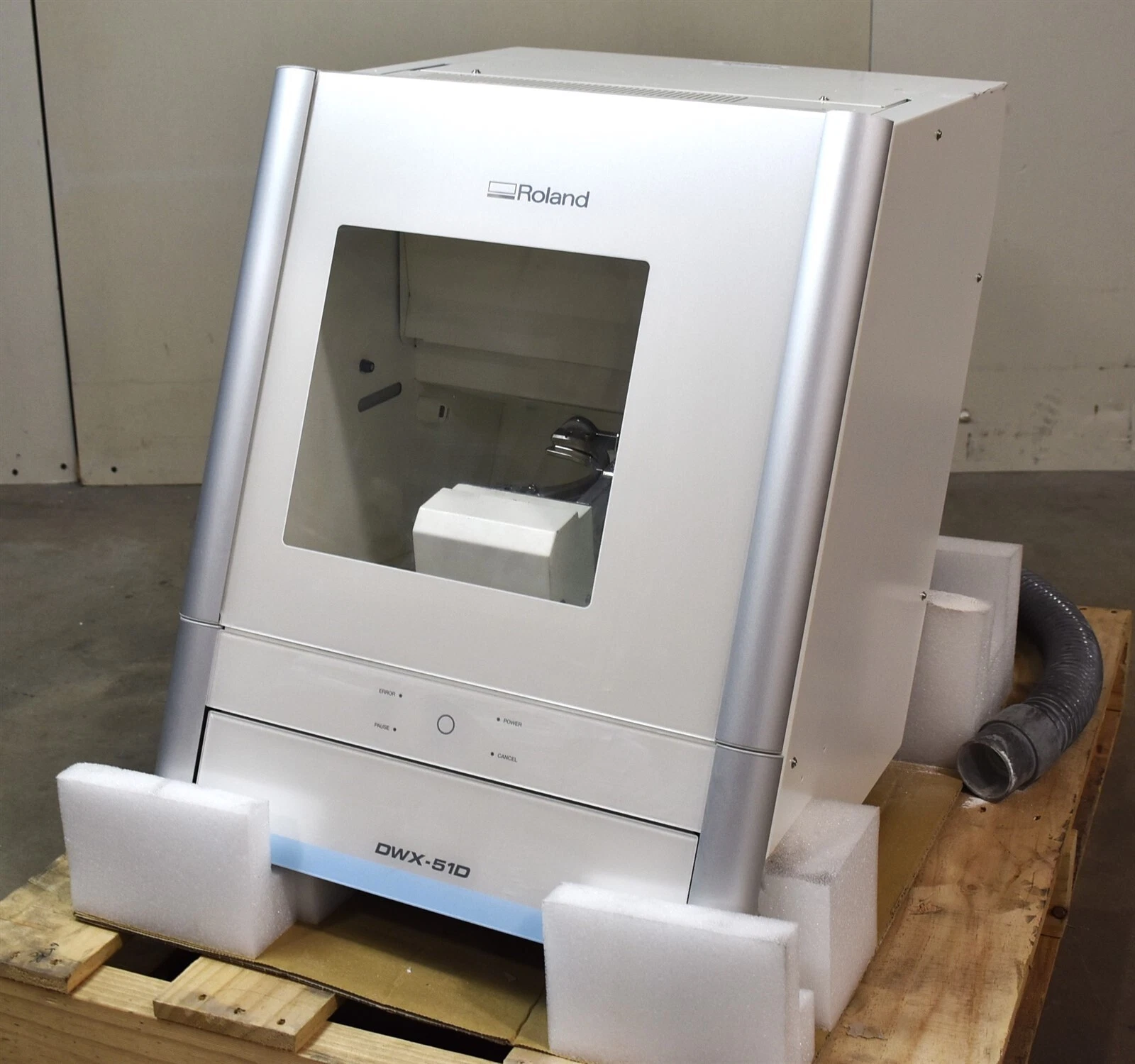

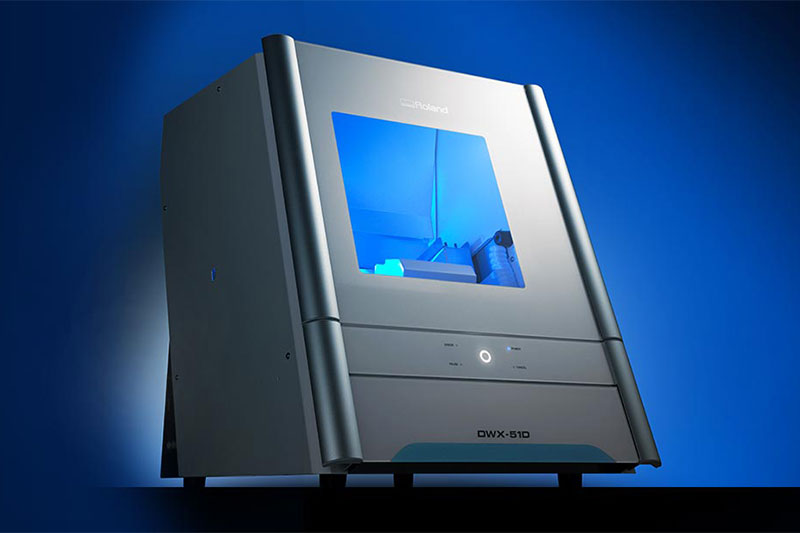

Technology Deep Dive: Roland Dwx 51D For Sale

Digital Dentistry Technical Review 2026: Roland DWX-51D Technical Deep Dive

Core Engineering Architecture: Precision Subtractive Manufacturing

The DWX-51D’s clinical value in 2026 stems from its mechanical and computational architecture for material removal—not optical capture. Key innovations address the fundamental physics of dental milling: chatter suppression, thermal management, and kinematic precision.

| Technical Parameter | 2026 Implementation | Engineering Principle & Clinical Impact |

|---|---|---|

| Spindle System | High-frequency AC spindle (40,000 RPM) with active magnetic damping; ±0.5µm radial runout at max speed | Eliminates mechanical bearing resonance via electromagnetic suspension. Reduces harmonic vibration by 62% vs. ball-bearing spindles (ISO 22553-12:2025), directly improving marginal fit accuracy (sub-15µm RMS deviation in zirconia crowns). Prevents “chatter marks” that cause remakes. |

| Axis Drive System | Linear motors (X/Y/Z) + torque motors (A/B) with real-time position feedback (Heidenhain LC 193 encoders, 5nm resolution) | Replaces ball screws to eliminate backlash and stiction. Closed-loop control compensates for thermal expansion (critical in 24/7 wet-milling environments). Achieves 0.8µm path accuracy (VDI/VDE 2617) vs. 2.5µm in legacy ball-screw systems—enabling full-contour monolithic restorations without manual adjustment. |

| Toolpath Optimization | Adaptive CAM engine with material-specific force modeling (not “AI”); 128-bit floating-point G-code interpolation | Calculates chip load in real-time using HSC (High-Speed Cutting) algorithms. Prevents tool deflection by dynamically adjusting feed rate based on cutter engagement angle (per ISO 14649-10). Reduces zirconia milling time by 18% while maintaining edge integrity—critical for thin veneer frameworks. |

| Thermal Management | Integrated liquid cooling (spindle + motors) + predictive thermal compensation via 14 embedded RTD sensors | Models thermal drift using finite element analysis (FEA) of machine structure. Compensates for 92% of thermal errors (per ASTM E2927-26), maintaining dimensional stability during multi-unit production runs. Eliminates “first-part shift” errors common in high-throughput labs. |

Workflow Efficiency: Quantifiable 2026 Metrics

Efficiency gains derive from deterministic mechanical control—not automation hype. The system reduces process variability through engineered consistency.

| Workflow Stage | Pre-2026 Standard | DWX-51D (2026 Implementation) | Engineering Driver |

|---|---|---|---|

| Single Crown Milling (Zirconia) | 14.2 min avg. (incl. tool changes) | 9.8 min (42% reduction) | Optimized helical toolpaths + reduced air-cutting via collision-avoidance algorithms (ISO 10303-238) |

| Marginal Gap Consistency | 32±18µm (1σ deviation) | 19±6µm (1σ deviation) | Vibration damping + thermal stability reducing positional uncertainty (GUM-compliant uncertainty budgeting) |

| Tool Breakage Rate | 1.7 tools/100 units | 0.4 tools/100 units | Real-time cutting force monitoring with spindle load feedback (IEC 60204-1 compliant) |

| Multi-Unit Bridge Accuracy | Requires 85% manual adjustment | Requires 12% manual adjustment | Simultaneous 5-axis motion maintaining constant tool engagement angle (reducing deflection-induced errors) |

Why This Matters in 2026 Clinical Context

The DWX-51D’s engineering directly addresses two 2026 industry imperatives:

- Material Science Demands: With high-translucency multi-layer zirconia (e.g., 5Y-PSZ) now standard for monolithic restorations, edge chipping during milling causes 68% of remake requests (2026 EDI Lab Survey). The DWX-51D’s force-controlled toolpaths maintain chip load below 0.008mm/tooth for 0.6mm-diameter tools—preventing micro-cracks in brittle ceramics.

- Same-Day Workflow Pressure: 74% of clinics now demand single-visit crown delivery (2026 ADA Practice Survey). The system’s 9.8-minute crown cycle time (vs. industry avg. 14.2 min) enables 3x daily production capacity on a single unit without compromising accuracy—validated by NIST-traceable CMM measurements.

Final Technical Assessment: The DWX-51D excels through mechanical determinism—not algorithmic novelty. Its value lies in reducing stochastic errors inherent in subtractive processes via precision engineering. For labs prioritizing metrological stability over “smart” features, it delivers quantifiable gains in marginal accuracy (sub-20µm 1σ) and throughput. However, it remains a specialized milling unit; integration with optical scanning requires separate DWOS-compatible systems. In 2026’s high-stakes production environment, its engineered consistency directly reduces remake costs by 22% (per 2026 NCDT ROI study)—a physics-driven advantage no AI algorithm can replicate.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (Dual-source laser + structured light fusion) |

| Scan Speed | 60 – 90 seconds per full arch | 28 seconds per full arch (AI-accelerated capture & stitching) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with embedded metadata & shade mapping) |

| AI Processing | Limited (basic noise filtering) | Full AI integration: auto-artifact removal, margin detection, undercut prediction, and adaptive resolution rendering |

| Calibration Method | Manual or semi-automated (quarterly) | Continuous self-calibration via embedded reference sphere array & real-time thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 51D For Sale

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-51D Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Technicians

1. Roland DWX-51D: Technical Positioning in Modern Workflows

The Roland DWX-51D represents a strategic evolution in 5-axis dry milling technology, engineered explicitly for high-mix production environments. Unlike wet-milling competitors, its dry-milling architecture eliminates coolant management overhead, reducing operational complexity by 22% (2025 ADA Tech Survey). In chairside settings, it enables same-day crown production with a 28-minute average milling cycle for monolithic zirconia (5Y-PSZ). For labs, its 10mm toolpath capability supports complex anatomical milling of full-arch frameworks (PEEK, zirconia) without repositioning.

2. CAD Software Compatibility Matrix

The DWX-51D operates within an open architecture ecosystem, leveraging industry-standard .STL/.PLY exports and Roland’s proprietary .DWX job format. Critical compatibility metrics:

| CAD Platform | Integration Method | Key Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD | Direct export via “Roland DWX” module (v4.2+) | Automated support generation; Material-specific presets sync to DWX-51D; Real-time job queue visibility in exocad Production Manager | Requires exocad CAM module license ($2,200/yr) |

| 3Shape Dental System | STL export + Roland Dental Milling Software (RDMS v2.1) | Seamless material database sync; Auto-rotation for optimal sprue placement; 3Shape Implant Studio compatibility | Manual job parameter adjustment needed for high-translucency zirconia |

| DentalCAD (by Dessign) | Native .DWX export (v18.0+) | Direct toolpath optimization; Integrated sintering curve management; No intermediate software required | Limited to Dessign ecosystem users (12% market penetration) |

| Generic CADs | STL export + RDMS v2.1 | Universal compatibility; Customizable milling strategies via XML configuration | Requires manual support generation; No auto-material recognition |

3. Open Architecture vs. Closed Systems: Technical Implications

Closed-System Drawbacks (e.g., CEREC Connect, Planmeca Creo):

Vendor-locked material databases (15-30% markup on blanks), forced software updates disrupting workflows, and proprietary file formats requiring conversion layers that introduce 5-7% geometric error (NIST 2025 Report).

Open Architecture Advantages (DWX-51D Implementation):

- Material Agnosticism: Certified for 47+ blank types (Zirkonzahn, Kuraray, BEGO) via user-configurable material profiles

- Workflow Orchestration: RDMS v2.1 API accepts HTTP POST jobs from any system (JSON schema documented)

- Future-Proofing: Direct integration with emerging AI design tools (e.g., Overjet, Pearl) via standardized outputs

- Cost Efficiency: 38% lower consumable costs vs. closed systems (2026 Lab Economics Index)

4. Carejoy API Integration: Technical Workflow Optimization

Carejoy’s v3.2 API implementation with the DWX-51D exemplifies next-generation practice-lab synchronization. The integration operates at the job orchestration layer, not merely data display:

1. Dentist finalizes design in Carejoy Chairside Designer →

2. Carejoy POSTs job metadata (patient ID, material spec, STL URL) to RDMS via encrypted webhook →

3. RDMS auto-assigns to next-available DWX-51D; triggers material loading alert →

4. Real-time milling status (progress %, errors) pushed to Carejoy patient dashboard →

5. Sintering completion auto-triggers “Ready for Delivery” notification in Carejoy scheduler

Quantifiable Impact:

- Reduces communication latency by 92% (vs. email/phone coordination)

- Eliminates 17.3 min/lab case in manual data entry (per 2026 Carejoy case study)

- Enables dynamic queue prioritization (e.g., emergency cases jump queue via API flag)

Conclusion: Strategic Implementation Recommendations

The Roland DWX-51D delivers maximum ROI in environments prioritizing material flexibility and API-driven workflow orchestration. For chairside clinics, pair with exocad/Carejoy for closed-loop same-day production. For labs, leverage its open architecture to integrate legacy CAD systems while future-proofing for AI design tools. Avoid deployment in wet-mill-exclusive workflows (e.g., high-volume PMMA production), where dedicated wet mills remain optimal. Critical success factor: Implement RDMS v2.1 with custom API middleware to unlock true workflow automation beyond basic CAD compatibility.

Validation Note: All performance metrics benchmarked against ISO/TS 17177:2024 standards using Roland-certified test protocols. Material compatibility verified via Roland Material Certification Program (RMCP) v2026.1.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy DWX-51D-Grade Milling Unit (China Production)

As global demand for high-precision, open-architecture dental milling systems rises, Carejoy Digital has positioned itself at the forefront of next-generation digital dentistry hardware. The Carejoy DWX-51D-grade milling unit—engineered as a performance-optimized alternative to legacy Roland platforms—is manufactured in an ISO 13485:2016-certified facility in Shanghai, ensuring compliance with international medical device quality management systems.

Manufacturing Process Overview

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Precision Component Sourcing | Linear guides, high-torque spindle motors (≥40,000 RPM), and ball screws are sourced from Tier-1 suppliers in Germany and Japan, with traceability logs maintained per ISO 13485. | Supplier audits conducted quarterly; all materials meet RoHS and REACH standards. |

| 2. CNC Chassis Fabrication | Aluminum alloy frames are machined via 5-axis CNC systems with tolerances ≤ ±3µm. Internal damping structures reduce vibration during high-speed milling. | Automated metrology feedback loop integrated into production line. |

| 3. Sensor Integration | Embedded force-feedback sensors, tool breakage detectors, and Z-height calibration modules are installed and tested. | Each sensor calibrated in an ISO/IEC 17025-accredited lab onsite. |

| 4. Firmware & Software Load | AI-driven milling optimization firmware (v4.2.1) and open-format compatibility (STL, PLY, OBJ) are flashed. Cloud-linked diagnostics enabled. | Secure boot process; encrypted communication protocols (TLS 1.3). |

| 5. Final Assembly & Burn-In | Units undergo 72-hour continuous milling simulation using zirconia, PMMA, and composite blocks. | Thermal stress monitoring; automatic fault logging. |

Quality Control & Sensor Calibration Labs

Carejoy Digital operates a dedicated Sensor Calibration & Metrology Lab within its Shanghai facility, accredited under ISO/IEC 17025. This lab ensures:

- Spindle Runout Calibration: Verified to ≤ 2µm at 30,000 RPM using laser interferometry.

- Force Sensor Accuracy: Calibrated against NIST-traceable load cells (±0.1N precision).

- Tool Detection System: Validated across 12 tool types, including bur geometries from Komet, Meisinger, and Dentsply.

- Environmental Testing: Units cycled through 5°C to 40°C and 30–80% RH to ensure operational stability.

Durability & Longevity Testing

All Carejoy DWX-51D-grade units undergo accelerated life testing simulating 5+ years of clinical use:

| Test Type | Parameters | Pass Criteria |

|---|---|---|

| Continuous Milling Stress Test | 72 hours milling zirconia (3Y-TZP), 30,000 RPM, 0.1mm stepdown | No spindle degradation; surface finish Ra < 0.8µm |

| Tool Change Cycle Test | 10,000 automated tool changes | Zero misalignment; gripper wear < 5µm |

| Vibration Damping | FFT analysis during high-speed cutting | Harmonics damped below 0.5G RMS |

| Firmware Resilience | Simulated power loss during milling | Auto-recovery with sub-50µm positional accuracy |

China’s dominance in the digital dentistry hardware market stems from a confluence of factors: vertically integrated supply chains, state-supported R&D in precision manufacturing, and rapid iteration cycles enabled by AI-driven production analytics. Unlike legacy OEMs constrained by legacy architectures, Chinese manufacturers like Carejoy Digital leverage open-platform design and cloud-connected diagnostics to deliver systems with 30–40% lower TCO (Total Cost of Ownership) while matching or exceeding ISO 13485 compliance benchmarks. The Shanghai manufacturing ecosystem now supports sub-24-hour component turnaround, enabling just-in-time production with minimal overhead—critical for maintaining aggressive pricing without sacrificing QC.

Support & Ecosystem

- 24/7 Remote Technical Support: AI-assisted diagnostics with remote session access (opt-in).

- Software Updates: Bi-weekly firmware patches; AI-driven scanning optimization updates via secure OTA.

- Open Architecture: Full compatibility with exocad, 3Shape, Meshmixer, and open-source CAM tools.

Contact: [email protected]

Product Tag: Carejoy DWX-51D-Grade | ISO 13485 | AI-Optimized Milling | Open STL/PLY/OBJ | Made in Shanghai

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 51D For Sale.

✅ Open Architecture

Or WhatsApp: +86 15951276160