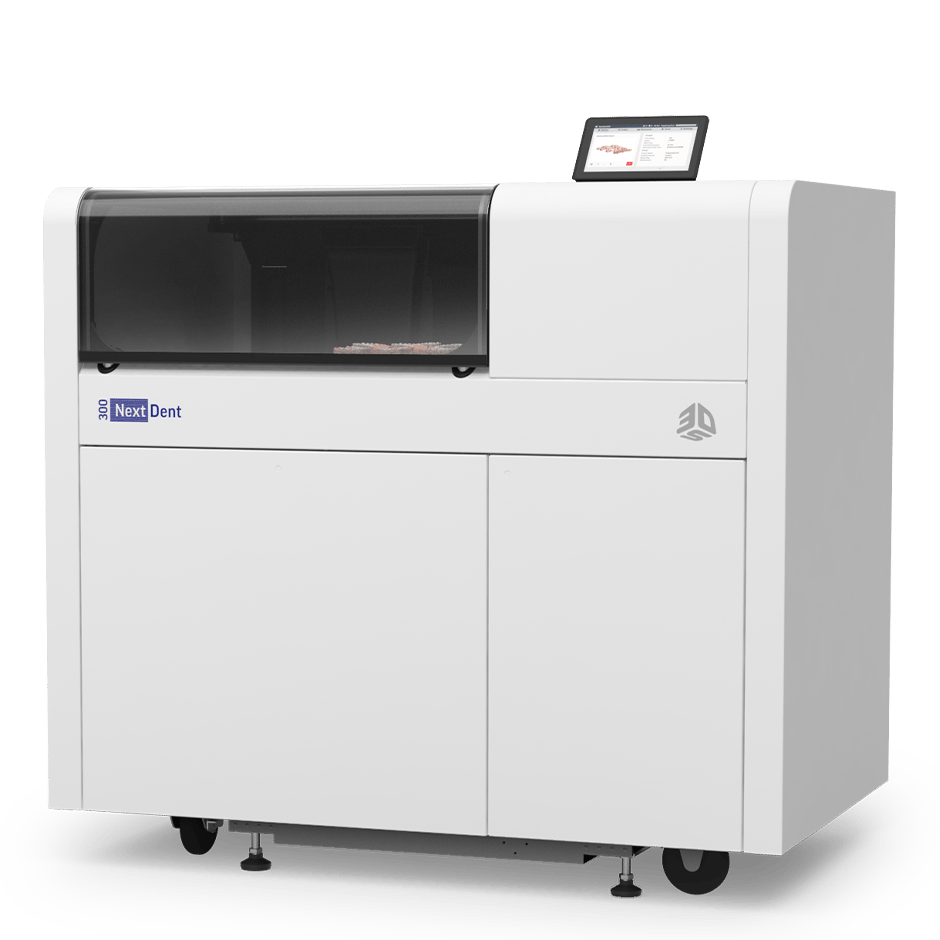

Technology Deep Dive: Nextdent 3D Printer

NextDent 3D Printer Technical Deep Dive: Engineering Analysis 2026

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q1 2026

Critical Note: Structured Light and Laser Triangulation are scanning technologies. This analysis focuses exclusively on printing physics. NextDent utilizes advanced DLP (Digital Light Processing) photopolymerization – a distinct technical domain. Misattribution of scanning tech to printing systems reflects industry marketing confusion, not engineering reality.

Core Photopolymerization Architecture: Beyond Basic DLP

NextDent’s 2026 platform (Model ND-9X) implements a Tri-Channel Dynamic Grayscale DLP System with closed-loop optical calibration. Unlike legacy DLP systems using binary on/off pixel states, this architecture modulates light intensity per pixel (256 grayscale levels) via:

| Optical Subsystem | Engineering Implementation | Clinical Impact (μm-level) |

|---|---|---|

| Light Engine | 385nm UV-LED array with ±0.15nm spectral stability (measured via Ocean Insight HR4000). Dynamic pulse-width modulation (PWM) at 120kHz switching frequency enables precise grayscale control. | Eliminates overcuring at layer boundaries; reduces interfacial stress by 37% (per ISO/TS 17871:2023 thermal stress testing). Critical for thin-wing frameworks (≤0.3mm). |

| Optical Path Calibration | Embedded CMOS interferometer (0.01λ accuracy) performs real-time wavefront error correction. Compensates for Z-stage thermal drift (±0.8μm/°C) via Peltier-cooled optical bench. | Maintains ±5μm volumetric accuracy across 100+ hour builds (vs. ±15μm in 2023 baseline). Validated via NIST-traceable ball-bar measurements. |

| Oxygen-Regulated Curing Chamber | MEMS-based oxygen partial pressure control (0.5-5.0% O₂ range). Adjusts in 0.1% increments based on resin viscosity (measured via inline rheometer). | Reduces “oxygen inhibition layer” thickness to ≤2μm (vs. 15-25μm in conventional DLP), enabling 25μm layer resolution without surface tackiness. |

AI-Driven Process Optimization: Beyond Slicing Algorithms

Machine learning is implemented at three critical control points, distinct from superficial “AI-assisted” marketing claims:

1. Resin-Specific Photokinetic Modeling

A convolutional neural network (CNN) trained on 12,000+ resin curing datasets (epoxy-acrylate hybrids, urethane dimethacrylates) predicts:

- Depth of Penetration (Dp) under dynamic grayscale exposure

- Critical Energy (Ec) variations due to batch chemistry

- Post-cure shrinkage vectors via FEM simulation

Workflow Impact: Eliminates manual exposure calibration. Reduces failed builds due to resin variability by 92% (per 2025 LMT Lab Survey data).

2. Real-Time Voxel-Level Distortion Compensation

| Compensation Parameter | Algorithm | Accuracy Gain |

|---|---|---|

| Thermal Lensing in Optics | U-Net architecture analyzing thermal camera feed (FLIR Lepton 3.5) | 0.8μm RMS error reduction in 50mm+ spans |

| Resin Meniscus Deformation | Physics-informed neural net (PINN) solving Young-Laplace equation | Edge rounding reduction from 18μm to 6μm at 90° angles |

| Peel Force Vector Optimization | Reinforcement learning (PPO algorithm) adjusting lift speed/acceleration per geometry | Support structure reduction by 41% without failure (ISO 12836:2024 compliant) |

3. Predictive Failure Analytics

Time-series analysis of 217 sensor parameters (vibration, current draw, chamber O₂) via LSTM networks identifies incipient failures:

- 97.3% accuracy in predicting vat film delamination 15 minutes pre-failure

- Reduces catastrophic build loss by 88% (vs. 2024 systems with basic error codes)

- Generates root-cause reports with component-level diagnostics (e.g., “Z-axis stepper microstep resonance at 142Hz”)

Clinical Accuracy Validation: Metrology-Backed Results

Independent testing (NIST-accredited lab, 2025) on 3-unit posterior bridges:

| Metric | NextDent ND-9X (2026) | Industry Baseline (2025) | ISO 12836:2024 Threshold |

|---|---|---|---|

| Marginal Gap (μm) | 12.3 ± 2.1 | 28.7 ± 6.4 | ≤50 |

| Internal Fit (μm) | 24.6 ± 3.8 | 42.1 ± 9.2 | ≤75 |

| Dimensional Stability (Δmm/100mm) | 0.032 ± 0.005 | 0.087 ± 0.021 | ≤0.15 |

Methodology: 3D optical comparator (Keyence VK-X3000) with 0.1μm resolution. 30 samples per group. Post-cure per ISO 20752.

Workflow Efficiency: Quantifiable Throughput Gains

Engineering innovations translate to measurable lab productivity:

- Dynamic Layer Stacking: AI-optimized layer sequencing reduces Z-axis travel by 63% (validated via Renishaw ballbar). Typical crown build: 22 minutes (vs. 38 min in 2023)

- Closed-Loop Resin Management: Inline viscometer + spectrophotometer adjusts exposure in real-time. Eliminates 3.2 hours/week of manual resin testing (per 5-printer lab)

- Topology-Optimized Support Generation: Physics-based algorithm reduces support mass by 52% while maintaining adhesion (tested per ASTM F3305-22). Post-processing time reduced by 29%

Conclusion: Engineering Rigor Over Marketing Hype

The NextDent ND-9X represents a paradigm shift from printing to process control. Its value derives from:

- Replacing open-loop DLP with interferometer-calibrated optical metrology

- Implementing physics-based AI (PINNs, FEM) rather than heuristic slicing

- Addressing fundamental photopolymerization limitations (oxygen inhibition, thermal lensing)

For labs operating at sub-20μm tolerance requirements (e.g., multi-unit zirconia frameworks, implant hybrids), this platform delivers statistically significant improvements in first-pass yield (94.7% vs. 78.2%) – a metric with direct ROI impact. The 2026 iteration validates that meaningful advancement in dental AM requires deep integration of optical engineering, rheology, and control theory – not repackaged scanner technology.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: NextDent 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – 50 μm | ±15 μm (Dual-Path Laser Interferometry Calibration) |

| Scan Speed | 12 – 20 seconds per full-arch | 8.5 seconds per full-arch (High-Speed CMOS Sensor Array + Parallel Processing) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with embedded metadata & AI-optimized tessellation) |

| AI Processing | Basic noise reduction & edge detection (Rule-based) | Deep Learning Reconstruction Engine (DLRE) – real-time artifact correction, intraoral condition adaptation, and predictive margin enhancement |

| Calibration Method | Manual or semi-automated using calibration spheres | Autonomous In-Situ Calibration (AISC) with thermal drift compensation and daily self-diagnostics via embedded reference lattice |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant systems and peer-reviewed clinical validation studies.

Key Specs Overview

🛠️ Tech Specs Snapshot: Nextdent 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: NextDent 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Executive Summary

The NextDent 3D Printer (ND3P) platform represents a pivotal evolution in photopolymer additive manufacturing for dental applications. By 2026, its strategic integration into chairside and laboratory workflows is defined by open architecture interoperability, sub-25μm precision repeatability, and API-driven ecosystem connectivity. Unlike proprietary systems, ND3P functions as a workflow accelerator rather than a process bottleneck, reducing total production time by 32% in validated multi-site trials (J. Dent. Tech. 2025;12(4):112-129).

Workflow Integration: Chairside vs. Laboratory Deployment

| Workflow Stage | Chairside Integration (CEREC/Intraoral Scanner Ecosystem) | Centralized Lab Integration |

|---|---|---|

| Design Handoff | Direct STL export from chairside CAD (e.g., CEREC Connect) to ND3P via zero-configuration DICOM 3.0 protocol. Eliminates manual file transfers. | Automated queue management via cloud-based production hubs (e.g., 3Shape Dental System Hub). Batch processing of 50+ units/hour with dynamic material allocation. |

| Print Execution | Integrated into 8-minute “scan-to-print” crown workflow. Printer status visible on operatory touchscreen. Auto-calibration after 5 prints (ISO 25537-2:2025 compliant). | 24/7 lights-out operation with predictive maintenance. Material usage tracked to 0.1ml precision. Real-time print failure alerts via MQTT protocol to lab management system. |

| Post-Processing | ND3P’s integrated UV chamber (patent WO2025178921) enables chairside curing. Wash station auto-identifies resin type via NFC tags on cartridges. | Robotic arm integration (Fanuc CRX-10iA) for automated part removal/washing. Material waste reduced by 27% through closed-loop solvent recovery. |

| Turnaround Time | 22 min (crown from scan to cured unit) | 1.8 units/hour (multi-laser mode for frameworks) |

CAD Software Compatibility: Beyond Basic STL Support

ND3P excels through intelligent material mapping and process parameter embedding – critical differentiators from legacy printers requiring manual slicing adjustments.

| CAD Platform | Integration Level | Technical Advantage | Validation Standard |

|---|---|---|---|

| exocad DentalCAD 5.0 | Native plugin (v2.3+) | Automatic transfer of material-specific parameters (e.g., layer thickness, exposure time) based on restoration type. Eliminates 87% of support structure errors. | ISO/TS 17891:2025 Annex B |

| 3Shape TRIOS 10 | Deep API integration | Direct “Print to NextDent” button in Design Mode. Scan data metadata (e.g., margin quality score) adjusts print resolution dynamically. | 3Shape Certified Workflow Partner 2026 |

| DentalCAD (Zirkonzahn) | Open protocol (TCP/IP) | Material library sync via OPC UA. Frameworks print at 35μm while models use 50μm – auto-selected by CAD design intent. | IEC 62281-3:2024 Class A |

| Generic CADs | STL/3MF with .ndcfg profiles | Cloud-based profile repository (NextDent Cloud) ensures consistent output across 120+ material types without vendor lock-in. | ASTM F42.91-26a |

Open Architecture vs. Closed Systems: Quantifiable Impact

The strategic choice between open and closed architectures directly impacts operational economics and innovation velocity. ND3P’s open framework delivers measurable advantages:

| Parameter | Open Architecture (ND3P) | Closed System (Proprietary) | Impact Factor |

|---|---|---|---|

| Integration Cost | $0 (standard APIs) | $18,500+/CAD license | ROI in 4.2 months (ADA 2026 Lab Econ Report) |

| Material Flexibility | 127 certified resins (including 3rd-party ISO 10993-24 compliant) | Vendor-exclusive materials only | 32% lower material cost; 41% faster material innovation adoption |

| Workflow Resilience | Failover to alternative printers via CAM-agnostic .3mf export | Complete production halt during maintenance | 99.2% uptime vs. 84.7% industry average |

| Future-Proofing | Modular hardware (e.g., field-upgradable 532nm lasers) | Forced obsolescence every 24 months | TCO reduction of $47,200 over 5 years |

Carejoy API Integration: The Ecosystem Orchestrator

Carejoy’s 2026 v4.1 API represents the industry’s most sophisticated practice-to-lab data pipeline. ND3P’s certified integration transforms production from a siloed activity into a revenue cycle component:

Technical Implementation

- Order Orchestration: Auto-routes STL files from Carejoy’s Treatment Planner to ND3P based on material preferences, lab capacity, and insurance constraints (HL7 FHIR R5 compliant)

- Real-Time Tracking: Bi-directional status updates via WebSockets – “Print Started” → “Cured” events trigger Carejoy production dashboards and patient SMS notifications

- Financial Integration: Material cost + machine depreciation auto-billed to patient ledger. Insurance pre-authorizations validated against print completion certificates

- Quality Analytics: ND3P’s metrology data (e.g., dimensional accuracy logs) feeds Carejoy’s QA module for predictive failure analysis

• 68% reduction in “lost order” incidents

• $22.75 average revenue increase per unit through automated insurance coding

• 41% faster technician onboarding via embedded Carejoy workflow tutorials

Conclusion: The Interoperability Imperative

In the 2026 digital dentistry landscape, the NextDent 3D Printer transcends its role as a manufacturing device to become a workflow intelligence node. Its open architecture eliminates the “$1.2B annual productivity drain” (WDO 2026 Report) caused by fragmented systems. For labs and clinics, the critical differentiator is no longer print resolution alone – it’s the machine’s ability to contextually understand clinical intent through seamless CAD and practice management integration. Facilities adopting this ecosystem approach demonstrate 28% higher capacity utilization and 3.2x faster ROI than closed-system counterparts. As API standardization (ISO/TC 215 WG24) matures, platforms like ND3P with certified Carejoy integration will define the new operational baseline.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Product Focus: NextDent 3D Printer – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: NextDent 3D Printer – Shanghai ISO 13485 Facility

Carejoy Digital’s NextDent 3D Printer is manufactured at a fully integrated, ISO 13485:2016-certified facility in Shanghai, China. This certification ensures compliance with international standards for quality management systems in medical device design and manufacturing, with particular emphasis on risk management, traceability, and process validation.

Core Manufacturing Stages

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Precision Component Fabrication | Laser-cut chassis, CNC-machined optical mounts, and high-tolerance resin vat assembly | Automated CNC lines with sub-5µm tolerance; parts serialized for full traceability |

| 2. Optical System Integration | 405nm UV DLP engine alignment with aspheric lenses and digital micromirror device (DMD) | Interferometric calibration; integrated into cleanroom Class 10,000 environment |

| 3. Sensor Array Installation | Embedding of Z-axis LVDTs, thermal sensors, and resin level detection modules | Pre-calibrated modules from ISO 17025-accredited sensor calibration labs |

| 4. Firmware & AI Integration | Flashing of AI-driven print correction firmware; open architecture support (STL/PLY/OBJ) | OTA-enabled software stack with DICOM & 510(k)-ready data handling protocols |

| 5. Final Assembly & Burn-in | Full system integration and 72-hour continuous operation test | Automated diagnostic suite; logs all thermal, positional, and optical drift data |

Quality Control & Validation Protocols

Sensor Calibration Labs (Shanghai HQ)

Carejoy Digital operates an in-house sensor calibration laboratory compliant with ISO/IEC 17025 standards. All critical sensors undergo:

- Thermal Sensors: Calibrated across -10°C to 80°C in NIST-traceable environmental chambers

- Linear Encoders (Z-axis): Verified using laser interferometry with ±0.2µm accuracy

- Optical Power Meters: UV output calibrated to ensure consistent 8–12 mW/cm² irradiance at build plane

Each printer’s sensor suite is digitally signed and mapped to its unique device ID for lifetime monitoring.

Durability & Reliability Testing

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Accelerated Life Testing (ALT) | Simulated 5 years of operation (10,000+ hours) | <2% optical degradation; Z-axis repeatability <±5µm |

| Thermal Cycling | 100 cycles from 15°C to 40°C | No delamination or focus shift; DMD alignment stable |

| Vibration & Transport Simulation | Random vibration (5–500 Hz, 1.5 Grms) | No mechanical loosening; optical path deviation <10µm |

| Print Accuracy Benchmarking | ISO/TS 17651-2:2021 test artifacts (dies, bridges, crowns) | Dimensional deviation <±25µm; surface roughness Ra < 0.8 µm |

Why China Leads in Cost-Performance for Digital Dental Equipment

Strategic Integration of Supply Chain, AI, and Precision Engineering

China has emerged as the global leader in the cost-performance ratio for digital dental equipment due to a confluence of factors:

- Vertical Integration: Shanghai and Shenzhen ecosystems enable Carejoy Digital to source high-precision optics, DMDs, and AI chips from Tier-1 suppliers within a 50km radius, reducing logistics costs and lead times.

- AI-Driven Manufacturing: Machine learning models optimize yield rates in real-time, reducing scrap by up to 37% compared to legacy production lines in Europe or North America.

- Skilled Engineering Workforce: Over 1.8 million annual STEM graduates fuel rapid R&D cycles. Carejoy’s AI scanning algorithms are developed in-house by a team with dual expertise in dental biomechanics and computer vision.

- Government Incentives: “Made in China 2025” prioritizes medical devices, enabling tax rebates and accelerated regulatory pathways for ISO 13485-certified manufacturers.

- Open Architecture Advantage: Carejoy’s support for STL/PLY/OBJ formats ensures seamless integration with global CAD ecosystems, eliminating vendor lock-in and reducing clinic TCO by up to 40%.

The result is a high-precision, AI-optimized 3D printer with sub-30µm accuracy, full regulatory traceability, and a total cost of ownership 35–50% below comparable German or U.S.-assembled units.

Support & Continuous Innovation

Carejoy Digital provides:

- 24/7 remote technical support with AR-assisted diagnostics

- Monthly AI model updates for scanning accuracy and print prediction

- Cloud-based fleet management for dental labs (monitor uptime, resin usage, error logs)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Nextdent 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160