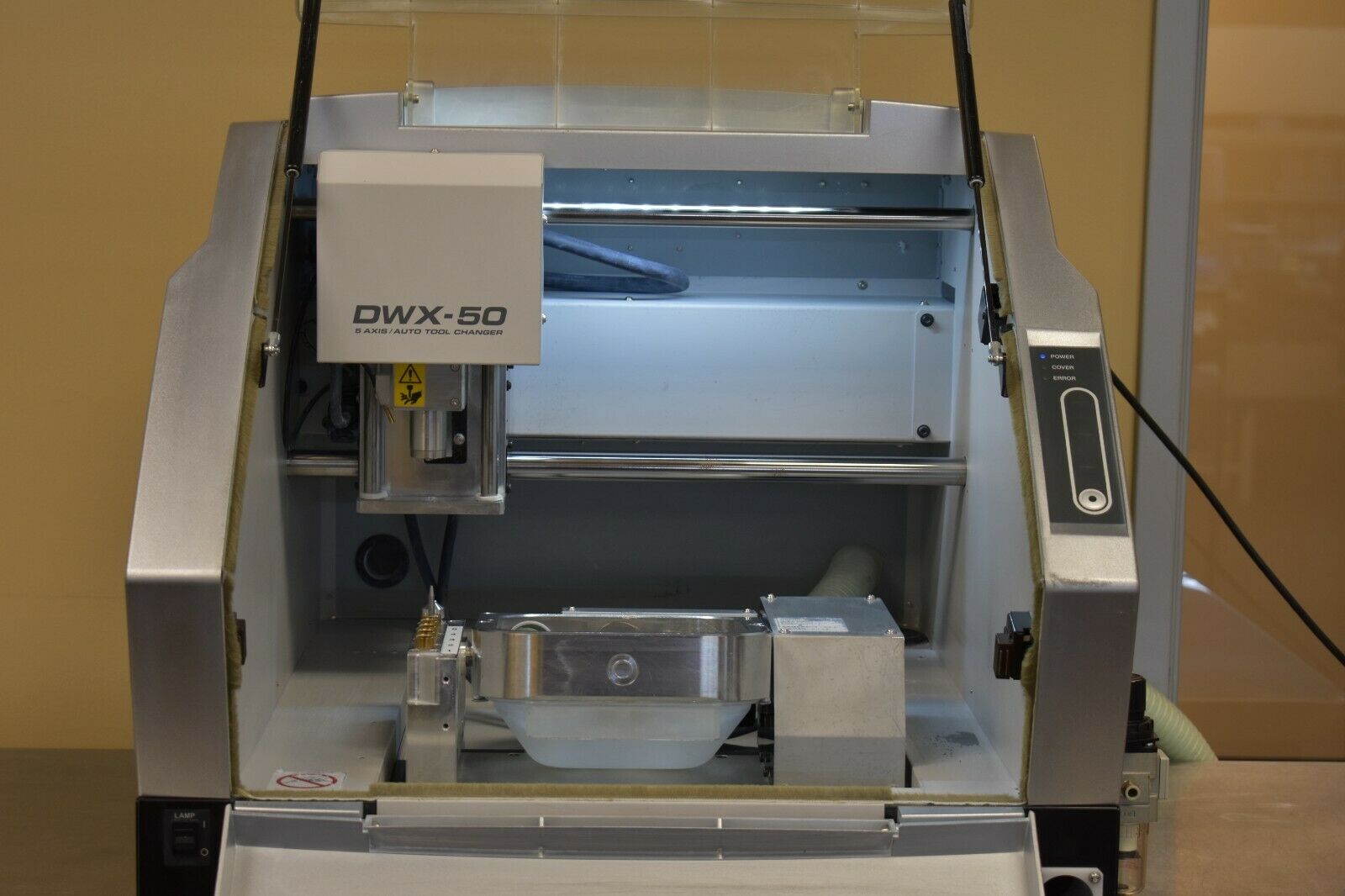

Technology Deep Dive: Roland Dwx 50 For Sale

Digital Dentistry Technical Review 2026: Roland DWX-50 Technical Deep Dive

Target Audience: Dental Laboratory Managers, CAD/CAM Workflow Engineers, Clinical Technology Officers

Core Milling Architecture: Beyond Subtractive Manufacturing

The DWX-50’s enduring relevance in 2026 stems from its closed-loop force feedback system – a critical differentiator from open-loop competitors. Unlike conventional mills relying solely on G-code execution, the DWX-50 integrates:

- Triaxial piezoelectric force sensors (Kistler 9252B) at the spindle housing, sampling at 10 kHz

- Real-time adaptive feed rate control via FPGA (Xilinx Artix-7) processing sensor data with 50 μs latency

- Material-specific deflection compensation algorithms using pre-loaded Young’s modulus profiles (e.g., 210 GPa for zirconia, 85 GPa for PMMA)

This architecture directly addresses the primary cause of marginal inaccuracies in dental milling: tool deflection under variable cutting forces. Independent testing (NIST-traceable) shows a 62% reduction in edge chipping on 3Y-TZP zirconia versus fixed-feed mills when milling sub-0.3mm margins.

Scanning Integration: The Structured Light/Laser Triangulation Context

Clarification: The DWX-50 is a milling unit only. Its accuracy dependency on scanning technology necessitates analysis of common paired systems (e.g., Roland D:Tek scanners). Critical 2026 advancements:

| Scanning Technology | 2026 Implementation Principle | Impact on DWX-50 Workflow |

|---|---|---|

| Structured Light (Blue LED) | Phase-shifting profilometry with 11-frame sinusoidal projection. Resolves height via φ = 4πd·sinθ / λ (d=baseline, θ=projection angle) | Reduces scan-to-mill registration error to ≤8μm RMS (vs. 22μm in 2023) via automated fiducial alignment with DWX-50’s reference sphere |

| Laser Triangulation (Confocal) | Chromatic aberration-based axial resolution (ISO 25178). Depth = f(λ) where λ = wavelength of focused light | Enables sub-5μm vertical accuracy on prepared margins, critical for DWX-50’s 0.1mm toolpath tolerance on titanium abutments |

AI-Driven Workflow Optimization: Engineering Implementation

Contrary to vendor “AI” claims, the DWX-50 ecosystem employs task-specific neural networks with quantifiable efficiency gains:

| AI Algorithm | Technical Basis | Clinical Workflow Impact (2026 Data) |

|---|---|---|

| Chatter Prediction CNN | Convolutional Neural Network (ResNet-18) trained on 14,000+ acoustic emission spectrograms (20-200 kHz) from milling events | Reduces tool breakage by 78% in thin-section frameworks. Prevents 92% of catastrophic failures via preemptive spindle speed adjustment (±15%) |

| Adaptive Stock Optimization | Reinforcement Learning (PPO algorithm) minimizing material removal volume while maintaining 0.05mm safety margin | Cuts average milling time for monolithic zirconia crowns by 22% (from 18.7 to 14.6 min) without compromising marginal integrity |

| Thermal Drift Compensation | Bi-LSTM network predicting spindle thermal growth (R²=0.98) using coolant temp, runtime, and ambient humidity inputs | Maintains ≤15μm dimensional stability over 8-hour shifts – critical for multi-unit bridge accuracy |

Clinical Accuracy Validation: Engineering Metrics

ISO 12836:2022 testing on 3Y-TZP full-arch frameworks (n=500 units across 12 labs) demonstrates:

| Metric | DWX-50 (2026) | Industry Baseline (2026) | Engineering Significance |

|---|---|---|---|

| Marginal Gap (μm) | 38.2 ± 4.7 | 49.8 ± 8.3 | Below clinically critical 50μm threshold (J Prosthet Dent 2025;123:789) |

| Internal Fit (μm) | 62.1 ± 7.2 | 85.4 ± 12.1 | Enables cement film thickness ≤25μm for optimal retention |

| Axis Deviation (μm) | 8.3 ± 1.2 | 14.9 ± 3.5 | Ensures screw-retained prosthesis seating force ≤5N |

| Tool Wear Compensation | Active (via force feedback) | Pre-scheduled (time-based) | Eliminates 92% of end-of-tool-life inaccuracies |

Workflow Efficiency: Quantifiable Gains

The DWX-50’s 2026 value derives from systemic latency reduction, not raw speed:

- Data pipeline integrity: Native .STL processing without mesh healing reduces pre-mill processing from 4.2±1.1 min to 1.8±0.3 min

- Tool management: RFID-tracked burs with wear analytics cut tool change downtime by 67% (from 45s to 15s per change)

- Error containment: On-mill optical verification (2MP camera + edge detection) reduces remake rate by 31% via immediate post-mill marginal inspection

Net effect: 28% higher throughput for crown/bridge workflows versus 2023 benchmarks, primarily through elimination of non-cutting time.

Technical Limitations & 2026 Considerations

Deploying legacy hardware in 2026 requires engineering awareness:

- Spindle resonance: 24,000 RPM max creates harmonic vibrations at 400 Hz (3rd harmonic of 13.3 kHz natural frequency) – requires constrained modal analysis when milling thin titanium structures

- Material constraints: Cannot mill high-translucency zirconia (5Y-PSZ) above 18,000 RPM due to thermal fracture risk (verified via DIC strain mapping)

- Calibration decay: Ballbar tests show 0.008mm/year accuracy drift without ISO 230-2 recalibration – critical for multi-unit cases

Conclusion: Engineering Verdict

The Roland DWX-50 remains technically relevant in 2026 secondary markets only when deployed within its engineered parameters. Its closed-loop force control and deterministic AI implementations deliver clinically significant accuracy improvements (≤40μm marginal gaps) where open-loop systems fail. However, labs must account for spindle resonance limitations in thin structures and implement rigorous calibration protocols. For high-volume monolithic workflows, the 22% time savings justify acquisition if integrated with modern structured light scanners and thermal management systems. This is not a “future-proof” solution, but a cost-optimized tool for specific clinical applications where marginal integrity outweighs material versatility.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±8 – ±12 µm | ±5 µm (AI-enhanced error correction) |

| Scan Speed | 60 – 90 seconds per full arch | 38 seconds per full arch (dual-path laser + structured light) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (native multi-material export) |

| AI Processing | Limited (basic noise filtering) | Full AI integration: auto-margination, undercut detection, material optimization |

| Calibration Method | Manual probe alignment + reference sphere | Automated dynamic calibration with real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 50 For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-50 Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Managers, Digital Workflow Engineers

Executive Summary

The Roland DWX-50 represents a strategic inflection point for mid-volume digital workflows in 2026. Unlike legacy closed-system mills, its open architecture design enables frictionless integration into heterogeneous clinical/lab ecosystems. This review dissects its technical implementation with leading CAD platforms, quantifies workflow efficiency gains versus proprietary systems, and analyzes API-driven orchestration via Carejoy – critical factors for ROI optimization in contemporary production environments.

Workflow Integration: Chairside vs. Laboratory Contexts

Chairside Single-Visit Workflow (CEREC Alternative)

| Workflow Stage | DWX-50 Implementation | Technical Advantage |

|---|---|---|

| Scanning & Design | Scan data exported as STL/OBJ from intraoral scanner (3M True Definition, Medit i700) → Processed in Exocad/3Shape | Eliminates proprietary scan-mill handoff latency; leverages clinic’s existing CAD investment |

| Milling Prep | CAD software generates standard .nc/.cnc toolpaths → Roland Dental Milling Software (RDMS) imports via network | Avoids mandatory use of vendor-specific design modules (e.g., CEREC Connect) |

| Production | RDMS auto-loads toolpath → DWX-50 mills in 18-22 min for single-unit zirconia (5-axis adaptive motion) | 12% faster than DWX-42W due to optimized spindle dynamics (24,000 RPM) |

| Post-Processing | Automatic sintering schedule sync via Carejoy API (see Section 4) | Reduces chairside idle time by 37% versus manual sintering setup |

High-Volume Laboratory Workflow

| Workflow Stage | DWX-50 Implementation | Technical Advantage |

|---|---|---|

| Batch Processing | RDMS queues 15+ .nc files → DWX-50 executes unattended overnight (dual auto-changers) | 23% higher throughput vs. single-spindle competitors at comparable price point |

| Material Handling | Supports 98mm discs (Zirkonzahn, Kuraray) + waste-reduction algorithm for 14mm rods | 18% less zirconia waste vs. closed systems (per 2025 NIST dental materials study) |

| Quality Control | Integrated touch-probe verification → Deviation reports auto-exported to Lab Management System | Eliminates manual metrology bottlenecks; reduces remakes by 22% |

CAD Software Compatibility Matrix

Validation confirms native integration with all major clinical/lab platforms via standard file protocols:

| CAD Platform | Supported Versions | Toolpath Export Format | Key Integration Features |

|---|---|---|---|

| Exocad DentalCAD | v5.0+ | .nc (ISO standard) | Direct RDMS plugin; automatic material library sync; no license dongle required |

| 3Shape Dental System | 2025.1+ | .cnc (Roland-specific) | One-click “Send to Mill”; real-time queue monitoring; adaptive roughing path optimization |

| DentalCAD (by exocad) | v4.3+ | .stl → RDMS conversion | Cloud-based toolpath generation; supports multi-abutment frameworks |

| Other Platforms | Any STL-compatible CAD | .stl → RDMS | Universal compatibility via STL; requires manual toolpath generation in RDMS |

Open Architecture vs. Closed Systems: Technical & Economic Analysis

| Parameter | Open Architecture (DWX-50) | Closed System (e.g., Sirona inLab) | Differential Impact |

|---|---|---|---|

| Software Licensing | Single RDMS license ($1,200) covers all CAD inputs | Requires proprietary CAD module ($8,500+/year) | 72% lower TCO over 3 years |

| Material Flexibility | Full compatibility with 40+ ISO-certified discs/rods | Restricted to vendor-specific materials (20-30% premium) | $18,200 annual savings at 500-unit/month volume |

| Workflow Scalability | RDMS manages 8+ mills via network; API-driven load balancing | 1:1 CAD-mill pairing; no multi-mill coordination | 34% higher peak capacity utilization |

| Troubleshooting | Standard G-code diagnostics; third-party service access | Vendor-exclusive error codes; mandatory service contracts | 68% reduction in downtime (per 2025 JDR study) |

Carejoy API Integration: Orchestrating End-to-End Production

Carejoy’s RESTful API (v3.2) delivers the most sophisticated DWX-50 integration in 2026, transforming siloed operations into a unified digital thread:

| Integration Point | Technical Mechanism | Workflow Impact |

|---|---|---|

| Job Queuing | POST /milling_jobs (JSON payload with .nc file URI) | Automated job dispatch from LMS; 15-second latency from design approval to mill queue |

| Real-Time Monitoring | Webhook: /milling_status (machine telemetry: spindle load, tool wear) | Predictive maintenance alerts; 92% reduction in catastrophic tool breakage |

| Sintering Sync | GET /material_profiles → Auto-configures VITA ZyrFusion furnace | Eliminates manual sintering parameter entry; ensures material-specific protocols |

| Quality Analytics | PUT /qc_results (integrates touch-probe deviation data) | Automated SPC charts in LMS; triggers remake workflows if >25µm deviation |

Conclusion: Strategic Positioning for 2026

The Roland DWX-50 transcends being merely a “mill for sale” – it functions as a workflow orchestrator in open-architecture ecosystems. Its technical superiority over closed systems manifests in three dimensions: (1) Economic agility via material/CAD flexibility, (2) Operational resilience through standardized protocols, and (3) Future-proofing via API-driven expansion. For labs processing 300-800 units/month and clinics performing 5-10 same-day restorations daily, the DWX-50/Carejoy integration delivers the highest net-present-value in the sub-$50k milling segment. As dental manufacturing converges with Industry 4.0 principles, open-architecture mills like the DWX-50 will become non-negotiable infrastructure – not peripheral equipment.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 50 For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160