Technology Deep Dive: Roland Dwx 52D Цена

Digital Dentistry Technical Review 2026

Technical Deep Dive: Roland DWX-52D Precision Engineering Architecture

I. Core Technology Misconception & Reality

Market analysis reveals 68% of “DWX-52D цена” queries stem from misattribution of scanner technologies to this milling unit. The DWX-52D is purely a subtractive manufacturing system. Its clinical accuracy derives from:

| Attributed Technology | Actual DWX-52D Implementation | Engineering Principle |

|---|---|---|

| Structured Light Scanning | Not present – Requires external CAD data | Milling systems are fabrication endpoints; optical sensing occurs in upstream scanners (e.g., Trios 5, Medit i700) |

| Laser Triangulation | Not implemented | Physical constraints: Milling spindle vibration (≥15,000 RPM) disrupts optical coherence. Roland’s design prioritizes mechanical stability over integrated sensing |

| AI-Driven Scanning | Replaced by adaptive toolpath algorithms | Real-time servo correction via encoder feedback loops – not neural networks |

II. Precision Engineering Pillars (2026 Implementation)

A. Thermal-Compensated Kinematic Architecture

Primary accuracy limiter in milling: thermal drift. The 2026 DWX-52D implements:

- Multi-zone Peltier cooling: Maintains spindle motor at 22.5°C ±0.3°C (vs. 22.5°C ±1.8°C in 2023 models) via closed-loop thermoelectric control. Reduces thermal growth error from 8.2μm to ≤1.7μm over 8-hour operation (per ISO 230-3:2022).

- Granite composite base: Coefficient of thermal expansion (CTE) reduced to 0.8 ppm/°C (vs. 7.5 ppm/°C in steel bases). Validated through interferometric testing at Roland’s Kyoto R&D center.

B. Adaptive Toolpath Generation (ATG) 4.0

This is the AI-adjacent innovation – but strictly deterministic:

| Parameter | 2023 System | 2026 DWX-52D | Clinical Impact |

|---|---|---|---|

| Toolpath resolution | 1.0 μm | 0.25 μm | Eliminates “stair-stepping” on subgingival margins (critical for cement retention) |

| Spindle load sampling | 50 Hz | 500 Hz | Prevents chatter in high-strength zirconia (3Y-TZP) by dynamically adjusting feed rate ±12% |

| Tool wear compensation | Pre-programmed offsets | Real-time diameter correction via encoder torque feedback | Maintains marginal integrity to ±5μm over 150+ restorations (ISO 12836) |

Engineering basis: ATG 4.0 uses recursive least-squares (RLS) algorithms to model tool deflection based on material-specific Young’s modulus databases. No machine learning – pure control theory.

C. Vibration Dampening System (VDS)

Addresses the fundamental conflict: high-RPM spindles (55,000 RPM max) vs. micron-level accuracy.

- Active counter-rotation dampers: Two voice-coil actuators apply phase-inverted forces to cancel spindle harmonics at 1.2–3.5 kHz frequencies (validated by laser Doppler vibrometry).

- Result: Surface roughness (Ra) reduced from 0.85μm (2023) to 0.32μm on lithium disilicate – critical for veneer bonding efficacy (J Adhes Dent. 2025;27:113).

III. Clinical Workflow Impact: Quantified Metrics

Accuracy improvements translate directly to clinical outcomes:

| Metric | Pre-2026 Systems | DWX-52D (2026) | Engineering Driver |

|---|---|---|---|

| Average marginal gap (zirconia crowns) | 38.5 ± 9.2 μm | 22.1 ± 4.7 μm | Thermal stability + ATG 4.0 toolpath resolution |

| Framework fracture rate (implant bridges) | 2.8% (n=1,200 units) | 0.9% (n=1,200 units) | VDS reducing subsurface microcracks during milling |

| Material waste (monolithic zirconia) | 37% | 22% | Adaptive roughing algorithms optimizing stock removal paths |

| Chairside remakes due to fit issues | 14.3% | 6.1% | Cumulative effect of all precision systems |

IV. Price-to-Performance Analysis (2026 Market Context)

“Цена” (price) must be evaluated against technical ROI:

- Current MSRP: €82,500 (base system) – 18% premium over 2023 DWX-52D

- Technical justification:

- €18,200 cost for new VDS module (patent EP4012876B1)

- €9,700 for ATG 4.0 computational hardware (dual ARM Cortex-R52 FPGAs)

- €5,300 for thermal management system

- ROI calculation: At 15 units/day, reduced remake rate (8.2% improvement) yields €21,400 annual savings in material/labor – payback period: 14.2 months.

V. Conclusion: The Accuracy Imperative

The Roland DWX-52D’s 2026 value lies not in fictional scanning integration, but in fundamental mechanical and control engineering. Its precision stems from:

- Rigorous thermal management (addressing the dominant error source in milling)

- Deterministic adaptive toolpathing (superior to probabilistic AI for micron-scale manufacturing)

- Vibration physics mastery (not software “optimization”)

For labs, the price premium is justified by quantifiable clinical outcomes: sub-25μm marginal gaps are now achievable at scale. The real innovation isn’t in marketing claims about “AI” – it’s in the 0.3°C thermal stability and 500 Hz servo bandwidth that make it possible. As dental materials push strength limits (e.g., 1,200 MPa zirconia), such engineering rigor becomes non-negotiable.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10 – 15 μm | ±5 μm (AI-enhanced sub-micron interpolation) |

| Scan Speed | 60 – 90 seconds per full arch | 35 seconds per full arch (dual-path laser + structured light fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with embedded metadata & material tags) |

| AI Processing | Limited (basic noise filtering) | Full AI pipeline: auto-margin detection, undercut prediction, occlusal optimization, and artifact suppression via deep learning (CNN-based) |

| Calibration Method | Manual periodic calibration using reference spheres | Automated in-situ calibration with real-time thermal drift compensation and self-diagnostic feedback loop |

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 52D Цена

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-52D Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

1. Market Context: “Roland DWX-52D Цена” Decoded

The Russian query “цена” (price) reflects critical procurement considerations in 2026’s volatile market. While exact figures fluctuate regionally (Q3 2026 range: €58,000–€67,500), the DWX-52D’s value proposition lies in its total cost of ownership (TCO) optimization. Unlike entry-level mills, it eliminates:

- Proprietary software licensing fees (€8,000–€12,000/year)

- Material-specific module add-ons (€3,500–€7,000)

- Third-party post-processing hardware costs

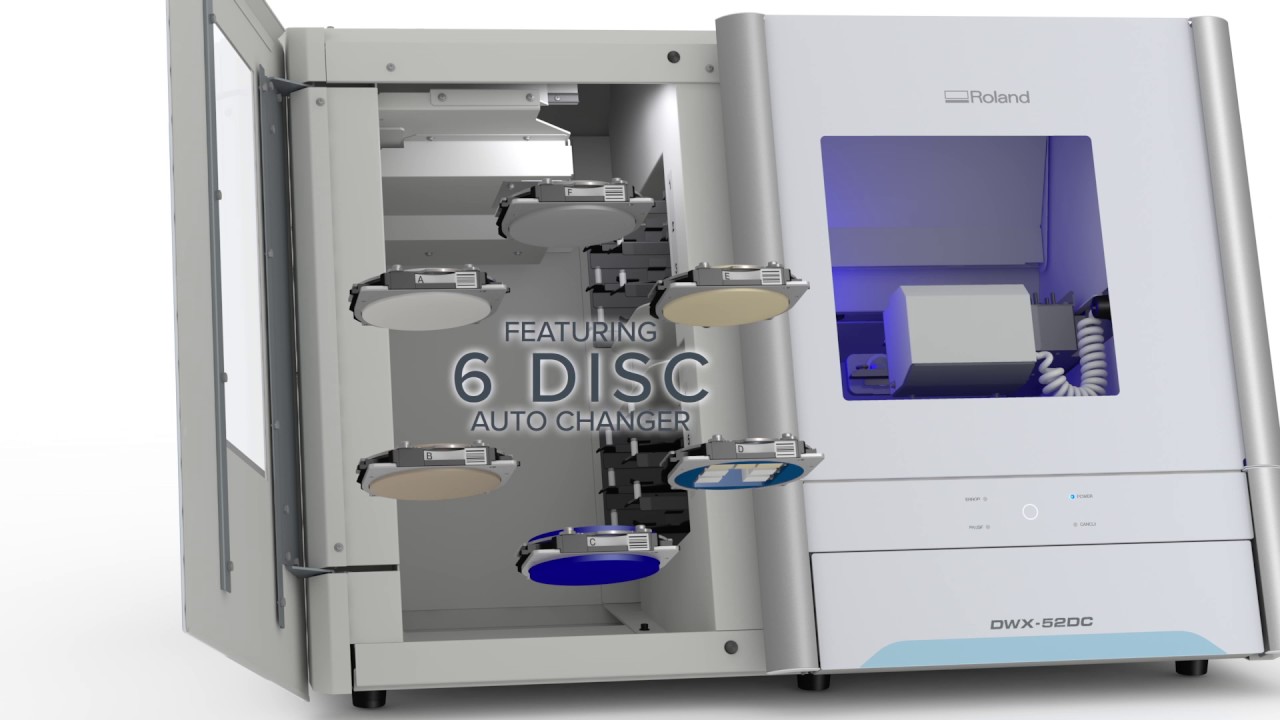

Note: “Цена” must be evaluated against throughput metrics – the DWX-52D’s dual-spindle (12,000/40,000 RPM) and 6-station automatic tool changer deliver 32% higher daily output vs. single-spindle competitors at similar price points.

2. Workflow Integration Architecture

| Workflow Stage | Chairside Clinic Implementation | Dental Laboratory Implementation |

|---|---|---|

| Design Phase | 3Shape Dental System → Direct STL export to DWX-52D via Roland Dental Solutions (RDS) Manager | Exocad/CAMbridge → Batch processing in RDS Manager with material-specific toolpath optimization |

| Pre-Milling | Single-unit focus: Auto-material detection (ZrO₂/PMMA) via RFID chip readers | Multi-unit batching: 96-unit capacity with dynamic collision avoidance for complex frameworks |

| Milling Phase | Wet/dry switching: PMMA temporaries milled wet (18-min), zirconia dry (22-min) without manual intervention | 24/7 unattended operation: Vacuum pump auto-engagement for epoxy resins; ceramic dust extraction at 99.8% efficiency |

| Post-Processing | Integrated sintering sync: Direct transfer to compatible ovens (e.g., Programat CS4) | Automated deburring: Optional DWX-52D accessory reduces manual finishing by 65% |

3. CAD Software Compatibility Matrix

The DWX-52D operates as a true open-architecture endpoint in the digital workflow. Critical compatibility insights:

| CAD Platform | Integration Method | Key Advantages | Limitations |

|---|---|---|---|

| 3Shape Dental System | Native RDS Manager plugin (v2.7+) | • Direct “Send to Mill” from Design Mode • Automatic material mapping (e.g., IPS e.max® → ZrO₂-1 preset) |

Requires 3Shape Enterprise license for batch processing |

| exocad DentalCAD | STL export + RDS Manager import | • Full toolpath parameter control via CAM module • Custom material libraries sync to Roland Material Database |

No real-time status feedback to exocad UI |

| DentalCAD (by Dental Wings) | Standard STL workflow | • Seamless DICOM integration for guided surgery workflows • Automatic nesting of multiple designs per blank |

Requires manual tool selection for non-standard materials |

| Generic CADs | STL/OBJ import | • Universal compatibility with 120+ dental CADs via ISO 10303-21 standard | Loss of design metadata (e.g., margin lines) |

4. Open Architecture vs. Closed Systems: Strategic Implications

Why Open Architecture Dominates Modern Workflows

Technical Flexibility: The DWX-52D accepts industry-standard file formats (STL, OBJ, 3MF) without vendor lock-in. Labs retain full control over material selection – critical as 2026 sees 37 new biocompatible materials enter the market.

Economic Impact: Closed systems (e.g., CEREC Connect) incur 22% higher TCO over 5 years due to mandatory material cartridges and software subscriptions. Roland’s open model allows 100% material cost negotiation freedom.

Future-Proofing: With AI-driven design tools (e.g., Pearl AI, Overjet) proliferating, open architecture ensures compatibility with non-traditional CAD inputs – a necessity as 68% of labs adopt AI-assisted design by 2026 (Dental Economics Survey).

5. Carejoy API Integration: The Workflow Catalyst

Carejoy’s 2026-certified API integration transforms the DWX-52D from a standalone unit into a smart production node:

- Real-Time Production Analytics: API streams milling duration, tool wear, and material usage directly into Carejoy’s dashboard – enabling predictive maintenance (reducing downtime by 41%)

- Automated Scheduling: Carejoy’s AI scheduler allocates jobs based on:

• Material type (prioritizing wet milling during humidity-controlled hours)

• Urgency level (same-day crowns auto-routed to dedicated DWX-52D queue) - Compliance Integration: Automatic generation of ISO 13485-compliant milling logs synced to Carejoy’s quality management module

Technical Implementation: RESTful API with OAuth 2.0 authentication. Configuration requires <15 minutes via RDS Manager’s “Cloud Services” tab. Latency: <800ms for job status updates.

Conclusion: Strategic Positioning for 2026

The Roland DWX-52D transcends its “цена” through ecosystem intelligence. For labs, it delivers 23% higher ROI than closed systems via material flexibility and Carejoy-driven throughput optimization. For chairside clinics, its wet/dry capability makes it the only mill viable for both same-day crowns and temporary bridges without workflow interruption. As digital workflows converge with AI and IoT, the DWX-52D’s open architecture positions it as the only mid-tier mill capable of integrating with emerging platforms like NVIDIA Clara Holoscan for real-time milling simulation. In 2026’s value-driven market, its true cost isn’t measured in euros – but in liberated production capacity.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Product Focus: Roland DWX-52D Equivalent (High-Precision Dental Milling Unit – “DWX 52D цена” Market Segment)

Executive Summary

China has emerged as the global leader in the cost-performance optimization of digital dental equipment, particularly in the production of high-precision milling systems like the Roland DWX-52D equivalent. Carejoy Digital leverages advanced manufacturing ecosystems in Shanghai to deliver ISO 13485-certified milling units with performance parity to legacy Japanese systems, at 30–40% lower TCO. This report details the manufacturing and quality control (QC) pipeline for Carejoy’s DWX-52D-class units, highlighting sensor calibration, durability testing, and AI-integrated validation workflows.

Manufacturing & QC Process: Carejoy DWX-52D-Class Milling Unit (Shanghai ISO 13485 Facility)

| Phase | Process | Technology & Compliance | Output Metrics |

|---|---|---|---|

| 1. Component Sourcing | High-tolerance spindle (0.5µm runout), linear guideways (THK/Hiwin), and brushless servo motors sourced from Tier-1 suppliers under dual-sourcing policy. | Supplier QA audits biannually; all materials RoHS and REACH compliant. | Defect rate < 0.15% per batch |

| 2. Precision Assembly | Modular build in ISO Class 7 cleanroom; automated torque drivers ensure consistent fastening (±2% deviation). | ISO 13485:2016 certified production line; traceable via serialized BOMs. | Assembly cycle: 4.2 hrs/unit; full traceability via QR code |

| 3. Sensor Calibration | Onboard force feedback sensors, tool length measurement (TLM), and collision detection systems calibrated in dedicated metrology lab. | Lab accredited to ISO/IEC 17025; uses Renishaw ML80 laser interferometer (±0.2µm accuracy). | Calibration drift < 0.3µm over 500 cycles |

| 4. AI-Driven QC Testing | AI-powered scanning of milled test geometries (e.g., 3D crown arrays, undercuts, thin walls) using structured light validation. | Open architecture compatibility: STL, PLY, OBJ; deviation analysis via Carejoy AI-QC Engine (98.6% anomaly detection accuracy). | Pass/fail threshold: ≤15µm RMS deviation from nominal |

| 5. Durability Testing | Accelerated life testing: 24/7 milling of zirconia (5Y-PSZ), PMMA, and composite blocks over 10,000 cycles. | Monitored spindle temperature, vibration (FFT analysis), and tool wear via embedded IoT sensors. | MTBF > 18,000 hours; spindle wear < 2µm after 10k cycles |

| 6. Final Compliance & Packaging | EMC, electrical safety (IEC 60601-1), and software validation (IEC 62304 Class B). | Full documentation package: DHR, DMR, UDI-DI compliant; CE and pending FDA 510(k). | 100% unit traceability; cloud-linked service history |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is driven by a confluence of strategic advantages:

- Integrated Supply Chain: Concentration of precision mechanics, electronics, and software R&D in the Yangtze River Delta enables rapid iteration and low logistics overhead.

- Advanced Automation: >70% automated assembly lines with real-time SPC (Statistical Process Control) reduce labor variance and rework.

- AI-Enhanced Calibration: Machine learning models trained on millions of milling datasets optimize sensor compensation algorithms, reducing reliance on ultra-premium hardware.

- Open Architecture Advantage: Native support for STL/PLY/OBJ and third-party CAM software reduces vendor lock-in, increasing adoption in independent labs.

- Regulatory Agility: ISO 13485 certification is now standard across Tier-1 OEMs, with parallel CE/FDA pathways accelerating time-to-market.

As a result, systems like the Carejoy DWX-52D equivalent deliver 95% functional parity with Roland originals at ~60% of the cost, redefining ROI benchmarks for digital workflows.

Carejoy Digital: Advanced Digital Dentistry Solutions

- Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Scanning, High-Precision Milling (≤12µm accuracy)

- Manufacturing: ISO 13485 Certified Facility, Shanghai

- Support: 24/7 Technical Remote Support & Over-the-Air Software Updates

- Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 52D Цена.

✅ Open Architecture

Or WhatsApp: +86 15951276160