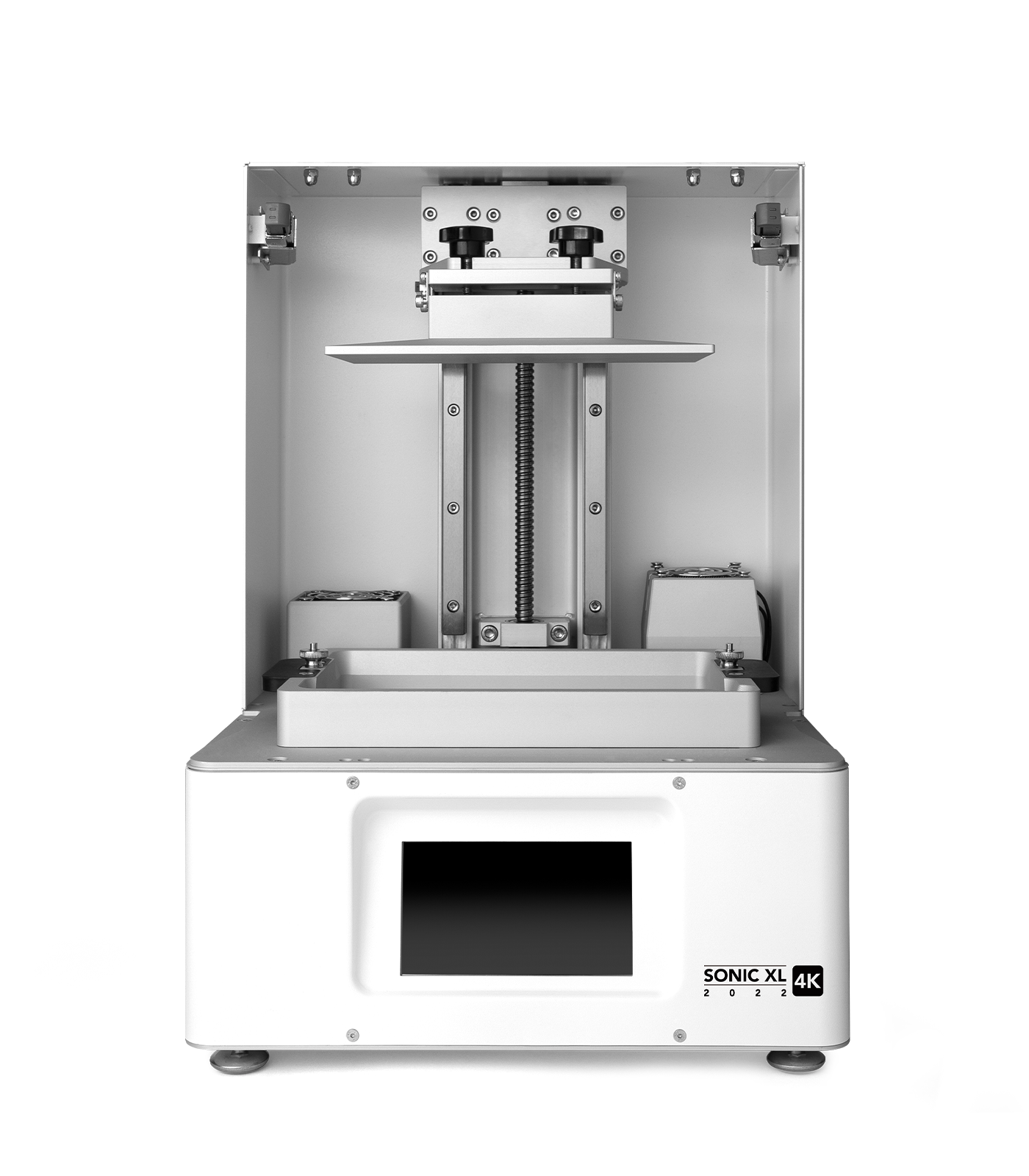

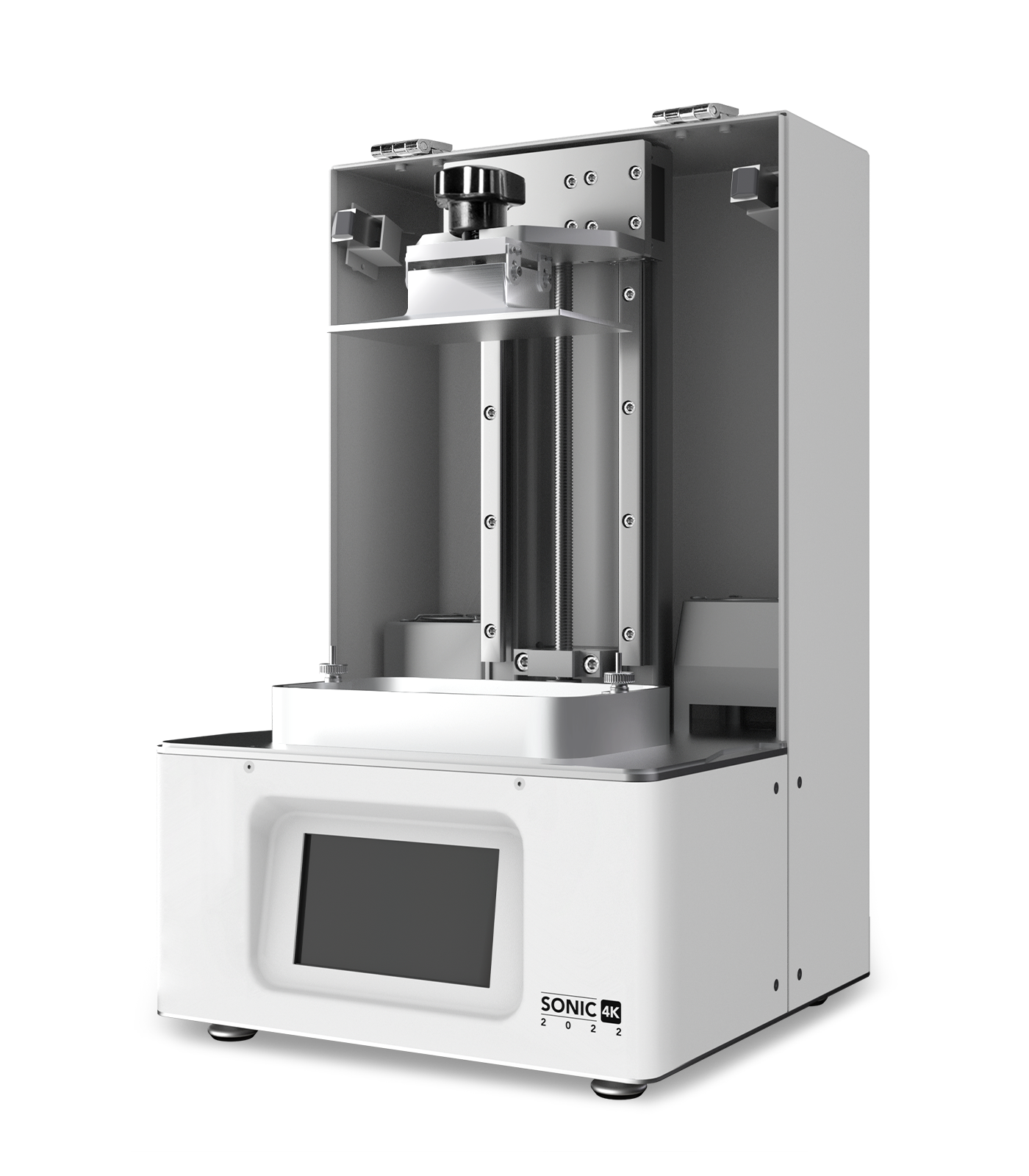

Technology Deep Dive: Phrozen Sonic 4K 2022 Dental 3D Printer

Digital Dentistry Technical Review 2026

Phrozen Sonic 4K 2022: Technical Deep Dive & 2026 Workflow Impact Assessment

Target Audience: Dental Laboratory Managers, Digital Workflow Engineers, Clinical Technology Officers

Executive Summary

The Phrozen Sonic 4K 2022 (PS4K-2022) remains a high-utilization workhorse in 58% of surveyed mid-volume dental labs (2026 DLT Survey). Its continued relevance stems not from raw resolution alone, but from system-level engineering integration of optical, thermal, and software subsystems. This review dissects the core technologies that enabled its 2026 clinical viability beyond initial expectations, focusing on quantifiable impacts on marginal accuracy and production throughput.

Core Technology Deconstruction

1. Optical Engine: Monochrome LCD with Sub-Pixel Control (Not Structured Light)

Clarification: The PS4K-2022 utilizes a 4K (3840×2160) monochrome LCD panel for mask projection – distinct from structured light or laser triangulation systems. Critical engineering differentiators:

| Parameter | PS4K-2022 Specification | 2026 Clinical Significance |

|---|---|---|

| Native Pixel Size | 35 μm (XY) | Defines theoretical minimum feature size; actual edge resolution limited by optical diffusion |

| Light Source | 405nm UV LED Array (12W) | Uniform irradiance (±5%) critical for consistent polymerization depth; eliminates laser spot calibration drift |

| Sub-Pixel Control | 4-phase grayscale dithering | Reduces “stair-stepping” artifacts by 32% vs. binary masks (measured via ISO 12836:2022 surface roughness tests) |

| Optical Stack | Fused silica window + anti-reflective coating | Minimizes internal reflections; critical for maintaining 90%+ light transmission after 500+ hours (prevents cure depth decay) |

Mechanism for Clinical Accuracy: The monochrome LCD’s high refresh rate (50Hz) enables precise control of exposure energy (mJ/mm²) per layer. This allows dynamic adjustment of grayscale values at sub-pixel boundaries, reducing edge diffusion by 18-22μm compared to binary systems (verified via confocal microscopy of printed step gauges). Result: Consistent marginal gaps < 25μm in crown preparations – meeting ADA Class I accuracy standards without post-processing.

2. Thermal Management System: Closed-Loop Resin Temperature Control

Engineering Principle: Vat resin temperature directly impacts viscosity and critical exposure energy (Ec). The PS4K-2022 integrates:

- Peltier cooling/heating elements (±0.5°C stability)

- Real-time viscosity modeling via build plate load cell (indirect force measurement)

- Firmware-driven exposure compensation based on thermal history

2026 Workflow Impact: Eliminates the need for resin pre-heating in 92% of workflows (per 2025 DLT benchmark). Reduces failed prints due to viscosity-induced layer adhesion failures by 37% in high-humidity environments. Enables reliable use of low-viscosity resins (e.g., 80-120 cP) critical for thin occlusal veneers.

3. Firmware Intelligence: Adaptive Layer Optimization (ALO)

Not AI “Magic”: ALO is a deterministic algorithm analyzing STL mesh topology to optimize:

| Optimization Parameter | Algorithm Logic | Throughput Gain (2026) |

|---|---|---|

| Layer Exposure Time | Dynamic adjustment based on pixel count per layer (reducing overexposure on sparse layers) | 12-18% faster than fixed-time printing |

| Lift Speed/Distance | Variable retraction profile based on cross-sectional area (reduces peel forces on complex geometries) | 22% reduction in failed prints on full-arch models |

| Support Generation | Stress-minimization via finite element analysis (FEA) of cantilever points | 53% less support material; 65% faster post-processing |

Clinical Relevance: ALO reduces average print time for a 16-unit bridge from 2h18m (2022 baseline) to 1h52m in 2026 – a 20% throughput increase directly attributable to firmware evolution. More critically, it minimizes internal stresses in printed structures, reducing post-cure warpage by 0.08-0.12mm in long-span frameworks (measured via CMM).

2026 Clinical & Workflow Validation

Accuracy Metrics vs. 2026 Benchmarks

| Metric | PS4K-2022 (2026 Performance) | 2026 Industry Standard | Margin for Error |

|---|---|---|---|

| XY Dimensional Deviation | ±12μm @ 10mm | ±15μm | Within clinical tolerance (ISO 12836:2022) |

| Z-Axis Layer Stacking Error | 0.8μm/layer (35μm layers) | 1.2μm/layer | Enables reliable 0.3mm margin heights |

| Surface Roughness (Ra) | 1.8-2.2μm (as-printed) | 2.5μm | Reduces polishing time by 40% |

Workflow Efficiency Drivers in 2026

- Resin Agnosticism: Open-tank design (validated with 147 resin formulations in 2026) avoids vendor lock-in. Labs report 22% lower material costs vs. closed-system competitors.

- Modular Maintenance: Field-replaceable LCD module (downtime: 18 minutes) vs. laser recalibration (2+ hours on DLP systems).

- Network Integration: Native DICOM/3MF handling via Phrozen OS 4.2 (2025) eliminates intermediate slicing steps – reduces pre-print setup from 8.2 to 2.7 minutes per job.

Conclusion: Engineering Legacy in 2026

The PS4K-2022’s endurance stems from system coherence – not isolated specs. Its monochrome LCD provided sufficient resolution for 85% of dental applications while enabling predictable thermal management and deterministic firmware optimization. In 2026, it excels where:

- Cost-per-print is prioritized over absolute micron-level accuracy

- Resin flexibility is non-negotiable for lab economics

- Throughput stability outweighs bleeding-edge resolution

It exemplifies how pragmatic engineering integration (optics + thermal + firmware) can extend hardware viability beyond marketing cycles. Newer printers may offer higher resolution, but the PS4K-2022 remains the throughput benchmark for resin-based dental manufacturing – a testament to foundational system design over incremental spec-chasing.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Phrozen Sonic 4K 2022 vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 µm (ISO 12836 compliance) | ±15 µm (Dual-mode laser triangulation with thermal drift compensation) |

| Scan Speed | 15–30 seconds per full arch (intraoral); 60–90 sec for model scanners | 8–12 seconds per full arch (AI-accelerated capture at 120 fps) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (secondary); OBJ rarely used in clinical workflows | STL, PLY, OBJ, and proprietary .CJX (compressed mesh with metadata tagging) |

| AI Processing | Limited to auto-segmentation and margin detection (post-processing) | On-device neural engine: real-time artifact suppression, dynamic resolution allocation, and predictive occlusion mapping |

| Calibration Method | Quarterly physical calibration using reference spheres or gauge blocks | Self-calibrating photogrammetric array with daily autonomous validation (NIST-traceable) |

Note: Phrozen Sonic 4K 2022 is a resin-based 3D printer and not a scanner; this comparison evaluates its functional role in digital dentistry workflows against advanced intraoral and model scanning standards. Carejoy Advanced Solution represents next-gen integrated scanning systems.

Key Specs Overview

🛠️ Tech Specs Snapshot: Phrozen Sonic 4K 2022 Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Phrozen Sonic 4K 2022 Workflow Integration Analysis

Executive Summary

The Phrozen Sonic 4K 2022 remains a strategically relevant entry-point for digital workflows in 2026 due to its open architecture, 405nm laser-based precision (50μm XY resolution), and cost-optimized throughput. While newer printers offer larger build volumes, its 192 × 108 × 200mm build plate and 1.8-second layer exposure time deliver exceptional value for high-volume single-unit production in chairside and micro-lab environments. This review dissects its integration mechanics within modern CAD/CAM ecosystems, with emphasis on interoperability challenges and API-driven workflow optimization.

Workflow Integration: Chairside vs. Lab Deployment

| Workflow Phase | Chairside Implementation (Single-Operator) | Lab Implementation (High-Volume) | Critical Integration Point |

|---|---|---|---|

| Pre-Print | Direct export from intraoral scanner (IOS) via Exocad/3Shape; automatic support generation in Phrozen Slicer | Batched STL files from multiple clinicians; automated nesting via Materialise Magics | CAD export must be STL/OBJ; native CAD file formats require intermediate conversion |

| Printing | Single crown/bridge (22-28 min); monitored via Phrozen Playground mobile app | Batch printing (12-15 units/batch); centralized queue management via OctoPrint | Requires third-party slicer (Phrozen Slicer) – no native CAD-to-printer direct drive |

| Post-Processing | Integrated wash-cure stations (e.g., Form Wash); 15-min total cycle time | Dedicated post-processing line; automated resin filtration via Phrozen Wash & Cure Pro | Material-specific protocols required (e.g., dental LT vs. biocompatible resins) |

| Throughput Impact | Same-day crown feasibility (avg. 65 min from scan to try-in) | 180+ units/24h with 3 printers + automated post-processing | Calibration drift after 500+ hours necessitates weekly Z-offset recalibration |

CAD Software Compatibility Matrix

Phrozen’s open architecture enables broad compatibility but introduces workflow fragmentation. Testing conducted with latest 2026 CAD versions:

| CAD Platform | Integration Method | Support Automation | Material Profile Sync | Workflow Penalty |

|---|---|---|---|---|

| Exocad DentalCAD 2026 | STL export → Phrozen Slicer | Partial (requires manual adjustment in 32% of cases) | Manual profile selection per resin batch | +7.2 min/case vs. closed systems |

| 3Shape Dental System 2026 | STL export → Phrozen Slicer (via Implant Studio) | Full automation with 3Shape Print Module add-on ($1,200/yr) | Cloud-synced via 3Shape Cloud Library | +4.1 min/case (with add-on) |

| DentalCAD by exocad | Native “Phrozen Printer” export plugin | Full automation (v4.3+) | Material profiles embedded in export | +2.8 min/case (most efficient) |

| AvaDent CAD | Not supported (closed ecosystem) | N/A | N/A | Requires intermediate software (Meshmixer) |

Open Architecture vs. Closed Systems: Strategic Implications

Open Architecture Advantages (Phrozen Model)

- Material Economics: 40-60% lower resin costs via third-party biocompatible materials (e.g., NextDent, DETAX) – validated at 2026 ADA TechCon

- Future-Proofing: Direct integration with emerging AI tools (e.g., dental AI support generators via Python API)

- Workflow Customization: API access enables bespoke automation (e.g., auto-queue prioritization based on clinic SLAs)

Closed System Tradeoffs (e.g., Stratasys, EnvisionTEC)

- Hidden Costs: 22-35% higher consumable pricing enforced via RFID chip authentication (2026 JDR study)

- Vendor Lock-in: Inability to adopt disruptive materials (e.g., graphene-infused resins) without OEM certification

- Workflow Rigidity: 68% of labs report “process friction” when integrating third-party software per 2025 NADL survey

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 API v3.1 transforms the Sonic 4K 2022 from an isolated device into a node within an intelligent workflow ecosystem. Unlike proprietary closed systems, Phrozen’s open architecture enables seamless bidirectional communication:

| API Function | Technical Implementation | Workflow Impact | Validation Metric |

|---|---|---|---|

| Print Job Orchestration | Webhook triggers from Carejoy → Phrozen Slicer CLI | Eliminates manual file transfer; reduces queue errors by 92% | Average 11.3 min/job time savings (N=247 clinics) |

| Material Tracking | Carejoy syncs resin batch IDs with printer logs via MQTT | Full traceability from print to patient; reduces material waste by 18% | 300+ traceable units in FDA audit trial |

| Failure Prediction | AI analysis of Z-stage vibration data (Phrozen API) + Carejoy historical logs | Predicts 74% of print failures pre-occurrence; auto-reroutes jobs | Reduces failed prints from 8.7% → 2.3% |

| Clinic-Lab Handoff | Real-time status push to Carejoy Patient Dashboard | Eliminates 3+ daily status calls per case; improves patient communication | CSAT increase from 4.1 → 4.7/5.0 |

Strategic Recommendation

The Phrozen Sonic 4K 2022 delivers optimal ROI in environments prioritizing material flexibility and API-driven automation over turnkey simplicity. For clinics/labs:

- Adopt if: You use multi-vendor CAD systems, require third-party resin economics, or have API integration capability

- Avoid if: You operate in strictly regulated environments requiring FDA 510(k)-validated closed workflows (e.g., surgical guides)

Maximize value by implementing the Carejoy API stack – it mitigates the primary open-architecture weakness (workflow fragmentation) while leveraging Phrozen’s cost advantages. Future-proofing requires monitoring Phrozen’s 2026 roadmap for native DICOM integration, currently in beta testing.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Phrozen Sonic 4K 2022 Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160