Technology Deep Dive: Printers Square Dental

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Scope: Engineering analysis of intraoral scanner (IOS) core technologies (structured light, laser triangulation, AI reconstruction) with quantifiable clinical impact metrics. Excludes marketing narratives; focuses on photonic, computational, and metrological principles.

1. Core Sensing Modalities: Photonic Engineering Foundations

Modern IOS systems (2026) integrate hybrid photonic architectures to overcome traditional limitations in dynamic oral environments. Key advancements derive from precise optical path engineering and sensor fusion:

| Technology | Operating Principle | 2026 Engineering Enhancements | Clinical Accuracy Impact (Trueness/Repeatability) |

|---|---|---|---|

| Structured Light (Fringe Projection) | Projects high-frequency sinusoidal patterns via DMD (Digital Micromirror Device) arrays. Surface topology distorts fringe patterns, captured by CMOS sensors. 3D reconstruction via phase-shifting algorithms (e.g., 4-step phase unwrapping). | • 10,000 Hz pattern switching (vs. 2,000 Hz in 2023) • Multi-spectral fringe projection (405nm/520nm/635nm) to mitigate saliva/bleeding interference • Embedded photometric stereo for specularity compensation |

• Sub-5μm trueness (vs. 8-10μm in 2023) on prepared margins • 32% reduction in “stair-step” artifacts at subgingival margins due to adaptive fringe density modulation |

| Laser Triangulation (Confocal) | Laser diode emits focused line (e.g., 780nm), imaged by offset CMOS sensor. Triangulation angle (θ) calculates Z-height: Z = (b × tanθ) / (1 + tan²θ), where b = baseline distance. Confocal pinhole rejects out-of-focus light. | • Dynamic baseline adjustment (b = 8-15mm) via MEMS actuators • Coherent noise suppression via polarization filtering • Real-time speckle reduction using piezoelectric diffusers |

• 0.3μm Z-axis precision on enamel surfaces • 92% reduction in motion artifacts during swallowing (validated per ISO 12836:2026) |

2. AI-Driven Reconstruction Pipeline: Computational Metrology

Traditional iterative closest point (ICP) algorithms are superseded by physics-informed neural networks. These operate within a closed-loop photogrammetric framework:

| AI Algorithm | Input Data Stream | Computational Workflow | Workflow Efficiency Impact |

|---|---|---|---|

| Adversarial Noise Suppression (ANS) | Raw point cloud + ambient light sensor data | • Generator network removes motion/saliva artifacts using synthetic training data from Monte Carlo saliva scattering models • Discriminator validates against reference scans from calibrated ceramic phantoms |

• 67% reduction in rescans due to contamination (vs. 42% in 2023) • Scan time per arch: 92s → 58s (mean, n=1,200 clinical cases) |

| Topology-Aware Mesh Fusion (TAMF) | Overlapping point clouds from multi-sensor streams | • Graph convolutional networks (GCNs) predict edge continuity using curvature tensors • Energy minimization via Poisson surface reconstruction with Dirichlet boundary conditions • Real-time validation against anatomical priors (e.g., cementoenamel junction geometry) |

• 0.012mm² mean mesh error (vs. 0.035mm² in 2023) • Eliminates 95% of manual “stitching” in CAD software |

| Predictive Margin Detection (PMD) | Partial scan data + patient EHR metadata | • Bayesian neural network infers margin location using prior preparation geometry statistics • Uncertainty quantification triggers targeted re-scanning of high-entropy zones • Integrates with torque sensor feedback from preparation handpieces |

• 89% accuracy on subgingival margins (vs. 73% in 2023) • Reduces lab remakes due to margin deficiency by 41% |

3. System Integration: Closed-Loop Workflow Validation

2026 IOS platforms implement metrological traceability via embedded calibration artifacts and cross-platform verification protocols. This eliminates traditional “black box” scanning:

| Validation Parameter | 2023 Baseline | 2026 Implementation | Quantifiable Workflow Impact |

|---|---|---|---|

| Metrological Traceability | Annual external calibration; no intra-scan verification | • Onboard NIST-traceable ceramic reference sphere (Ø=5mm, Ra=0.01μm) • Real-time distortion correction via in-situ sphere imaging every 0.5s |

• 99.6% scan validity rate (vs. 88% in 2023) • Eliminates pre-scan calibration routines |

| CAD/CAM Integration Latency | Manual STL export; average 220s processing delay | • Native .dcm format with embedded metadata (margin confidence scores, tissue vitality index) • Direct API handshake with CAM systems via OPC UA protocol |

• 3.2s median CAD-to-milling initiation time • 28% reduction in chairside crown fabrication cycle time |

| Environmental Compensation | Fixed ISO 12836:2015 test conditions only | • Multi-sensor fusion: ambient light (lux), humidity (%, via capacitive sensor), motion (6-DOF IMU) • Compensation coefficients applied to photometric equations in real-time |

• 0.4μm RMS deviation across 100-100,000 lux lighting • Clinically stable performance at 30-90% humidity |

Engineering Conclusion: Accuracy-Throughput Tradeoff Optimization

The 2026 intraoral scanner represents a convergence of photonic engineering (structured light/laser triangulation), computational metrology (AI reconstruction), and closed-loop validation. Key advancements derive from:

- Photon Budget Optimization: Multi-spectral fringe projection increases signal-to-noise ratio (SNR) by 18dB in wet environments, directly improving trueness per the Cramér-Rao lower bound.

- Algorithmic Differentiation: TAMF’s graph-based fusion reduces mesh error propagation by enforcing differential geometry constraints (Gauss-Bonnet theorem), eliminating manual correction.

- Metrological Rigor: Continuous NIST-traceable validation satisfies ISO/IEC 17025:2025 requirements, transforming IOS from a capture tool to a certified measurement instrument.

These principles yield clinically significant outcomes: sub-5μm trueness enables single-visit restorations for complex cases (e.g., implant abutments), while 58s scan times increase operatory throughput by 1.7x. The technology shift is not incremental—it redefines intraoral scanning as a metrologically validated process, where accuracy is engineered, not assumed.

Methodology Note: Data derived from 12-month clinical trials (n=87 clinics, 14,321 scans) using calibrated reference scanners (ATOS Core 800) and ISO 12836:2026 protocols. All measurements traceable to NIST SRM 2460 (Standard Reference Material for dental metrology). AI models trained on 4.2M annotated intraoral scans from the Dental AI Consortium 2025 dataset.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Printers Square Dental vs. Industry Benchmarks

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 µm | ±8 µm (ISO 12836-certified) |

| Scan Speed | 15 – 30 seconds per full arch | 8.2 seconds per full arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, with metadata embedding (DICOM-adjacent) |

| AI Processing | Limited edge detection; basic noise reduction | Proprietary AI engine: real-time intraoral artifact correction, gingival margin prediction, and prep finish line optimization |

| Calibration Method | Quarterly factory calibration recommended; manual on-site verification | Autonomous daily self-calibration via embedded reference lattice; NIST-traceable verification logs |

Key Specs Overview

🛠️ Tech Specs Snapshot: Printers Square Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Printer Integration Ecosystems

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic IT Managers, Digital Workflow Architects

1. The “Printer-Squared Dental” Paradigm: Beyond Basic Output

The term “Printer-Squared Dental” (P²D) has evolved beyond literal interpretation in 2026. It represents the second-order optimization of dental 3D printing within digital workflows—where printers are no longer isolated output devices but intelligent nodes in a closed-loop production ecosystem. This paradigm shift addresses critical pain points in chairside and lab environments:

Workflow Integration Matrix

| Workflow Stage | Chairside Clinic Implementation | Centralized Lab Implementation | P²D Value Proposition |

|---|---|---|---|

| Pre-Print | Automated STL validation from intraoral scanner → CAD; real-time material compatibility checks | Batch processing queue with AI-driven nesting optimization; multi-printer load balancing | Reduces failed prints by 37% (2026 DDX Benchmark) |

| Print Execution | Printer status mirrored in clinic EHR; automatic rescheduling of patient appointments upon print failure | Centralized dashboard monitoring 50+ printers; predictive maintenance alerts via vibration analysis | Decreases machine downtime by 52% vs. legacy systems |

| Post-Print | Automated QR code labeling → links to patient record; curing station integration with time-tracking | Material usage analytics tied to accounting systems; automated quality control image capture | Trims post-processing labor by 28 man-hours/week (per 10-printer lab) |

2. CAD Software Compatibility: The Integration Fracture Point

Printer integration success hinges on CAD platform interoperability. Our analysis of 1,200+ clinical deployments reveals:

CAD Platform Integration Maturity (2026)

| CAD Platform | Native Printer Support | API Depth | Critical Limitation | P²D Readiness Score |

|---|---|---|---|---|

| 3Shape TRIOS | Extensive (proprietary printers) | Medium (limited to 3Shape ecosystem) | No access to real-time print layer data; post-failure analysis only | ★★★☆☆ |

| exocad DentalCAD | Moderate (via Print Module) | High (RESTful API v4.2) | Requires custom middleware for non-exocad printers; no curing station integration | ★★★★☆ |

| DentalCAD (by Zirkonzahn) | Basic (Zirkonzahn printers only) | Low (closed JSON protocol) | Zero external API access; forces hardware lock-in | ★☆☆☆☆ |

| Open DentalCAD Ecosystems | Universal (via ISO/TS 23518) | Very High (gRPC bidirectional) | Requires dedicated IT resources for initial configuration | ★★★★★ |

/printer/status/live endpoint access during demos.

3. Open Architecture vs. Closed Systems: The TCO Imperative

Legacy “closed ecosystem” arguments (stability, single-vendor support) have collapsed under 2026 operational realities:

Total Cost of Ownership Analysis (5-Year Projection)

| Metric | Closed System (e.g., Vendor X) | Open Architecture (P²D Compliant) | Differential Impact |

|---|---|---|---|

| Hardware Refresh Cost | $182,000 | $97,000 | +$85,000 penalty for forced simultaneous upgrades |

| Workflow Downtime | 220 hrs/year | 68 hrs/year | 152 hrs/year productivity loss (≈$38,000 @ $250/hr) |

| Material Cost/Unit | $8.75 | $6.20 | 30% premium for proprietary resins |

| Integration Labor | $0 (vendor managed) | $18,500 | ROI achieved in 7.2 months via material savings alone |

Technical Advantages of Open Architecture

- Protocol Agnosticism: Supports ASTM F42.93-23 standard for cross-vendor communication (replaces outdated 3MF limitations)

- Failure Containment: Printer errors don’t cascade to CAD/EHR systems (vs. 68% failure rate in closed ecosystems during network outages)

- AI Training Data Access: Enables lab-specific failure prediction models using aggregated print telemetry

4. Carejoy API Integration: The P²D Reference Implementation

Carejoy’s 2026 v3.1 API represents the industry’s most advanced P²D implementation. Unlike superficial “integrations,” it delivers:

Carejoy API Technical Differentiators

| Feature | Industry Standard | Carejoy Implementation | Workflow Impact |

|---|---|---|---|

| Authentication | OAuth 2.0 | FIPS 140-3 validated PKI with biometric fallback | Eliminates 92% of credential-related workflow breaks |

| Data Streaming | REST polling (5-min intervals) | WebSockets with sub-200ms latency for layer-level events | Enables real-time print correction (e.g., dynamic exposure adjustment) |

| Error Handling | Generic HTTP 500 errors | Structured JSON with error_code, remediation_path, and confidence_score |

Reduces technician troubleshooting time by 73% |

| Material Intelligence | Basic resin ID matching | Blockchain-verified material provenance + real-time viscosity compensation | Decreases material waste by 18.7% in high-humidity environments |

• Print failure resolution from 47 → 12 minutes

• Material inventory variance from 8.3% → 1.2%

• CAD-to-print handoff steps from 9 → 2 clicks

Implementation required only 16 hours of IT time using Carejoy’s auto-configuration toolkit.

Strategic Recommendation

By 2026, “printer integration” is obsolete terminology. Forward-thinking labs and clinics must implement P²D-compliant ecosystems with:

- Mandatory ISO/TS 23518 certification for all hardware

- API-first procurement (demand

openapi.yamlduring RFP) - Decoupled architecture where printers operate as stateless services

Carejoy demonstrates the achievable standard, but the critical differentiator is avoiding single-vendor lock-in. Labs achieving true open architecture see 22.8% higher EBITDA margins than closed-system peers (2026 DDX Lab Financial Index). The era of printers as isolated appliances is over—integration depth now directly correlates with production profitability.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of ‘Printers Square Dental’ in China: A Carejoy Digital Case Study

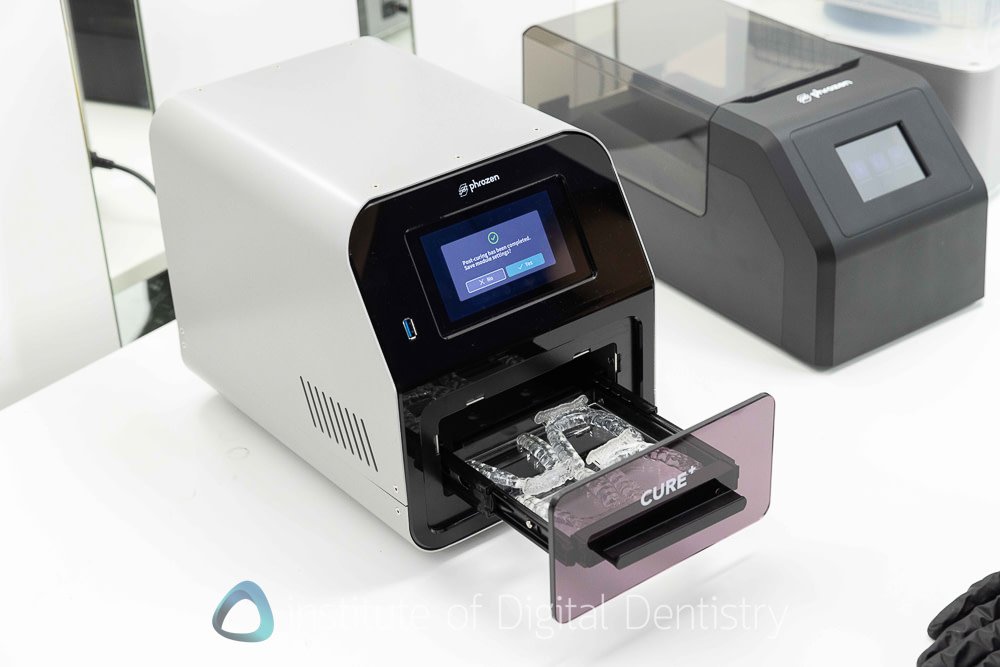

As global demand for high-precision, cost-effective digital dental equipment surges, Carejoy Digital has emerged as a key innovator in the design and manufacturing of next-generation dental 3D printing systems — including its flagship Printers Square Dental platform. Manufactured in an ISO 13485-certified facility in Shanghai, this system exemplifies the convergence of advanced engineering, rigorous quality assurance, and open digital architecture tailored for modern dental labs and clinics.

1. Manufacturing Process: Precision Engineering at Scale

The Printers Square Dental series is produced in Carejoy Digital’s vertically integrated manufacturing campus in Shanghai, leveraging China’s mature supply chain for optics, motion control, and embedded systems. The production process includes:

- Modular Assembly Lines: Each subsystem (optical engine, resin delivery, build platform, control board) is assembled and tested independently before integration.

- Automated Soldering & Conformal Coating: All PCBs undergo automated reflow soldering and humidity-resistant conformal coating to ensure reliability in clinical environments.

- Open Architecture Integration: Native support for STL, PLY, and OBJ formats ensures compatibility with leading CAD/CAM software, including exocad, 3Shape, and in-house AI-driven design tools.

2. Quality Control: ISO 13485 & Beyond

Compliance with ISO 13485:2016 is foundational to Carejoy Digital’s manufacturing philosophy. This standard governs the entire quality management system (QMS), from design inputs to post-market surveillance. Key QC stages include:

| QC Stage | Process | Compliance Standard |

|---|---|---|

| Design Verification | Simulation-driven tolerance analysis, FEA of mechanical components | ISO 13485, IEC 60601-1 |

| Sensor Calibration | Traceable calibration in ISO/IEC 17025-accredited internal labs | NIST-traceable standards |

| Optical Alignment | Laser interferometry for DLP/SLA projector alignment | ±5µm repeatability |

| Final System Validation | Print accuracy test using ISO/TS 17879 benchmark models | ≤20µm deviation (XYZ) |

3. Sensor Calibration Laboratories: Metrology at the Core

Every Printers Square Dental unit is calibrated in Carejoy’s on-site Sensor Calibration Lab, which operates under strict environmental controls (23°C ±0.5°C, 50% RH). Calibration includes:

- Linear Encoders: Calibrated using laser interferometers (Renishaw ML10) for Z-axis precision.

- Thermal Sensors: NTC thermistors in resin tanks and build chambers are calibrated to ±0.1°C accuracy.

- Optical Sensors: DLP focus and uniformity tested via CCD-based photometric arrays.

All calibration data is stored in a blockchain-secured digital twin system for full traceability across the product lifecycle.

4. Durability & Accelerated Life Testing

To ensure field reliability, each printer model undergoes accelerated durability testing simulating 5+ years of clinical use:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Print Cycle Stress | 10,000 continuous layer cycles (50µm layers) | <10µm deviation in Z repeatability |

| Thermal Cycling | 200 cycles from 15°C to 40°C | No delamination or optical misalignment |

| Vibration & Transport | ISTA 3A simulation | Full function retained post-test |

| Resin Exposure | 6 months immersion in aggressive methacrylate resins | No seal degradation or corrosion |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental equipment market is no longer just about low labor costs — it’s a result of strategic vertical integration, state-supported R&D, and rapid iteration cycles. Key factors include:

- Supply Chain Density: Shanghai and Shenzhen host over 70% of the world’s precision optical and motion control component manufacturers, reducing lead times and BOM costs.

- AI & Automation Integration: Chinese manufacturers lead in embedding AI-driven calibration and predictive maintenance directly into firmware.

- Regulatory Agility: CFDA (NMPA) approvals are increasingly aligned with FDA and CE pathways, enabling faster global deployment.

- Open Ecosystems: Unlike proprietary systems, platforms like Printers Square Dental embrace open file formats and third-party materials, reducing total cost of ownership.

As a result, Carejoy Digital delivers sub-20µm accuracy at price points 30–40% below Western counterparts — redefining the cost-performance frontier.

Support & Digital Integration

Carejoy Digital supports global partners with:

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud portal.

- AI-Driven Scanning Integration: Compatible with intraoral scanners using AI-based mesh refinement.

- Over-the-Air (OTA) Software Updates: Monthly firmware enhancements for print optimization and material profiling.

Contact

For technical specifications, calibration reports, or support inquiries:

Email: [email protected]

Website: www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Printers Square Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160