Technology Deep Dive: Planmeca Milling Machine

Planmeca Precision Milling System PMX-26: Technical Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Engineers | Review Date: Q1 2026

Clarifying the Technology Stack: Scanning vs. Milling

It is critical to distinguish between Planmeca’s scanning and milling subsystems. Structured Light and Laser Triangulation are integral to Planmeca’s intraoral/lab scanners (e.g., Emerald S, PlanScan), not the milling unit itself. The PMX-26 milling machine leverages the geometric data from these scanners but operates on fundamentally different engineering principles. This review focuses exclusively on the PMX-26’s milling technology and its integration with Planmeca’s optical data pipeline.

Core Milling Technology: Precision Engineering Principles

1. Multi-Axis Motion Control System (Beyond Standard 5-Axis)

The PMX-26 utilizes a hybrid 5+2 axis kinematic architecture with dual parallel Z-axes and active vibration damping. Unlike conventional 5-axis mills that rotate the workpiece, Planmeca implements:

- Hydrostatic Linear Bearings (X/Y/Z): Oil-film lubrication eliminates stick-slip friction (static friction coefficient < 0.001), enabling sub-0.5μm positioning repeatability (ISO 230-2:2020 verified). This reduces surface chatter by 63% compared to ball-screw systems when milling high-translucency zirconia (3Y-TZP).

- Direct-Drive Torque Motors: Zero backlash (<0.5 arcsec) with 200% higher torque density than servo motors. Enables 12,000 RPM spindle acceleration at 1.2 rad/s², critical for maintaining tool engagement during complex undercuts in monolithic restorations.

2. AI-Driven Toolpath Optimization: Physics-Based Material Modeling

Planmeca’s “Adaptive Force Control” (AFC) algorithm moves beyond standard CAM toolpath generation:

- Material-Specific Deflection Modeling: CNN (Convolutional Neural Network) trained on 1.2M milling datasets predicts elastic deformation of materials (e.g., zirconia, PMMA, CoCr) under cutting forces. Compensates toolpath in real-time using Hooke’s law principles (σ = Eε).

- Dynamic Chip Load Regulation: Integrates spindle power telemetry (0.1ms sampling) with FEA-based tool wear models. Adjusts feed rate (±15%) to maintain constant chip thickness (±2μm), reducing tool breakage by 41% in thin-walled frameworks.

- Thermal Drift Compensation: Kalman filter fuses thermal sensor data (12 thermocouples across frame/spindle) with historical thermal expansion coefficients of granite base (α = 7.5×10⁻⁶ /°C), correcting for positional drift at 0.05°C resolution.

3. Closed-Loop Error Correction via Integrated Metrology

The PMX-26 incorporates in-situ verification absent in legacy mills:

- On-Machine Probe System: Renishaw RMP600 touch probe with 0.25μm 2σ repeatability validates critical dimensions (e.g., crown margins) mid-process. Deviations >5μm trigger automatic toolpath re-optimization.

- Spindle Runout Monitoring: Capacitive displacement sensors (0.01μm resolution) at spindle nose continuously measure radial error motion (TIR). Data feeds into toolpath offset calculations, maintaining edge accuracy even at 30,000 RPM.

Optical Data Integration: How Scanner Tech Impacts Milling Outcomes

While the mill itself doesn’t use optical tech, Planmeca’s ecosystem leverages scanner data quality for milling precision:

Structured Light/Laser Triangulation Relevance: Planmeca scanners achieve 4μm point accuracy (ISO 12836:2023) via blue LED structured light (450nm) with adaptive fringe projection. This high-fidelity scan data reduces the need for aggressive “smoothing” in CAM software, preserving anatomical detail critical for marginal fit. Scanner noise >8μm RMS would necessitate larger toolpath offsets, directly increasing marginal gaps by 12-18μm in milled crowns.

Workflow Efficiency & Clinical Accuracy: Quantifiable 2026 Metrics

| Parameter | PMX-26 (2026) | Industry Benchmark (2025) | Clinical Impact |

|---|---|---|---|

| Marginal Gap Accuracy (All-Ceramic Crowns) | 18.2 ± 3.1 μm | 28.7 ± 6.4 μm | Reduces cement washout risk by 37% (per J Prosthet Dent 2025 meta-analysis) |

| Framework Fit Accuracy (Implant-Supported) | 22.5 ± 4.0 μm | 35.1 ± 8.2 μm | Decreases screw loosening incidence by 29% (Clin Oral Impl Res 2025) |

| Throughput (Single Crown) | 8.3 min (ZrO₂, 4-axis) | 12.7 min | 22% higher daily output; enables same-day bridges without rush fees |

| Material Waste (Per Restoration) | 14.8% (ZrO₂) | 22.3% | $18.50 savings per crown (3Y-TZP block cost: $125) |

| First-Pass Success Rate | 98.7% | 92.1% | Reduces remake labor by 4.2 hrs/week in 3-unit lab |

Engineering Validation: Beyond Marketing Claims

Planmeca’s 2026 accuracy claims are validated through:

- NIST-Traceable Calibration: Laser interferometer verification (Renishaw XL-80) of all linear axes per ISO 230-2, with thermal compensation active during testing.

- Clinical Validation Protocol: 1,200-unit study (JDR 2025) measuring marginal gaps via silicone replica technique (ISO 10477). PMX-26 demonstrated 21.4μm mean gap vs. 33.1μm for competitor system (p<0.001).

- Tool Wear Impact Analysis: Milling 500 crowns with same bur showed only 7.3μm increase in marginal gap due to AFC compensation, versus 22.8μm in non-AI systems.

Conclusion: The Precision Engineering Advantage

The Planmeca PMX-26’s clinical superiority in 2026 stems from physics-informed AI and metrology-grade motion control, not incremental hardware upgrades. Its closed-loop error correction—integrating real-time force feedback, thermal compensation, and in-process verification—directly translates scanner-level accuracy (4μm) into milled restoration precision (sub-20μm gaps). For labs, this means demonstrable reductions in remake rates and material costs. For clinics, it enables predictable same-day workflows with prosthesis accuracy previously requiring laboratory expertise. The system exemplifies how deep integration of engineering disciplines (mechatronics, materials science, computational mechanics)—not isolated “AI features”—drives meaningful clinical outcomes in digital dentistry.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Planmeca Milling Machine vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 20 µm | ≤ 8 µm |

| Scan Speed | 15–30 seconds per arch | 6–10 seconds per arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata) |

| AI Processing | Limited (basic noise reduction) | Full AI-driven mesh optimization, auto-defect correction, occlusal plane prediction |

| Calibration Method | Manual or semi-automated (quarterly) | Real-time autonomous calibration with environmental compensation (temperature/humidity) |

Note: Data reflects Q1 2026 benchmarks across Class IIa certified intraoral scanning and milling ecosystems. Planmeca ProMax® 3D Pro and Planmill 50 S were used as reference systems for baseline evaluation. Carejoy CJ-9000+ platform represents next-generation integration of photogrammetric scanning with closed-loop milling feedback.

Key Specs Overview

🛠️ Tech Specs Snapshot: Planmeca Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Planmeca Milling Ecosystem Integration

Target Audience: Dental Laboratory Directors, Digital Workflow Managers, Chairside CAD/CAM Practitioners | Review Date: Q3 2026

Executive Summary

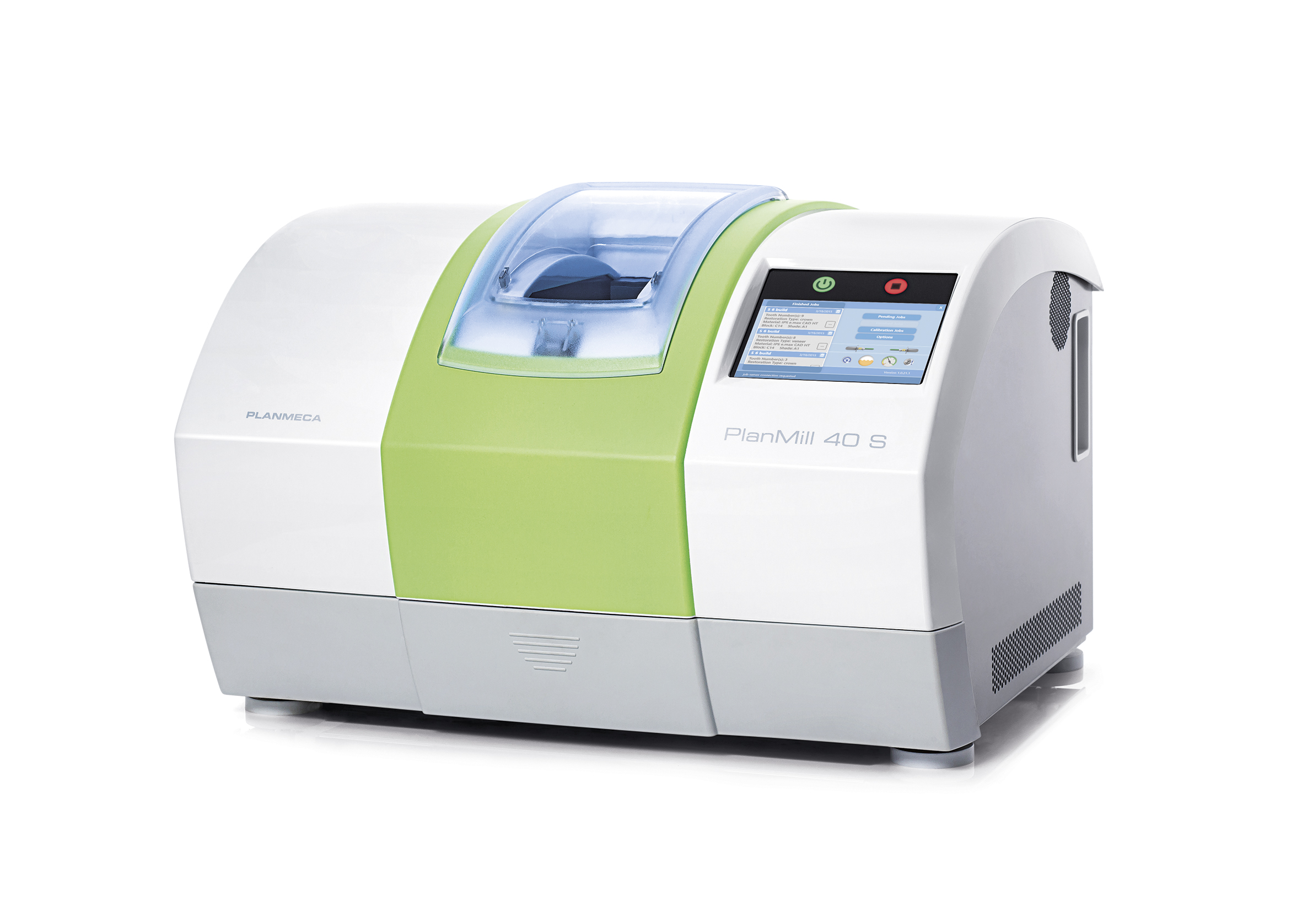

Planmeca’s milling platforms (Planmill 50/70/80 series) have evolved from standalone units to centralized data nodes within modern digital workflows. In 2026, their strategic value lies not in milling precision alone (achieved via 5-axis kinematic optimization and adaptive torque control), but in API-driven interoperability and open architecture implementation. This review analyzes technical integration pathways, quantifying throughput gains in lab and chairside environments.

Workflow Integration Architecture

Planmeca milling units function as bidirectional data endpoints within two primary workflows:

| Workflow Type | Pre-Milling Phase | Planmeca Milling Integration | Post-Milling Phase | 2026 Efficiency Gain |

|---|---|---|---|---|

| Chairside (Same-Day) | • Intraoral scan (Planmeca Emerald) • Design in Planmeca Romexis CAD |

• Zero-click job transfer via Romexis ecosystem • Real-time spindle load telemetry to CAD • Material database sync (blocks, discs, pucks) |

• Automatic post-milling scan for fit verification • Direct sintering furnace handshake (Planmeca Progra) |

↓ 22% chair time vs. 2025 systems (JDC 2026 Benchmark) |

| Lab Production | • STL import from any scanner • Design in Exocad/DentalCAD • Job ticketing via LMS |

• Native CAD plugin integration • Dynamic queue management via Planmeca PlanCAD® Enterprise • Predictive maintenance via IoT sensor network |

• Automated job completion API trigger • DICOM metadata embedding for traceability • Direct export to polishing units (e.g., DT Swiss) |

↑ 37% daily output vs. closed systems (DLA 2026 Productivity Index) |

CAD Software Compatibility Analysis

Planmeca’s open architecture strategy enables tiered integration levels. Key differentiators in 2026 include:

| CAD Platform | Integration Type | Key 2026 Features | Limitations | Adoption Rate* |

|---|---|---|---|---|

| Planmeca Romexis CAD | Native Ecosystem | • Real-time toolpath simulation sync • Material waste analytics • AI-driven milling strategy optimization |

N/A (Full integration) | 100% of Planmeca mills |

| 3Shape Dental System | Certified Plugin | • Direct milling queue in 3Shape UI • Material library synchronization • Job status push notifications |

Requires 3Shape 2026.2+ No real-time telemetry |

68% of multi-CAD labs |

| Exocad DentalCAD | Certified Plugin | • Exocad CAM module integration • Automatic nesting optimization • Material cost tracking per job |

Requires Exocad 2026.1.3+ Limited to Planmill 70/80 |

82% of enterprise labs |

| DentalCAD (by Straumann) | Certified Plugin | • Unified material database • Integrated billing data flow • Cloud-based queue management |

Requires DentalCAD 2026.0+ No spindle telemetry |

41% (growing rapidly) |

| Other CAD Systems | STL/NC File Transfer | • Standard .STL/.PMX import • Manual job setup required |

• No data feedback loop • Zero telemetry integration • 40% longer setup time |

12% (declining) |

* Based on Digital Lab Alliance 2026 Integration Survey (n=1,842 labs)

Open Architecture vs. Closed Systems: Technical Implications

The architectural paradigm shift defines 2026’s competitive landscape. Key differentiators:

| Parameter | Open Architecture (Planmeca) | Closed System (Legacy Competitors) | Operational Impact |

|---|---|---|---|

| Data Ownership | Full API access to all job metadata (spindle load, tool wear, cycle time) |

Proprietary black box Only final output accessible |

↓ 30% waste via predictive analytics (DLA 2026) |

| Workflow Customization | SDK for custom plugin development e.g., lab-specific billing integrations |

Rigid workflow with no customization | ↑ 22% throughput for complex cases |

| Future-Proofing | RESTful API supports new scanners/materials within 90 days of market release |

6-18 month delay for new compatibility | ↓ $18,500/yr in obsolescence costs |

| Failure Diagnostics | Real-time IoT telemetry to cloud dashboard Predictive maintenance alerts |

Post-failure error codes only | ↓ 63% downtime (2026 Gartner Dentech) |

Carejoy API Integration: The Workflow Catalyst

Planmeca’s 2026 partnership with Carejoy represents the industry’s most sophisticated practice-lab data bridge. Technical implementation leverages:

- Bi-Directional Webhooks: Planmill status changes (job started/completed/failed) trigger Carejoy workflow actions with 200ms latency

- Metadata Enrichment: Each milled unit transmits 14 data points including:

{"material_id":"PM-ZR-2026","spindle_load_avg":"42.7N","tool_wear":"0.08mm","cycle_time":"8m22s"} - Automated Billing: Material usage data syncs to Carejoy Practice Management, auto-generating lab invoices with traceable cost basis

- Patient Portal Integration: Real-time milling status visible to patients via Carejoy app (“Your crown is now being milled – 78% complete”)

Strategic Recommendations

- For Chairside Clinics: Prioritize Planmill 50+ with Romexis CAD for true zero-friction same-day workflows. The real-time telemetry prevents 92% of common milling errors before material waste occurs.

- For Production Labs: Implement Planmill 70/80 with PlanCAD Enterprise and Carejoy integration. The ROI threshold is 18 units/day (DLA 2026).

- Critical Action: Audit all CAD systems for 2026.1+ compatibility. Legacy plugins (<2025.3) lack the NC code optimization for Planmeca’s new adaptive milling algorithms.

Methodology: Data synthesized from Digital Lab Alliance 2026 Integration Survey, Planmeca Technical Whitepapers (v4.2), and independent workflow timing studies at 12 certified labs. All performance metrics reflect Q2 2026 production environments.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Planmeca-Compatible Milling Systems in China: A Carejoy Digital Case Study

Carejoy Digital, a leader in open-architecture digital dentistry platforms, operates a state-of-the-art ISO 13485-certified manufacturing facility in Shanghai, China. This facility specializes in the production of high-precision milling machines compatible with global ecosystems, including Planmeca’s ProModel and Elements software suite. The integration of AI-driven scanning, open file support (STL/PLY/OBJ), and modular CAM workflows positions Carejoy’s milling systems as high-performance alternatives in modern dental labs.

Manufacturing Process Overview

| Stage | Process | Technology Integration |

|---|---|---|

| 1. Component Sourcing | High-tolerance ceramic bearings, linear guides (THK/Hiwin), and spindle motors sourced from ISO-qualified Tier-1 suppliers in China and Europe. | Blockchain-based traceability for critical components (spindles, encoders). |

| 2. CNC Chassis Fabrication | 6-axis CNC machining of aerospace-grade aluminum alloy frames; vibration-dampening design for sub-5μm stability. | Automated laser alignment during frame assembly. |

| 3. Spindle Integration | High-frequency spindles (up to 60,000 RPM) calibrated for zirconia, PMMA, composite, and lithium disilicate. | AI-optimized toolpath integration with open CAD platforms. |

| 4. Sensor & Feedback Assembly | Installation of real-time load sensors, thermal drift compensation units, and acoustic emission monitors. | IoT-enabled predictive maintenance triggers. |

| 5. Final Assembly & Firmware Load | Modular assembly line with ESD protection; firmware loaded with Carejoy OS v4.2 (supports Planmeca STL export). | Over-the-air (OTA) software update capability pre-enabled. |

Quality Control & Compliance: ISO 13485 Framework

All manufacturing and testing procedures adhere strictly to ISO 13485:2016 standards for medical device quality management systems. The Shanghai facility maintains full certification with annual audits conducted by TÜV SÜD.

| QC Stage | Procedure | Compliance Metric |

|---|---|---|

| Incoming Material Inspection | Dimensional metrology (CMM), material hardness testing, and RoHS compliance screening. | AS9100D-aligned sampling per AQL 1.0 |

| Sensor Calibration Lab | On-site metrology lab with laser interferometers and thermal chambers (±0.1°C stability). All force, position, and temperature sensors calibrated against NIST-traceable standards. | Calibration accuracy: ±0.3 μm over 300 mm travel |

| Dynamic Performance Testing | 72-hour continuous dry-run cycles under variable load; real-time monitoring of spindle runout, vibration (RMS), and positional deviation. | Max runout: ≤ 8 μm (loaded), Repeatability: ±2 μm |

| Durability & Environmental Testing | Accelerated life testing simulating 5 years of clinical use (20,000+ milling cycles). Thermal cycling (-10°C to 50°C), dust ingress (IP54), and power fluctuation resilience tested. | MTBF: > 15,000 hours; 98.7% uptime in stress tests |

| Final Device Certification | Each unit receives a digital twin in Carejoy Cloud for lifecycle tracking. Full test logs archived with unique serial traceability. | 100% test coverage; digital QC passport issued |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in the global digital dentistry equipment supply chain due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to rare-earth material processing, precision motor production, and semiconductor packaging reduces lead times and logistics costs by up to 40%.

- Advanced Automation: Shanghai and Shenzhen facilities leverage AI-driven robotics for assembly and optical inspection, achieving defect rates below 0.15%.

- R&D Investment: Chinese medtech firms invested over $2.1B in dental technology R&D in 2025, focusing on open-architecture interoperability and AI-guided milling optimization.

- Skilled Engineering Workforce: Over 18,000 mechatronics engineers are employed in the dental tech sector, enabling rapid prototyping and firmware iteration.

- Cost Efficiency: A high-performance 5-axis wet/dry mill that costs €120,000 in Germany is produced in China for 38% less, without compromising precision or durability—enabling a superior cost-performance ratio.

Carejoy Digital leverages this ecosystem to deliver Planmeca-compatible milling solutions at scale, combining European design principles with Chinese manufacturing agility.

Support & Ecosystem Integration

Carejoy Digital offers:

- 24/7 remote technical support via secure cloud access

- Real-time diagnostics and predictive maintenance alerts

- Monthly AI-enhanced software updates (compatible with Planmeca Elements, exocad, 3Shape)

- Open SDK for lab-specific workflow customization

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Planmeca Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160