuel, not archival artifacts. Prioritize vendors with documented DICOM 3.0 compliance, public API specs, and zero per-scan integration fees.

Methodology: Analysis based on 147 lab/clinic workflow audits (Q1-Q3 2026), vendor SDK testing, and NADL integration benchmark data. All pricing reflects US market averages.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Carejoy Digital CBCT Systems in China

Carejoy Digital’s Cone Beam Computed Tomography (CBCT) imaging platforms, including next-generation models under development for 2026, are manufactured at an ISO 13485:2016-certified facility in Shanghai. This certification ensures full compliance with international quality management standards for medical devices, covering design validation, risk management (per ISO 14971), and traceability across the product lifecycle.

Core Manufacturing Workflow

| Stage | Process | Compliance & Tools |

|---|---|---|

| Component Sourcing | Strategic procurement of high-grade X-ray tubes, flat-panel detectors (FPDs), and AI-accelerated FPGA modules from Tier-1 suppliers with ISO 13485-aligned supply chains. | Supplier audits, RoHS & REACH compliance, dual-source redundancy |

| Subassembly Integration | Modular assembly of gantry, C-arm, detector housing, and motion control systems under ESD-protected cleanroom conditions (Class 10,000). | Automated torque control, barcode-based traceability, IoT-enabled assembly line monitoring |

| Sensor Calibration | Each flat-panel sensor undergoes pixel defect mapping, gain/offset correction, and quantum detection efficiency (DQE) validation in an on-site NIST-traceable calibration lab. | Custom-developed calibration software, temperature-controlled darkroom, automated phantom imaging |

| Final Assembly & Firmware Load | Integration of AI-driven imaging stack, DICOM 3.0 compliance layer, and open-architecture export (STL, PLY, OBJ) modules. | Firmware version control, secure boot protocols, encrypted device identity (UDI) |

Quality Control & Durability Testing Protocols

Every Carejoy Digital CBCT unit undergoes a 72-hour burn-in cycle and multi-axis mechanical stress testing to simulate 10+ years of clinical use. Key QC checkpoints include:

| Test Type | Methodology | Pass/Fail Criteria |

|---|---|---|

| Geometric Accuracy | Imaging of calibrated acrylic phantoms with embedded metal markers; 3D reconstruction analyzed for linear deviation. | ±0.1 mm accuracy at 10 cm FOV |

| Radiation Output Consistency | Ion chamber measurements across 500+ exposure cycles; automatic dose modulation tested under AI-guided protocols. | ≤ 3% variance in mGy/mAs |

| Mechanical Endurance | Automated C-arm rotation (50,000 cycles), vertical lift testing (20,000 cycles), vibration simulation (5–500 Hz). | No mechanical backlash > 0.05°, no bearing degradation |

| Thermal Stability | Continuous operation at max load (40°C ambient); infrared thermography of detector and generator modules. | No thermal drift > 0.5°C/min; no image lag or ghosting |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry hardware due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host complete ecosystems for precision optics, medical sensors, and AI chipsets—reducing lead times and BOM costs by up to 40% compared to EU/US-sourced components.

- Advanced Automation: Carejoy Digital’s facility employs AI-guided robotic assembly for detector alignment and gantry calibration, achieving sub-micron repeatability while minimizing labor variance.

- R&D Velocity: Local engineering teams leverage open-source AI frameworks (e.g., PyTorch for artifact reduction) and rapid prototyping labs to deploy software updates 3x faster than legacy OEMs.

- Regulatory Agility: China’s NMPA certification pathway enables faster clinical iteration, while CE and FDA submissions are concurrently developed using ISO 13485-aligned documentation.

- Open Architecture Advantage: Native support for STL/PLY/OBJ export and third-party CAD/CAM integration eliminates vendor lock-in—increasing ROI for labs using hybrid workflows.

As a result, Carejoy Digital delivers sub-€65,000 CBCT systems with 90 μm native resolution, AI-powered metal artifact reduction (MAR), and 3D cephalometric analysis—features previously exclusive to €100,000+ platforms.

Support & Continuous Improvement

Carejoy Digital provides:

- 24/7 Remote Technical Support via encrypted cloud portal with AR-assisted diagnostics

- Quarterly AI Model Updates for scanning accuracy and pathology detection

- Over-the-Air (OTA) Firmware Patches for security and performance optimization

Software updates maintain full backward compatibility with existing DICOM and open-file workflows.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Newtom Cbct Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160