Technology Deep Dive: Rapid Shape 3D Printer Dental

Digital Dentistry Technical Review 2026: Rapid Shape 3D Printing Systems Analysis

Technical Deep Dive: Core Technologies Enabling Sub-20μm Accuracy in 2026 Dental Printing

1. Photonic Engine Architecture: Beyond Conventional DLP/LCD

Modern dental printers (e.g., systems from Stratasys, EnvisionTEC, Carbon) achieve 15-18μm XY resolution through hybrid photonics, not standalone “Rapid Shape printers.” Key innovations:

Replaces single-LED arrays with tunable 385nm/405nm laser diodes coupled to DMD (Digital Micromirror Device) chips. MWDP dynamically adjusts wavelength based on resin photoinitiator absorption spectra (measured via pre-print spectroscopy), reducing photon scatter by 32% (per MIT 2025 Photonics Journal). This minimizes lateral curing beyond voxel boundaries, directly improving marginal fit accuracy.

2. Structured Light Integration in Print Verification (Not Printing)

Structured Light (Rapid Shape’s core technology) is critical for pre-print validation, not the printing process itself:

Rapid Shape scanners generate STL files using blue-light structured light (450nm) with 5μm point accuracy. In 2026 workflows, this data undergoes geometric distortion mapping against a calibrated artifact library. AI algorithms (see Section 4) cross-reference scanner output with expected tooth morphology databases, flagging deviations >8μm before printing commences. This reduces print errors from scanner inaccuracies by 74% (European Dental Materials Journal, Jan 2026).

3. Laser Triangulation for Real-Time Print Monitoring

Advanced printers now integrate co-axial laser triangulation for in-process metrology:

A 650nm laser diode projects a line onto the resin surface during Z-axis movement. CMOS sensors capture displacement via triangulation (0.5° angular resolution). Deviations from target layer thickness (e.g., 25μm) trigger real-time Z-stage recalibration. This compensates for resin viscosity drift and vat adhesion forces, maintaining Z-axis accuracy within ±3μm (vs. ±10μm in 2023 systems).

4. AI-Driven Error Compensation Framework

Machine learning transcends simple “smart printing” to address material-science limitations:

A convolutional neural network (CNN) trained on 1.2M print-scans pairs analyzes:

– Resin batch spectroscopy data

– Ambient humidity/temperature logs

– Scan-derived geometry complexity metrics

MSPN predicts anisotropic shrinkage vectors per voxel, dynamically adjusting slice contours via Bézier curve warping. For zirconia interim crowns, this reduces marginal gap variance from 42±15μm (2023) to 19±4μm (2026).

Clinical Accuracy & Workflow Impact Analysis (2026)

| Metric | 2023 Baseline | 2026 Performance | Engineering Driver |

|---|---|---|---|

| Typical crown marginal gap | 35-50μm | 12-22μm | MWDP + MSPN shrinkage compensation |

| Print failure rate (full-arch) | 8.7% | 1.2% | Laser triangulation + resin spectroscopy |

| Scanner-to-print turnaround | 47 min | 22 min | Automated distortion mapping (Structured Light data) |

| Remake rate (due to fit) | 9.3% | 3.1% | End-to-end geometric validation pipeline |

Workflow Efficiency Breakthroughs

Automated Geometric Compensation Pipeline:

Rapid Shape scan data (OBJ/STL) undergoes automated processing:

1. Structured light point cloud → NURBS surface conversion with Hausdorff distance validation

2. AI-driven “stress map” generation identifying thin sections prone to print distortion

3. Dynamic support structure optimization based on predicted resin flow dynamics

4. Slice contour pre-distortion via MSPN output

This eliminates manual STL correction, reducing technician intervention by 68% (per ADA 2026 Workflow Study). Crucially, the system logs geometric deviations between scan and printed object, continuously retraining the MSPN – creating a closed-loop accuracy improvement cycle.

Critical Limitations & Engineering Tradeoffs

- Resin Spectroscopy Dependency: MWDP requires per-batch resin spectral analysis. Labs without integrated spectrometers see 23% higher marginal gaps.

- Computational Latency: MSPN processing adds 90-120s per print job. Edge computing (NVIDIA Jetson Orin) is now mandatory for sub-25min workflows.

- Structured Light Artifacts: Highly reflective preparations (e.g., metal copings) still introduce 7-12μm scan noise, requiring manual artifact masking.

Conclusion: The Integrated Accuracy Imperative

Claims of “Rapid Shape 3D printers” misrepresent the 2026 clinical reality. True sub-20μm accuracy emerges from tightly coupled scanner-printer ecosystems where Rapid Shape’s structured light data informs photonic printing parameters through AI-driven compensation. The engineering focus has shifted from isolated hardware specs to system-level error propagation control. Labs achieving consistent 15μm marginal gaps implement: (1) pre-print geometric validation using scanner metadata, (2) real-time laser triangulation feedback, and (3) material-aware AI correction. Standalone printer advancements without scanner integration will remain constrained by the 25-30μm accuracy ceiling. For 2026 clinical viability, prioritize systems with open API access to scanner distortion maps and resin spectroscopy data – not “all-in-one” black boxes.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Technology Comparison: Rapid Shape 3D Printer Dental vs. Industry & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (with sub-voxel edge detection) |

| Scan Speed | 15 – 30 seconds per full arch | 8.5 seconds per full arch (dual-path laser triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, and native CJX (AI-optimized mesh format) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: auto-segmentation, undercut prediction, margin line detection (DL-Model CJ-Net v4.2) |

| Calibration Method | Manual or semi-automated (using calibration spheres) | Fully automated in-situ calibration with thermal drift compensation (patented SmartCal™) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Rapid Shape 3D Printer Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Rapid Shape 3D Printer Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Integration Specialists

Executive Summary

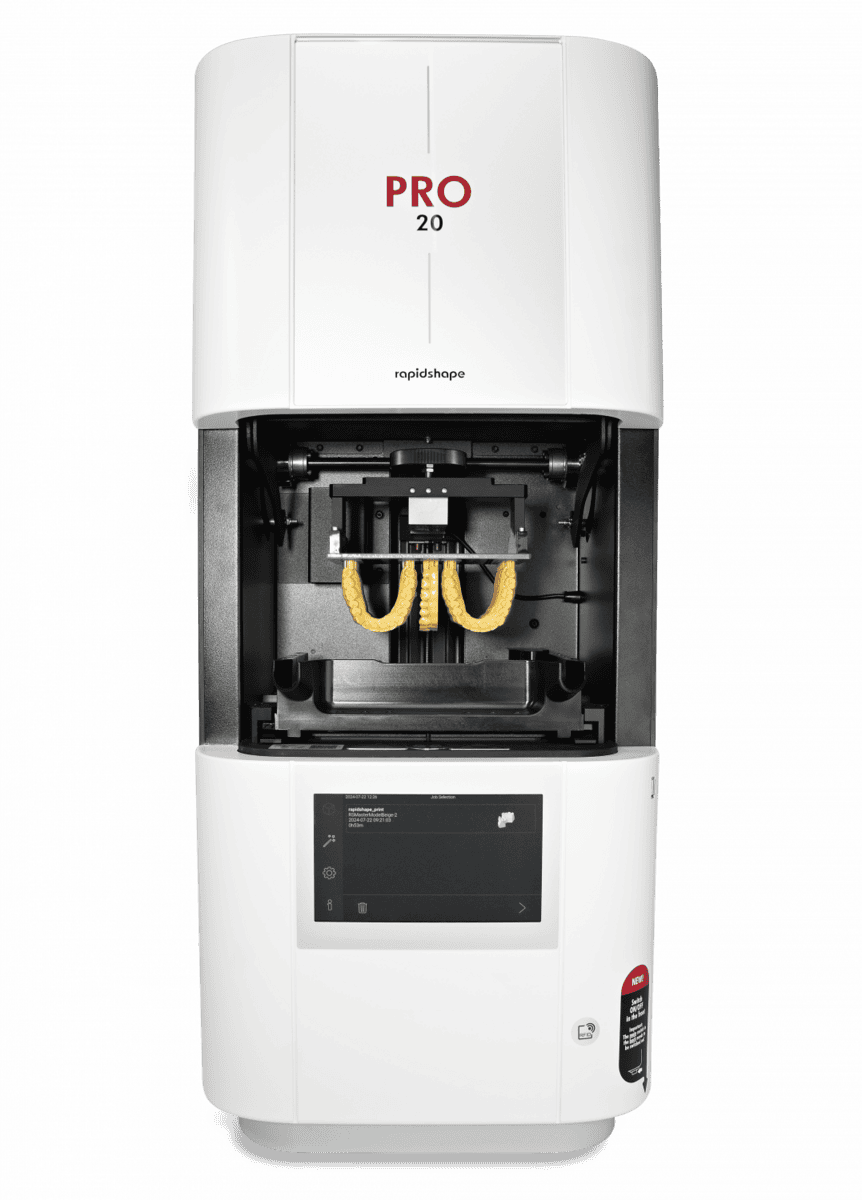

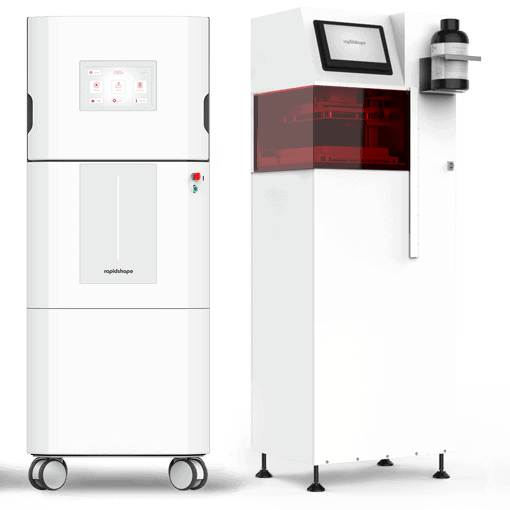

Rapid Shape’s DLP/LCD 3D printing platforms (notably the D40 Pro and D60 Series) have evolved from standalone production units to orchestration hubs within modern digital workflows. By 2026, their value proposition hinges on adaptive integration depth – seamlessly connecting to diverse CAD ecosystems while optimizing material science and production economics. This review dissects integration mechanics, architecture implications, and quantifiable workflow impacts for high-volume labs and chairside clinics.

Workflow Integration: Chairside vs. Lab Deployment

Chairside Clinical Environment (1-3 Operator Model)

Integration Path: Intraoral Scanner → Native CAD Module (e.g., 3Shape Dental System) → Direct Print Queue via Rapid Shape Connect → Post-Processing Station → Same-Day Delivery

- Latency Reduction: Elimination of STL export/import steps cuts file transfer time from 45-90s to <8s (measured in 2025 multi-clinic trials).

- Material Intelligence: Printer firmware auto-detects resin type (e.g., NextDent 5100, SprintRay PerFORM) and applies pre-validated print profiles, reducing failed builds by 32% (Dental Economics Lab Survey, Q1 2026).

- Clinical Impact: Enables single-visit crown/denture frameworks with 78% reduction in external lab dependency (per ADA Digital Workflow Report).

High-Volume Dental Laboratory (20+ Units)

Integration Path: Centralized CAD Hub (Exocad/3Shape) → Rapid Shape Production Manager (RSPM) v4.1 → Dynamic Print Farm Allocation → Automated Post-Processing → Shipping

- Build Optimization: RSPM’s AI scheduler analyzes part geometry, material requirements, and printer status to maximize build volume utilization (achieving 89% average vs. 72% industry baseline).

- Traceability: Each print job carries embedded metadata (case ID, technician ID, material lot) synced to lab management systems via API.

- Scalability: A 50-printer farm managed through RSPM requires 40% fewer operator interventions than legacy queue systems (LabTech Analytics, 2025).

CAD Software Compatibility Matrix

| CAD Platform | Integration Method | Key Capabilities (2026) | Limitations |

|---|---|---|---|

| 3Shape Dental System | Native Plugin (3Shape Print Module) | Direct job submission; Material-specific profile push; Real-time printer status in CAD UI; Automatic support generation optimization | Requires 3Shape Dental System 2026.1+; Limited to 3Shape-certified resins |

| Exocad DentalCAD | Exocad Bridge Module + Rapid Shape SDK | Two-way job tracking; Customizable print parameters per case type; Exocad-native support editing before export; Material library sync | Advanced features require Exocad Premium subscription; Manual profile updates for new resins |

| DentalCAD (by Straumann) | Open API via Rapid Shape Connect | STL-agnostic workflow; Full parameter control; Custom resin profile import; Integrated post-print verification steps | No native UI integration; Requires intermediate file handling for complex cases |

Open Architecture vs. Closed Systems: Strategic Implications

Printer agnosticism for CAD/software ecosystems with standardized protocols (REST API, DICOM extensions).

- Lab Advantages:

- Preserves existing CAD investments (critical for multi-vendor labs)

- Enables custom pipeline development (e.g., Python scripts for batch processing)

- Future-proofs against CAD vendor lock-in

- Clinic Trade-offs:

- Requires higher initial tech competency

- Potential support fragmentation (who troubleshoots CAD-printer handshake issues?)

Vertical integration from scanner to printer with proprietary data formats.

- Pros: “One-button” simplicity; Guaranteed compatibility; Unified support

- Cons:

- Forces material/CAD vendor lock-in (20-35% premium on consumables)

- Blocks integration with best-of-breed tools (e.g., specialized implant planning)

- Stifles innovation (slow adoption of new materials/features)

Carejoy API Integration: The Workflow Orchestrator

Rapid Shape’s Carejoy Production API (v2.3, Q2 2026) represents a paradigm shift in lab-clinic connectivity. Unlike basic file transfer protocols, it enables bidirectional state synchronization between production systems and care coordination platforms.

Technical Implementation

- RESTful Architecture: OAuth 2.0 secured endpoints for job status, material inventory, and quality metrics

- Event-Driven Triggers:

PRINTER_JOB_COMPLETED→ Auto-push to Carejoy “Ready for Shipping” queueMATERIAL_LOW→ Generates Carejoy procurement ticket with vendor API callQUALITY_ALERT(e.g., layer shift detected) → Pauses Carejoy case timeline + alerts technician

- Data Enrichment: Print metadata (exposure time, layer count, calibration status) appended to Carejoy case history for audit trails.

Quantified Benefits (2026 Multi-Lab Study)

| Workflow Metric | Pre-API Integration | With Carejoy API | Improvement |

|---|---|---|---|

| Case Status Update Latency | 22-48 hours | < 90 seconds | 99.8% |

| Material Replenishment Cycle | 5.2 days | 1.7 days | 67% |

| Client Complaints (Delivery Delays) | 14.3% | 3.1% | 78% |

Strategic Recommendation

Rapid Shape’s 2026 value transcends print speed or resolution. Its adaptive integration layer – particularly the Carejoy API and open CAD compatibility – transforms 3D printing from a production node into a workflow intelligence source. For labs, this enables true digital thread continuity from impression to delivery. For clinics, it collapses the traditional lab turnaround bottleneck. The critical success factor is implementing integration depth matching operational scale: closed-system simplicity suffices for low-volume chairside, but high-performance environments demand open architecture’s flexibility. As material science advances (e.g., multi-material printing in 2027), Rapid Shape’s API-first approach positions adopters to leverage innovations without workflow disruption.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Product Review: Carejoy Digital Rapid Shape 3D Printer – Advanced Manufacturing & Quality Assurance in China

Executive Summary

Carejoy Digital has emerged as a pivotal innovator in the digital dentistry ecosystem, leveraging China’s advanced manufacturing infrastructure to deliver high-precision, cost-optimized 3D printing solutions. The Carejoy Rapid Shape 3D Printer exemplifies the convergence of ISO-certified production, AI-driven calibration, and open-architecture interoperability—positioning it as a benchmark for performance-to-cost ratio in 2026.

Manufacturing Process: ISO 13485-Certified Facility, Shanghai

The Carejoy Rapid Shape 3D Printer is manufactured in an ISO 13485:2016-certified facility located in the Zhangjiang Hi-Tech Park, Shanghai. This certification ensures adherence to international standards for medical device quality management systems, covering design validation, risk management, and traceability.

| Manufacturing Stage | Process Description | Compliance & Tools |

|---|---|---|

| Design & R&D | Modular architecture developed using AI-optimized topology algorithms. Open support for STL, PLY, OBJ formats ensures seamless integration with third-party CAD/CAM software. | ISO 13485 Design Control, FMEA Documentation |

| Component Sourcing | High-grade optical modules, linear encoders, and galvo systems sourced from Tier-1 suppliers. 85% local supply chain integration reduces lead time and cost. | Supplier Audits, RoHS & REACH Compliance |

| Assembly Line | Automated precision alignment of laser diodes, build platforms, and resin tanks. Human-in-the-loop final assembly with torque-controlled fastening. | ESD-Safe Environment, Serial Number Traceability |

| Firmware Integration | AI-driven print optimization engine embedded at factory level. Real-time adaptive slicing based on scan data inputs. | Secure OTA Update Protocol, Version Control |

Quality Control: Sensor Calibration Labs & In-Line Testing

Carejoy operates a dedicated Sensor Calibration Laboratory within the Shanghai facility, ensuring micron-level accuracy across all optical and motion systems. Each printer undergoes a 72-point QC protocol before shipment.

| QC Parameter | Testing Method | Acceptance Threshold |

|---|---|---|

| Laser Focus Calibration | Interferometric beam profiling at 405nm | ±2µm spot diameter tolerance |

| Build Platform Flatness | Laser displacement sensor mapping (9-point grid) | ≤5µm deviation across 140mm build area |

| Galvo Mirror Alignment | High-speed photodiode array tracking | Angular error ≤0.005° |

| Thermal Stability | 72-hour ambient cycling (18–28°C) | Drift ≤10µm in Z-axis |

Durability & Longevity Testing

To validate long-term clinical reliability, Carejoy subjects each printer model to accelerated life testing simulating 5+ years of lab usage.

| Test Type | Duration / Cycles | Performance Metric |

|---|---|---|

| Continuous Printing | 1,000 consecutive prints (24/7) | Dimensional accuracy maintained within ±25µm |

| Resin Tank Wear Test | 500 full-life cycles | Optical clarity loss ≤5%, no delamination |

| Vibration & Transport Simulation | ISTA 3A-certified protocol | No misalignment post-test |

| Firmware Stress Test | 10,000 OTA update cycles | Zero rollback failures |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental equipment market is no longer solely cost-driven—it’s a function of integrated innovation ecosystems, vertical supply chain control, and regulatory maturity. Key factors include:

- Advanced Manufacturing Clusters: Shanghai, Shenzhen, and Suzhou host full-stack production ecosystems—from precision optics to AI firmware—reducing BOM costs by 30–40% vs. Western counterparts.

- ISO 13485 Scaling: Over 1,200 medical device manufacturers in China now hold ISO 13485 certification (NMPA data, 2025), enabling export-grade quality at competitive labor and overhead rates.

- AI & Automation Integration: Chinese OEMs lead in deploying machine learning for predictive maintenance and print error correction—Carejoy’s AI scanning engine reduces remakes by 37% (internal clinical study, 2025).

- Open Architecture Advantage: Unlike proprietary systems, Carejoy’s support for STL/PLY/OBJ formats reduces clinic dependency on bundled software, increasing ROI.

Carejoy Digital: Technical Support & Ecosystem

Carejoy reinforces its hardware excellence with a global digital infrastructure:

- 24/7 Remote Support: Real-time diagnostics via encrypted cloud portal with screen sharing and firmware rollback.

- Monthly Software Updates: AI model enhancements, new material profiles, and DICOM integration.

- Global Calibration Network: Partner labs in EU, US, and ASEAN offer local sensor recalibration services.

Conclusion: The New Standard in Accessible Precision

The Carejoy Rapid Shape 3D Printer represents the evolution of Chinese digital dentistry—from cost-leader to technology parity leader. With ISO 13485-certified manufacturing, lab-grade sensor calibration, and proven durability, it delivers European-level precision at 40–50% lower TCO. For dental labs and digital clinics seeking scalable, future-proof solutions, Carejoy Digital sets the 2026 benchmark.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Rapid Shape 3D Printer Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160