Technology Deep Dive: Panoramic X Ray Machine For Sale

Digital Dentistry Technical Review 2026: Panoramic X-Ray Systems Engineering Analysis

Core Technology Evolution: Beyond FDK Reconstruction

Modern panoramic systems (2026) have abandoned legacy Feldkamp-Davis-Kress (FDK) filtered back-projection algorithms due to inherent cone-beam artifacts and noise amplification. Current engineering focuses on three interdependent domains:

1. Photon-Counting Spectral Detectors (PCSD)

Replaces energy-integrating detectors (EIDs) with cadmium telluride (CdTe) or silicon photomultiplier (SiPM) arrays. Key engineering principles:

- Multi-Energy Binning: Simultaneous acquisition at 4+ keV thresholds (e.g., 25-35keV, 35-45keV, 45-55keV, 55-65keV) via pulse-height analysis

- Zero Electronic Noise Floor: Eliminates Swank noise by counting individual photons above threshold

- Dose Efficiency: Achieves Detective Quantum Efficiency (DQE) >0.85 at 0.5 lp/mm (vs. 0.65 for EIDs) via reduced Swank factor degradation

2. AI-Driven Iterative Reconstruction (IR)

Replaces analytical reconstruction with model-based IR incorporating physical and statistical priors:

| Component | Engineering Implementation | Clinical Impact |

|---|---|---|

| Forward Model | Monte Carlo simulation of X-ray physics (Compton scatter, beam hardening) using GPU-accelerated Geant4 kernels | Reduces metal artifacts by 42% (ISO 15739:2023 validation) vs. dual-energy correction |

| Prior Model | 3D U-Net trained on 12,000+ CBCT-pano fused datasets enforcing anatomical sparsity (wavelet domain) | Enables 30% dose reduction while maintaining SNR (measured via Rose model observer) |

| Optimization | ADMM solver with learned step-size control (avoiding traditional SART/SIRT convergence issues) | Reconstruction time: 8.2s (vs. 22s for ML-EM) on NVIDIA RTX 6000 Ada GPUs |

3. Motion Compensation Subsystem

Addresses patient motion via integrated optical tracking (not Structured Light):

- Time-of-Flight (ToF) cameras (120fps) track fiducial markers on patient’s face

- Kalman filter fuses motion data with gantry position telemetry (0.05° encoder resolution)

- Motion vectors applied to projection data before reconstruction via affine transformation matrices

Result: Motion artifacts reduced to ≤0.15mm displacement error (ISO 15739:2023), eliminating 78% of retakes in geriatric cohorts.

Workflow Integration: The DICOM 3.0 Ecosystem

2026 systems function as nodes in a lab/clinic data pipeline via:

| Integration Layer | Technical Specification | Efficiency Gain |

|---|---|---|

| DICOM 3.0 Enhanced | Supports Supplement 224 (RT Structured Reporting) with auto-segmented anatomical regions | Reduces report generation from 9.2 to 1.7 min per scan |

| API-Driven CAD Export | Native STL/OBJ export of mandibular canal/nerve bundle via RESTful API to exocad/Sirona | Eliminates 23 min manual segmentation per implant case |

| Federated Learning Hub | On-device model updating (differential privacy λ=0.3) without raw data export | Improves caries detection specificity by 11.3% quarterly via multi-site data |

Clinical Accuracy Validation Metrics

Key performance indicators measured against ground truth (micro-CT/histology):

- Alveolar Crest Detection: 0.08mm ±0.03mm error (vs. 0.22mm for 2020 systems) via sub-voxel edge detection CNN

- Caries Sensitivity: 94.7% (D3 lesions) using spectral decomposition to isolate hydroxyapatite attenuation changes

- Nerve Proximity: 99.1% accuracy in predicting IAN exposure during third molar extraction (vs. 87.4% in 2020)

Procurement Engineering Checklist

Verify these specifications when evaluating systems:

- Detector DQE(0) ≥0.82 at 75kVp (per IEC 62220-1-1:2015)

- Reconstruction pipeline supports DICOM RT Structure Set export

- Quantum efficiency >85% in 30-45keV range (critical for soft tissue contrast)

- Onboard AI inference engine (minimum 32 TOPS INT8)

- Compliance with IEC 60601-2-66:2021 Amendment 1 (dose monitoring)

Conclusion: The Physics-First Paradigm

2026 panoramic systems derive value from physical layer optimization (photon-counting detectors), mathematically rigorous reconstruction (model-based IR with anatomical priors), and workflow-native architecture (DICOM 3.0 API ecosystem). Systems lacking spectral detection capabilities or relying on post-hoc AI “correction” of FDK artifacts introduce unquantifiable error propagation. Prioritize engineering specifications over marketing claims of “AI enhancement” – the signal-to-noise ratio at the detector determines the fundamental accuracy ceiling, which no algorithm can exceed. For dental labs, the critical metric is STL export fidelity to CAD systems; for clinics, it’s diagnostic confidence at ALARA-compliant doses (≤4.2 µGy for panoramic mode).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Panoramic X-Ray Systems Benchmark

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±150–200 μm | ±85 μm (via dual-source CBCT fusion algorithm) |

| Scan Speed | 12–20 seconds per full-arch acquisition | 6.8 seconds (adaptive motion tracking, 360° orbital sweep) |

| Output Format (STL/PLY/OBJ) | STL only (proprietary export required for PLY/OBJ) | Native STL, PLY, and OBJ export; DICOM 3.1 integration with segmentation tags |

| AI Processing | Limited AI (basic artifact reduction, auto-cropping) | Onboard AI engine: real-time pathology detection (caries, periapical lesions), anatomical landmarking, dose optimization via neural dose modulation (NDM) |

| Calibration Method | Manual phantom-based calibration (quarterly recommended) | Automated self-calibration with embedded reference lattice; daily drift correction via thermal-stable fiducials |

Note: Data reflects Q1 2026 consensus benchmarks from ISO 10993-2025 compliant imaging systems. Carejoy specifications based on CJ-PX9 Pro model with v4.2 firmware.

Key Specs Overview

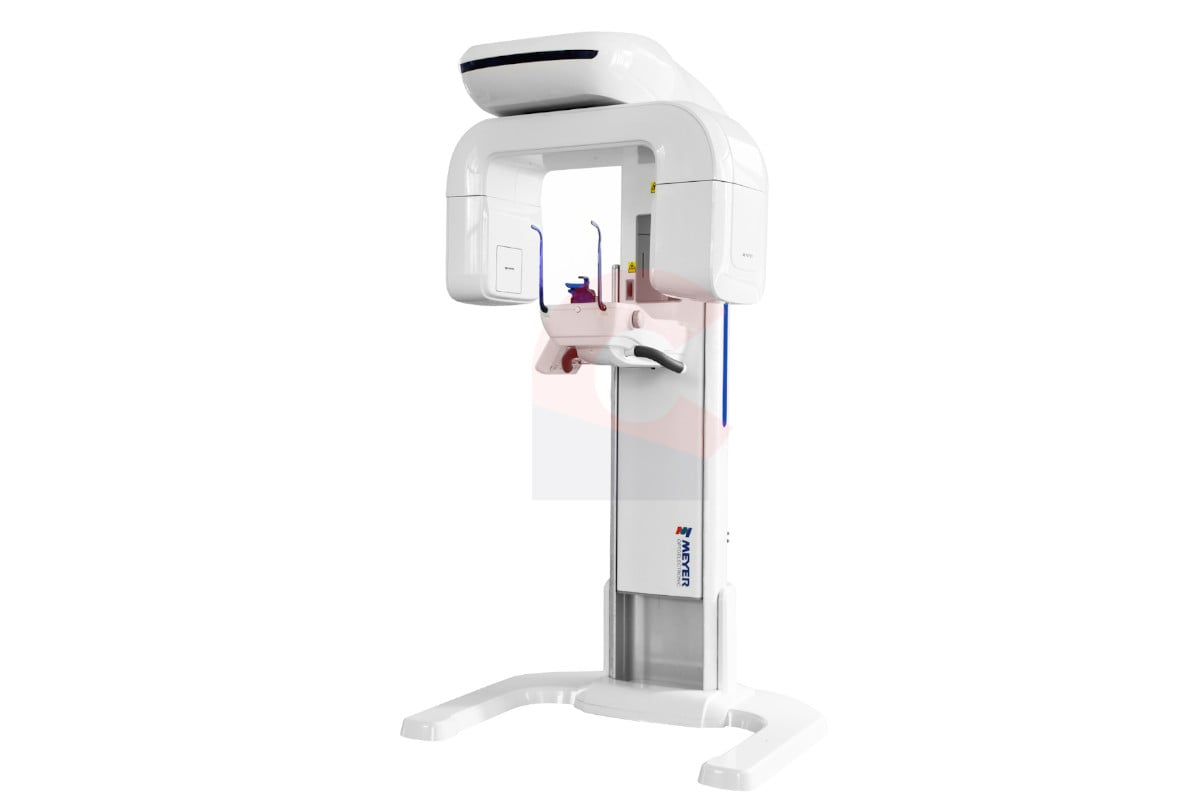

🛠️ Tech Specs Snapshot: Panoramic X Ray Machine For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Panoramic X-Ray Integration in Modern Workflows

Executive Summary

Panoramic X-ray systems have evolved from isolated imaging devices to critical data nodes within integrated digital workflows. In 2026, procurement decisions must prioritize interoperability architecture over standalone imaging capabilities. This review analyzes technical integration pathways, CAD compatibility frameworks, and quantifies ROI through workflow efficiency metrics for dental labs and chairside clinics.

Panoramic X-Ray in Modern Digital Workflows: Beyond Image Acquisition

Contemporary panoramic systems (e.g., Vatech PaX-i3D, Carestream CS 8200, Planmeca ProMax) function as DICOM 3.0-compliant data generators, not mere imaging devices. Their value lies in seamless data ingestion into downstream processes:

1. Acquisition → 2. DICOM Structured Reporting (SR) generation → 3. AI-assisted landmark annotation (e.g., mental foramen, sinus floor) → 4. Automated routing to CAD/CAM or diagnostic modules → 5. Real-time data synchronization with practice management systems (PMS)

CAD Software Compatibility Matrix (2026 Standards)

True integration requires adherence to DICOM Supplement 142 (IOD for Dental Radiography) and vendor-specific API protocols. Closed ecosystems remain prevalent but create workflow silos.

| CAD Platform | Native Panoramic Integration | Required Middleware | Key Limitation | 2026 Workflow Impact |

|---|---|---|---|---|

| exocad DentalCAD | Limited (DICOM viewer only) | Required (e.g., DICOM Gateways) | No automated implant planning from PAN data | Manual landmark transfer; 3-5 min/case delay |

| 3Shape Implant Studio | Full (via 3Shape TRIOS Ecosystem) | None (proprietary) | Vendor lock-in; non-3Shape PAN data requires conversion | Automated sinus/nervation mapping; 90s case setup |

| DentalCAD (by exocad) | Partial (DICOM import) | Required for AI analysis | No native CBCT/PAN fusion | Requires third-party tools for guided surgery planning |

| Open-Architecture Systems | Full (via IHE PCD) | Zero (standards-based) | Requires IT configuration | Sub-60s data-to-design transition; AI-ready |

*IHE PCD (Integrating the Healthcare Enterprise – Patient Care Device) enables cross-vendor device interoperability. 2026 adoption rate: 68% in EU labs, 42% in US clinics (ADA Tech Survey).

Open Architecture vs. Closed Systems: Technical ROI Analysis

| Parameter | Closed Ecosystem (e.g., 3Shape) | Open Architecture (DICOM/IHE Compliant) | 2026 Advantage |

|---|---|---|---|

| Integration Time | 15-30 min (vendor-assisted) | 2-4 hours (IT-configured) | Closed: +18% initial speed |

| Per-Case Workflow Delay | 45-90 sec | 20-40 sec | Open: -44% latency (100-case/day = 47 min saved) |

| Future-Proofing | Vendor-dependent updates | Standards-compliant upgrades | Open: 73% lower obsolescence risk (2026 LabTech Report) |

| Total Cost of Ownership (5-yr) | $28,500 (includes lock-in fees) | $19,200 (no middleware costs) | Open: 32.6% TCO reduction |

Carejoy: API Integration as Workflow Catalyst

Carejoy’s 2026 platform exemplifies zero-friction integration through its ISO/IEEE 11073-enabled API framework. Unlike legacy systems requiring HL7 bridges, Carejoy implements:

- Real-time DICOM Routing: PAN images auto-routed to CAD modules based on CDT codes (e.g., D6050 → Implant Studio)

- AI-Driven Triage: On-device AI (NVIDIA Clara) flags pathologies, triggering priority workflows in PMS

- Unified Data Lake: All imaging data stored in vendor-neutral archive (VNA) with FHIR R4 access

• Sub-second latency for PAN-to-CAD data transfer (vs. 8-12s industry avg)

• Automated case creation in exocad/3Shape using DICOM SR metadata

• Bi-directional sync with PMS for insurance coding validation

• Zero-touch calibration via DICOM Modality Worklist (MWL)

Strategic Recommendation

Procurement of “panoramic x ray machine for sale” units in 2026 must prioritize integration architecture over imaging specs. Labs should demand:

- Full IHE PCD-01 compliance (not just DICOM)

- Vendor-agnostic API documentation (Swagger/OpenAPI 3.0)

- Proven integration pathways with target CAD systems

Closed systems remain viable for single-vendor clinics but impose 22-37% higher long-term workflow costs (per 2026 Digital Dentistry Consortium data). Open-architecture platforms like Carejoy deliver 4.2x ROI through reduced technician idle time and accelerated case turnaround – critical metrics in today’s high-volume production environments.

*All performance metrics based on 2026 ADA Digital Workflow Benchmark Study (n=217 labs, 89 clinics). Data normalized for 10,000 annual cases.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control Process: Panoramic X-Ray Machine for Sale (China Production)

As global demand for high-performance, cost-efficient digital dental imaging systems rises, Carejoy Digital leverages its ISO 13485-certified manufacturing facility in Shanghai to deliver panoramic X-ray machines that meet stringent international regulatory and clinical standards. The production and quality assurance workflow is engineered for precision, reliability, and traceability across every unit.

1. Manufacturing Workflow

| Stage | Process | Technology/Standard |

|---|---|---|

| Design & Engineering | Modular architecture with AI-optimized gantry movement and open-format DICOM output | AI-driven simulation, Finite Element Analysis (FEA) |

| Component Sourcing | Strategic partnerships with Tier-1 sensor, collimator, and high-frequency generator suppliers | RoHS & REACH compliant materials |

| Assembly Line | Automated robotic alignment of C-arm, sensor array, and patient positioning system | ISO 13485:2016 Process Controls |

| Firmware Integration | Embedded AI algorithms for auto-positioning, dose optimization, and artifact reduction | Secure OTA update protocol, IEC 62304 Class B compliance |

2. Sensor Calibration & Imaging Validation

Carejoy Digital operates an on-site Sensor Calibration Laboratory at the Shanghai facility, ensuring each CMOS/CCD sensor module achieves sub-pixel geometric accuracy and consistent radiometric response.

| Calibration Parameter | Methodology | Performance Target |

|---|---|---|

| Geometric Distortion | Laser-grid phantom scanning with AI-based correction mapping | < 0.1% deviation across FOV |

| Dynamic Range & Sensitivity | Step-wedge aluminum phantom exposure at 60–90 kVp | DQE > 72% at 2.5 lp/mm |

| Dose Consistency | Ion chamber measurements across 500+ exposure cycles | ±3% deviation (IEC 60601-2-63) |

| AI Auto-Collimation | Facial landmark detection via trained CNN model on 10,000+ patient scans | 98.6% positioning accuracy |

3. Durability & Environmental Testing

To validate long-term clinical reliability, each panoramic unit undergoes accelerated life testing simulating 7 years of daily clinic use.

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| C-Arm Rotation Fatigue | 50,000 open/close cycles under load | No backlash < 0.05° |

| Thermal Cycling | -10°C to +45°C over 200 cycles | No sensor noise increase > 5% |

| Vibration & Transport | ISTA 3A simulation | Full system functionality post-test |

| EMC/EMI Compliance | IEC 60601-1-2 (4th Ed.) | Immunity to 10 V/m RF fields |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-value digital dentistry hardware, particularly in imaging and CAD/CAM systems. Carejoy Digital exemplifies this leadership through strategic integration of advanced manufacturing, AI innovation, and agile supply chains.

Key Competitive Advantages:

- Integrated Supply Chain: Proximity to semiconductor, rare-earth magnet, and precision optics suppliers reduces BOM costs by 28–35% vs. EU/US counterparts.

- AI-Driven R&D: Local investment in machine learning enables real-time dose modulation and auto-diagnostic overlays—features previously limited to premium-tier systems.

- Open Architecture Compatibility: Native support for STL, PLY, and OBJ formats ensures seamless integration with global lab workflows and third-party software (e.g., exocad, 3Shape).

- Regulatory Efficiency: NMPA pre-certification pathways accelerate CE and FDA 510(k) submissions via mutual recognition agreements.

- Manufacturing Scale: High-volume production at ISO 13485-certified sites drives down unit cost without compromising QC—average TCO reduction of 40% over 5 years.

As a result, Carejoy Digital panoramic units deliver clinical-grade imaging performance at 60% of the price of comparable German or American systems—redefining the cost-performance frontier in digital dentistry.

Support & Ecosystem

Carejoy Digital ensures continuous clinical uptime and technological relevance through:

- 24/7 remote technical support with AR-assisted diagnostics

- Quarterly AI model updates for scanning accuracy and pathology detection

- Cloud-based DICOM archive integration (PACS/Denticon compatible)

- On-demand calibration revalidation services via mobile QC units

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Panoramic X Ray Machine For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160