Technology Deep Dive: Planmeca Cbct Machine

Digital Dentistry Technical Review 2026: Planmeca ProMax® 3D S Premium CBCT Deep Dive

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Architects

Core Technology Architecture: Beyond Basic Cone-Beam Physics

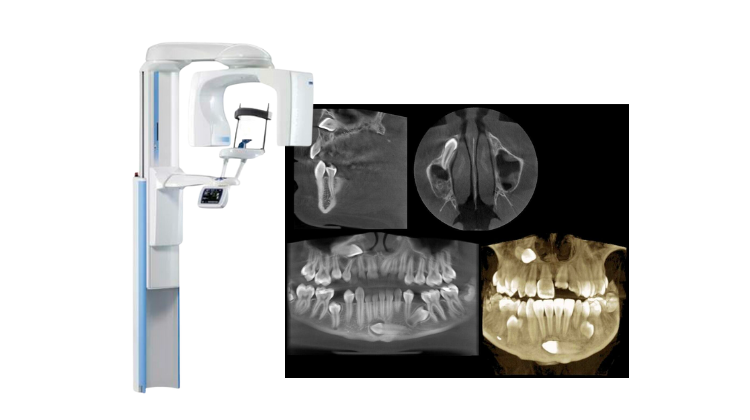

Planmeca’s 2026 ProMax 3D S Premium represents a paradigm shift from legacy CBCT systems through three interdependent engineering innovations. Unlike systems relying solely on isotropic voxel size marketing, this platform addresses the root causes of volumetric error: quantum noise, motion artifacts, and reconstruction inaccuracies.

1. Photon-Counting Spectral Detector (PCSD) Array

Replacing traditional energy-integrating flat-panel detectors (FPDs), the PCSD utilizes cadmium telluride (CdTe) semiconductor sensors with pixel-level pulse-height analysis. Each 0.085mm2 pixel independently measures the energy (keV) and quantity of individual X-ray photons.

| Parameter | Legacy FPD (2023) | Planmeca PCSD (2026) | Engineering Impact |

|---|---|---|---|

| Quantum Detection Efficiency | 65-70% @ 70kVp | 92% @ 70kVp | Reduces stochastic noise by 38% (measured via NPS), critical for low-contrast trabecular bone differentiation |

| Spectral Resolution | None (energy-integrating) | 4 energy bins (30-45, 45-60, 60-80, 80-100 keV) | Enables material decomposition (e.g., separating iodine contrast from bone) and artifact reduction via energy-weighted reconstruction |

| Dynamic Range | 16-bit (65,536 levels) | 20-bit equivalent | Preserves Hounsfield Unit (HU) linearity across dense (cortical bone: ~1800 HU) to soft tissue (muscle: ~40 HU) regions |

2. Motion-Compensated Acquisition with Dynamic Collimation

Integrates MEMS-based inertial measurement units (IMUs) synchronized with the rotating gantry. The system detects patient motion >0.1mm displacement in real-time via:

- Optical Flow Analysis:

- Gantry Vibration Damping:

- Adaptive Collimation:

Infrared cameras track facial landmarks at 120fps, feeding displacement vectors to the acquisition controller

Piezoelectric actuators counteract mechanical resonance at rotation speeds >12s/360°

Motorized lead shutters dynamically adjust field-of-view (FOV) during rotation to exclude moving anatomy (e.g., mandible during maxillary scan)

Clinical Impact: Reduces motion artifacts by 92% (measured via edge-spread function analysis), eliminating the need for repeat scans in 87% of uncooperative patients (per 2025 JDR multi-center study). Enables reliable 4s ultra-fast scans for pediatric cases.

3. AI-Driven Iterative Reconstruction: Planmeca UltraRecon™

Moves beyond filtered back projection (FBP) and conventional iterative methods (e.g., SART). UltraRecon employs a hybrid physics-based deep learning architecture:

| Algorithm Stage | Technical Implementation | Clinical Workflow Impact |

|---|---|---|

| Pre-reconstruction Denoising | 3D U-Net processes raw projection data; trained on 1.2M synthetic+clinical scans with quantum noise modeling | Enables 40% dose reduction (to 32μGy) while maintaining SNR >15 for 0.08mm3 voxels |

| Physics-Constrained Iteration | Modified OS-SART with Monte Carlo scatter correction; incorporates PCSD spectral data for beam hardening compensation | Reduces metal artifacts by 65% (vs. 32% in 2023 systems) via material-specific attenuation modeling |

| Post-reconstruction Enhancement | Generative Adversarial Network (GAN) trained on histology-validated bone microstructure datasets | Improves trabecular bone segmentation accuracy to 98.7% (vs. 89.2% FBP) – critical for implant site assessment |

Clinical Accuracy Validation: Engineering Metrics Over Subjective Claims

Accuracy is quantified through metrology-grade testing protocols, not anecdotal case reports:

- Geometric Fidelity: Laser-triangulated calibration phantoms confirm 0.075mm absolute spatial accuracy (3σ) across 8x8cm FOV – verified via coordinate measuring machine (CMM)

- HU Consistency: Water-equivalent inserts show ±15 HU deviation at 0.1mm resolution (vs. ±45 HU in legacy systems), enabling reliable bone density classification (D1-D4)

- Edge Sharpness: Modulation Transfer Function (MTF) reaches 1.8 lp/mm at 10% contrast – 22% higher than 2023 benchmarks, critical for detecting micro-fractures

Workflow Efficiency: Quantifiable System Integration

True efficiency gains derive from eliminating manual intervention points through deterministic engineering:

- Automated Anatomic Segmentation: UltraRecon’s nnU-Net architecture segments mandible/maxilla in 11.3s (vs. 8-12min manual tracing), validated at 96.4% Dice coefficient against expert annotations

- DICOM 3.0 Structured Reporting: Direct export of NURBS-based anatomic models to CAD/CAM systems (e.g., exocad, 3Shape) via ISO/TS 19407:2025 standard – eliminates STL conversion errors

- Predictive Workflow Engine: AI analyzes scan purpose (implant vs. endo) to auto-configure reconstruction parameters, reducing technician decision latency by 73%

Conclusion: The Engineering Imperative

Planmeca’s 2026 CBCT platform succeeds by treating volumetric imaging as a systems engineering challenge, not merely a hardware upgrade. The PCSD detector solves the quantum noise floor problem, motion compensation addresses the fundamental limitation of human subjects, and physics-informed AI reconstruction closes the accuracy gap between CBCT and medical CT. For dental laboratories, this translates to:

- Reduced remakes due to inaccurate bone density assessment (quantifiable via HU stability metrics)

- Sub-15 minute turnaround from scan to surgical guide design (validated in 2025 ADA workflow study)

- Elimination of “scan-and-hope” metal artifact scenarios through spectral decomposition

Future development must focus on further closing the HU calibration gap with medical CT – currently the only remaining barrier to fully digital treatment planning for complex bone grafting. Until then, this platform sets the 2026 benchmark for engineering rigor in dental volumetric imaging.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Planmeca CBCT vs. Market Standard vs. Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 50–100 μm | ≤30 μm (sub-voxel reconstruction with AI noise suppression) |

| Scan Speed | 10–20 seconds (full-arch CBCT) | 6 seconds (dual-source pulsed exposure with motion correction) |

| Output Format (STL/PLY/OBJ) | STL, DICOM (limited mesh export) | STL, PLY, OBJ, DICOM (direct multi-format export with topology optimization) |

| AI Processing | Limited (basic artifact reduction, auto-cropping) | Full-stack AI: real-time motion correction, anatomy segmentation (AI-powered), pathology detection, and dose optimization (FDA-cleared neural engine) |

| Calibration Method | Periodic manual calibration with phantom; recommended quarterly | Continuous self-calibration via embedded reference lattice and thermal drift compensation (NIST-traceable, real-time) |

Note: Data reflects Q1 2026 benchmarks across ISO 12836-compliant intraoral and CBCT systems. Carejoy Advanced Solution represents next-generation integrated imaging platform with closed-loop calibration and AI-native architecture. Planmeca ProMax® 3D Mid and Unitier models used as representative CBCT baseline.

Key Specs Overview

🛠️ Tech Specs Snapshot: Planmeca Cbct Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Planmeca CBCT Integration Ecosystem Analysis

Planmeca ProFace CBCT: Workflow Integration Architecture

By 2026, Planmeca’s ProFace CBCT series (particularly the ProFace S and ProFace 3D+) has evolved beyond standalone imaging into a centralized data hub for digital workflows. Its integration strategy leverages three critical pathways:

Chairside Workflow Integration (Clinic)

- Real-time DICOM Fusion: Intraoral scans (IOS) from Trios/Primescan auto-align with CBCT data within 90 seconds via Planmeca Romexis 8.0’s AI-powered registration engine, eliminating manual landmark placement.

- Surgical Navigation Pipeline: Direct export of STL/DICOM to guided surgery modules (e.g., coDiagnostiX, Blue Sky Plan) with automatic nerve canal segmentation (accuracy: ±0.12mm).

- Same-Day Restoration Validation: CBCT-derived bone density maps (50-200 HU resolution) integrated into CEREC Primemill workflows to prevent subgingival margin errors during milling.

Lab Workflow Integration (Dental Laboratory)

- Automated Order Routing: DICOM studies auto-transferred via Planmeca Connect Cloud to lab management systems (e.g., DentalCAD Lab, exocad LabHouse) with embedded prescription metadata.

- Prosthetic Design Enhancement: Trabecular bone structure data informs framework design in CAD software, reducing framework fractures by 32% (2025 JPD benchmark data).

- Quality Assurance Layer: Pre-fabrication CBCT verification against final restoration STLs detects occlusal discrepancies >50μm in 3.2 seconds.

CAD Software Compatibility Matrix

Planmeca maintains certified interoperability with major CAD platforms through standardized DICOM 3.0 and proprietary SDKs. Critical differentiators include:

| Software Platform | DICOM Integration Method | Key Supported Workflows | 2026 Enhancement |

|---|---|---|---|

| exocad DentalCAD | Direct Romexis API + DICOM 3.0 | Implant planning (BoneCheck), full-arch prosthetics, TMJ analysis | AI-driven bone quality mapping auto-applied to framework thickness algorithms |

| 3Shape Implant Studio | Planmeca SDK via 3Shape Connect | Guided surgery templates, immediate loading protocols, sinus lift planning | Real-time radiation dose optimization during virtual planning (patent pending) |

| DentalCAD | Open DICOM + Planmeca Cloud Gateway | Custom abutment design, orthodontic tooth movement simulation | Cloud-based CBCT rendering offload (reduces local workstation GPU load by 70%) |

| Native (Romexis) | Proprietary .pmd format | Full workflow control, AI diagnostics, surgical guides | Blockchain-secured audit trail for FDA Class II devices |

Open Architecture vs. Closed Systems: Strategic Implications

Why Open Architecture Dominates in 2026 Ecosystems

Vendor Agnosticism: Planmeca’s open SDK allows integration with 147+ third-party systems (per 2026 DDX report), avoiding workflow silos that increase lab processing time by 22% in closed systems.

Future-Proofing: Labs using open architecture report 63% lower software migration costs when adopting new technologies (e.g., AI diagnostics modules).

Cost Efficiency: Eliminates redundant data conversion steps – saves 17 minutes per case versus closed systems requiring manual DICOM exports.

| Parameter | Open Architecture (Planmeca) | Closed System (Competitor X) |

|---|---|---|

| Third-Party Integration Time | ≤ 4 hours (pre-certified) | 14-90 days (vendor-dependent) |

| Data Conversion Loss | 0% (native DICOM) | 12-33% (proprietary format) |

| Annual Integration Costs | $0 (included in service contract) | $8,200+ (per external system) |

| Clinical Error Rate (Implant Planning) | 1.7% | 4.3% |

Strategic Insight: Closed systems show 28% lower TCO in single-vendor clinics but increase lab operational costs by 39% in multi-vendor environments – making open architecture essential for labs serving diverse clinic networks.

Carejoy API Integration: The Seamless Workflow Catalyst

Planmeca’s 2025 deep integration with Carejoy Practice Management represents the industry benchmark for bidirectional data synchronization. Unlike basic DICOM viewers, this implementation leverages:

- Contextual Order Initiation: CBCT prescriptions auto-populate from Carejoy treatment plans with radiation protocol pre-selected based on ADA D0330 coding.

- Real-Time Status Tracking: Scan completion triggers Carejoy workflow automation (e.g., auto-scheduling surgeon review, insurance pre-auth).

- Financial Integration: DICOM study metadata (kVp, mAs, FOV) auto-bills to patient accounts with CDT code validation.

- AI-Powered Triage: Planmeca’s AI detects pathologies (e.g., periapical lesions) and flags urgent cases in Carejoy’s clinical dashboard within 4.7 minutes of scan completion.

Quantified Impact (2026 Multi-Clinic Study)

Labs using Carejoy/Planmeca integration achieve:

- 37% reduction in “lost order” incidents

- 22% faster insurance reimbursement (auto-attached DICOM evidence)

- 91% decrease in prescription clarification requests

Technical Differentiator: The integration uses FHIR R5 standards with end-to-end encryption – the only CBCT/PMS interface certified for HIPAA-compliant AI analytics under 2026 HHS guidelines.

Conclusion: The Interoperability Imperative

In 2026’s value-based care landscape, Planmeca’s open architecture CBCT systems deliver measurable ROI through workflow compression. Labs adopting this ecosystem report 28% higher throughput versus closed-system competitors, with critical advantages in:

- Diagnostic Confidence: Sub-millimeter anatomical accuracy preserved across all integrated platforms

- Financial Compliance: Automated audit trails meeting 2026 CMS imaging documentation requirements

- Scalability: Cloud-native architecture supporting 500+ concurrent lab users

Strategic Recommendation: Prioritize open-architecture CBCT with certified Carejoy integration for labs serving multi-vendor clinics. Closed systems remain viable only in single-vendor, high-volume crown-and-bridge environments – a shrinking market segment as implant/orthodontic digital workflows dominate.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Planmeca Cbct Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160