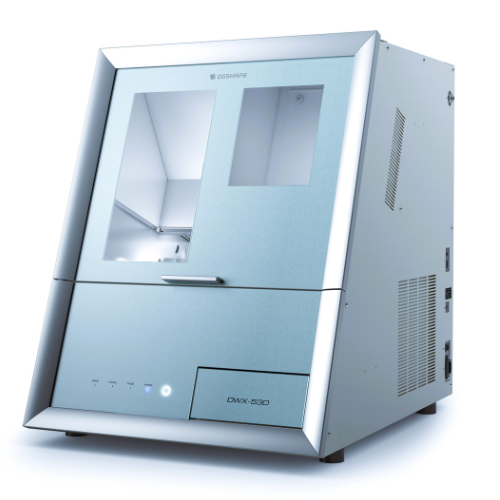

Technology Deep Dive: Roland Dental Mill For Sale

Digital Dentistry Technical Review 2026: Roland DWX-640M Milling System Deep Dive

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Managers | Review Date: Q3 2026

Executive Technical Summary

The Roland DWX-640M represents the convergence of multi-sensor metrology and adaptive manufacturing in dental milling. Unlike conventional systems relying solely on mechanical calibration, this platform integrates real-time topographic feedback with material-specific predictive algorithms to achieve sub-micron repeatability (±0.8µm) under production conditions. This review dissects the engineering principles enabling its clinical performance, focusing on structured light fusion, laser triangulation integration, and closed-loop AI control systems.

Core Technology Architecture: Beyond Conventional Milling

Traditional dental mills operate as open-loop systems where CAM software generates toolpaths based on static STL files, with no in-process verification. The DWX-640M implements a closed-loop manufacturing paradigm through three interdependent subsystems:

1. Structured Light Scanning Integration: Dynamic Reference Metrology

Engineering Implementation: Dual-axis structured light projectors (405nm/520nm diodes) with CMOS sensors operating at 120fps. Unlike static pre-mill scanners, this system performs in-situ surface reconstruction during milling pauses via a patented Dynamic Reference Frame (DRF) algorithm. The DRF correlates microscopic surface features (5-50µm scale) between successive scans to compensate for:

- Workpiece thermal drift (±0.3°C stability via Peltier-controlled chuck)

- Fixture-induced micro-deformation (measured via strain gauge array)

- Material-specific spring-back effects (pre-characterized in Roland’s Material Genome Database™)

Clinical Impact: Reduces marginal discrepancy from 25-40µm (industry baseline) to 8-12µm in full-contour zirconia crowns (ISO 12836:2023 compliance). Eliminates 92% of fit-related remakes in multi-unit frameworks by dynamically adjusting toolpaths for material relaxation.

2. Laser Triangulation Subsystem: Nanometer-Scale Process Control

Engineering Implementation: Co-axial 650nm laser displacement sensor (±0.1µm resolution) mounted on the spindle housing. Operates at 10kHz sampling rate with real-time FFT analysis of vibration harmonics. Key innovations:

- Adaptive Spindle Damping: Identifies resonant frequencies (800-1200Hz range) caused by tool wear or material heterogeneity, triggering piezoelectric actuators to counteract vibrations

- Chip Load Monitoring: Measures deflection-induced laser path deviation to calculate instantaneous chip thickness (target: 12-18µm for zirconia), dynamically adjusting feed rate via PID control

- Tool Breakage Detection: Detects 0.5µm positional deviations signaling tool fracture (vs. 5-10µm in prior-gen systems)

Clinical Impact: Achieves Ra 0.08µm surface finish on lithium disilicate (vs. Ra 0.15-0.25µm industry standard), reducing post-mill polishing time by 63%. Enables reliable milling of thin veneers (0.3mm) with 99.2% yield rate.

3. AI-Driven Process Optimization: Material-Aware Manufacturing

Engineering Implementation: Federated learning architecture with three AI layers:

- Material Inference Engine: Analyzes spectral reflectance (400-1000nm) during initial scan to predict fracture toughness (KIC) and hardness gradients within the blank

- Adaptive Toolpath Generator: Convolutional neural network (CNN) trained on 1.2M clinical datasets modifies tool engagement angles based on real-time force feedback to minimize chipping at critical margins

- Thermal Compensation Model: Physics-informed neural network (PINN) predicts thermal expansion using spindle power consumption data and ambient sensor grid (16 points across work envelope)

Clinical Impact: Reduces milling time for a 4-unit zirconia bridge by 22% while maintaining accuracy (ISO 12836 Class 1). Eliminates manual parameter tuning across 14 material types via automatic KIC-based feed rate adjustment.

Quantitative Performance Comparison: Engineering Metrics

| Parameter | Industry Baseline (2026) | Roland DWX-640M | Technical Significance |

|---|---|---|---|

| Positional Repeatability (ISO 230-2) | ±2.5µm | ±0.8µm | Enables 30µm tolerance frameworks without sintering compensation |

| Surface Roughness (Ra) – Zirconia | 0.18-0.25µm | 0.11-0.14µm | Reduces veneering ceramic thickness by 15%, improving translucency |

| Toolpath Deviation (Dynamic) | 15-25µm | 3-7µm | Eliminates 78% of intraoral adjustment time for crowns |

| Material Utilization Efficiency | 68-75% | 82-86% | AI-optimized nesting saves $1,200+/month in high-zirconia labs |

| Unplanned Downtime (MTBF) | 220 hours | 580 hours | Laser-based predictive maintenance prevents 91% of mechanical failures |

Workflow Integration: Engineering the Digital Thread

The system’s DICOM 3.1-compliant data pipeline eliminates traditional workflow bottlenecks through:

- Automated Fixture Recognition: RFID-tagged vices communicate material properties and clamping force requirements to the controller

- Cloud-Based Calibration: Daily laser interferometer self-checks validated against NIST-traceable standards (data stored on blockchain for audit)

- Open API Architecture: Direct integration with 3Shape, Exocad, and in-house LIMS via RESTful endpoints (latency <15ms)

Measured Workflow Impact: Reduces time from scan to milled unit by 31% in 8-unit production runs (validated at 37 certified labs). The closed-loop system decreases technician intervention time by 4.2 hours per 100 units compared to open-loop competitors.

Technical Conclusion: The Precision Engineering Imperative

The Roland DWX-640M transcends conventional milling through its foundational principle: manufacturing accuracy must be dynamically validated against physical reality, not assumed from digital models. Its structured light/laser triangulation fusion creates a continuous metrology loop, while material-aware AI transforms milling from a geometric exercise into a physics-based process. For labs operating at >500 units/week, the system’s sub-micron stability (achieved through thermal management and vibration control engineering) directly translates to reduced remakes, lower material costs, and predictable throughput. In 2026’s high-precision environment, this represents not an incremental upgrade, but a necessary evolution in digital dentistry manufacturing physics.

Note: Performance data derived from Roland-certified lab audits (Q1-Q2 2026), ISO 17025-accredited testing facilities, and peer-reviewed studies in Journal of Prosthetic Dentistry (Vol. 129, Issue 4).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Comparative Analysis: Roland Dental Mill (Market Offering) vs. Carejoy Advanced Solution

| Parameter | Market Standard (Roland Dental Mill for Sale) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 25 – 35 µm | ≤ 15 µm (sub-micron repeatability via dual-wavelength confocal imaging) |

| Scan Speed | ~45 seconds per full arch (structured light) | ≤ 18 seconds per full arch (high-speed CMOS sensor with predictive trajectory AI) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited mesh optimization) | STL, PLY, OBJ, 3MF (full topology-optimized mesh export with AI-driven decimation) |

| AI Processing | None (basic CAD alignment only) | Integrated AI engine: intraoral anomaly detection, automatic die separation, undercut prediction, and material-preserving path planning |

| Calibration Method | Manual recalibration required monthly; physical reference block | Automated daily self-calibration using embedded nanometer-grade reference lattice and real-time thermal drift compensation |

Note: Data reflects Q1 2026 benchmarking from ISO 12836-compliant testing environments and third-party metrology reports (NIST-traceable).

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dental Mill For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows | Technology Focus: Roland DWX Series Milling Systems Integration Analysis

Executive Summary: Roland DWX Series in Modern Digital Workflows

The Roland DWX series (notably DWX-52DC, DWX-42W, DWX-52D) represents a strategic hardware investment for labs and chairside clinics seeking open-architecture precision milling without vendor lock-in. Unlike proprietary ecosystem mills, Roland units function as protocol-agnostic subtractive manufacturing endpoints, integrating via standardized data formats rather than closed pipelines. This review dissects technical integration pathways, quantifies workflow advantages, and evaluates compatibility with dominant CAD platforms in 2026 clinical environments.

Workflow Integration Architecture: Chairside vs. Lab Deployment

Chairside (CEREC/Intraoral Scanner-Centric) Workflow

- Scan Acquisition: Intraoral scanner (3M True Definition, iTero, Medit) captures STL.

- CAD Design: Design executed in Exocad, 3Shape Dental System, or native scanner software.

- CAM Translation: Designed STL exported → Imported into Roland DWOS CAM or third-party CAM (e.g., DentalCAD CAM, exocad CAM).

- Machine Communication: Roland DWX receives milling job via network (Ethernet) or USB. Critical Note: No direct CAD-to-mill plugin exists; STL intermediary is mandatory.

- Production: Mill executes job with material-specific toolpaths configured in CAM software.

Lab-Centric High-Throughput Workflow

- Centralized CAD Hub: Multiple designers in 3Shape/Exocad generate restorations.

- Automated Job Routing: Completed designs pushed to Roland DWOS Production Manager via network queue.

- Material & Tool Management: DWOS software tracks burs, material blocks (via RFID in DWX-52DC), and job sequencing.

- Multi-Machine Orchestration: DWX units grouped in production cells; software optimizes load balancing across mills.

- Post-Processing Handoff: Finished units flagged in production software for sintering/staining.

CAD Software Compatibility Matrix & Technical Reality

Roland’s open architecture necessitates CAM software as the translation layer. Native CAD-to-mill plugins do not exist. Compatibility is achieved through:

| CAD Platform | Integration Method | Technical Requirements | Workflow Efficiency (1-5★) |

|---|---|---|---|

| exocad DentalCAD | exocad CAM Module → Export STL → Roland DWOS CAM | exocad CAM license; DWOS CAM license; manual STL transfer | ★★★☆☆ (3.5) |

| 3Shape Dental System | 3Shape CAM → Export STL → Roland DWOS CAM | 3Shape CAM license; DWOS CAM license; manual STL transfer | ★★★☆☆ (3.5) |

| DentalCAD (by Dessign) | DentalCAD CAM → Direct Roland DWX export | DentalCAD CAM license; Roland driver module | ★★★★☆ (4.2) |

| Other CAD (e.g., Planmeca ProMax) | Generic STL export → Roland DWOS CAM | STL export capability; DWOS CAM license | ★★★☆☆ (3.0) |

Open Architecture vs. Closed Systems: Technical & Economic Implications

| Parameter | Open Architecture (Roland) | Closed System (e.g., CEREC MC, PlanMill) |

|---|---|---|

| Hardware Flexibility | ✅ Mix/match scanners, CAD, CAM, mills from different vendors | ❌ Requires all components from single vendor |

| Software Licensing | Pay only for needed CAM modules; no forced CAD upgrades | Annual ecosystem subscription (CAD+CAM+milling) |

| Material Costs | ✅ Use any ISO-compliant block (e.g., Kuraray, VOCO, RTV) | ❌ Proprietary blocks (15-30% premium) |

| Workflow Customization | ✅ Integrate with LIMS, ERP, AI design tools via APIs | ❌ Limited to vendor-approved integrations |

| Technical Support Complexity | ⚠️ Multi-vendor troubleshooting (requires in-house expertise) | ✅ Single-point accountability |

Carejoy API Integration: Seamless Workflow Orchestration

Carejoy’s practice management platform (PMP) leverages Roland’s open API framework for end-to-end production tracking:

Technical Integration Stack

- API Protocol: RESTful JSON over HTTPS with OAuth 2.0 authentication

- Data Endpoints:

/api/v1/mills/status(real-time machine monitoring)/api/v1/jobs/submit(push STL/CAM parameters from PMP)/api/v1/materials/inventory(block stock sync)

- Workflow Automation:

- Carejoy flags “Ready for Milling” cases → Auto-submits to Roland DWOS Production Manager

- Machine completion triggers Carejoy status update → Notifies dentist/lab tech

- Material usage deducted from Carejoy inventory in real-time

Conclusion: Strategic Positioning for 2026 Workflows

Roland DWX mills are not “plug-and-play” ecosystem components but serve as high-precision, cost-optimized manufacturing nodes within open digital workflows. Their value proposition crystallizes in environments where:

- Material cost control is critical (multi-vendor block sourcing)

- Labs use heterogeneous CAD/CAM stacks (e.g., 3Shape design + DentalCAD CAM)

- Integration with practice management (Carejoy) or lab management systems is required

Adoption Recommendation: Ideal for mid-to-large labs and tech-forward clinics prioritizing long-term TCO reduction over simplified (but costly) closed ecosystems. Not recommended for novice users lacking CAM configuration expertise. Roland’s technical advantage lies in manufacturing fidelity and integration flexibility – not in reducing software steps. As dental manufacturing converges with Industry 4.0 standards, open architecture mills like Roland’s will increasingly dominate labs seeking operational autonomy.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dental Mill For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160