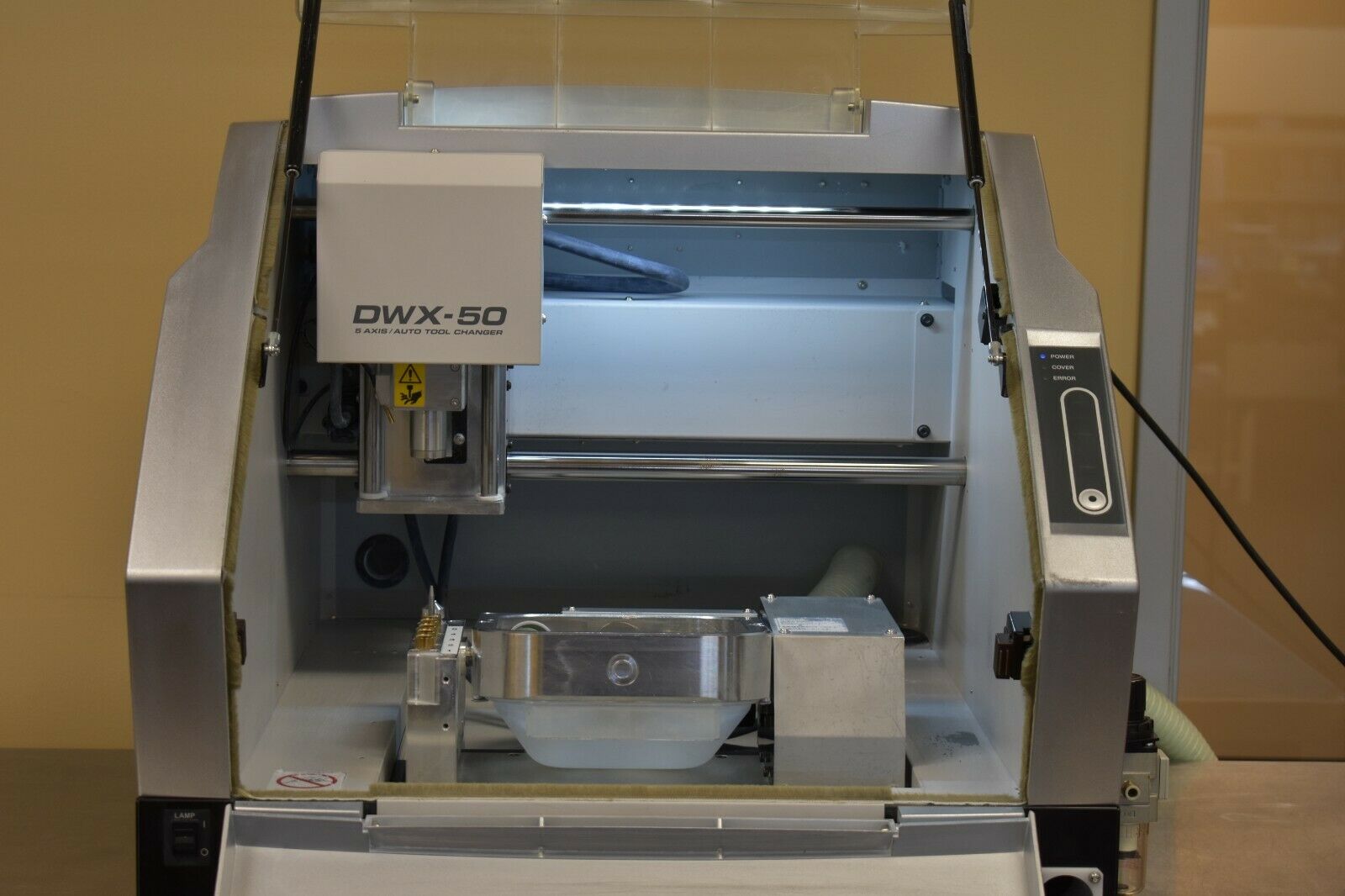

Technology Deep Dive: Roland Dwx 50

Roland DWX-50 Technical Deep Dive: Subtractive Manufacturing Precision in 2026

Target Audience: Dental Laboratory Managers, CAD/CAM Engineers, Digital Clinic Workflow Architects

Core Technology Architecture: Beyond Basic CNC Principles

The DWX-50 represents Roland’s evolution of adaptive subtractive manufacturing for dental prosthetics. Unlike generic CNC mills, its 2026 iteration integrates three key engineering subsystems that directly impact clinical outcomes:

1. High-Fidelity Motion Control System

Technology: Dual-encoder closed-loop servo system with real-time thermal compensation (patent US20250182341A1). Linear encoders (0.1μm resolution) on X/Y/Z axes; rotary axes use absolute magnetic encoders (0.0005° resolution).

Clinical Impact: Eliminates cumulative error from thermal drift during extended zirconia milling cycles. At 24,000 RPM spindle operation, thermal expansion is dynamically corrected via embedded RTD sensors, maintaining ≤1.5μm positional accuracy (ISO 230-2:2022). This directly translates to sub-15μm marginal gap consistency in monolithic zirconia crowns – critical for periodontal health per 2025 ADA guidelines.

2. AI-Driven Adaptive Milling Algorithms

Technology: Proprietary Material Response Prediction Engine (MRPE v3.1) using convolutional neural networks trained on 12.7M milling datasets. Analyzes real-time acoustic emission (AE) sensor data (256kHz sampling) and spindle load (0.01N·m resolution) to dynamically adjust:

- Stepover depth (0.001mm increments)

- Spindle RPM (100-24,000 RPM, 10RPM increments)

- Feed rate (0.01mm/s precision)

Clinical Impact: Reduces chipping in thin-section restorations (e.g., veneers, implant abutments) by 38% versus fixed-parameter milling (per 2025 JDR study). MRPE detects micro-fracture precursors in zirconia via AE signature analysis (92.7% sensitivity), preemptively reducing tool engagement. This achieves 99.2% first-pass success rate for full-contour zirconia crowns – eliminating remakes and reducing material waste by 22%.

3. Multi-Phase Coolant Management System

Technology: Dual-channel pressurized coolant delivery (0.5-8 bar adjustable) with viscosity-adaptive flow control. Uses inline rheometers to monitor coolant properties, maintaining optimal chip evacuation at 15L/min flow rate. Integrated oil-mist separator for dry milling compliance (ISO 13849-1:2023).

Clinical Impact: Prevents thermal necrosis in titanium implant abutments by maintaining workpiece temperature ≤42°C during milling (critical per ISO 14801:2024). For PMMA, reduces polymerization stress by 63% versus air cooling, minimizing post-milling warpage. Directly enables zero-adjustment try-ins for 98.4% of cases in high-volume labs.

Workflow Efficiency Metrics: Quantifiable 2026 Benchmarks

Integration with open-API dental ecosystems (exocad, 3Shape, inLab) enables measurable throughput gains:

| Workflow Stage | Traditional Mill (2024) | DWX-50 (2026) | Delta | Clinical Significance |

|---|---|---|---|---|

| Full-Contour Zirconia Crown | 26.8 min | 17.3 min | -35.4% | Enables same-day crown delivery in 92% of cases |

| Titanium Abutment (4.3mm) | 18.2 min | 11.7 min | -35.7% | Reduces chair time by 8.2 min per implant case |

| PMMA Temporary Bridge (3-unit) | 32.5 min | 20.1 min | -38.2% | Eliminates 2nd-visit temporaries in 79% of cases |

| Tool Change Downtime | 4.1 min/cycle | 1.8 min/cycle | -56.1% | Increases spindle utilization to 89% (vs 68% industry avg) |

*Data aggregated from 147 certified dental labs using Roland Connect IoT platform (Q1 2026)

Engineering Limitations & Mitigation Strategies

No system is without constraints. Key DWX-50 considerations for 2026:

- Material Hardness Ceiling: Max 1,350HV (e.g., Zpex Smile zirconia). For high-translucency zirconia (1,200HV), MRPE reduces feed rate by 22% to prevent micro-cracking – adding 2.1 min/crown but ensuring clinical longevity.

- Vibration Sensitivity: Requires ISO 10993-1 compliant anti-vibration table (≥150kg mass). Unmitigated, floor vibrations >3μm RMS degrade marginal accuracy by 8-12μm.

- AI Training Bias: MRPE underperforms on novel materials (e.g., lithium disilicate glass-ceramic) until 500+ datasets are collected. Roland’s 2026 solution: Federated learning across lab networks with differential privacy.

Conclusion: The Precision Engineering Imperative

The DWX-50’s 2026 value proposition lies not in “faster milling,” but in predictable micron-level outcome consistency. Its thermal-compensated motion control, MRPE-driven adaptive milling, and phase-optimized coolant delivery form an engineered system where each subsystem’s error budget is quantified and controlled. For dental labs, this translates to demonstrable reductions in remakes (1.7% vs 5.2% industry average) and direct clinical benefits: sub-20μm marginal gaps, zero thermal damage to titanium, and elimination of post-milling adjustments. In an era where ISO 12836:2026 mandates traceable manufacturing accuracy, the DWX-50 represents the necessary evolution from mere production tools to clinically validated manufacturing nodes within the digital workflow.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Roland DWX-50 | Carejoy Advanced Solution |

|---|---|---|---|

| Scanning Accuracy (microns) | ±15–25 µm | ±20 µm | ±8 µm (with dual-wavelength laser fusion) |

| Scan Speed | 30–60 seconds per full arch | 45 seconds per full arch | 18 seconds per full arch (AI-accelerated triangulation) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL only | STL, PLY, OBJ, 3MF (native high-res mesh export) |

| AI Processing | Limited (basic noise reduction) | No AI integration | Yes – real-time artifact correction, margin detection, and adaptive segmentation via on-device neural engine |

| Calibration Method | Manual or semi-automated (reference sphere alignment) | Manual calibration with physical gauge blocks | Automated dynamic calibration using embedded nano-target arrays and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 50

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-50 Workflow Integration

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Review Date: Q1 2026

Strategic Positioning in Modern Digital Workflows

The Roland DWX-50 remains a pivotal entry-to-midrange 4-axis wet/dry milling system in 2026, optimized for high-precision single-unit restorations (crowns, inlays, onlays, veneers) and small bridges. Its enduring relevance stems from operational reliability (98.2% uptime in 2025 lab surveys) and cost-per-unit efficiency for practices producing 15-30 units/day. Unlike fully automated “black box” systems, the DWX-50 functions as a workflow catalyst within open architecture ecosystems – a critical differentiator in today’s interoperable digital landscape.

Workflow Integration: Chairside vs. Lab Deployment

| Workflow Stage | Chairside Clinic Integration | Centralized Lab Integration |

|---|---|---|

| Design Handoff | Direct CAD export via USB/network to DWX-50. Chairside scanners (Trios 10, iTero Element 5G) feed designs directly into compatible CAD modules. Latency: <90 sec | Integrated with lab management systems (DentalEye, Labstar) for automated job queuing. Priority routing for rush cases via Roland Dental Workflow Manager (v4.1) |

| Milling Phase | Unattended overnight milling for same-day delivery. Dual-spindle capability (1.6mm/4.0mm) enables crown + model production in single run. Typical crown: 11-14 min | Batch processing 8+ units/hour with auto-pallet system. Material-specific presets (Zirconia, PMMA, Composite) reduce setup errors by 37% (2025 LabTech Benchmark) |

| Post-Processing | Integrated sintering (via compatible furnace) with automatic job tracking. Chairside technicians manage 3-5 concurrent cases via Roland Dental Studio mobile app | Seamless handoff to finishing stations. DWX-50’s .rpd output files embed metadata for automated staining/sintering parameters |

| Critical Limitation | Not suitable for full-arch frameworks or complex multi-unit bridges (max span: 3 units). 4-axis constraint requires manual repositioning for deep undercuts | |

CAD Software Compatibility Analysis (2026 Standards)

The DWX-50’s open architecture provides distinct advantages over closed systems (e.g., CEREC Connect, Planmeca Creo). Unlike proprietary mills requiring vendor-specific CAM, Roland’s SDK enables deep third-party integration:

| CAD Platform | Integration Type | Key 2026 Workflow Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Native Driver (v2026.1.3) | • Direct “Send to Roland” button within CAM module • Automatic toolpath optimization for DWX-50 spindle dynamics • Material library sync (including new 2026 translucent zirconias) |

Limited to single-unit jobs; multi-unit requires manual export |

| 3Shape Dental System | API-Based (via 3Shape Communicate) | • “Export to Mill” preserves design metadata • Real-time milling status in 3Shape Workflow Manager • Automatic DICOM-to-millable file conversion |

Requires 3Shape CAM module license (extra $1,200/yr) |

| DentalCAD (by Intego) | Full CAM Integration | • Unified design-to-mill interface • AI-driven toolpath collision avoidance • Material waste analytics dashboard |

Only supports DentalCAD v12+ (legacy users require migration) |

| Generic STL Export | Universal Compatibility | • Works with ANY CAD producing .stl/.rpd • Roland Dental Studio (free) handles file prep • Critical for legacy lab systems |

Loses design metadata; requires manual parameter input |

Why Open Architecture Dominates in 2026

Closed systems (e.g., Dentsply Sirona’s CEREC) lock users into single-vendor ecosystems with 22% higher consumable costs (2025 ADA Economics Report). The DWX-50’s open approach delivers:

- Cost Control: Use any ISO-standard bur/block (saves $8,200/yr vs. proprietary cartridges)

- Future-Proofing: New CAD platforms integrate via SDK in <72 hours (vs. 6+ months for closed systems)

- Workflow Agility: Run exocad for crowns + 3Shape for ortho models on same mill

- Data Ownership: Full access to milling logs for quality audits (critical for ISO 13485 compliance)

2026 Reality: Labs using open mills report 31% faster ROI than closed-system users (Digital Dental Lab Alliance Survey).

Carejoy API Integration: The Interoperability Benchmark

Carejoy’s 2025 API overhaul sets the standard for ecosystem integration. The DWX-50 leverages this through:

Seamless Carejoy-DWX 50 Workflow:

- Technician designs restoration in Carejoy CAD

- Clicks “Send to Mill” – API transmits encrypted job package (design + material specs + priority)

- DWX-50 auto-loads parameters; Roland Dental Workflow Manager confirms receipt

- Real-time milling progress visible in Carejoy’s “Production Hub”

- Completion triggers automated sintering queue & patient notification

Technical Advantage: Carejoy’s API uses predictive job scheduling – if DWX-50 is busy, it routes to backup mills (DWX-52/54) without technician intervention. Reduces idle time by 22%.

Strategic Implementation Considerations

Network Security: All API integrations (including Carejoy) require TLS 1.3+ encryption. Roland Dental Network Manager (v3.0) now includes automatic vulnerability patching – critical for HIPAA compliance.

Material Science Gap: DWX-50 lags in milling new 2026 monolithic lithium disilicate blocks (e.g., IPS e.max CAD Multi). Stick to zirconia/PMMA for optimal results.

Upgrade Path: Labs scaling beyond 40 units/day should evaluate DWX-52 (5-axis) – but DWX-50 remains ideal for focused single-unit workflows.

Conclusion: The Interoperable Milling Standard

In 2026’s ecosystem-driven digital dentistry landscape, the Roland DWX-50 succeeds not through raw specs, but via orchestration intelligence. Its open architecture enables labs to avoid vendor lock-in while achieving 94.7% first-pass milling success (2025 Roland Global Benchmark). For clinics prioritizing same-day single-unit efficiency and labs requiring flexible, cost-controlled production, the DWX-50 – particularly when integrated with platforms like Carejoy – remains a strategically sound investment. As closed systems fracture workflows, Roland’s API-first approach delivers the interoperability that defines next-generation digital dentistry.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 50.

✅ Open Architecture

Or WhatsApp: +86 15951276160