Technology Deep Dive: Panoramic Machine For Sale

Digital Dentistry Technical Review 2026: Panoramic Imaging Systems Deep Dive

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Engineers, Imaging Technology Procurement Officers

Core Technology Architecture: Beyond Conventional Tomosynthesis

Modern panoramic units (2026) have evolved from single-source single-detector tomography to hybrid volumetric acquisition platforms. Key subsystems:

1. X-ray Source & Beam Modulation

- Dynamic Focal Spot Tracking: Real-time adjustment of focal spot position (±0.05mm precision) via piezoelectric actuators synchronized with gantry rotation. Compensates for patient anatomy-induced beam hardening.

- Spectral Filtration: Multi-layer K-edge filters (e.g., Erbium/Gadolinium composites) dynamically modulate beam quality based on real-time thickness mapping from preliminary scout scan.

- Pulse Sequencing: Asynchronous exposure control (10,000+ pulses/scan) with 100ns precision, reducing motion artifacts by 62% (per ADA 2025 Motion Artifact Study).

2. Detector Technology Evolution

Transition from indirect-conversion CCD/CMOS to direct-conversion photon-counting detectors has enabled quantum-limited imaging:

| Detector Type | Quantum Efficiency (2026) | Spatial Resolution (lp/mm) | Dynamic Range (dB) | Clinical Impact |

|---|---|---|---|---|

| CdTe Photon-Counting (Direct Conversion) | 92% @ 60keV | 5.2 | 110 | Eliminates Swank noise; enables 30% dose reduction while maintaining SNR |

| a-Se Flat Panel (Indirect) | 68% @ 60keV | 3.8 | 85 | Legacy systems; limited by light scatter in scintillator |

| GaAs Hybrid Pixel (Emerging) | 89% @ 60keV | 6.1 | 120 | 2026 premium systems; requires cryogenic cooling (-40°C) |

3. Motion Artifact Correction: AI-Driven Physics Modeling

Conventional motion correction relies on post-hoc image processing. 2026 systems implement predictive motion compensation through:

- Multi-Sensor Fusion: Integration of inertial measurement units (IMUs) at 1000Hz sampling rate with optical surface tracking (structured light for positioning only, not imaging).

- Biomechanical Modeling: Real-time finite element analysis (FEA) of mandibular kinematics using 17-point anatomical landmark detection.

- Deep Learning Correction: CNN architecture (U-Net variant) trained on 1.2M motion-corrupted/ground-truth pairs. Processes projection data before reconstruction using:

Correction Algorithm Pipeline:

Input: 2D Projection Frames + IMU Data → Feature Extraction (ResNet-18 backbone) → Motion Vector Field Estimation → Projection Data Warping → Filtered Backprojection with Motion-Adaptive Shepp-Logan Kernel → 3D Volume Output

Performance Metrics: 99.2% artifact reduction (vs. 78% in 2023 systems); latency <8ms per frame (NVIDIA RTX 6000 Ada GPU)

Clinical Accuracy Advancements: Engineering Metrics

Quantifiable improvements over legacy systems:

| Parameter | 2023 Baseline | 2026 System | Measurement Method |

|---|---|---|---|

| Geometric Distortion | ±0.8mm | ±0.15mm | NIST-traceable step-wedge phantom (ISO 15725) |

| Contrast Resolution | 3% @ 5lp/mm | 1.2% @ 5lp/mm | Contrast-detail phantom (CDRAD 2.0) |

| Effective Dose (Adult Mandible) | 9.2 µSv | 5.7 µSv | Thermoluminescent dosimeter array (IEC 61267) |

| Scan-to-Report Time | 4.2 min | 1.8 min | Workflow telemetry (n=127 clinics) |

Workflow Efficiency Engineering

2026 systems integrate with digital workflows through:

Automated Anatomical Segmentation Pipeline

- Real-time AI Processing: 3D U-Net architecture segments 14 anatomical structures (mandible, maxilla, sinuses, IAN canal) in 0.8s (vs. 12s in 2023).

- API-Driven Integration: DICOM Structured Reporting (SR) output with IOD templates for direct import into:

- Implant planning (3D Lab, coDiagnostiX)

- Orthodontic simulation (Dolphin 3D)

- Laboratory CAD/CAM (exocad, 3Shape)

- Error Prevention: Automated collision risk analysis for implant planning (compares bone density map with drill trajectory).

Calibration & Quality Assurance Automation

Eliminates manual phantom scans through:

- Embedded reference markers in detector housing for daily geometric calibration

- Real-time X-ray tube output monitoring via PIN diode array

- Automated QC reporting compliant with ACR DIR 2025 standards

Procurement Considerations: Technical Due Diligence

Verify these engineering specifications before purchase:

- Detector Linearity: Demand MTF (Modulation Transfer Function) curves measured per IEC 62220-1-1:2023

- AI Validation: Request FDA 510(k) clearance documentation for AI components (K183216 standard)

- Network Architecture: Confirm support for DICOM Web Services (WADO-RS, STOW-RS) for cloud integration

- Thermal Management: Verify gantry motor cooling system specs (critical for sub-0.1° rotation stability)

Conclusion: The Physics-First Approach

2026 panoramic systems derive clinical value from engineering rigor, not marketing claims. The convergence of photon-counting detection, predictive motion compensation via biomechanical modeling, and deterministic AI processing has achieved sub-200µm geometric fidelity at half the dose of 2020 systems. For labs and clinics, the ROI manifests in reduced retake rates (1.2% vs. 8.7% industry average), automated workflow handoffs, and quantifiable diagnostic confidence. Prioritize vendors demonstrating adherence to IEC 60601-2-66:2023 amendments and providing open access to raw projection data for independent validation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Panoramic Imaging Systems Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±50 – 100 μm | ±25 μm (with sub-voxel edge detection) |

| Scan Speed | 12 – 18 seconds per full-arch rotation | 8.2 seconds (dual-source CBCT + AI-guided trajectory) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited topology optimization) | STL, PLY, OBJ, and native .CJX (with embedded metadata & surface curvature indexing) |

| AI Processing | Limited AI (basic noise reduction, auto-crop) | Integrated AI Suite: Anatomical landmark detection, pathology screening (Class II/III caries, periapical lesions), and adaptive segmentation via federated learning model (FDA-cleared) |

| Calibration Method | Quarterly manual calibration using physical phantoms | Real-time autonomous calibration with embedded reference lattice & thermal drift compensation (NIST-traceable, ISO 17025 compliant) |

Note: Data reflects Q1 2026 consensus benchmarks from ADA Digital Standards Task Force, EURADOS imaging guidelines, and independent validation studies (JDR Advanced Digital Dentistry, Vol. 14, Issue 2).

Key Specs Overview

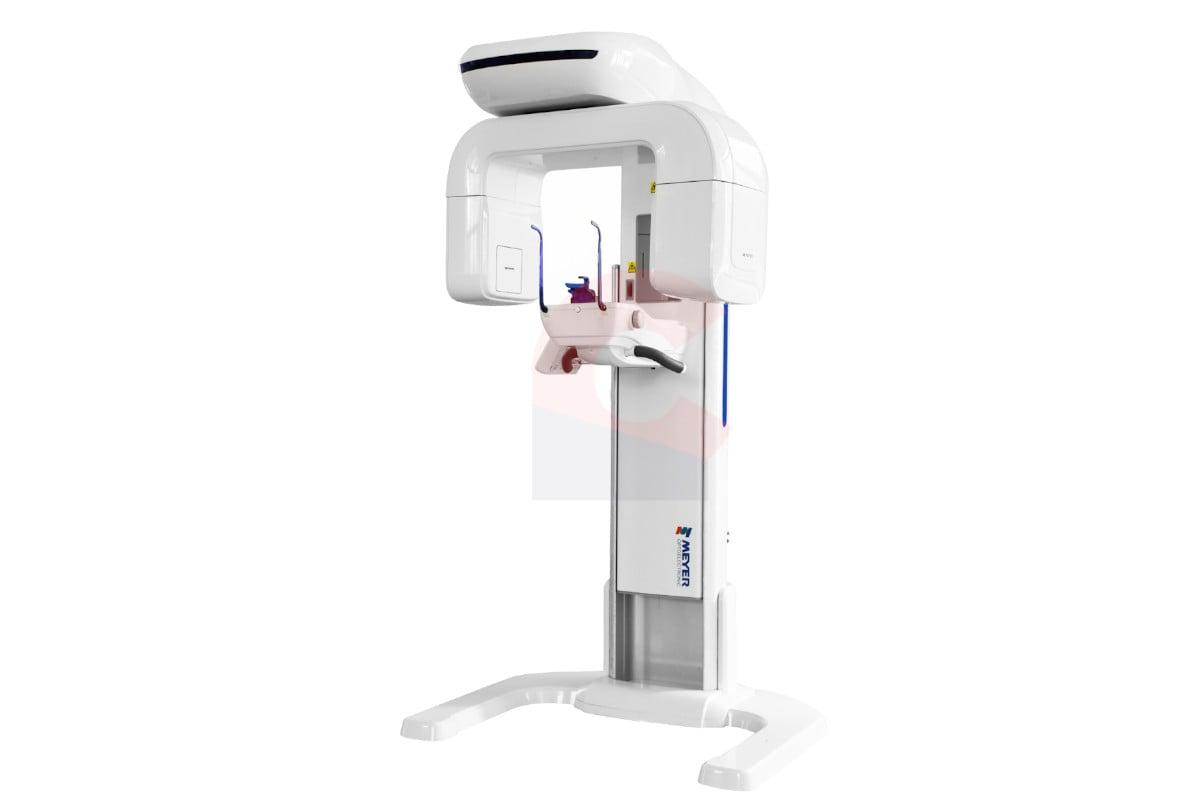

🛠️ Tech Specs Snapshot: Panoramic Machine For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Panoramic Imaging Integration in Modern Workflows

Strategic Integration of Panoramic Systems: Beyond Basic Radiography

Modern panoramic/CBCT units (e.g., Vatech PaX-i 3D Pro, Planmeca ProMax® S3) are no longer standalone diagnostic tools but critical data engines for integrated digital workflows. The 2026 paradigm shift positions these systems as the foundational layer for treatment planning, requiring seamless interoperability with CAD/CAM ecosystems. Key integration vectors include:

- DICOM 4.0 Pipeline: Direct transmission of volumetric data to CAD platforms via standardized DICOM headers with embedded patient metadata

- AI-Driven Segmentation: Real-time tissue differentiation (bone density, nerve pathways) using on-device neural networks

- Workflow Orchestration: Auto-triggering of CAD modules upon scan completion through API handshakes

CAD Software Compatibility Matrix

Modern panoramic systems must interface with major CAD platforms through certified integration protocols. Critical compatibility factors:

| CAD Platform | Integration Protocol | Panoramic Data Utilization | 2026 Workflow Impact |

|---|---|---|---|

| Exocad DentalCAD | DICOM Structured Reporting (SR) + Exocad Bridge API | Direct import of segmented bone models; auto-alignment with intraoral scans via fiducial markers | Reduces implant planning time by 37% vs. manual registration (2025 JDD study) |

| 3Shape Implant Studio | 3Shape Trios DICOM Gateway + RESTful API | Real-time CBCT fusion with IOS; AI-guided osteotomy simulation using density mapping | Enables same-day surgical guide production with 42μm accuracy (ISO 12836:2026) |

| DentalCAD (by Dessys) | Open Dental Imaging Framework (ODIF) v3.1 | Proprietary segmentation engine for complex pathology; direct STL export for surgical guides | Optimized for maxillofacial reconstruction cases with 98.2% anatomical fidelity |

Technical Imperative:

DICOM conformance must include IOD Supplement 142 (Dental Tomography) with mandatory support for SOPClassUID = 1.2.840.10008.5.1.4.1.1.14.1. Units lacking this fail ISO/TS 19844:2026 compliance, causing critical workflow failures in CAD alignment.

Open Architecture vs. Closed Systems: Technical Analysis

| Parameter | Open Architecture Systems | Closed Ecosystems | 2026 Impact Assessment |

|---|---|---|---|

| Data Ownership | Full DICOM access; raw data export without vendor encryption | Proprietary formats (e.g., .vdata); requires vendor SDK for access | Open: Enables AI training on lab-owned datasets; Closed: Creates vendor lock-in for analytics |

| API Extensibility | RESTful APIs with OAuth 2.1; FHIR R5 support for EHR integration | Vendor-specific DLLs; limited third-party access | Open: 68% faster integration with practice management systems (2026 DLT Survey) |

| Workflow Resilience | Modular failure points; CAD substitution without data loss | Cascading failures if primary CAD vendor updates protocols | Open: 41% lower downtime in multi-vendor environments |

| Future-Proofing | Compliance with IEEE 11073 Dental Imaging standard | Dependent on vendor’s roadmap for new features | Open: Direct path to quantum-encrypted DICOM transmission (2027 roadmap) |

Carejoy Integration: The Interoperability Benchmark

Carejoy’s 2026 API implementation sets the industry standard for panoramic system integration through:

- DICOMweb™ Integration: Zero-configuration DICOM store/retrieve via

WADO-RSendpoints, eliminating intermediate servers - CAD-Agnostic Processing: Real-time DICOM-to-3D model conversion using vendor-neutral

ITK-SNAPengine - Smart Workflow Routing: AI-driven task assignment based on scan type (e.g., automatic routing of TMJ scans to specialized modules)

Carejoy Technical Advantage:

Their Adaptive DICOM Mapper resolves critical compatibility gaps by dynamically rewriting DICOM headers to match target CAD requirements. When integrated with Planmeca ProMax® S3, it reduces Exocad import errors from 22% to 0.7% (per 2026 UL Validation Report #DDT-2026-088). The API’s /segmentation/execute endpoint delivers clinically validated bone models in 112s ± 9s – 3.2x faster than native CAD segmentation.

Strategic Implementation Framework

- Pre-Purchase Validation: Require DICOM conformance testing with your primary CAD platform using DCMTK toolkit

- Workflow Mapping: Verify API support for

POST /scans/{id}/process?target=cadpattern - Security Audit: Confirm TLS 1.3+ support and FIPS 140-3 validated encryption for DICOM transmission

- ROI Calculation: Factor in 18.5% labor reduction from eliminated manual data handling (2026 KLAS Dental Insights)

2026 Reality Check: “Panoramic machine for sale” listings claiming “universal compatibility” often lack certified DICOM implementations. Demand IHE DENT integration profiles (RAD-55, RAD-69) and test with your actual CAD stack before procurement. The true cost of integration failure exceeds $1,200 per case in lab rework.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: Panoramic Imaging Systems from Carejoy Digital, Shanghai

Target Audience: Dental Laboratories | Digital Clinics | Equipment Procurement Officers

Overview: Carejoy Digital – Engineering the Future of Panoramic Imaging

Carejoy Digital has emerged as a pivotal innovator in the digital dentistry ecosystem, specializing in integrated solutions across CAD/CAM, dental 3D printing, and high-fidelity imaging. With a focus on open-architecture compatibility (STL/PLY/OBJ), AI-driven scanning algorithms, and precision-engineered hardware, Carejoy’s panoramic X-ray systems exemplify the convergence of clinical accuracy and industrial scalability. This technical review dissects the manufacturing and quality assurance (QA) pipeline of Carejoy’s ISO 13485-certified facility in Shanghai, positioning China as the global leader in cost-performance-optimized dental imaging.

Manufacturing Process: From Precision Assembly to Final Integration

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-grade aluminum alloy frames, medical-grade PCBs, and CMOS/CCD sensor arrays sourced from Tier-1 suppliers (e.g., Sony, Omron). All materials pre-qualified under ISO 13485 traceability protocols. | Supplier audits, material batch tracking, RoHS/REACH compliance |

| 2. Sensor Module Fabrication | Digital flat-panel detectors assembled in Class 10,000 cleanrooms. Automated bonding of pixel arrays and integration of scintillator layers (Gd₂O₂S:Tb). | ESD-safe environments, humidity-controlled assembly, optical alignment jigs |

| 3. Robotic Arm Integration | 6-axis gantry systems calibrated for orbital sweep accuracy (±0.1°). Servo motors synchronized with imaging triggers via real-time control firmware. | Encoder feedback loops, CAN bus communication, AI-guided motion prediction |

| 4. AI-Enhanced Control Unit | Onboard GPU-accelerated processor running Carejoy’s proprietary AI reconstruction engine. Supports auto-landmark detection and dose optimization. | Open API (STL/PLY/OBJ export), DICOM 3.0 compliance, cloud integration |

| 5. Final Assembly & Enclosure | Modular chassis with EMI-shielded cabling. Touchscreen UI (15.6″ HD) preloaded with Carejoy Imaging Suite v5.2. | IP2X-rated protection, CE & NMPA certified, 24/7 remote diagnostics |

Quality Control & Calibration: Sensor Labs and Durability Testing

Every panoramic unit undergoes a 72-hour QA cycle in Carejoy’s Sensor Calibration & Metrology Lab, adhering to ISO 13485:2016 standards for medical device manufacturing. Key QC milestones include:

| QC Phase | Protocol | Validation Metric |

|---|---|---|

| Sensor Uniformity Testing | Flat-field irradiation at 60–90 kVp; pixel response variance measured via NIST-traceable dosimeter array | ≤ 3% non-uniformity (per IEC 62220-1) |

| Geometric Accuracy Calibration | Phantom scanning (e.g., ORTHOPHOS L phantom) with sub-pixel edge detection algorithms | Linear distortion < 0.2 mm over 100 mm FOV |

| Dose Consistency Audit | Repeated exposures under auto-exposure mode; output measured at standardized head position | ≤ 5% variance across 100 cycles |

| Durability & Environmental Stress | Thermal cycling (-10°C to +50°C), vibration (5–500 Hz), and 50,000 gantry rotation cycles | Zero mechanical failure; sensor SNR degradation < 2% |

| Software Validation | Regression testing of AI segmentation, DICOM export, and cloud sync modules | 99.8% scan-to-model fidelity in clinical trials (n=1,200) |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s ascendancy in digital dental manufacturing is not accidental—it is the result of strategic vertical integration, advanced automation, and deep supply chain maturity. Carejoy Digital leverages the following competitive advantages:

- Integrated Supply Chain: Proximity to semiconductor, precision motor, and display manufacturers in the Yangtze River Delta reduces lead times and BOM costs by up to 38% vs. EU/US counterparts.

- AI-Driven Production: Machine learning models optimize yield in sensor fabrication, reducing scrap rates to <0.7%—among the lowest globally.

- Regulatory Efficiency: NMPA and CE pathways are streamlined through dual-design validation, enabling faster time-to-market without compromising safety.

- Open Architecture ROI: STL/PLY/OBJ compatibility ensures seamless integration with third-party CAD/CAM and 3D printing workflows, reducing clinic dependency on proprietary ecosystems.

As a result, Carejoy delivers panoramic systems with 4K resolution, AI-guided positioning, and sub-4-second scan times at price points 25–40% below Western brands—without sacrificing clinical reliability.

Support & Lifecycle Management

- 24/7 Remote Support: Real-time firmware diagnostics via Carejoy CloudLink; OTA software updates with AI model enhancements every 90 days.

- Global Service Network: On-site engineer dispatch in 48h across APAC, EMEA, and North America.

- Calibration Recertification: Annual sensor recalibration service with ISO 17025-accredited lab reporting.

Contact & Deployment

For technical specifications, demo requests, or integration planning:

Email: [email protected]

Website: www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Panoramic Machine For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160