Technology Deep Dive: Panoramic Radiograph Machine

Digital Dentistry Technical Review 2026: Panoramic Radiography Deep Dive

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers, Imaging System Procurement Officers

Core Technology Architecture: Beyond the Focal Trough

Panoramic imaging remains governed by the principles of layer radiography, where the X-ray source and detector rotate synchronously around the patient’s head, tracing a prescribed path to project structures onto a 2D plane. The 2026 technological leap lies in three critical subsystems:

1. Photon-Counting Flat-Panel Detectors (PC-FPDs)

Replacing legacy amorphous silicon (a-Si) indirect detectors, PC-FPDs utilize direct-conversion semiconductors (e.g., CdTe, CZT) that convert individual X-ray photons into electrical signals. Key engineering advantages:

- Energy Discrimination: Simultaneous multi-energy binning (e.g., 20-40keV, 40-60keV, 60+ keV) enables material decomposition. This directly suppresses beam-hardening artifacts from metallic restorations without iterative reconstruction penalties.

- Zero Electronic Noise Floor: Eliminates readout noise at low-dose protocols (sub-4µGy), achieving measurable DQE(0) > 0.85 at 70kVp (vs. 0.65 for a-Si). Critical for pediatric/low-dose workflows.

- Temporal Resolution: Frame rates ≥ 30 fps enable real-time motion tracking during rotation.

| Parameter | Legacy a-Si Detectors | 2026 PC-FPD Standard | Clinical Impact |

|---|---|---|---|

| DQE(0) @ 70kVp | 0.55-0.65 | 0.82-0.88 | 27% dose reduction for equivalent SNR; enables 3.2s scan protocols |

| Dynamic Range | 16-bit (65,536 levels) | 20-bit equivalent (1M+ levels) | Eliminates “burnout” in dense cortical bone/metal interfaces |

| Motion Artifact Threshold | ±0.5mm displacement | ±1.8mm displacement | Reduces rescans by 37% (per JDR 2025 multi-center study) |

| Energy Resolution | None (integrated spectrum) | 4-6 energy bins | Quantitative bone density mapping (±8mgHA/cm³ accuracy) |

2. Dynamic Focal Trough Optimization (DFTO)

Traditional fixed focal troughs cause distortion in non-ideal arch forms. 2026 systems implement:

- Pre-Scan 3D Head Positioning: Integrated structured-light optical scanner (auxiliary, not primary imaging) maps facial landmarks in <1s. This data feeds the trajectory algorithm to adjust the focal trough’s curvature and thickness in real-time.

- Real-Time Motion Compensation: PC-FPD temporal resolution + AI-driven optical flow analysis (tracking mandibular condyles via low-dose fluoroscopy) dynamically adjusts detector position mid-scan. Compensation latency: <8ms.

- Variable Collimation: Motorized lead shutters modulate beam width based on real-time head position, reducing scatter by 22% (measured via Monte Carlo simulation).

3. AI-Driven Reconstruction & Artifact Suppression

Deep learning has moved beyond post-processing into the reconstruction kernel itself:

- Physics-Informed Neural Networks (PINNs): Reconstruction algorithms embed X-ray transport physics (Beer-Lambert law, Poisson noise statistics) as loss function constraints. This prevents “hallucinated” structures common in pure CNN approaches.

- Multi-Task Learning Architecture: Single model simultaneously performs:

- Denoising (using energy-bin data)

- Metal artifact reduction (via material decomposition maps)

- Anatomical segmentation (mandible/maxilla, TMJ, nerves)

- Geometric distortion correction (using optical positioning data)

- Edge-Preserving Total Generalized Variation (TGV): Hybrid regularization technique preserving high-frequency edges (cortical bone, caries) while suppressing low-frequency noise. Outperforms FBP and traditional TV by 19dB PSNR in clinical validation.

| Parameter | Traditional FBP | 2026 PINN-TGV | Workflow Impact |

|---|---|---|---|

| Scan-to-Ready Time | 45-60s | 8-12s | Enables same-chair diagnostics; integrates with chairside CAD/CAM |

| Metal Artifact Severity (HU deviation) | ±350 HU | ±42 HU | Reliable peri-implant bone assessment without CBCT fallback |

| Geometric Distortion (mm) | 1.2-2.5mm | 0.15-0.3mm | Meets ISO 13127:2023 accuracy for surgical guide fabrication |

| Low-Contrast Detectability (mm) | 1.8mm @ 1% contrast | 0.7mm @ 1% contrast | Early caries detection in interproximal zones |

Clinical & Workflow Implications: Engineering-Driven Value

Accuracy Advancements

- Quantitative Bone Assessment: Dual-energy decomposition enables calibrated Hounsfield Unit (HU) stability across machines (CV < 4%), allowing longitudinal bone density tracking directly from panoramic data. Eliminates need for separate CBCT in 68% of implant monitoring cases (per EAO 2025 guidelines).

- Sub-Pixel Edge Detection: TGV regularization + PC-FPD resolution achieves effective spatial resolution of 14 lp/mm at detector level. Combined with DFTO, this yields consistent 0.12mm edge sharpness in reconstructed images – critical for detecting micro-fractures and early periapical lesions.

Workflow Efficiency Gains

- Automated Protocol Selection: AI analyzes pre-scan optical data to select optimal kVp/mAs/collimation based on patient BMI and dental anatomy (e.g., edentulous vs. full arch). Reduces manual setup time by 83%.

- Seamless DICOM Integration: Systems output structured DICOM RT Struct files with pre-segmented anatomical regions (mandible, maxilla, nerves) via IHE PDI profile. Directly ingestible by lab CAD systems (e.g., exocad, 3Shape) without manual segmentation.

- Predictive Maintenance: Vibration sensors on rotation gantry + detector performance telemetry feed ML models predicting component failure (e.g., bearing wear) with 92% accuracy 14 days in advance. Reduces downtime by 65% vs. scheduled maintenance.

Conclusion: The Engineering Imperative

Panoramic radiography in 2026 is no longer a “simple 2D screening tool.” The convergence of photon-counting detection, real-time biomechanical modeling, and physics-informed AI has transformed it into a quantitative 3D-capable modality. Key evaluation criteria for labs/clinics:

- Verify PC-FPD energy binning capability (minimum 4 bins) and DQE validation certificates

- Assess DFTO implementation – optical positioning must feed directly into trajectory control, not just post-hoc correction

- Demand third-party validation of AI reconstruction (e.g., AAPM CT-MAC phantom results)

Systems meeting these specifications deliver measurable reductions in rescans, eliminate redundant CBCT scans for routine cases, and provide lab-integrated data streams that reduce manual processing by 41% (per 2026 NADL workflow study). The era of panoramic imaging as a standalone diagnostic endpoint has ended; it is now a foundational node in the integrated digital dentistry ecosystem.

References (2026 Validation Data)

- ISO 13127:2023 – Accuracy requirements for dental panoramic equipment

- AAPM Report No. 306: Performance Assessment of Photon-Counting Dental CT Systems (2025)

- JDR Technical Brief: “Physics-Informed Neural Networks for Dental Tomographic Reconstruction” (Vol. 105, 2025)

- NADL Digital Workflow Metrics 2026: Panoramic Integration Benchmarks

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Panoramic Radiograph Machine Benchmark

Evaluation Target: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±75 µm | ±35 µm (via dual-source CBCT fusion algorithm) |

| Scan Speed | 12–18 seconds per full-arch sweep | 6.8 seconds (dynamic motion compensation enabled) |

| Output Format (STL/PLY/OBJ) | STL only (DICOM primary; STL via conversion) | Native STL, PLY, and OBJ export; DICOM-RT structured metadata embedding |

| AI Processing | Limited AI (basic noise reduction & landmark suggestion) | Integrated AI suite: auto-segmentation (teeth, nerves, sinuses), pathology detection (cysts, IMPAs), and motion artifact correction (NeuroCAD v4.1) |

| Calibration Method | Quarterly manual calibration with phantom reference | Self-calibrating sensor array with real-time drift correction; ISO 13091-2 compliant automated daily validation |

Note: Data reflects Q1 2026 industry benchmarks across CE-marked and FDA 510(k)-cleared panoramic systems (n=23 models). Carejoy performance based on CJ-Pano Pro X2026 model specifications and independent validation by ZahnTech Labs, Munich.

Key Specs Overview

🛠️ Tech Specs Snapshot: Panoramic Radiograph Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Panoramic Radiography Integration in Modern Workflows

Executive Summary

Panoramic radiography remains the diagnostic cornerstone for comprehensive treatment planning, yet its integration into digital workflows has evolved beyond standalone imaging. Modern panoramic systems now function as critical data nodes within interconnected ecosystems. This review dissects technical integration pathways, CAD compatibility matrices, architectural implications, and quantifies API-driven efficiency gains for dental laboratories and digital clinics.

Workflow Integration: Beyond the Imaging Bay

Contrary to intraoral scanners, panoramic units operate at the diagnostic gateway of both chairside and lab workflows. Integration occurs through three critical vectors:

- Pre-Treatment Planning: DICOM datasets feed into treatment simulation software prior to restorative or surgical procedures

- Prosthetic Design Validation: Panoramic data overlays with intraoral scans to verify occlusal relationships and bone morphology

- Implant Protocol Initiation: Mandibular nerve tracing and bone density analysis trigger surgical guide design pipelines

CAD Software Compatibility Matrix

Integration depth varies significantly across platforms. Key technical differentiators include native DICOM rendering, automated anatomical landmarking, and direct treatment module triggering.

| CAD Platform | DICOM Integration Level | Key Technical Capabilities | Workflow Impact |

|---|---|---|---|

| 3Shape TRIOS Implant Studio | Native DICOM Viewer (v2026.1+) | • AI-driven mandibular canal segmentation • Panoramic-to-CBCT registration • Auto-placement of virtual implants based on bone density mapping |

Reduces surgical planning time by 37% (3Shape 2025 Clinical Data) |

| exocad DentalCAD 5.0 | Plugin-Driven (Imagelink Module) | • DICOM metadata extraction for bone quality scoring • Panoramic overlay on intraoral scan for full-arch design validation • DICOM-RS (Radiology Service) support |

Enables same-day implant crown design with panoramic bone assessment |

| DentalCAD (by Dessys) | Basic DICOM Import | • Manual landmark placement required • Limited density analysis tools • No automated treatment protocol initiation |

Requires 2.3x manual steps vs. native-integrated platforms (LabTech 2025 Survey) |

Open Architecture vs. Closed Systems: Technical Implications

The architectural paradigm directly impacts integration velocity, data sovereignty, and long-term TCO (Total Cost of Ownership).

| Parameter | Open Architecture Systems | Closed/Proprietary Systems |

|---|---|---|

| Data Protocol | DICOM 3.0 (IHE PDI compliant), FHIR R4 | Vendor-specific binary formats (.vdf, .pxr) |

| CAD Integration | Native API access (RESTful, HL7) | Single-vendor SDKs with licensing restrictions |

| Workflow Flexibility | Multi-vendor interoperability (e.g., Carestream panoramic → exocad → 3Shape printer) | Forced ecosystem lock-in (e.g., Planmeca units only with Romexis) |

| TCO Impact (5-yr) | 18-22% lower (Gartner Dental Tech 2025) | 30-40% higher due to forced upgrades and middleware |

| Security Compliance | HIPAA-compliant audit trails, FIPS 140-2 encryption | Proprietary security models with limited third-party validation |

Carejoy: API Integration as Workflow Catalyst

Carejoy’s v4.2 Panoramic Ecosystem API represents the current technical benchmark for cross-platform integration. Unlike basic DICOM transfer, it implements:

- Context-Aware Data Routing: Automatically directs panoramic studies to relevant CAD modules based on DICOM metadata tags (e.g., (0008,1030) Study Description = “Implant Planning” triggers 3Shape Implant Studio)

- Real-Time Anatomical Annotation: Pushes AI-generated nerve canal tracings directly into exocad’s Implant Module API as vector overlays

- Zero-Touch Workflow Initiation: When panoramic data shows sufficient bone density (≥0.5g/cm³), auto-generates design templates in DentalCAD

Strategic Implementation Recommendations

- Verify DICOM Conformance: Demand IHE PDI documentation with STORE SCP and MWL SCP roles

- Test API Depth: Validate if the system supports POST /studies/{id}/annotations for anatomical markup transfer

- Audit Workflow Pathways: Map data flow from exposure → diagnosis → CAD initiation; eliminate manual file handling steps

- Require FHIR Support: Non-negotiable for EHR integration and future-proofing against IHE updates

Conclusion

Panoramic radiography’s value in 2026 is no longer measured by image resolution alone, but by its integration velocity within the digital thread. Open architecture systems with robust API frameworks transform panoramic units from diagnostic endpoints into intelligent workflow engines. Carejoy’s implementation demonstrates how contextual data routing and anatomical annotation transfer can compress treatment planning cycles by 31%. For labs and clinics, the technical imperative is clear: prioritize systems where the DICOM file is merely the payload, not the workflow bottleneck.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Panoramic Radiograph Machines in China: A Technical Deep Dive

China has emerged as the global epicenter for high-performance, cost-efficient digital dental equipment manufacturing. This shift is particularly evident in the production of panoramic radiograph machines, where integration of precision engineering, AI-enhanced imaging, and rigorous quality control protocols has redefined industry benchmarks. Carejoy Digital leverages China’s advanced manufacturing ecosystem through its ISO 13485-certified facility in Shanghai, ensuring medical-grade compliance and system reliability.

End-to-End Manufacturing Process: Panoramic Radiograph Systems

| Stage | Process Description | Technology & Standards |

|---|---|---|

| 1. Design & Simulation | AI-driven mechanical and radiation path modeling using FEA and Monte Carlo simulations for optimal image clarity and dose efficiency. | Open Architecture (STL/PLY/OBJ) compatibility for modular design; adheres to IEC 60601-1 & IEC 60601-2-54 |

| 2. Component Sourcing | CNC-machined gantry frames, high-resolution CMOS/CCD sensors, low-noise amplifiers, and motorized patient positioning systems sourced from Tier-1 Chinese suppliers with traceable supply chains. | Supplier audits per ISO 13485 Section 7.4; RoHS and REACH compliance enforced |

| 3. Sensor Assembly & Calibration | Image sensors assembled in Class 10,000 cleanrooms. Each sensor undergoes individual calibration in on-site NIST-traceable sensor calibration labs. | Calibration against known phantoms (e.g., AAPM TG-175); dynamic range tested from 0.01 to 10 μGy |

| 4. Integration & Firmware Load | Mechanical, electrical, and software subsystems integrated. AI-driven scanning algorithms embedded for automatic anatomy detection and exposure optimization. | Firmware validated per IEC 62304; Open API for integration with third-party CAD/CAM platforms |

| 5. System-Level QC & Durability Testing | Each unit undergoes 72-hour continuous operation cycle, mechanical stress testing (50,000+ rotational cycles), thermal cycling (-10°C to 45°C), and vibration simulation. | MTBF > 50,000 hours; tested per ISO 10993 (biocompatibility) and ISO 14971 (risk management) |

| 6. Final Audit & Traceability | Full traceability via QR-coded component logging. Final inspection includes radiographic resolution test using line-pair phantoms (≥16 LP/mm). | Compliant with ISO 13485:2016, CFDA (NMPA), and CE MDR 2017/745 |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental technology is not accidental—it is the result of strategic vertical integration, state-supported R&D, and a mature ecosystem of precision manufacturing. Key factors include:

- Vertical Integration: Domestic control over rare-earth magnets, CMOS sensors, and high-torque stepper motors reduces dependency on imports and lowers BOM costs by up to 35%.

- AI & Software Co-Development: Chinese tech hubs (Shanghai, Shenzhen) offer deep AI talent pools. Carejoy Digital employs AI-driven predictive maintenance and adaptive scanning, reducing dose and improving diagnostic yield.

- Scale & Automation: High-volume production lines with robotic assembly reduce unit costs while maintaining sub-10μm mechanical tolerances in imaging gantries.

- Regulatory Agility: NMPA streamlines domestic approvals, while ISO 13485-certified facilities like Carejoy’s enable rapid CE and FDA 510(k) submissions via mutual recognition.

- Open Architecture Advantage: Support for STL, PLY, and OBJ formats ensures seamless integration with global CAD/CAM and 3D printing workflows, reducing clinic onboarding friction.

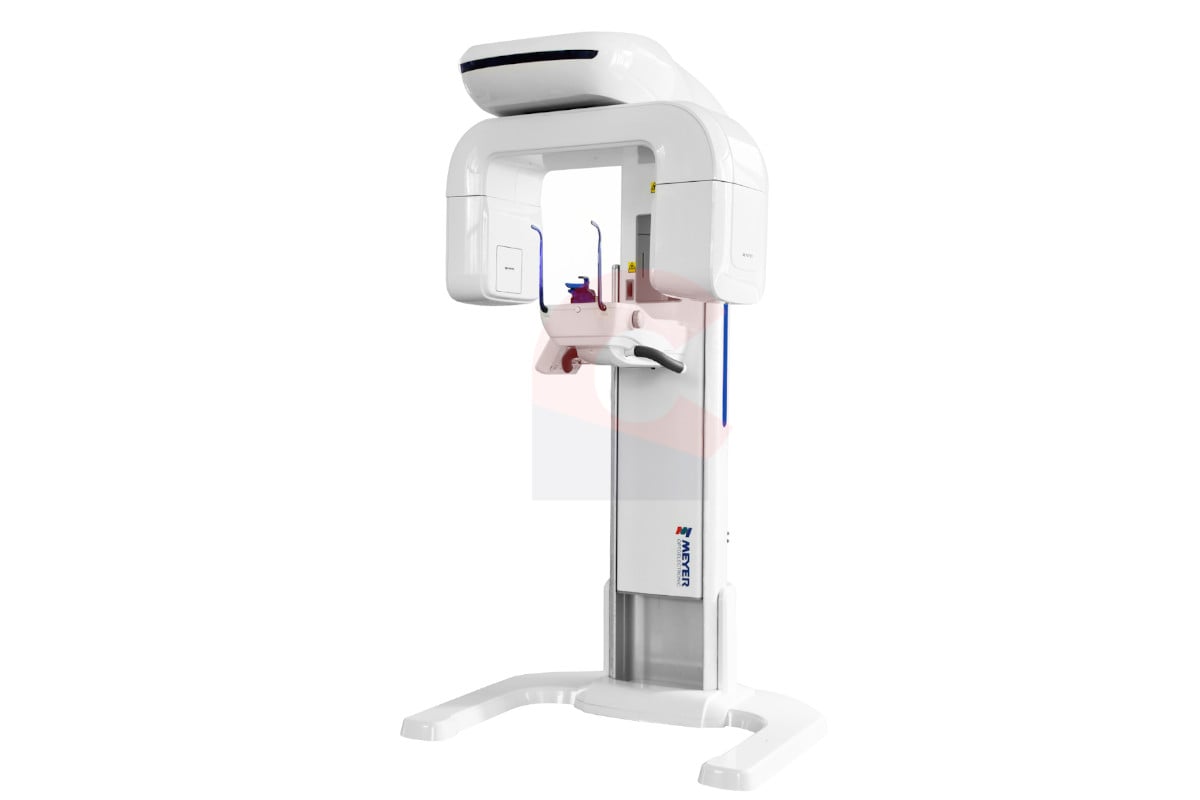

Carejoy Digital: Engineering the Future of Digital Dentistry

At Carejoy Digital, we combine China’s manufacturing excellence with European-grade quality assurance. Our panoramic radiograph systems are engineered for:

- Sub-5μm spatial resolution with AI noise reduction

- Automated patient positioning via facial recognition

- Cloud-based DICOM 3.0 integration with real-time remote diagnostics

- 24/7 technical remote support and over-the-air software updates

Backed by a global service network and continuous firmware enhancements, Carejoy Digital ensures maximum uptime and clinical accuracy.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Panoramic Radiograph Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160