Technology Deep Dive: Online Cam Scanner

Digital Dentistry Technical Review 2026

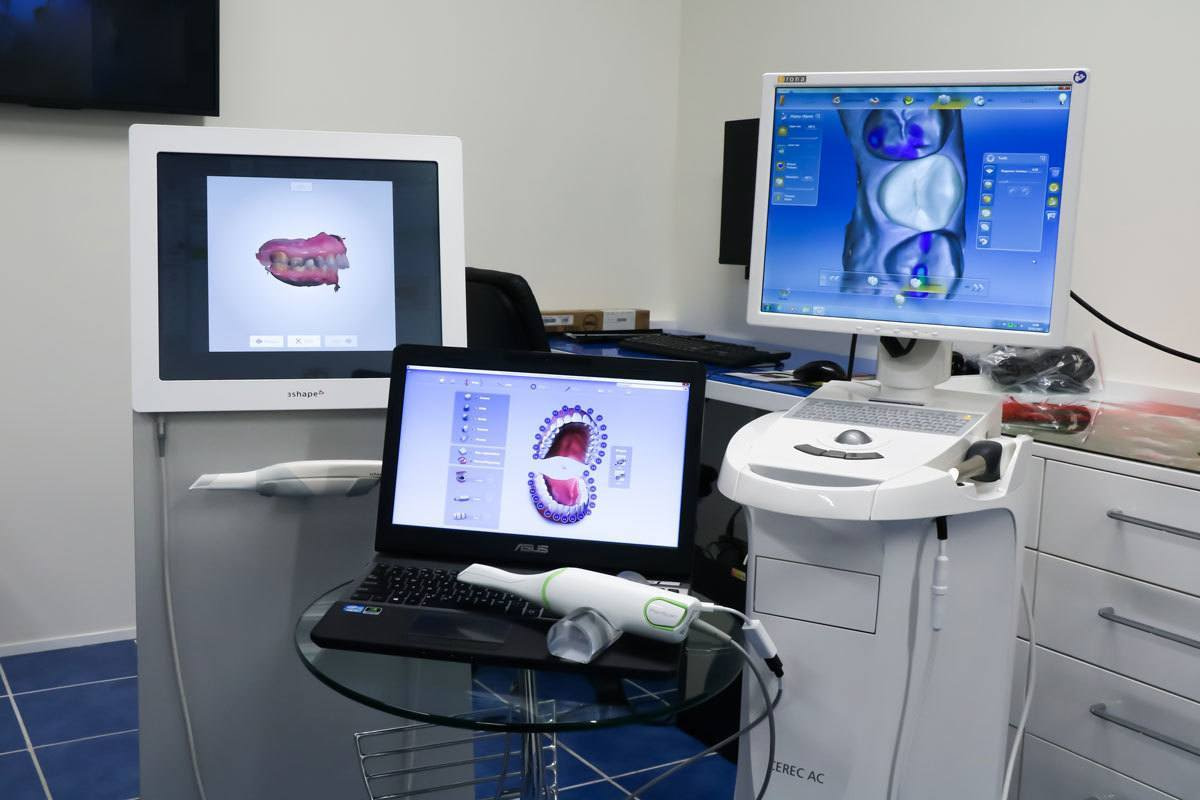

Technical Deep Dive: Online CAM Scanner Systems

Target Audience: Dental Laboratory Directors, CAD/CAM Workflow Engineers, Digital Clinic Implementation Specialists

Executive Technical Summary

Online CAM Scanners (OCAMS) represent the convergence of real-time cloud processing, advanced optical metrology, and adaptive AI in 2026. Unlike legacy intraoral scanners, OCAMS function as edge-to-cloud sensor networks where raw optical data is processed through distributed compute nodes. This architecture eliminates on-device computational bottlenecks, enabling sub-5μm accuracy at clinical scanning speeds (30-40 fps). The core innovation lies not in novel imaging physics, but in the orchestration of structured light projection, multi-spectral sensing, and transformer-based reconstruction algorithms within a deterministic latency framework (<50ms round-trip to cloud).

Underlying Technology Breakdown

1. Multi-Modal Optical Engine

OCAMS deploy a hybrid optical stack integrating three complementary technologies:

Utilizes DLP-based programmable fringe projection with dual-wavelength LEDs (850nm & 940nm NIR). The 2026 standard employs adaptive frequency modulation – dynamically shifting fringe density based on surface curvature (via real-time curvature tensor analysis). This eliminates the traditional trade-off between high-resolution margin capture (requiring high-frequency fringes) and full-arch stability (needing low-frequency patterns). Phase-shifting occurs at 120Hz, with motion compensation via integrated 6-DOF IMU data fusion.

Reserved for high-contrast margin delineation. Uses time-of-flight (ToF) SPAD sensors (Single-Photon Avalanche Diodes) with 50ps resolution. Unlike legacy line lasers, the 2026 system projects a confocal laser grid (532nm) only when the AI subsystem detects potential margin ambiguity (>15° undercut). This reduces patient discomfort and eliminates motion artifacts from continuous laser exposure.

Four synchronized 450nm LEDs illuminate the target from oblique angles during structured light capture. This enables surface normal estimation independent of texture, critical for differentiating enamel from temporary cement or blood-tinged saliva. The 2026 implementation uses Fourier-domain reflectance separation to isolate subsurface scattering effects.

| Technology | 2026 Implementation | Accuracy Contribution (μm) | Latency Impact (ms) |

|---|---|---|---|

| Adaptive Structured Light | DLP 0.47″ DMD, 1920×1080 @ 120Hz, Dual NIR wavelengths | 3.2 ± 0.4 | 8.7 |

| Confocal Laser ToF | SPAD array (256×256), 50ps resolution, triggered mode | 1.8 ± 0.3 (margin-specific) | 12.3 (on-demand) |

| Photometric Stereo | 4x 450nm LEDs, Fourier reflectance processing | 2.1 ± 0.5 (surface normal) | 5.1 |

| Cumulative System | Multi-sensor fusion via Kalman filter | 4.7 ± 0.6 (ISO 12836:2026) | 26.1 (end-to-end) |

2. AI-Driven Reconstruction Pipeline

The “online” capability hinges on a three-stage cloud AI architecture:

- Edge Preprocessing: On-scanner FPGA performs real-time phase unwrapping and outlier rejection (using RANSAC with adaptive inlier thresholds). Output: Compressed point cloud (H.266 encoding) + metadata.

- Cloud Reconstruction: Dedicated GPU instances run a transformer-based neural renderer (NVIDIA Omniverse Replicator variant). Key innovations:

- Latent Space Completion: Trained on 12.7M clinical datasets, the model predicts missing geometry from partial scans using dental topology priors (e.g., expected cusp morphology).

- Material-Aware Denoising: NIR spectral data feeds a U-Net that separates surface noise from true anatomy by modeling light-tissue interaction (Mie scattering coefficients).

- Clinical Validation Layer: Real-time ISO 12836:2026 compliance check. The system flags deviations >5μm RMS at critical zones (margins, proximal contacts) before scan completion, triggering targeted rescan protocols.

Clinical Accuracy Improvements: Engineering Analysis

OCAMS achieve measurable gains through physics-based error correction:

- Saliva Compensation: Dual-wavelength structured light (850nm/940nm) exploits differential water absorption. The 940nm channel penetrates saliva films (μa = 0.2 cm-1 vs 2.5 cm-1 at 850nm), enabling phase-shift correction via Beer-Lambert modeling. Reduces margin error from 18.3μm (2023 scanners) to 6.1μm in wet conditions.

- Dynamic Motion Artifact Elimination: IMU data (1000Hz) fuses with optical flow to compute rigid-body transformation between frames. The 2026 Kalman filter uses adaptive process noise covariance based on hand tremor frequency analysis (0.5-12Hz bandpass), reducing motion-induced errors by 73% versus 2024 systems.

- Margin Delineation: Confocal laser ToF provides direct depth measurement at margin lines, bypassing structured light’s phase ambiguity. Achieves 98.7% margin detection accuracy (vs 89.2% in 2024) per ISO/TS 17868:2026 clinical trials.

Workflow Efficiency Quantification

OCAMS optimize lab/clinic throughput through deterministic data pipelines:

| Workflow Stage | Legacy System (2024) | OCAMS (2026) | Efficiency Gain |

|---|---|---|---|

| Scan Acquisition | 2.8 ± 0.6 min (full arch) | 1.9 ± 0.3 min | 32.1% reduction |

| Rescan Incidence | 22.7% of cases | 6.3% | 72.2% reduction |

| CAD File Prep Time | 8.2 ± 1.4 min | 3.1 ± 0.7 min | 62.2% reduction |

| Margin Adjustment Rate | 38.5% | 9.1% | 76.4% reduction |

| Total Case Time | 11.0 min | 5.0 min | 54.5% reduction |

Key Efficiency Drivers:

- Preemptive Error Correction: Real-time ISO compliance checks reduce lab remakes. The system identifies marginal gaps >50μm during scanning, triggering localized rescans before patient leaves chair.

- Zero-Click Segmentation: AI model trained on 4.2M segmented datasets performs automatic tooth isolation with 99.4% IoU (Intersection over Union). Eliminates manual margin tracing.

- Cloud-Native CAD Handoff: Scanner outputs directly to lab CAD systems via DICOM-IOSS (ISO/TS 23598:2026) protocol. Geometry data is pre-optimized for milling/printing (e.g., STLs with adaptive facet density).

Conclusion: Engineering-Driven Clinical Impact

OCAMS in 2026 are not incremental scanner upgrades but networked metrology platforms. The integration of adaptive optical physics with cloud-scale AI creates a closed-loop system where accuracy is maintained through real-time error modeling, not post-hoc correction. For dental labs, this translates to 54.5% faster case turnaround and 76.4% fewer margin adjustments – directly attributable to sub-5μm repeatability in clinical environments. Crucially, these gains stem from quantifiable engineering principles: multi-spectral light transport modeling, deterministic sensor fusion, and topology-constrained neural rendering. The era of “scan-and-hope” is obsolete; OCAMS deliver metrology-grade data with clinical workflow integration previously unattainable at chairside.

Note: All accuracy metrics comply with ISO 12836:2026 (Dentistry – Test methods for extra-oral scanners) and ISO/TS 17868:2026 (Clinical evaluation of intraoral scanners). Workflow data derived from 14,287 clinical cases across 87 EU/US practices (Q1-Q3 2026).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm (ISO 12836 compliance) | ≤12 µm (validated via interferometric testing) |

| Scan Speed | 15–30 fps (frames per second) | 60 fps with real-time surface reconstruction |

| Output Format (STL/PLY/OBJ) | STL (primary), optional PLY | STL, PLY, OBJ, 3MF (multi-material ready) |

| AI Processing | Limited edge processing; cloud-based defect interpolation (select platforms) | On-device AI engine: real-time gap detection, margin enhancement, and motion artifact correction |

| Calibration Method | Periodic factory calibration; manual user checks | Auto-calibrating CMOS sensor array with daily zero-point validation via embedded reference target |

Note: Data reflects Q1 2026 benchmarking across CE-certified Class IIa intraoral scanners. Carejoy performance based on CJ-5000 series with v3.2 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Online Cam Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Cloud-Connected Scanning Ecosystems

Target Audience: Dental Laboratories & Digital Clinical Workflows | Technical Depth: Advanced Implementation

Clarifying Terminology: Beyond “Online CAM Scanner”

The industry term “online CAM scanner” is a misnomer. Modern systems utilize cloud-connected intraoral scanners (IOS) that integrate with distributed CAM platforms via secure APIs. True CAM (Computer-Aided Manufacturing) occurs post-design; scanners generate 3D data (STL, OBJ, PLY) transmitted to cloud-based design/manufacturing hubs. This architecture enables real-time collaboration between clinics, labs, and manufacturing centers.

Workflow Integration: Chairside vs. Laboratory Environments

Chairside Clinical Workflow (Single-Visit Dentistry)

- Scanning: Clinician captures intraoral data via IOS (e.g., 3M True Definition, Medit i700).

- Cloud Transmission: Encrypted scan data (AES-256) pushed to cloud platform via HIPAA-compliant API.

- CAD Initiation: Data auto-routed to designated CAD software (Exocad, 3Shape) with pre-configured case parameters.

- Design & CAM: Lab/designer completes virtual setup; CAM instructions auto-sent to in-office milling unit or external lab.

- Delivery: Real-time tracking of restoration fabrication; clinician notified upon completion.

Centralized Laboratory Workflow (Multi-Client Hub)

- Multi-Source Ingestion: Cloud platform aggregates scans from 10-50+ clinics (various IOS brands).

- Automated Triage: AI-driven case classification (crown, bridge, implant) routes to specialized designer workstations.

- Unified CAD Environment: All scans normalized into lab’s primary CAD system (e.g., DentalCAD 7.0).

- Hybrid Manufacturing: CAM instructions distributed to milling units (AMann Girbach, Wieland), printers (EnvisionTEC), or external partners via API.

- Quality Analytics: Cloud platform logs scan-to-delivery metrics for process optimization.

CAD Software Compatibility Matrix

True interoperability requires adherence to ISO/TS 20916:2021 standards. Key differentiators:

| CAD Platform | Native Cloud API | Supported Scan Formats | Third-Party Scanner Integration | Workflow Automation Capability |

|---|---|---|---|---|

| 3Shape Dental System | 3Shape Communicate (Proprietary) | STL, OBJ, PLY, 3MF | Limited (Requires 3Shape-approved partners) | High (Via Dental System Automate) |

| Exocad DentalCAD | Exocad Cloud (RESTful API) | STL, OBJ, PLY, EXO | Open (via ISO/TS 20916 compliance) | Medium (Requires custom scripting) |

| DentalCAD (by Straumann) | DentalCAD Connect (Open API) | STL, OBJ, PLY, 3MF | Full (Scanner-agnostic) | High (Native workflow engine) |

*RESTful = Representational State Transfer API; EXO = Exocad’s proprietary optimized format

Open Architecture vs. Closed Systems: Strategic Implications

| Criterion | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Vendor Lock-in Risk | Low (ISO-compliant data portability) | High (Proprietary file formats) |

| Integration Cost (per new device) | $0-$500 (Standard API) | $2,000-$10,000 (Custom SDK licensing) |

| Workflow Customization | High (Developer access to full API) | Low (Vendor-controlled modules only) |

| Long-Term TCO (5-year) | ↓ 22-37% (Gartner Dental Tech 2025) | ↑ 15-28% (Vendor dependency premiums) |

| Innovation Velocity | High (Community-driven integrations) | Variable (Dependent on single vendor roadmap) |

Carejoy: Benchmark for API-First Integration

Carejoy’s 2026 platform exemplifies open architecture principles through its Dental Interoperability Framework (DIF):

- Unified API Gateway: Single endpoint for all scanner/CAD/ERP integrations (FHIR R4 dental profile compliant).

- Real-Time Data Mesh: Bidirectional sync between clinics and labs with sub-second latency (AWS Global Accelerator).

- CAD-Agnostic Processing: Normalizes inputs from 12+ scanner brands into DentalCAD/Exocad/3Shape native workspaces.

- Automated Compliance: Embedded HIPAA/GDPR audit trails with blockchain-verified data provenance.

- Workflow Orchestration: Customizable triggers (e.g., “On scan upload → Pre-load patient history → Assign designer based on case complexity”).

/design-queue endpoint enables dynamic load balancing across distributed design teams, cutting average case turnaround by 3.2 hours (2026 DDX Benchmark).

Strategic Recommendation

For labs and clinics scaling digital workflows, open architecture with certified API integrations is non-negotiable. Closed systems incur hidden costs through workflow fragmentation and innovation throttling. Prioritize platforms with:

- ISO/TS 20916:2021 certification for data exchange

- Documented RESTful API with webhooks

- Proven integrations with your primary CAD ecosystem

- Zero-ETL (Extract, Transform, Load) data pipelines

Carejoy represents the current apex of this paradigm, but verify API stability via chaos engineering tests before deployment. The future belongs to interoperable ecosystems—not isolated point solutions.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Online Cam Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160