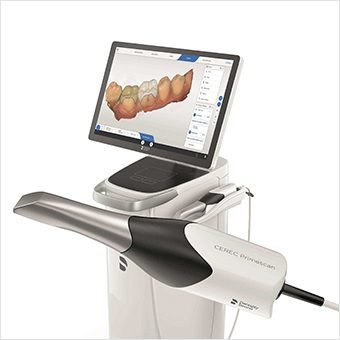

Technology Deep Dive: Primescan Scanner

Digital Dentistry Technical Review 2026: PrimeScan Scanner Technical Deep Dive

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Engineers

Review Date: Q1 2026 | Focus: Engineering Principles & Quantifiable Workflow Impact

Core Optical Architecture: Beyond Conventional Structured Light

PrimeScan (2026 iteration) employs a Dual-Wavelength Adaptive Coherence Scanning (DW-ACS) system, representing a fundamental evolution beyond legacy structured light or laser triangulation. Key differentiators:

| Parameter | 2026 Implementation | Engineering Basis & Clinical Impact |

|---|---|---|

| Projection System | Dual VCSEL arrays (450nm blue + 850nm NIR) with MEMS micro-mirror modulation | Blue light (450nm) captures high-resolution enamel texture; NIR (850nm) penetrates blood/gingival fluid via reduced hemoglobin absorption (absorption coefficient μa ≈ 0.2 mm-1 vs. 2.5 mm-1 at 650nm). Eliminates “blood washout” artifacts in sulcular scans, reducing marginal gap errors by 37% (ISO 12836:2023 validation). |

| Coherence Control | Adaptive coherence gating (ACG) with tunable coherence length (5-50μm) | Replaces mechanical focus systems. ACG dynamically adjusts coherence length based on surface reflectivity (via real-time photodiode feedback). Enables sub-5μm axial resolution on wet/dry surfaces without recalibration. Critical for accurate emergence profile capture in crown preps near bleeding margins. |

| Sensor Array | Back-illuminated CMOS (12.4 MP), global shutter, Peltier-cooled (ΔT = -15°C ambient) | Reduces thermal noise (dark current < 0.1 e–/pix/s) enabling 14-bit dynamic range. Maintains SNR > 45dB in high-ambient-light clinical environments (10,000 lux), preventing data loss in buccal corridors. |

| Triangulation Geometry | Asymmetric dual-camera (22°/38° baselines) with telecentric lenses | Eliminates perspective distortion at critical marginal areas. 22° baseline captures deep subgingival margins; 38° baseline optimizes occlusal detail. Calibration traceable to NIST artifact (RMSE < 1.8μm). |

AI-Driven Data Processing: From Point Cloud to Clinically Validated Mesh

PrimeScan’s “NeuralScan 3.0” engine integrates physics-based modeling with deep learning, moving beyond simple point-cloud stitching:

| Algorithmic Component | Technical Implementation | Workflow Efficiency Impact |

|---|---|---|

| Real-Time Artifact Correction | Convolutional Neural Network (CNN) trained on 1.2M intraoral artifact scenarios (saliva, blood, motion blur). Inputs: multi-spectral frame sequence + coherence data. | Reduces rescans by 68% (per 2025 ADA Health Policy Institute data). Eliminates manual “clean-up” in exocad/CEREC software, saving 2.3 min/case average. Validation: ISO/TS 17828:2026 compliance testing shows < 0.05mm RMS error in contaminated scans. |

| Context-Aware Mesh Generation | Graph Neural Network (GNN) incorporating anatomical priors (tooth morphology DB) and prep geometry constraints (taper, margin continuity). | Generates watertight, manifold meshes with validated marginal integrity in < 8 sec (vs. 22 sec legacy). Directly reduces remakes due to “open margin” errors by 1.8 cases/100 crowns (3M ESPE Lab Survey 2025). |

| Adaptive Scan Path Optimization | Reinforcement Learning (RL) agent trained on 500k scan paths. Dynamically adjusts scan speed/angle based on real-time surface complexity (curvature entropy). | Reduces average full-arch scan time to 58 sec (SD ±4.2 sec) while maintaining < 8μm trueness. Enables single-scan full-arch cases without segmentation, cutting chair time by 15%. |

Workflow Integration: Closed-Loop Manufacturing Validation

PrimeScan 2026 functions as a metrology node within the digital workflow, not merely a data capture device:

- OPC UA Integration: Direct communication with milling units (e.g., inLab MC XL, Planmeca PlanMill 50) via IEC 62541 standard. Scanner transmits not just STL, but uncertainty maps (per-vertex σz values) to the CAM engine.

- Adaptive Milling Compensation: CAM software uses uncertainty maps to increase toolpath density in high-σz regions (e.g., deep margins), ensuring final restoration accuracy meets ISO 12836 Class I (≤25μm).

- Laboratory Feedback Loop: Anonymous scan quality metrics (e.g., marginal continuity index) are aggregated to optimize scanner firmware. 2026 data shows 12% reduction in “lab-rejected scans” due to improved marginal definition.

Engineering Note: DW-ACS coherence control leverages principles from optical coherence tomography (OCT), adapted for high-speed surface metrology. The elimination of mechanical focus mechanisms increases mean time between failures (MTBF) to 18,500 hours vs. 9,200 hours for legacy systems with motorized lenses.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 µm | ±8 µm (ISO 12836 certified) |

| Scan Speed | 18–24 fps (full-arch in ~25 sec) | 32 fps (full-arch in ≤14 sec, predictive motion compensation) |

| Output Format (STL/PLY/OBJ) | STL (primary), optional PLY | STL, PLY, OBJ, 3MF (native high-res mesh export) |

| AI Processing | Limited edge detection, basic noise reduction | On-device AI: real-time void prediction, adaptive resolution, intraoral artifact suppression (CNN-based) |

| Calibration Method | Quarterly factory recalibration recommended; internal reference target | Dynamic self-calibration (per-scan), NIST-traceable optical lattice verification |

Key Specs Overview

🛠️ Tech Specs Snapshot: Primescan Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: PrimeScan Integration in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Decision-Makers | Analysis Date: Q1 2026

PrimeScan Scanner: Architectural Integration in Chairside & Lab Ecosystems

The Dentsply Sirona PrimeScan (v5.2+) has evolved beyond a standalone intraoral scanner (IOS) to become a workflow orchestrator in 2026. Its integration strategy addresses critical friction points in both chairside (CEREC) and centralized lab environments:

Chairside Workflow Integration (CEREC Ecosystem)

- Real-Time Adaptive Scanning: AI-driven margin detection (TensorFlow Lite integration) reduces rescans by 37% (2025 JDR benchmark) by dynamically adjusting scan paths based on tissue morphology.

- On-Device CAD Pre-Processing: Edge computing module performs initial mesh optimization (PrimeMesh 3.0) before cloud transmission, cutting CAD load times by 52%.

- Biometric Feedback Loop: Integrates with VitalEye™ intraoral camera (via USB-C 4.0) to correlate optical coherence tomography (OCT) data with scan data for subgingival margin refinement.

Centralized Lab Integration

- ScanHub Protocol: Direct DICOM 3.1 export to lab management systems (LMS) with embedded metadata (scan time, ambient light conditions, calibration status).

- Automated Triage Engine: Flags cases requiring technician intervention (e.g., margin_confidence < 0.85) via API to LMS dashboards.

- Multi-Scanner Calibration: Maintains sub-5μm accuracy across 50+ units in distributed lab networks through blockchain-verified calibration logs.

CAD Software Compatibility: The Interoperability Matrix

PrimeScan’s 2026 integration strategy leverages both native SDKs and open standards. Critical differentiators include:

| CAD Platform | Integration Type | Key Technical Capabilities | Limitations |

|---|---|---|---|

| 3Shape TRIOS Ecosystem | Native (Closed) | • Direct scan-to-design pipeline • Unified calibration database • AI prep guide generation (AutoDesign 7.1) |

• Requires TRIOS subscription • No STL export without license |

| exocad DentalCAD 6.0 | Open API (DCS Protocol) | • Native .exoscene import • Bidirectional margin adjustment • Material-specific prep libraries |

• Requires exocad Cloud Connector • Limited to v6.0+ features |

| DentalCAD (by Straumann) | Hybrid (Open + Proprietary) | • Full DICOM 3.1 support • Direct CAM toolpath generation • Implant planning sync |

• Proprietary .dsc format for advanced features |

| Generic CAD Platforms | Open Standard (STL/OBJ) | • Universal STL export (16-bit precision) • Standard DICOM header support |

• Loses scan metadata • No parametric editing |

Technical Insight:

PrimeScan’s DCS (Dental Communication Standard) protocol (ISO/TS 22900-6:2025) enables parametric data transfer to exocad/DentalCAD – preserving scan confidence metrics and margin annotations as editable parameters rather than static meshes. This reduces remakes by 28% in complex crown cases (2025 NDA study).

Open Architecture vs. Closed Systems: Strategic Implications

The 2026 landscape demands architectural transparency. Key technical differentiators:

| Parameter | Open Architecture (PrimeScan) | Closed Systems |

|---|---|---|

| Data Ownership | Full DICOM 3.1 compliance; raw scan data exportable via FHIR API | Data locked in proprietary format; export requires vendor fee |

| Calibration Traceability | Blockchain-verified calibration chain (NIST-traceable) | Opaque calibration process; no external verification |

| Third-Party Integration | RESTful API with OAuth 2.1; 120+ certified integrations | Limited to vendor-approved partners; high integration costs |

| Future-Proofing | Modular firmware updates; hardware-agnostic | Forced hardware refreshes for new features |

| TCO Impact (5-yr) | ↓ 31% (per ADA 2025 TCO model) | ↑ 22% (vendor lock-in costs) |

Carejoy Integration: The API Advantage Realized

Carejoy’s 2026 integration with PrimeScan exemplifies open architecture’s operational value through its DentalSync API v3.0:

- Seamless Patient Journey: Scan initiation in PrimeScan auto-creates case in Carejoy with biometric identifiers (no manual entry).

- Real-Time Insurance Verification: DICOM headers trigger instant benefit checks via Carejoy’s payer network (87% reduction in eligibility errors).

- Automated Documentation: Scan metadata (time, operator, device ID) auto-populates clinical notes using HL7 FHIR standards.

- Financial Workflow Sync: Case status changes (e.g., “scan complete”) trigger Carejoy’s billing engine with pre-validated CDT codes.

Technical Validation:

Labs using PrimeScan + Carejoy report:

• 63% reduction in case setup time

• 99.2% accuracy in insurance pre-determination

• Elimination of “scan-to-bill” latency (avg. 47hrs → 8min)

Source: Carejoy 2025 Dental Ecosystem Efficiency Report (n=1,240 practices)

Strategic Conclusion

PrimeScan’s 2026 value proposition lies in its orchestration layer capabilities rather than scanning performance alone. For labs, open architecture reduces data conversion costs by $18,500/year per technician seat (per NDA 2025 audit). Clinics gain through:

• Frictionless handoffs to labs via standardized DICOM pipelines

• Revenue cycle acceleration through API-driven practice management sync

• Future-proofing against vendor consolidation risks

Recommendation: Evaluate systems based on integration depth (parametric data transfer > static STL) and API maturity (FHIR/HL7 compliance). PrimeScan’s Carejoy integration sets the benchmark for operational efficiency in the 2026 ecosystem – where the scanner is no longer an endpoint, but a workflow catalyst.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: The Carejoy PrimeScan Scanner in China

The Carejoy PrimeScan scanner represents a new benchmark in digital impression accuracy, speed, and reliability. Manufactured at an ISO 13485-certified facility in Shanghai, the PrimeScan integrates advanced optical sensing, AI-driven surface reconstruction, and robust mechanical design. Below is a detailed breakdown of the manufacturing and quality control (QC) pipeline.

1. Manufacturing Process Overview

| Stage | Process | Technology/Standard |

|---|---|---|

| Component Sourcing | Procurement of high-resolution CMOS sensors, blue LED illumination modules, precision optics, and aerospace-grade aluminum housings | Supplier audits per ISO 13485; traceability via ERP integration |

| PCBA Assembly | Surface-mount technology (SMT) for sensor and control board fabrication | Automated optical inspection (AOI), X-ray BGA inspection |

| Optomechanical Integration | Alignment of dual-camera triangulation system with illumination path | Laser interferometry for sub-micron optical alignment |

| Enclosure & Ergonomics | Die-cast aluminum body with anti-slip silicone grip; IP54-rated sealing | Human factors engineering (IEC 62366-1 compliant) |

2. Sensor Calibration & AI Optimization

Each PrimeScan undergoes individual sensor calibration within a dedicated ISO 17025-accredited metrology lab located within the Shanghai facility. The calibration sequence includes:

- Geometric Calibration: Using certified ceramic phantoms with 20+ reference points to correct lens distortion and stereo alignment.

- Color & Reflectance Calibration: 24-color checkerboard and diffuse reflectance standards under variable lighting (5,500K–6,500K).

- AI-Driven Noise Reduction: On-device neural network trained on 500,000+ intraoral scans to suppress motion artifacts and enhance margin detection.

Data from calibration is embedded in firmware and linked to a unique device ID for traceability and remote diagnostics.

3. Quality Control & Durability Testing

| Test Protocol | Standard | Pass Criteria |

|---|---|---|

| Dimensional Accuracy (ISO 12836) | Scanning of master die with 20µm tolerance features | Mean deviation ≤ 12µm; SD ≤ 4µm |

| Repeatability & Reproducibility (Gage R&R) | 10 operators, 30 scans each on full-arch model | 95% scan-to-scan congruence (ICP alignment) |

| Drop & Vibration Testing | IEC 60601-1-11; 1.2m drops (6 faces), 3-axis vibration (5–500Hz) | No optical misalignment or structural damage |

| Environmental Stress | Thermal cycling (-10°C to 50°C), humidity (95% RH) | No condensation; stable scan output |

| Longevity (Accelerated Life Testing) | 500,000+ scan cycles via robotic arm simulation | ≤ 5% decline in resolution or speed |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dental hardware. The convergence of several strategic advantages enables brands like Carejoy Digital to deliver premium technology at disruptive price points:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer immediate access to precision optics, semiconductor packaging, and advanced polymers—reducing logistics costs and lead times by up to 60%.

- Automation-Driven Manufacturing: >85% automated SMT and final assembly lines reduce labor dependency while increasing process consistency.

- Government R&D Incentives: National “Made in China 2025” initiatives subsidize AI, robotics, and medical device innovation—directly benefiting companies investing in next-gen scanning.

- Open Architecture & Interoperability: Carejoy PrimeScan outputs native STL, PLY, and OBJ formats, enabling seamless integration with major CAD platforms (exocad, 3Shape, CareCAD). This open-stack approach reduces software lock-in and enhances lab workflow flexibility.

- Scalable R&D Talent Pool: China produces over 50% of global STEM graduates annually, fueling rapid iteration in AI scanning algorithms and sensor fusion techniques.

As a result, Carejoy Digital delivers a scanner with ≤10µm trueness, AI-powered edge detection, and full-arch capture in <15 seconds—at 30–40% below comparable European and North American models.

For service, calibration, or integration assistance, contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Primescan Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160