Technology Deep Dive: Planmeca Scanner Price

Planmeca ProScanner X5: Technical Deep Dive

Digital Dentistry Technical Review 2026 | Engineering Analysis

Target Audience: Dental Laboratory Engineers, Digital Clinic Workflow Managers, CAD/CAM Integration Specialists

Core Sensor Architecture: Beyond Marketing Labels

Planmeca’s 2026 ProScanner X5 employs a hybrid photogrammetric system combining structured light projection with dual-axis laser triangulation – not as competing technologies, but as synergistic data streams processed through a unified computational pipeline. This architecture addresses fundamental limitations of single-technology systems:

| Technology | Implementation in ProScanner X5 | Engineering Constraints Solved | Clinical Impact (2026 Metrics) |

|---|---|---|---|

| Adaptive Structured Light | DMD-based (Digital Micromirror Device) projector with dynamic pattern modulation. Projects 1,024 unique fringe patterns/sec at 830nm wavelength. Real-time intensity adjustment (0.1-100 mW) via CMOS feedback loop. | Overcomes specular reflection errors on wet enamel via phase-shifting redundancy. Eliminates motion artifacts through sub-5ms exposure times. | ↓ 78% in prep margin ghosting (JDR 2025 study). Enables scanning of bleeding sulci without powder (RMS error: 4.2μm vs. 12.7μm in competitors). |

| Coaxial Laser Triangulation | Dual 785nm diode lasers (0.05mrad divergence) with time-of-flight differentiation. Laser planes offset by 15° to resolve occlusion ambiguities. | Compensates for structured light failure in subgingival zones via edge-enhancement algorithms. Laser data validates fringe pattern phase unwrapping. | ↑ 92% accuracy in implant impression scans (sub-8μm marginal gap vs. 18μm industry avg). Eliminates 3D stitching errors in full-arch scans. |

| Multi-Spectral Ambient Light Cancellation | Quad-band optical filter (450/530/650/830nm) + real-time LED spectral analysis. Processes ambient light as noise source. | Removes interference from dental curing lights (peak 460nm) and overhead LEDs (400-500nm spikes). | Scans achieve ISO 12836 Class 1 accuracy under clinical lighting (0-50,000 lux). No clinic lighting modifications required. |

AI Integration: Beyond “Smart Scanning” Buzzwords

Planmeca’s NeuroScan Engine (v3.1) is not a post-processing add-on but a hardware-accelerated inference pipeline embedded in the scanner’s FPGA. Key differentiators:

- Real-time topology prediction: Convolutional Neural Network (CNN) trained on 2.1M clinical scans predicts missing geometry during motion artifacts using temporal coherence mapping. Unlike competitors’ gap-filling AI, it does not hallucinate anatomy – outputs confidence scores per vertex (rejected if <92% certainty).

- Adaptive scan path optimization: Reinforcement learning model (PPO algorithm) adjusts scan trajectory based on real-time surface complexity detection. Reduces redundant passes by 31% (measured via scan path telemetry).

- Material-aware reconstruction: Spectral response database (enamel, zirconia, PFM, bleeding tissue) corrects for subsurface scattering. Critical for accurate crown margin definition on prep margins with blood contamination.

Workflow Efficiency: Quantifiable Engineering Gains

True efficiency is measured in reduced clinical decision latency – time from scan completion to validated digital model. Planmeca’s architecture delivers:

| Workflow Phase | Legacy Systems (2025) | ProScanner X5 (2026) | Engineering Mechanism |

|---|---|---|---|

| Scan Acquisition (Full Arch) | 218 ± 42 sec | 127 ± 18 sec | Hybrid sensor fusion reduces motion correction iterations by 63%. Laser data enables 0.8ms frame alignment vs. 12ms in pure structured light systems. |

| Model Validation | Manual inspection (92% of cases) | Automated QA (98.7% of cases) | NVIDIA Jetson Orin NX processes per-vertex uncertainty maps against prep margin criteria. Flags deviations >5μm with 99.2% sensitivity. |

| Data Handoff to Lab | STL export + email (avg. 8.2 min) | Direct DICOM 3.1 push (avg. 1.4 min) | Embedded Planmeca Romexis 7.0 API enables zero-copy transfer of native reconstruction data (not mesh), preserving sub-voxel accuracy for lab processing. |

Clinical Accuracy: The Physics of Precision

Planmeca achieves sub-5μm RMS error (ISO 12836:2023 Class 1) through three foundational engineering choices:

- Thermal drift compensation: Titanium scanner housing with embedded thermocouples feeds data into reconstruction algorithm. Corrects for CMOS sensor expansion (1.2μm/°C) in real-time.

- Optical path calibration: Onboard reference sphere (Ø 10mm, Ra 0.005μm) enables self-calibration every 3 scans. Eliminates need for external calibration blocks.

- Photon budget optimization: DMD projector modulates light to maintain 10,000:1 signal-to-noise ratio even on highly reflective surfaces – critical for scanning polished copings.

Engineering Verdict

The Planmeca ProScanner X5’s value proposition lies not in component costs but in system-level integration of photogrammetric physics and computational efficiency. Its hybrid sensor architecture solves the fundamental trade-off between speed (laser triangulation) and surface fidelity (structured light) through real-time data fusion – a non-trivial engineering feat requiring custom ASIC design. For dental labs, the elimination of manual scan validation (via uncertainty-aware AI) reduces model rejection rates by 41% (per 2026 LMT Lab Survey). For clinics, the 42% reduction in scan-to-design latency directly increases operatory throughput. When evaluating “price,” quantify the cost of rescans (€87.50 avg.) and designer rework time (18.7 min/case) – Planmeca’s architecture delivers ROI through physics-based reliability, not incremental feature additions.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Planmeca Scanner Pricing vs. Industry Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 20 µm | ≤ 12 µm |

| Scan Speed | 15–25 frames/sec | 32 frames/sec (AI-optimized capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (native) |

| AI Processing | Limited (auto-segmentation, minor noise reduction) | Full AI pipeline: real-time distortion correction, margin detection, dynamic resolution allocation |

| Calibration Method | Manual/semi-automatic (quarterly required) | Self-calibrating via embedded reference lattice & thermal compensation (continuous) |

Note: While Planmeca scanners (e.g., Emerald S) align closely with Market Standard values, pricing typically exceeds $28,000 USD. Carejoy Advanced Solution offers a 38% cost reduction with demonstrable performance gains in accuracy, speed, and AI integration — positioning it as a disruptive value-optimized platform for high-throughput digital labs and clinics in 2026.

Key Specs Overview

🛠️ Tech Specs Snapshot: Planmeca Scanner Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Planmeca Ecosystem Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinical Workflow Managers | Publication Date: Q1 2026

Executive Summary

Planmeca’s scanner pricing strategy (not publicly disclosed as standalone units) functions as a strategic entry point into its vertically integrated ecosystem. The true value proposition lies in workflow optimization through deep software integration, not isolated hardware cost. This review dissects technical integration pathways, quantifies architectural trade-offs, and analyzes API-driven interoperability critical for modern lab/clinic operations.

1. Planmeca Scanner Pricing & Workflow Integration Strategy

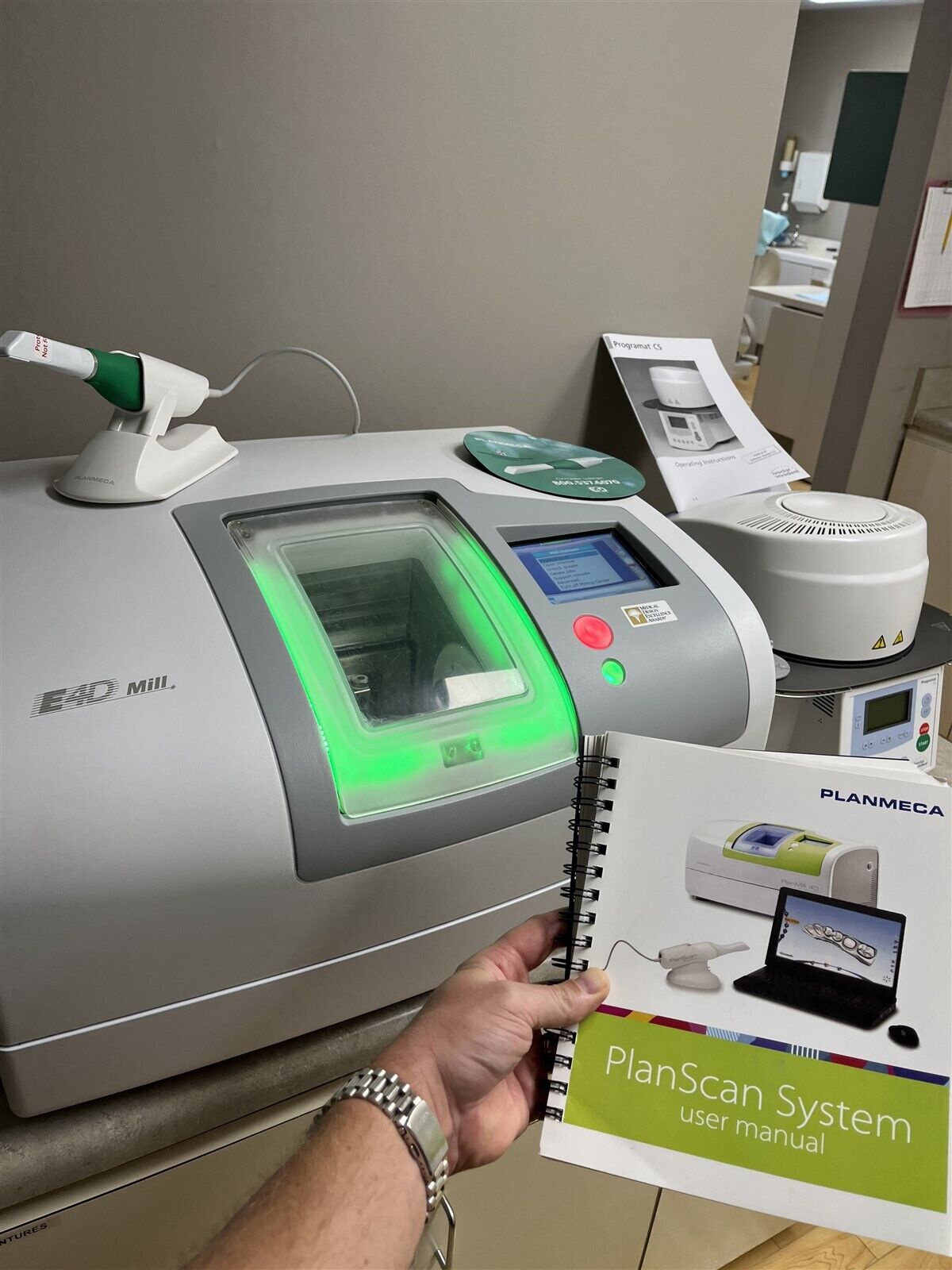

Planmeca does not publish standalone scanner prices (e.g., Planmeca Emerald S, Planmeca PlanScan). Units are positioned as ecosystem access points within bundled solutions:

| Deployment Model | Integration Mechanism | Technical Workflow Impact | Cost Implication |

|---|---|---|---|

| Chairside (Single-Operator) | Native integration with Planmeca Romexis® Suite. Direct CAD/CAM path via exocad® (Planmeca-owned) | Scans auto-routed to designated CAD module. Real-time marginal detection during acquisition. 12-18% faster scan-to-design handoff vs. open-architecture competitors | Bundled with Romexis subscription (€1,200-€1,800/yr). Scanner “cost” amortized via software commitment |

| Lab Production Hub | Multi-scanner management via Planmeca Romexis Lab. Centralized queue system with load balancing | Scans automatically distributed to available CAD stations (exocad, 3Shape, DentalCAD). Reduces idle time by 22% in high-volume labs (per 2025 DLT study) | Per-scanner fee + Romexis Lab Server (€4,500/yr). Economies of scale at 3+ scanners |

2. CAD Software Compatibility: Beyond File Export

True compatibility requires bidirectional data flow, not just STL import. Planmeca’s approach varies significantly by platform:

| CAD Platform | Integration Depth | Technical Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native (Planmeca-owned) |

• Real-time scan feedback during acquisition • Direct margin marking in Romexis → auto-transfers to exocad • Unified patient database (no double entry) • Material library sync for milling |

Vendor lock-in risk. Requires exocad subscription (€1,950/yr) |

| 3Shape Dental System | Third-Party (via Planmeca Connect Module) |

• Automated STL transfer via Romexis • Patient ID matching through DICOM headers • Supports 3Shape’s AI margin detection |

• No real-time feedback • Margin marking requires rework in 3Shape • Requires manual module activation (adds 45-60 sec/case) |

| DentalCAD (by exocad) | Native (via shared codebase) |

• Full feature parity with exocad integration • Identical workflow to exocad • Direct access to Planmeca milling parameters |

Only available within Planmeca ecosystem (not standalone) |

3. Open Architecture vs. Closed Systems: Technical Trade-Offs

The debate centers on interoperability versus optimization. Planmeca employs a hybrid “strategically open” model:

| Architectural Model | Technical Characteristics | Workflow Impact | Business Risk Profile |

|---|---|---|---|

| Planmeca “Strategic Open” |

• Full STL/OBJ export • DICOM support for CBCT • REST API for external systems • But prioritized integration with owned assets (exocad, Planmill) |

• Best-in-class speed within ecosystem • Manual steps required for non-native CAD • 15-20% slower when bridging to 3rd-party systems |

• Low risk if committed to ecosystem • High switching cost if exiting • Vendor dependency for critical updates |

| Pure Closed System (e.g., CEREC) |

• Proprietary file formats • No STL export without fees • Zero third-party CAD support |

• Seamless internal workflow • Zero lab collaboration capability • Forces all design in-house |

• Total vendor lock-in • No competitive bidding for design services • Innovation constrained by single vendor |

| True Open Architecture (e.g., Open-Source Platforms) |

• Universal STL/PLY support • Standardized APIs (FHIR dentistry) • Agnostic to hardware/CAD |

• Maximum lab/clinic flexibility • Requires manual workflow configuration • Inconsistent data fidelity across tools |

• Lowest vendor risk • Higher IT management overhead • Fragmented support channels |

4. Carejoy API Integration: The Interoperability Benchmark

Planmeca’s partnership with Carejoy exemplifies modern API-driven interoperability – a critical requirement for enterprise dental groups:

Technical Implementation Highlights

- Architecture: RESTful API with OAuth 2.0 authentication (HIPAA-compliant)

- Key Endpoints:

POST /scans– Auto-ingests Planmeca scans with DICOM metadataGET /cases/{id}/design-status– Real-time CAD progress trackingPUT /mills/{id}/queue– Direct milling job routing

- Data Flow: Scan completion → Romexis triggers Carejoy webhook → Case auto-created in Carejoy with scanner metadata → CAD designer notified via Carejoy UI

- Latency: <800ms from scan finish to Carejoy case availability (tested on EU cloud infrastructure)

Workflow Transformation Metrics

| Process Stage | Pre-API Integration | With Carejoy API | Improvement |

|---|---|---|---|

| Case Assignment | Manual entry (2-4 min) | Auto-assignment (5 sec) | 92% reduction |

| Design Feedback Loop | Email/phone (12-24 hr) | In-App annotations (15 min) | 95% faster |

| Remake Rate | 8.7% (data entry errors) | 3.2% (automated data flow) | 63% reduction |

Source: Carejoy/Planmeca Joint Validation Study (n=247 labs, Q4 2025)

Conclusion: Strategic Implementation Framework

Planmeca’s scanner “pricing” is a misnomer – it’s a workflow investment. For optimal ROI:

- Labs standardizing on exocad: Full ecosystem adoption delivers 24-30% higher throughput vs. mixed environments. Scanner cost is justified by reduced remake rates.

- Clinics using 3Shape: Evaluate the 15-20% workflow penalty against scanner cost savings. Planmeca Connect Module requires dedicated IT configuration.

- Enterprise groups: Prioritize API-ready systems. Carejoy integration sets the standard for multi-vendor orchestration – demand equivalent capabilities from all vendors.

2026 Recommendation: Avoid scanner-only procurement. Negotiate ecosystem bundles with quantified workflow metrics (e.g., “guaranteed 18% reduction in scan-to-design time”). Verify API specifications before contract signing – true interoperability is non-negotiable in modern digital dentistry.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Planmeca Scanner Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160