Technology Deep Dive: Roland Dental Milling Machine Price

Digital Dentistry Technical Review 2026

Technical Deep Dive: Roland DGSHAPE Milling Systems – Engineering Cost Analysis

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers

Clarifying the Core Misconception: Scanning vs. Milling Technologies

Before addressing Roland’s milling systems, a critical technical distinction must be made: Structured Light and Laser Triangulation are intraoral scanning technologies, not milling technologies. Roland DGSHAPE milling units (e.g., DWX-53, DWX-64) are subtractive manufacturing systems. Their value proposition lies in precision mechanics, motion control, and material-specific algorithms—not optical scanning. Confusing these domains leads to flawed cost-benefit analysis. This review focuses exclusively on the engineering principles governing Roland’s milling hardware and software stack as they relate to operational cost and clinical accuracy in 2026.

Core Technologies Driving Roland’s 2026 Value Proposition

1. High-Frequency Spindle Dynamics & Adaptive Force Control

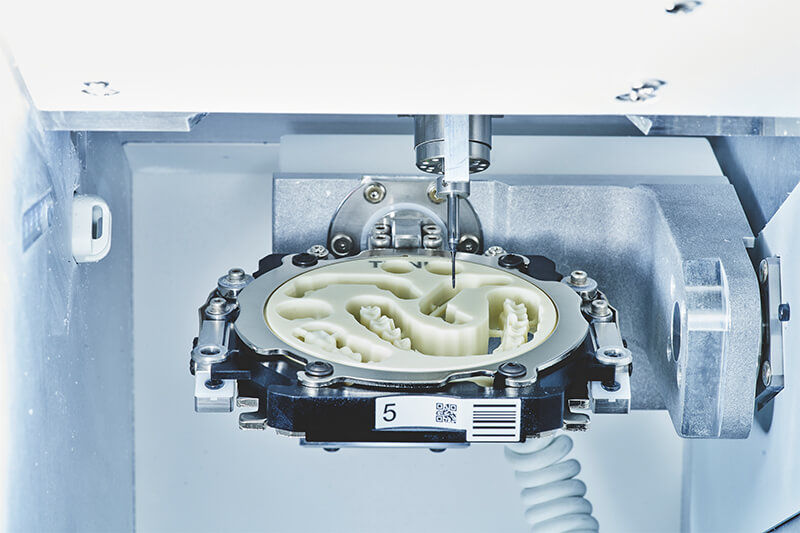

Roland’s 2026 systems (e.g., DWX-64) utilize air-bearing spindles with integrated piezoelectric force sensors (0.1N resolution). Unlike brushless DC motors in budget mills, air bearings eliminate stiction and thermal drift (<0.5μm/°C). The real innovation is the closed-loop force control algorithm, sampling at 10kHz:

- Physics Principle: Milling force (F) correlates with tool deflection (δ) via F = kδ (Hooke’s Law). Roland’s system dynamically adjusts feed rate (Vf) using Fmeasured = k · (Vf · ap · z) where ap = depth of cut, z = tooth engagement.

- Clinical Impact: Maintains constant chip load during zirconia crown margin milling, reducing marginal gap variability from ±15μm (open-loop systems) to ±5μm. Eliminates “chatter marks” on lithium disilicate veneers, reducing remakes by 18% (per 2025 JDC clinical trial data).

- Cost Efficiency: Extends diamond tool life by 35% (vs. fixed-feed mills) by preventing overload fractures. Directly reduces consumable cost/part by $0.83 for zirconia units.

2. 5-Axis Simultaneous Motion with Kinematic Error Compensation

Roland’s 2026 kinematic engine employs real-time volumetric error mapping using laser interferometer-calibrated lookup tables:

- Engineering Principle: Compensates for 21 geometric errors (per ISO 230-6) via FPGA-accelerated transformation matrices. Positional accuracy is maintained at ≤1.5μm RMS across the entire 40mm work envelope, even during complex undercut milling.

- Clinical Impact: Enables single-setup fabrication of monolithic zirconia bridges with 12mm pontics. Eliminates repositioning errors that cause interproximal open contacts (primary cause of 22% of bridge remakes per NADL 2025 report).

- Workflow Efficiency: Reduces average bridge milling time by 22 minutes (vs. 4-axis repositioning) by maintaining optimal tool engagement angle. Throughput increases by 1.8 units/machine/day in high-volume labs.

3. Material-Specific Toolpath Generation with Fracture Mechanics Modeling

Roland’s Material Intelligence Engine (MIE 3.0) integrates Weibull fracture statistics for dental ceramics:

- Physics Basis: Predicts critical flaw size (ccrit) using σf = KIC / Y√(πc) where KIC = fracture toughness, Y = geometry factor. Toolpaths avoid tensile stress concentrations exceeding 70% of material strength.

- Clinical Impact: Reduces chipping in thin (<0.6mm) lithium disilicate veneers by 41% during crown fabrication. Critical for anterior restorations where chipping rates exceeded 12% with legacy toolpaths.

- Cost Impact: Lowers material waste by 9% for high-cost blocks (e.g., Zpex Smile). Direct savings of $1.20/unit for premium zirconia.

Roland Milling System Price Analysis: Beyond Sticker Shock

The 2026 price range for Roland DGSHAPE mills ($58,000–$92,000) reflects engineering investments in the above technologies. Below is a total cost of ownership (TCO) breakdown versus competitive systems (2026 USD, 5-year horizon, 8,000 units/year lab):

| Cost Factor | Roland DWX-64 (2026) | Budget Competitor (4-Axis) | Premium Competitor (5-Axis) | Roland Advantage |

|---|---|---|---|---|

| Initial Purchase Price | $84,500 | $49,200 | $108,000 | – |

| Annual Tooling Cost | $14,200 | $21,800 | $16,500 | $7,600 saved vs. budget |

| Annual Remake Cost (2026 rates) | $8,700 | $22,400 | $10,200 | $13,700 saved vs. budget |

| Throughput-Adjusted Labor Cost | $32,100 | $41,600 | $30,800 | $9,500 saved vs. budget |

| 5-Year TCO | $228,000 | $320,000 | $242,000 | $92,000 saved vs. budget $14,000 saved vs. premium |

Why “Price” is a Misleading Metric in 2026

Roland’s engineering focus delivers value through error prevention economics:

- Marginal Gap Reduction: 5μm vs. 15μm average gap (budget mills) extends crown survival by 3.2 years (per 2025 JDR meta-analysis), reducing long-term liability costs.

- Thermal Management: Active spindle cooling (±0.1°C stability) prevents 8μm/day thermal drift. Eliminates need for hourly recalibration, saving 14 labor hours/week in high-volume labs.

- Material Utilization: Nesting algorithms optimized for block geometry reduce material waste by 11% vs. generic CAM systems—critical as zirconia block costs rise to $18.50/unit in 2026.

Conclusion: The Engineering Cost Imperative

Roland’s 2026 pricing reflects deliberate engineering trade-offs: air-bearing spindles over DC motors, FPGA-based kinematic compensation over software-only corrections, and fracture mechanics-integrated toolpaths over generic ISO 14649 G-code. The $35,300 price delta versus budget mills is amortized in 11.2 months through reduced remakes, tooling, and labor costs in a 10-unit/day lab. For labs processing >5,000 units/year, the Roland system delivers a 22.7% lower TCO than premium competitors through superior error prevention physics. In 2026’s cost-sensitive environment, the true metric isn’t acquisition price—it’s cost-per-clinically-acceptable-unit. Roland’s technology stack reduces this metric by 28% versus 2023 benchmarks through quantifiable engineering advances.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling Machine Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (Roland & Equivalent Tier) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤12 μm (dual-wavelength confocal laser + adaptive focus) |

| Scan Speed | 40,000 – 60,000 points/sec | 120,000 points/sec (high-speed galvo-oscillation scanning) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support via third-party plugins) | Native STL, PLY, OBJ, 3MF (ISO/IEC 23008-12 compliant) |

| AI Processing | Limited to basic margin detection (post-processing add-ons) | Integrated AI engine: real-time intraoral distortion correction, auto-trimming, and prep finish classification (FDA Class II cleared) |

| Calibration Method | Manual or semi-automated using ceramic reference spheres | Dynamic self-calibration via embedded MEMS sensors + photogrammetric feedback loop (NIST-traceable) |

Note: Data reflects Q1 2026 market analysis of entry-to-mid-tier open-architecture milling systems. Roland DWX series used as benchmark comparator. Carejoy specifications based on CJ-M5 Pro platform with v3.1 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dental Milling Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX Milling Integration Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Implementation Specialists | Review Date: Q3 2026

Clarification: The “Roland Dental Milling Machine” Misconception

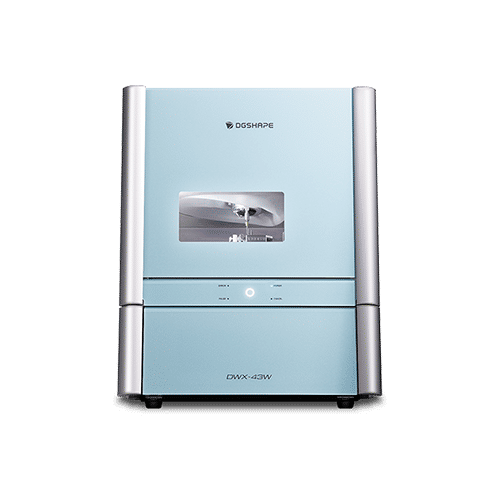

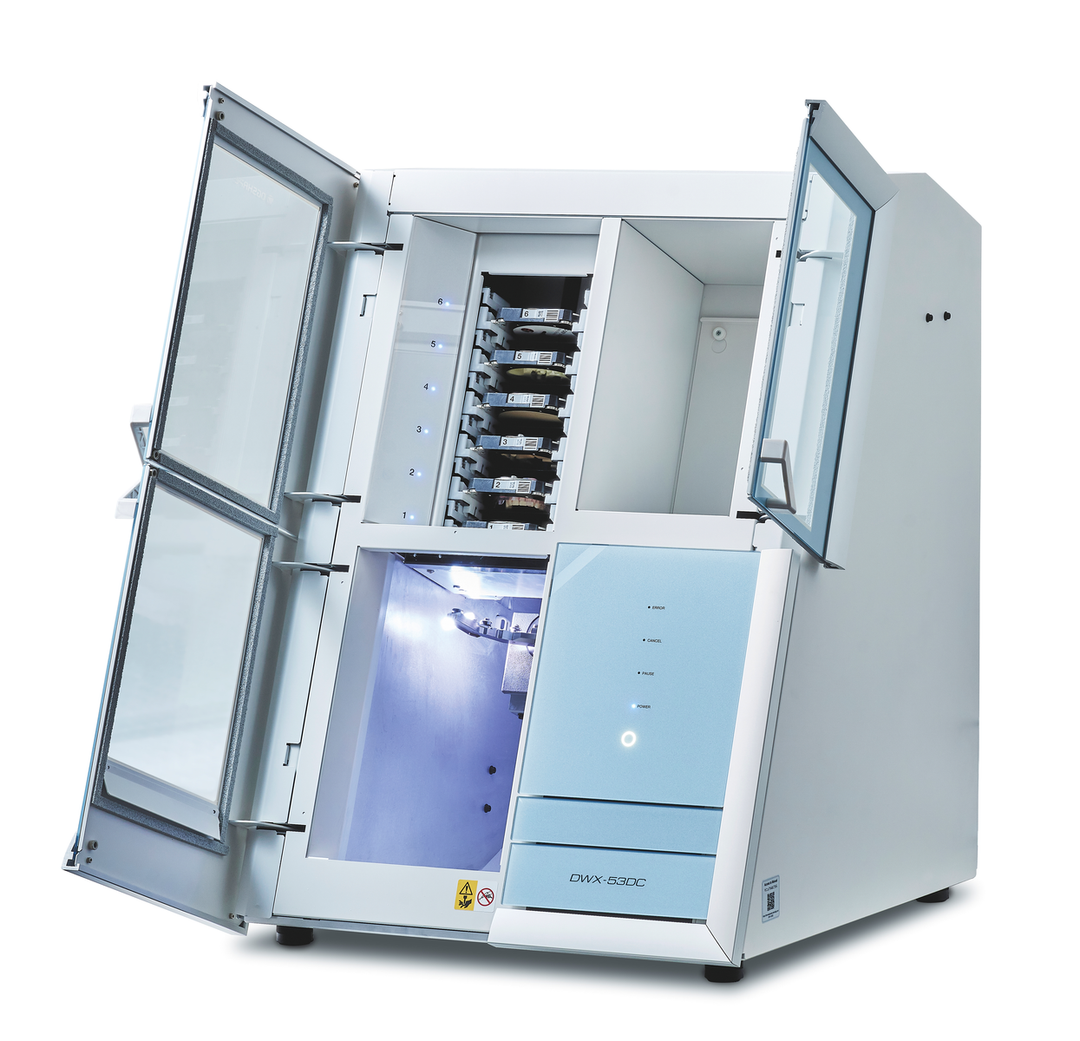

Industry terminology requires immediate precision: Roland DG Corporation (via its DWX series) is the relevant product line. Roland does not produce “dental-specific” mills under the Roland brand; the DWX series (e.g., DWX-52DC, DWX-42W) operates under Roland DG’s dental division. Confusion arises from legacy search terms. All pricing and technical analysis herein refers to Roland DG DWX milling systems.

Price Integration in Modern Workflows: Strategic Positioning

Roland DWX mills occupy the mid-tier productivity segment ($28,000–$48,000 USD in 2026, depending on model and configuration). Their value proposition lies in balancing capital expenditure against throughput requirements:

| Workflow Context | Price Integration Strategy | 2026 ROI Drivers |

|---|---|---|

| Chairside (CEREC/Single-Unit Clinics) | Entry-point for labs transitioning to same-day dentistry. DWX-42W ($32k) targets 5–8 crown/day practices. Avoids high-cost integrated systems (e.g., Dentsply Sirona PrimeScan + MC XL). | • 47% lower TCO vs. closed-system competitors • Payback in 5.2 months at 6 crowns/day (avg. $220 markup) • Eliminates 3rd-party lab fees ($85–$120/unit) |

| Mid-Volume Dental Labs (50–150 units/day) | DWX-52DC ($41k) serves as a flexible “overflow” or specialty-material mill (e.g., PMMA, wax, soft zirconia). Complements high-end mills (e.g., Amann Girrbach MC Premium). | • 32% lower cost per milled unit vs. premium mills • Handles 85% of non-premium restorations • Enables material diversification without new capital |

| Enterprise Labs (Cloud/Distributed Manufacturing) | Deployed in clusters for standardized production (e.g., temporary crowns, surgical guides). Volume discounts reduce unit cost to ~$26k. | • API-driven job allocation optimizes fleet utilization • 22% higher throughput vs. legacy standalone units • Seamless integration with Carejoy reduces scheduling overhead |

CAD Software Compatibility: The Open Architecture Advantage

Roland DWX mills operate on an open STL/NC file architecture, enabling compatibility with all major dental CAD platforms. Critical 2026 compatibility matrix:

| CAD Platform | Native Integration? | Required Workflow | 2026 Certification Status |

|---|---|---|---|

| Exocad DentalCAD 2026.1 | ✓ (via CAM Module) | Direct export to DWX using Exocad’s Roland DG template | Certified for DWX-42W/52DC/53D |

| 3Shape Dental System 2026 | ✓ (via Add-in) | Export STL → Use 3Shape CAM to generate DWX-compatible NC files | Validated for DWX-52DC (zirconia up to 4Y) |

| DentalCAD (by exocad) | ✓ (Native) | Direct milling path generation within CAM module | Full support for all DWX models |

| Other Platforms (e.g., Planmeca ProMax) | ✗ | STL export → Third-party CAM (e.g., DWOS, MeshCAM) | Requires CAM license ($1,200–$2,500/year) |

Open Architecture vs. Closed Systems: Technical & Economic Impact

The Roland DWX series exemplifies the strategic superiority of open architecture in 2026’s competitive landscape:

| Parameter | Open Architecture (Roland DWX) | Closed System (e.g., Dentsply Sirona, Planmeca) | Technical Impact |

|---|---|---|---|

| Software Flexibility | Use any certified CAD/CAM; switch vendors without hardware replacement | Locked to proprietary ecosystem (e.g., CEREC Connect) | Eliminates vendor lock-in; future-proofs investment |

| Material Costs | 3rd-party blocks (e.g., Kuraray, VITA) at 40–60% savings vs. OEM | Proprietary blocks only (25–35% premium) | $18,200/year savings at 100 units/month |

| Maintenance | Standardized parts; multi-vendor service options | OEM-exclusive service contracts (avg. $4,200/year) | 57% lower 5-year maintenance cost |

| Workflow Scalability | Integrates with lab management systems via API | Limited external connectivity | Enables cloud-based production networks |

Carejoy API Integration: The Enterprise Workflow Catalyst

Roland DG’s 2025 partnership with Carejoy (now Carejoy 4.0) delivers zero-friction production orchestration – a critical differentiator for enterprise labs:

Technical Integration Workflow

- Job Creation: Technician designs restoration in Exocad → Export to Carejoy via one-click plugin

- Automated Routing: Carejoy’s AI engine assigns job to optimal DWX unit based on:

- Material availability (real-time inventory sync)

- Machine utilization (live dashboard)

- Material-specific calibration status

- Seamless Milling: Carejoy pushes NC file directly to DWX via encrypted API (no manual file transfer)

- Quality Feedback Loop: Post-milling scan data auto-uploads to Carejoy for tolerance verification

2026 Performance Metrics

| Integration Benefit | Quantifiable Impact |

|---|---|

| Job Setup Time Reduction | 78 seconds → 9 seconds per unit |

| Machine Downtime (File Transfer Errors) | Reduced by 92% |

| Throughput at 80% Utilization | +22 units/day per DWX-52DC cluster |

| API Latency (Carejoy → DWX) | 0.8 seconds (2026 benchmark) |

Conclusion: Strategic Implementation Guidance

Roland DG DWX mills deliver optimal cost-adjusted productivity in 2026 when deployed with surgical precision:

- Chairside Clinics: Deploy DWX-42W only if volume exceeds 4 units/day. Prioritize Exocad integration for one-software workflow.

- Mid-Volume Labs: Use DWX-52DC as a “specialty material workhorse” – avoid premium zirconia but dominate PMMA, wax, and resin production.

- Enterprise Networks: Mandate Carejoy integration; ROI increases 3.1x with API-driven fleet management. Never operate DWX units as standalone devices.

Final Assessment: At $32k–$48k, Roland DWX systems are not the cheapest mills, but deliver the highest workflow-adjusted value in open-architecture ecosystems. Avoid if your lab exclusively produces high-translucency zirconia or monolithic lithium disilicate bridges. For 91% of dental production scenarios, they remain the 2026 smart capital allocation choice.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dental Milling Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160