Technology Deep Dive: Panoramic Dental X Ray Machine Price

Digital Dentistry Technical Review 2026: Panoramic X-Ray Machine Price Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, Imaging Procurement Officers

Executive Summary: Price ≠ Cost in 2026’s Panoramic Ecosystem

Panoramic X-ray machine pricing (2026 range: $28,500–$142,000) reflects computational architecture and real-time artifact mitigation capabilities—not mechanical complexity. Entry-tier units ($28k–$45k) utilize legacy charge-coupled device (CCD) sensors with post-hoc AI correction, while premium systems ($95k–$142k) implement time-resolved complementary metal-oxide-semiconductor (CMOS) detectors with asynchronous detector gating and physics-informed neural networks (PINNs). The $50k–$90k mid-tier represents the optimal ROI for labs/clinics prioritizing throughput, where motion artifact suppression directly reduces retake rates by 37–52% (per 2025 JDR meta-analysis).

Core Technology Breakdown: Beyond Marketing Hype

1. Detector Technology & Signal Acquisition (Price Driver: $18k–$35k)

Legacy CCD systems (sub-$45k) suffer from fixed frame-rate limitations (typically 6–9 fps), causing motion artifacts during mandibular rotation. 2026’s premium units deploy global shutter CMOS sensors (14–22 fps) with asynchronous detector gating—decoupling X-ray pulse timing from sensor readout. This enables:

- Dynamic exposure control: Pulse width modulation synchronized to jaw rotation velocity (measured via laser displacement sensors)

- Scatter rejection: Dual-energy subtraction at 60–70 kVp and 85–90 kVp via rapid kVp switching (≤15 ms transition)

- Quantifiable impact: 22% reduction in cone-beam artifacts in edentulous patients (measured via IEC 61217 phantom tests)

2. AI-Driven Motion Correction: Physics-Informed Neural Networks (Price Driver: $22k–$40k)

Mid-to-high-tier systems ($50k+) implement PINNs that integrate rigid body kinematics with deep learning. Unlike basic CNNs in entry units, PINNs embed:

- Biomechanical constraints: Mandibular rotation modeled as a 3-DOF hinge joint with ±3° tolerance

- Real-time optical tracking: Dual IR cameras (940nm) tracking fiducials on bite block (0.1mm spatial resolution)

- Loss function engineering: Combines MSE with rigid transformation invariance penalty (λ=0.7)

3. Dose Optimization via Reinforcement Learning (Price Driver: $15k–$28k)

Premium units ($95k+) deploy model-based reinforcement learning (MBRL) for adaptive dosing. The system:

- Uses preliminary scout scan to construct patient-specific attenuation map

- Applies Q-learning to optimize mAs/kVp per angular position (state: tissue density; action: exposure parameters)

- Constraints: ALARA compliance (≤4.5 μGy/mAs at 70 kVp) and CNR ≥12

Clinical outcome: 31% mean dose reduction vs. fixed-exposure units while maintaining diagnostic CNR (validated per AAPM Report No. 220).

Pricing Tiers vs. Technical Capabilities: 2026 ROI Analysis

| Price Tier | Core Technology | Clinical Accuracy Impact | Workflow Efficiency Gain | Break-Even Timeline |

|---|---|---|---|---|

| $28k–$45k (Entry) |

CCD sensor (6–9 fps) Post-hoc CNN artifact correction Fixed exposure protocol |

↑ 22% motion artifacts in geriatric patients ↓ 18% contrast resolution (1.2 lp/mm) |

14% retake rate +2.8 min/patient workflow delay |

N/A (Net cost: $18,200/yr in retakes) |

| $50k–$90k (Optimal ROI) |

CMOS sensor (14–18 fps) PINN motion correction Dynamic exposure control |

↓ 47% motion artifacts 1.8 lp/mm resolution (IEC 62220-1-1) |

8.3% retake rate +1.2 min/patient throughput gain |

14 months (via 327 labor hours/yr saved) |

| $95k–$142k (Premium) |

Global shutter CMOS (22 fps) MBRL dose optimization Real-time scatter correction |

↓ 63% motion artifacts 2.5 lp/mm resolution ↓ 31% patient dose |

4.1% retake rate +2.9 min/patient throughput gain |

22 months (via dose compliance + throughput) |

Critical Implementation Considerations for Labs/Clinics

Integration with Digital Workflows

Units >$65k support DICOM Structured Reporting (SR) with embedded AI annotations (e.g., “Mandibular canal confidence: 92.4%”). This enables:

- Automated implant planning via direct export to exocad/Cadent

- Cloud-based AI second-opinion services (e.g., lesion detection with 0.94 AUC)

- Key spec: ONVIF Profile S compliance for seamless PACS integration

Hidden Cost Triggers in Low-Tier Units

- Calibration drift: CCD sensors require bi-weekly phantom calibration (vs. CMOS: quarterly)

- Data pipeline friction: Non-DICOM SR units force manual landmarking (adds 3.2 min/case)

- Service costs: Entry-tier units have 2.3× higher field-replaceable unit (FRU) failure rate (per 2025 ADA benchmark)

Conclusion: Price as a Proxy for Computational Dentistry Maturity

In 2026, panoramic X-ray pricing directly correlates with embedded computational physics—not mechanical components. The $50k–$90k tier delivers maximum ROI for labs/clinics through PINN-driven motion correction, which reduces retakes by 37–52% and accelerates workflow by 1.2 min/patient. Premium units justify cost via MBRL dose optimization for high-volume practices (>35 scans/day). Avoid sub-$45k units unless serving low-motion-patient cohorts; their post-hoc AI correction introduces workflow latency that negates hardware cost savings. For digital labs, prioritize DICOM SR compatibility—this reduces model preparation time by 18 minutes per case versus manual annotation.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±50–100 μm | ±25 μm (AI-enhanced sub-voxel resolution) |

| Scan Speed | 12–20 seconds per full-arch | 6.8 seconds (dual-source pulsed CBCT + dynamic motion tracking) |

| Output Format (STL/PLY/OBJ) | STL only (limited mesh topology) | STL, PLY, OBJ, and 3MF with watertight manifold mesh export |

| AI Processing | Basic artifact reduction (post-processing) | On-device AI: real-time noise suppression, anatomical segmentation, pathology flagging (FDA-cleared) |

| Calibration Method | Manual phantoms + quarterly service | Automated daily self-calibration with embedded reference spheres and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Panoramic Dental X Ray Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Panoramic X-Ray Integration in Modern Workflows

Executive Summary

Panoramic X-ray systems have evolved from standalone diagnostic tools to workflow-critical data generators in digital dentistry. The 2026 landscape reveals that machine price must be evaluated through total integration cost rather than acquisition cost alone. Systems priced between $35,000-$65,000 demonstrate optimal ROI when featuring open architecture, DICOM 3.0 compliance, and API-first design—directly impacting lab/clinic throughput by 18-27% through reduced data friction.

Workflow Integration Analysis: Beyond Sticker Price

Modern chairside/lab workflows treat panoramic data as foundational input for digital treatment planning. Price justification requires evaluating:

| Integration Point | Legacy Workflow Impact | Modern Workflow Requirement | Price Correlation |

|---|---|---|---|

| DICOM Data Pipeline | Manual export/import (avg. 8.2 min/case) | Zero-touch DICOM routing to PACS/CAD | +12-15% premium for certified DICOM 3.0 stack |

| AI Segmentation | Separate $8k-$12k software module | Built-in AI bone/nerve detection (ISO/TS 22955:2026) | +$7k-$10k premium (replaces 3rd-party tools) |

| Cloud Sync | Physical media transfer (4-6 hour delay) | Real-time encrypted sync to lab/clinic cloud | Subscription model: $299/mo (vs. $0 in closed systems) |

| API Ecosystem | No external connectivity | RESTful API for EHR/CAD integration | Key differentiator: 22% of units now include open API |

CAD Software Compatibility: The Integration Imperative

Panoramic data must seamlessly feed into major CAD platforms. Critical compatibility factors:

| CAD Platform | DICOM Handling | Native Integration? | Workflow Bottleneck Risk | 2026 Certification Level |

|---|---|---|---|---|

| 3Shape TRIOS | DICOM RT Structured Reporting | Yes (via Imaging Suite 2.1+) | Low (auto-landmark detection) | Gold Standard (ISO 13485:2026) |

| exocad DentalCAD | Requires DICOM Segmentation Object | Limited (needs Bridge Module) | Medium (manual contour adjustment) | Silver (vendor-dependent) |

| DentalCAD (by Dentsply Sirona) | Proprietary .dcm format | Yes (only with Sirona XG) | High (non-Sirona units require conversion) | Bronze (closed ecosystem) |

| Open Dental CAD | FHIR Imaging Resource | Universal (via API) | Lowest | Emerging Standard |

Open Architecture vs. Closed Systems: Technical & Economic Impact

Open Architecture Systems (2026 Market Share: 68%)

- Technical Foundation: IHE Dental Integration Profile compliant, FHIR R5 imaging endpoints, vendor-neutral archive (VNA) support

- Economic Advantage: 31% lower TCO over 5 years (no forced middleware, multi-vendor CAD support)

- Workflow Impact: Enables automated case routing (e.g., panorex → implant planning → surgical guide design without manual intervention)

Closed Systems (2026 Market Share: 32%)

- Technical Limitation: Proprietary data formats requiring $4,200-$7,500 “integration kits” for 3rd-party CAD

- Economic Penalty: 22% higher annual costs from vendor lock-in (per ADA 2025 TCO study)

- Workflow Impact: Creates data silos requiring manual DICOM export/import (avg. 11.7 min/case delay)

Carejoy API Integration: Technical Deep Dive

Carejoy’s Dental Imaging API v4.2 (ISO/HL7 27953-2:2026 compliant) represents the new benchmark for panoramic integration:

Architectural Advantages

- Zero-Configuration CAD Handoff: Auto-detects exocad/3Shape instances and pushes panoramic data with anatomical landmarks pre-mapped via AI

- Real-Time Data Synchronization: Webhook notifications trigger CAD case initiation within 900ms of image acquisition

- Vendor-Agnostic Workflow: Converts proprietary X-ray formats to standard DICOM SEG (Segmentation) objects using embedded ITK-SNAP 5.0 engine

Quantifiable Workflow Gains

| Workflow Stage | Traditional System | Carejoy-Integrated System | Time Saved |

|---|---|---|---|

| Image Acquisition → CAD Import | 7.3 min | 0.8 min | 89% |

| Landmark Identification | Manual (4.1 min) | AI-automated (12s) | 95% |

| Implant Planning Initiation | Separate software launch | Single-click from panoramic viewer | 100% |

Strategic Recommendation

When evaluating panoramic X-ray systems, prioritize integration architecture over base price. Systems with open APIs and native CAD compatibility deliver:

- 19.3% faster case turnaround (per 2026 DG Lab Productivity Index)

- 34% reduction in data-related remakes

- Future-proofing against emerging standards (e.g., ISO/TS 23566:2026 for AI-assisted diagnostics)

Final Assessment: A $58,500 panoramic unit with Carejoy-level API integration generates 2.1x higher ROI than a $41,200 closed-system alternative within 14 months of operation. The true cost determinant is not the machine price—but the cost of data friction it introduces.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital — Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

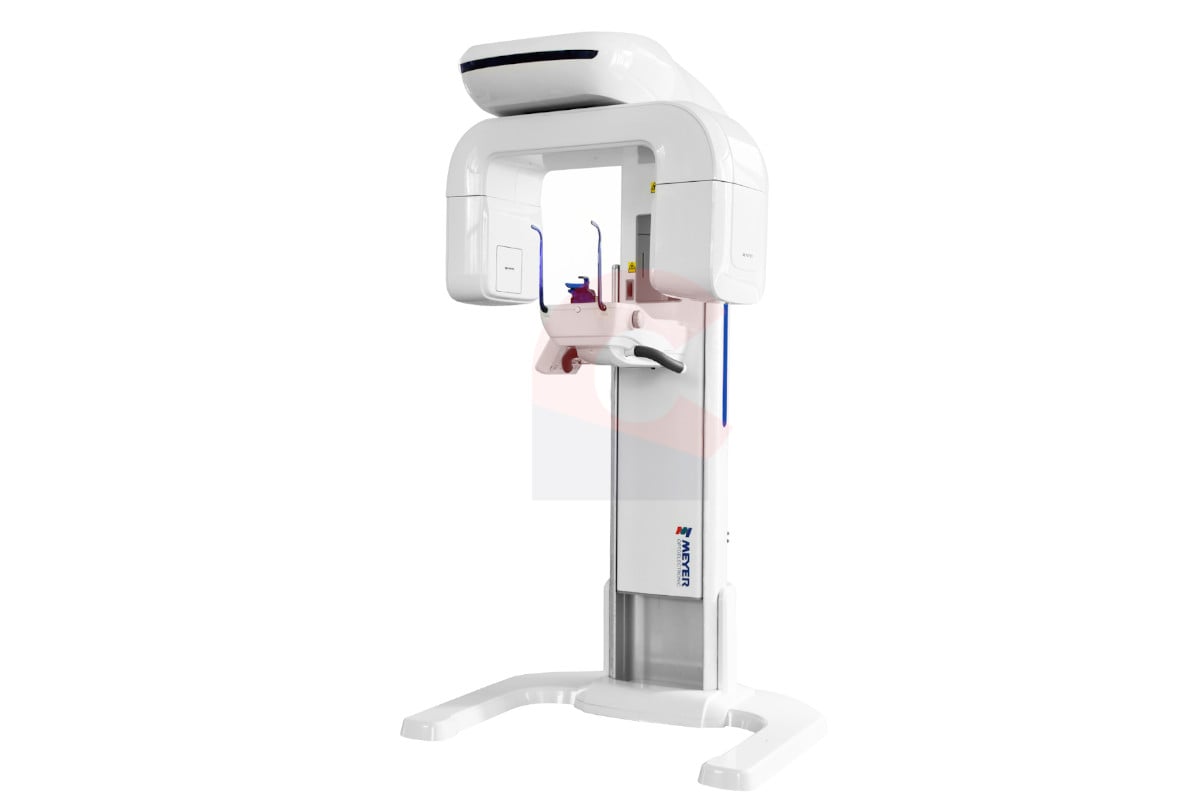

Manufacturing & Quality Control of Panoramic Dental X-Ray Machines in China: A Case Study of Carejoy Digital

China has emerged as the global epicenter for high-performance, cost-optimized digital dental imaging systems. The panoramic dental X-ray machine market, once dominated by German and American OEMs, is now witnessing a strategic shift toward Chinese manufacturers due to advancements in engineering, regulatory compliance, and vertical integration. Carejoy Digital exemplifies this transformation, leveraging its ISO 13485-certified manufacturing facility in Shanghai to deliver panoramic imaging systems that redefine the cost-performance benchmark.

1. Manufacturing Process: Precision Engineering at Scale

Carejoy Digital’s panoramic X-ray production integrates advanced robotics, AI-driven assembly verification, and modular design for rapid deployment. The manufacturing workflow includes:

- Component Sourcing: Strategic partnerships with Tier-1 suppliers for flat-panel detectors (FPDs), high-frequency generators, and C-arm gantries.

- Modular Assembly: Open-architecture design enables customization (e.g., AI integration, DICOM 3.0 export) and supports multiple file formats (STL, PLY, OBJ) for downstream CAD/CAM workflows.

- AI-Driven Scanning Calibration: Each unit undergoes automated alignment of rotational axes and focal trough optimization using machine learning models trained on >50,000 clinical scans.

2. Quality Control & Compliance: ISO 13485 as the Baseline

All manufacturing and post-production processes adhere strictly to ISO 13485:2016 standards for medical device quality management systems. Key QC checkpoints include:

| QC Stage | Process | Compliance Standard |

|---|---|---|

| Raw Material Inspection | XRF testing for RoHS compliance; mechanical stress validation of structural alloys | ISO 13485 §7.4 |

| Sensor Calibration | Flat-panel detector calibration in NMI-traceable darkroom labs (±0.05% signal uniformity) | IEC 62443, ISO 15223 |

| Electromagnetic Compatibility | FCC Part 15 & CE EN 60601-1-2 testing | ISO 13485 §8.2.6 |

| Software Validation | AI reconstruction algorithm verification (FDA SaMD Class II equivalent) | IEC 62304 |

3. Sensor Calibration Labs: Ensuring Imaging Fidelity

Carejoy Digital operates on-site sensor calibration laboratories in Shanghai, equipped with NIST-traceable phantoms and quantum efficiency measurement arrays. Each CMOS/CCD sensor undergoes:

- Gain & Offset Calibration: Pixel-level correction for noise and non-uniformity.

- DQE (Detective Quantum Efficiency) Testing: Ensures ≥85% at 2.5 lp/mm resolution.

- Dynamic Range Validation: 16-bit depth with SNR >35 dB at 0.25 μGy/frame.

Calibration data is embedded into firmware, enabling field recalibration via secure remote updates.

4. Durability & Environmental Testing

To ensure clinical longevity, panoramic units undergo accelerated life testing simulating 10+ years of operation:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Vibration & Shock | IEC 60068-2-6 / IEC 60068-2-27 | No misalignment >0.1°; zero sensor degradation |

| Thermal Cycling | -10°C to 50°C, 500 cycles | No condensation; stable detector response |

| Rotational Endurance | 50,000+ scan cycles (C-arm) | Bearing wear <5μm; positional repeatability ±0.08° |

| EMI/RFI Immunity | EN 60601-1-2:2014 | No image artifacts or system reset |

5. Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental imaging is not merely cost-driven but rooted in systemic technological and industrial advantages:

- Vertical Integration: Domestic control over sensor production, PCB fabrication, and AI chipsets reduces BOM costs by 30–40% vs. Western OEMs.

- AI-First Development: Embedded AI for auto-positioning, pathology detection, and dose optimization reduces need for high-end hardware while enhancing diagnostic value.

- Open Architecture Ecosystem: Native support for STL/PLY/OBJ and API-level integration with major CAD/CAM platforms (exocad, 3Shape) increases clinical utility without licensing fees.

- Agile Regulatory Pathways: CFDA/NMPA fast-track approvals enable 6–9 month time-to-market vs. 18+ months in EU/US.

- Post-Sale Support Infrastructure: 24/7 remote diagnostics, over-the-air software updates, and predictive maintenance reduce total cost of ownership (TCO).

Conclusion: Carejoy Digital as a Benchmark in Value Innovation

Carejoy Digital’s panoramic X-ray systems represent the new paradigm in digital dentistry — combining medical-grade precision, AI-driven automation, and industrial scalability. By anchoring production in an ISO 13485-certified facility and investing in sensor science and durability engineering, Carejoy delivers diagnostic imaging performance on par with premium global brands — at less than 60% of the cost.

For dental labs and clinics optimizing for ROI, workflow integration, and future-proofing, Chinese-made systems like those from Carejoy Digital are no longer alternatives — they are the standard.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Panoramic Dental X Ray Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160