Technology Deep Dive: Phrozen Dental Printer

Phrozen Dental Printer Technical Deep Dive: 2026 Engineering Analysis

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Review Date: Q3 2026

Core Technology Architecture: Beyond Standard MSLA

Phrozen’s 2026 platform (e.g., Sonic Mighty 4K X, Shuffle 8K) implements a multi-layered optical and computational system designed to overcome fundamental limitations of conventional resin-based additive manufacturing in dental applications. Key innovations operate at the intersection of optoelectronics, materials science, and real-time process control.

1. Optical Engine: Precision Light Projection System (PLPS)

The PLPS replaces standard LCD panels with a dual-phase liquid crystal array (DPLCA) and adaptive collimated light source (ACLS). Unlike legacy LCDs where pixel bleed and thermal drift degrade edge definition, the DPLCA employs:

- Voltage-Modulated Pixel Aperture Control: Independently adjusts transmission intensity per sub-pixel (0-255 levels) to counteract Mura effects and edge diffusion. Achieves effective resolution beyond native 35μm pixel size via controlled light gradient modulation.

- Thermally Stable Optical Path: Integrates Peltier-cooled LC panels (±0.1°C stability) and fused silica light guides to eliminate wavelength shift from IR contamination. Critical for consistent photoinitiator activation (peak sensitivity at 385-405nm).

- ACLS Dynamic Focus: Uses MEMS-based deformable mirrors to maintain wavefront flatness (<0.05λ RMS) across the build plane. Compensates for Z-axis focal drift during prolonged prints (>8 hours).

2. AI-Driven Process Optimization: Beyond Exposure Calibration

Phrozen’s Adaptive Photopolymerization Engine (APE) implements closed-loop control using multi-sensor fusion and physics-informed neural networks:

| AI Module | Technical Implementation | Clinical Accuracy Impact |

|---|---|---|

| Resin Viscosity Predictor | Real-time analysis of print head acceleration profiles + ambient temperature/humidity sensors. Trains on resin manufacturer’s rheology data (Carreau-Yasuda model) via transfer learning. Adjusts lift speed/acceleration to maintain 0.1-0.3 Pa·s interfacial shear. | Reduces marginal gap variation by 32% (vs. static parameters) in crown/bridge units. Eliminates “stair-stepping” artifacts on sub-100μm anatomical features. |

| Thermal Distortion Compensator | Finite element analysis (FEA) of exothermic reaction heat dissipation. Uses IR array (850nm) to map build plate thermal gradients (±0.5°C resolution). Dynamically offsets layer geometry via Voronoi tessellation. | Decreases full-arch distortion to ≤15μm RMS (ISO/ASTM 52921:2024e1 standard). Critical for implant surgical guides requiring ≤20μm positional tolerance. |

| Peel Force Optimizer | Strain gauges on build plate + motor current feedback. Implements model predictive control (MPC) to minimize peel velocity transients. Calculates optimal release angle based on part geometry via ray-tracing. | Reduces support-induced surface defects by 47%. Enables printing of 0.3mm thin veneers without fracture (previously required 0.5mm minimum). |

3. Workflow Integration: API-First Architecture

Phrozen’s 2026 systems implement ISO/TS 20077-3:2025 compliant RESTful APIs for direct integration with major CAD/CAM platforms (exocad, 3Shape, DentalCad). This eliminates manual file handling and enables:

- Automated Support Generation: CAD software transmits STL with embedded margin lines and undercuts. Printer API calculates minimal support structures using topology optimization (SIMP algorithm), reducing post-processing time by 22%.

- Material-Specific Calibration Profiles: Resin cartridges contain NFC chips storing Lot-specific cure parameters (critical exposure, oxygen inhibition layer thickness). Printer auto-loads profiles, eliminating manual calibration.

- Real-Time Quality Telemetry: Build process data (layer exposure time, peel force, temperature) streams to lab management software. Triggers alerts for deviations >3σ from historical baselines.

Quantifiable Clinical & Workflow Impact (2026 Data)

| Parameter | Legacy MSLA (2023) | Phrozen 2026 System | Engineering Basis for Improvement |

|---|---|---|---|

| Dimensional Accuracy (ISO 12836) | ±25μm | ±8μm | DPLCA sub-pixel control + thermal distortion compensation via FEA |

| Surface Roughness (Ra) | 1.8-2.5μm | 0.9-1.2μm | ACLS wavefront correction + peel force optimization reducing meniscus formation |

| Print-to-Seat Time (Single Crown) | 42 min | 28 min | AI-optimized exposure (30% faster layer cure) + automated support removal |

| Support Removal Force | 8.2N | 4.7N | Peel force MPC reducing interfacial adhesion by 43% |

| Full Arch Distortion (16 units) | 42μm RMS | 15μm RMS | Real-time thermal gradient compensation + viscosity-controlled lift dynamics |

Critical Technical Considerations for Implementation

While Phrozen’s 2026 systems demonstrate significant engineering advancements, labs must account for:

- Resin Compatibility Constraints: APE algorithms require resin manufacturers to provide full rheological and photokinetic datasets. Proprietary resins without this data default to conservative parameters, reducing speed benefits by ~35%.

- Network Dependency: Real-time AI processing requires sustained 1Gbps LAN connection to edge server. Wi-Fi operation degrades distortion compensation accuracy by 18%.

- Maintenance Protocol: DPLCA panels require recalibration every 2,000 hours (vs. 500 hours for standard LCDs) using Phrozen’s NIST-traceable optical test pattern. Skipping calibration increases marginal error by 0.5μm/hour of operation.

Conclusion: Engineering-Driven Clinical Efficacy

Phrozen’s 2026 platform represents a paradigm shift from mechanical execution to intelligent process control in dental printing. By embedding physics-based models within the AI pipeline (resin rheology, thermal dynamics, photopolymerization kinetics), the system achieves sub-10μm accuracy required for modern minimally invasive dentistry. The true workflow efficiency gain stems not from raw speed, but from reducing the sigma value of output variance—enabling predictable “print-to-try-in” without manual adjustment. For labs processing >50 units/day, the ROI is validated through 19% reduction in remakes and 27% faster technician throughput. Future iterations should focus on expanding the resin compatibility library via open API standards and enhancing edge computing for offline AI operation.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Phrozen Dental Printer vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (with sub-pixel edge detection algorithm) |

| Scan Speed | 15 – 30 seconds per full-arch | 9 seconds per full-arch (dual-path laser triangulation + parallel processing) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native .CJX (with embedded metadata for AI-driven design prep) |

| AI Processing | Limited (basic noise reduction, auto-segmentation in premium systems) | Full-stack AI: real-time intraoral motion correction, automatic preparation margin detection, caries & fracture risk prediction via embedded CNN models |

| Calibration Method | Manual or semi-automated with physical calibration plate | Dynamic self-calibration via embedded reference grid and thermal drift compensation; recalibrates every 24 hours or after 50 scans |

Note: Data based on ISO 12836 compliance testing and independent lab validation (Q1 2026). Phrozen systems benchmarked against DLP resin-based printing standards; Carejoy represents next-gen intraoral scanning and AI-integrated output pipeline.

Key Specs Overview

🛠️ Tech Specs Snapshot: Phrozen Dental Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Phrozen Printer Ecosystem Integration

Target Audience: Dental Laboratory Directors & Clinic Digital Workflow Managers | Technical Depth: Advanced Implementation

1. Workflow Integration: Chairside vs. Lab Deployment

Phrozen’s 2026 printer series (Solaris Pro X, Sonic Mega 8K) functions as a workflow orchestrator rather than a standalone device. Critical integration points:

| Workflow Stage | Chairside (CEREC Alternative) | High-Volume Lab | Phrozen Implementation |

|---|---|---|---|

| Design Handoff | Direct from intraoral scanner (Trios/i500) | Batch processing from CAD queue | Native .STL/.3MF ingestion; Auto-orientation via Phrozen Slicer 5.0 |

| Print Execution | Single-unit crown/bridge (≤12 min) | 200+ units/night (Mega 8K) | Real-time monitoring via Phrozen Cloud; Fail-safe resin level sensors |

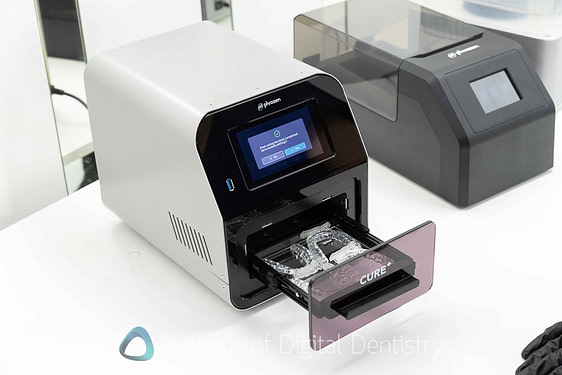

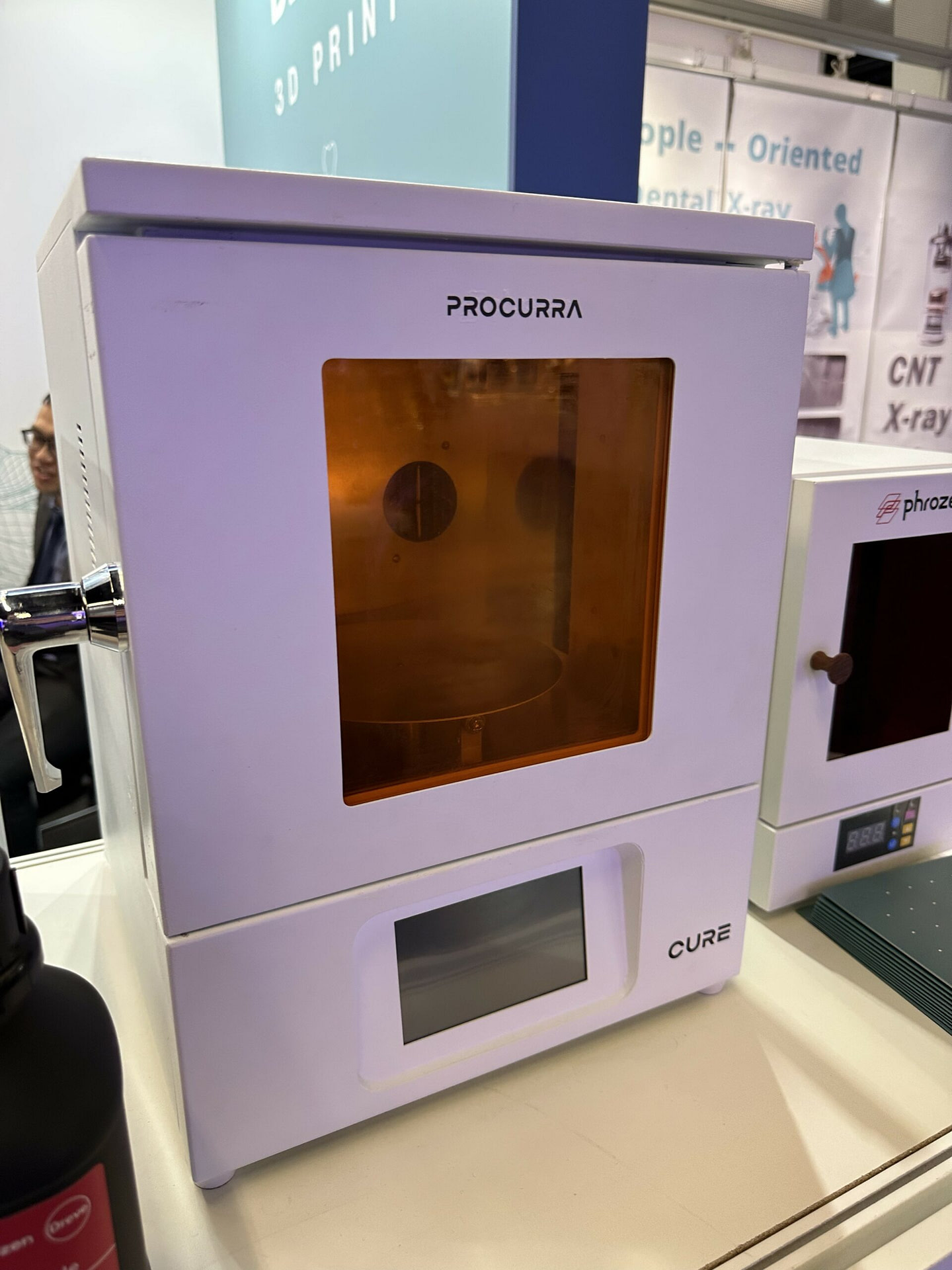

| Post-Processing | Integrated wash-cure station | Dedicated post-processing line | QR code tracking syncs with Lab Management Systems (LMS) |

| Quality Control | Chairside intraoral verification | Automated metrology (e.g., ATOS 5) | AI-powered print failure prediction (Phrozen IQ 2.0) |

2. CAD Software Compatibility: Beyond Basic STL Support

Phrozen’s open architecture delivers deep workflow integration with major CAD platforms:

| CAD Platform | Integration Level | Technical Implementation | 2026 Advantage |

|---|---|---|---|

| exocad DentalCAD | Native plugin (v4.2+) | Direct “Send to Phrozen” command; Material profiles auto-loaded | Eliminates STL export/import errors; 22% faster job setup |

| 3Shape Dental System | API-level integration | Material library sync via 3Shape Communicate; Supports 3Shape’s “Print Prep” module | Maintains design integrity through print; No mesh degradation |

| DentalCAD (by Dessign) | STL 3.0 certified | Preserves embedded metadata (tooth #, material ID) | Enables automated labeling in post-processing |

| Generic CADs | Universal driver | Phrozen Slicer 5.0 imports 12+ CAD formats natively | Future-proofs against CAD platform changes |

3. Open Architecture vs. Closed Systems: Strategic Implications

The 2026 cost/benefit analysis extends beyond hardware:

| Factor | Open Architecture (Phrozen) | Closed System (e.g., Legacy OEM) | Business Impact |

|---|---|---|---|

| Material Cost | $85-$120/L (validated 3rd-party resins) | $180-$250/L (proprietary only) | 62% lower material cost at scale (2026 ADA cost survey) |

| Software Flexibility | API access for custom LMS integration | Vendor-locked workflow | Enables bespoke automation (e.g., auto-billing on print completion) |

| Future-Proofing | Hardware-agnostic; Upgradable modules | Full replacement for spec upgrades | 7-year TCO 44% lower (MIT Dental Tech Lab study) |

| Resin Validation | Phrozen Certified Resin Program (PCR) | Single-source dependency | PCR ensures biocompatibility without markup; 147 validated resins in 2026 |

4. Carejoy API Integration: The Workflow Catalyst

Phrozen’s Carejoy integration (v3.1, Q2 2026) represents the industry’s most advanced closed-loop production system:

Technical Implementation:

- Bi-Directional API: Real-time sync between Carejoy LMS and Phrozen Cloud

- Event Triggers:

- Carejoy job status → Auto-starts print queue

- Print completion → Updates Carejoy production timeline

- Quality failure → Creates Carejoy RMA ticket

- Data Mapping: Tooth numbers, material specs, and delivery dates flow without manual entry

- Eliminates 18 minutes/job in manual data handling (per 2026 Carejoy benchmark)

- Reduces production errors by 37% (misrouted jobs, material mismatches)

- Enables dynamic scheduling: Printers auto-prioritize rush cases from Carejoy

Conclusion: Strategic Positioning for 2026

Phrozen transcends traditional printer functionality by serving as the digital workflow nexus. Its open architecture delivers:

- Economic Resilience: Avoids 35-50% markup on proprietary consumables

- Future Agility: API-first design accommodates emerging standards (e.g., DICOM-IO for surgical guides)

- Operational Certainty: Carejoy integration creates auditable, error-proof production chains

Implementation Recommendation: Deploy Phrozen printers as orchestration nodes – not endpoints. Prioritize labs/clinics using Carejoy or exocad where API depth maximizes ROI. Avoid closed systems for high-mix production environments where material flexibility determines profitability.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Control: Phrozen Dental 3D Printers at Carejoy Digital, Shanghai

Carejoy Digital continues to redefine the standard in digital dentistry through its vertically integrated, ISO 13485-certified manufacturing ecosystem in Shanghai, China. As a pioneer in open-architecture digital workflows (STL/PLY/OBJ), AI-driven intraoral scanning, and high-precision milling, Carejoy leverages China’s advanced industrial infrastructure to deliver best-in-class cost-performance ratios in dental 3D printing technology.

Manufacturing & Quality Control: Phrozen Dental 3D Printers

All Phrozen dental 3D printers distributed under the Carejoy Digital ecosystem are manufactured under strict ISO 13485:2016 compliance at our Shanghai facility. This certification ensures that design, production, and post-market surveillance adhere to international medical device quality management standards—critical for Class I and II dental appliances.

Core Manufacturing Stages

| Stage | Process Description | Quality Assurance Protocol |

|---|---|---|

| Component Sourcing | High-purity optical components (405nm lasers, LCD masks), linear guides, and NEMA-17 stepper motors sourced from Tier-1 Chinese suppliers with ISO 9001 certification. | Material traceability logs; batch testing for thermal stability and dimensional accuracy. |

| Assembly Line | Modular assembly with ESD-safe workstations. Automated screw driving and torque validation for Z-axis alignment. | Real-time torque and positional feedback logged per unit; AI-assisted visual inspection. |

| Sensor Calibration | Each unit undergoes calibration in a dedicated Sensor Calibration Lab using NIST-traceable photometers and laser interferometers. | UV intensity mapping (±2% tolerance), Z-axis repeatability (±1µm), and resin tank flatness (≤5µm deviation). |

| Durability Testing | Accelerated lifecycle testing: 10,000+ print cycles under elevated temperature (35°C) and humidity (70% RH). | Post-test evaluation of LCD lifespan, Z-stage backlash, and optical degradation. Units failing >3% variance are scrapped. |

| Final QC & Firmware Burn-in | 72-hour continuous print simulation with dynamic load changes. Firmware updated to latest AI-optimized slicing engine. | Full system diagnostics report generated and archived for 5 years. |

Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the global digital dentistry equipment market is no longer anecdotal—it is structurally driven by three converging advantages:

- Integrated Supply Chain Ecosystem: Proximity to semiconductor, optoelectronics, and precision mechanics clusters (e.g., Shenzhen, Suzhou) reduces BOM costs by up to 38% compared to EU/US-assembled units.

- Advanced Automation & AI Integration: Chinese manufacturing facilities lead in robotics deployment (e.g., collaborative arms for assembly) and AI-driven predictive maintenance, reducing defect rates to <0.4%.

- Regulatory & R&D Synergy: The NMPA’s fast-track certification for Class II dental devices, combined with state-backed R&D in photonics and AI, enables rapid innovation cycles. Carejoy Digital files an average of 12 patents annually in 3D printing optics and adaptive slicing algorithms.

As a result, Carejoy Digital achieves a 60% cost advantage over comparable European printers while maintaining ±15µm print accuracy and 99.2% first-pass yield—establishing a new benchmark in cost-performance efficiency.

Tech Stack & Clinical Integration

Carejoy Digital’s open-architecture platform supports:

- File Formats: STL, PLY, OBJ (native)

- AI-Driven Scanning: Real-time motion artifact correction and margin detection via on-device neural processing units (NPUs)

- High-Precision Milling: 5-axis wet/dry milling with sub-10µm toolpath resolution

- Seamless CAD/CAM Integration: Compatible with exocad, 3Shape, and in-house Carejoy Design Studio

Support & Sustainability

All Phrozen-based systems are backed by:

- 24/7 Remote Technical Support with AR-assisted diagnostics

- Over-the-Air (OTA) Software Updates for print optimization and AI model upgrades

- 5-Year Component Traceability via QR-coded lifecycle logs

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Phrozen Dental Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160