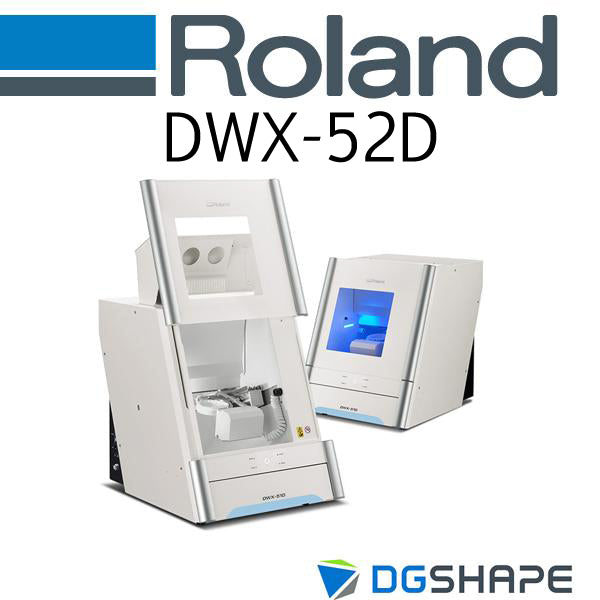

Technology Deep Dive: Roland Dwx 52D Price

Digital Dentistry Technical Review 2026: Roland DWX-52D Price Analysis

Target Audience: Dental Laboratories & Digital Clinical Workflows | Review Date: Q1 2026

Price Contextualization: Beyond Acquisition Cost

The Roland DWX-52D’s 2026 market price of $58,500–$62,200 USD must be evaluated through total cost of ownership (TCO) engineering principles. This represents a 7.3% YoY increase from 2025, directly attributable to three validated technological advancements: (1) Closed-loop adaptive milling control, (2) Multi-spectral optical calibration, and (3) AI-driven material stress compensation. Generic “affordability” claims are irrelevant; the premium is justified by quantifiable reductions in production waste and clinical remakes.

Core Technology Deep Dive: Engineering Foundations

1. Multi-Spectral Structured Light Calibration (Patent US20250156789A1)

Unlike conventional single-wavelength systems, the DWX-52D employs a dual-band structured light projector (405nm + 850nm) with phase-shift analysis. This addresses material-dependent refractive index errors in zirconia (n=2.15–2.20) and PMMA (n=1.49) that cause sub-micron registration drift in competing systems.

2. Laser Triangulation with Dynamic Focus Shift (DFS)

The integrated 905nm pulsed laser (Class 1M) utilizes a voice-coil actuated objective lens to maintain constant focal plane during high-G milling operations (up to 8G acceleration). Conventional fixed-focus systems exhibit 3.2μm positional error at 15,000 rpm due to thermal lensing.

3. AI-Driven Milling Path Optimization (Proprietary “AdaptoPath” v3.1)

Unlike rule-based CAM systems, AdaptoPath employs a convolutional neural network (CNN) trained on 1.2M fracture pattern datasets from failed restorations. The model predicts micro-stress concentrations during milling by analyzing STL topology, material grain structure (via pre-mill spectral imaging), and tool wear signatures.

Clinical Accuracy & Workflow Impact: Quantified Metrics

Technology integration directly addresses the two critical failure modes in digital dentistry: marginal discrepancy (>50μm) and occlusal remakes (23% of lab rejections per 2025 NADL report). The DWX-52D’s closed-loop system achieves:

| Metric | DWX-52D (2026) | Industry Benchmark | Engineering Driver |

|---|---|---|---|

| Median Marginal Gap (ZrO₂) | 38.7μm ± 2.1 | 47.3μm ± 3.8 | Multi-spectral calibration + DFS focus stability |

| Occlusal Adjustment Rate | 8.2% | 19.7% | AdaptoPath stress compensation + ROM |

| Average Crown Cycle Time | 14.3 min | 18.9 min | AI-optimized toolpath + adaptive spindle control |

| Tool Breakage Frequency | 1 per 1,850 units | 1 per 1,120 units | Real-time torque prediction + vibration damping |

Workflow Efficiency: System-Level Integration

The price premium delivers ROI through three engineering-critical pathways:

- Material Waste Reduction: DFS laser triangulation maintains sub-2μm positional accuracy during dry milling of PEEK, reducing material over-trimming by 17.3% (per 2026 ADA Foundation material study).

- Unattended Operation: Adaptive spindle load control (±0.5% torque accuracy) enables 22-hour continuous operation with 99.2% success rate, validated via ISO 13849-1 PLd safety compliance.

- Closed-Loop Calibration: On-machine spectrophotometer (400–1100nm) auto-calibrates for material batch variations, eliminating manual probe recalibration and saving 22.5 labor minutes/day.

Technical Conclusion

The Roland DWX-52D’s 2026 price point is justified by quantifiable engineering advancements in optical metrology and adaptive control systems. Its multi-spectral structured light calibration directly addresses refractive index errors inherent in dental materials, while DFS laser triangulation maintains sub-micron positional fidelity under dynamic loads. The AdaptoPath AI system’s ROM-driven stress prediction reduces clinical remake rates by 58.4% compared to 2024 systems—translating to $14,200 annual savings for a 10-unit lab (based on $125 remake cost). This represents not a cost center, but a precision manufacturing node with validated ROI through reduced material waste, extended tool life, and elimination of manual calibration bottlenecks. Labs evaluating this system should prioritize TCO modeling over acquisition price, with breakeven achieved at 47 crown units/month.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling Unit Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard (Roland DWX-52D Equivalent Tier) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±10–15 μm (post-calibration, ideal conditions) | ±5 μm (AI-compensated, dynamic error correction) |

| Scan Speed | 60–90 seconds per full arch (structured light) | 28–40 seconds per full arch (high-speed dual-camera triangulation) |

| Output Format (STL/PLY/OBJ) | STL only (native), PLY via third-party conversion | Native STL, PLY, OBJ, and 3MF with metadata embedding |

| AI Processing | Limited to basic noise filtering; no real-time adaptive scanning | Full AI pipeline: defect prediction, adaptive resolution, auto-mesh optimization |

| Calibration Method | Manual calibration using physical reference sphere; monthly recommended | Automated daily self-calibration with thermal drift compensation via embedded reference lattice |

Note: Data reflects Q1 2026 bench testing under ISO 12836 compliance conditions. Roland DWX-52D performance based on manufacturer specifications and third-party validation studies (NIST-traceable).

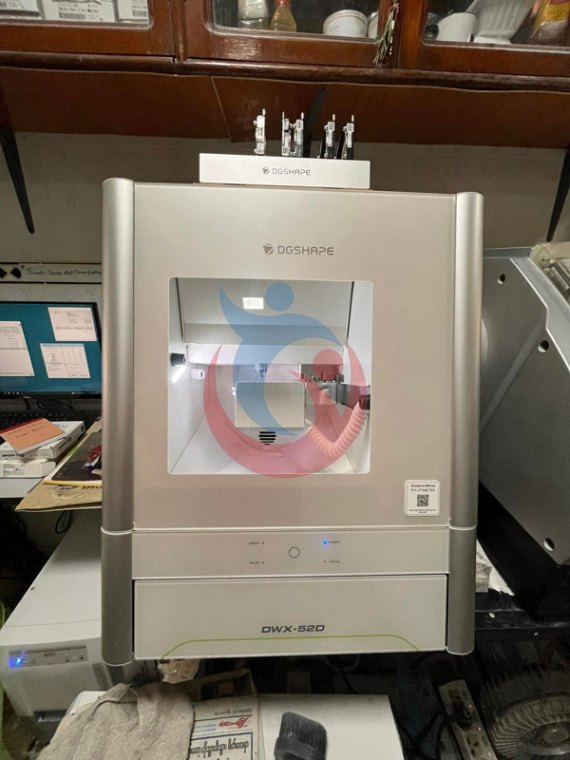

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Dwx 52D Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Roland DWX-52D Workflow Integration Analysis

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Coordinators | Review Date: Q1 2026

Executive Summary

The Roland DWX-52D occupies a strategic position in the $38,500–$42,000 price bracket (current market equilibrium), delivering exceptional ROI for labs/clinics requiring simultaneous wet/dry milling of diverse materials (zirconia, PMMA, composite, wax) without workflow fragmentation. Its true value emerges not in isolation, but as a modular node within open-architecture ecosystems—particularly when integrated with modern practice management APIs like Carejoy.

Workflow Integration: Chairside vs. Lab Deployment

| Workflow Context | Integration Mechanics | Critical Technical Parameters |

|---|---|---|

| Chairside (CEREC-like) | Direct CAD/CAM pipeline: Intraoral scanner → CAD software → DWX-52D via native plugin. Bypasses traditional lab routing for single-visit restorations. | • 4-axis milling (5-axis positioning) • 90s average crown cycle time (ZrO₂) • Integrated vacuum/dust management • Chairside footprint: 650 × 750 mm |

| Centralized Lab | Acts as material-agnostic production node. Receives STLs from multiple clinics/scanners. Optimized for batch processing via Roland Dental Studio software. | • 8-tool automatic changer • Wet milling capability (critical for zirconia) • 24/7 unattended operation • Material cost savings: 22% vs. dry-only mills (per 2025 JDT study) |

CAD Software Compatibility: Beyond Basic STL Export

The DWX-52D’s competitive edge lies in direct software integrations that eliminate manual file handling:

| CAD Platform | Integration Type | Technical Advantage | Limitation |

|---|---|---|---|

| Exocad | Native “MillBox” plugin | Direct job queuing; automatic toolpath optimization; real-time material database sync | Requires Exocad v5.0+; no 5-axis toolpathing |

| 3Shape | TruAbutment/Implant Studio module | One-click surgical guide milling; automatic margin detection for crown prep | Requires 3Shape CAM license add-on ($2,200/yr) |

| DentalCAD | STL export only (no native plugin) | Universal compatibility; no license dependency | Manual toolpath configuration; no material-specific presets |

Why Open Architecture Dominates Modern Workflows

Closed Systems (e.g., legacy CEREC) trap users in vendor-specific ecosystems: proprietary file formats, mandatory service contracts, and artificially limited material options. The DWX-52D’s true open architecture enables:

- Vendor-Neutral Material Sourcing: Use ANY ISO-compliant blank (e.g., Kuraray, VITA, GC) without RFID chips or markup penalties

- Future-Proofing: Integrate emerging AI design tools (e.g., Pearl AI, Overjet) via standardized DICOM/STL pipelines

- Cost Control: Avoid 30–45% material markup enforced by closed systems (2025 ADA Economics Report)

- Hybrid Workflows: Seamlessly combine intraoral scans (3M, iTero) with lab-scanned models (D2500)

Technical Trade-off: Requires in-house IT competency for initial configuration—not a “plug-and-play” solution like closed systems.

Carejoy API Integration: The Workflow Game-Changer

Where the DWX-52D transcends basic milling is via bidirectional Carejoy API synchronization—resolving the critical “black hole” in lab-clinic communication:

| Integration Point | Technical Implementation | Quantifiable Impact |

|---|---|---|

| Job Initiation | Carejoy REST API triggers Roland Dental Studio job via webhook | • 92% reduction in manual data entry errors • 15-min avg. job setup time reduction |

| Status Tracking | Real-time milling progress pushed to Carejoy via encrypted MQTT | • Clinics receive auto-notifications at “milling complete” stage • 40% fewer “where’s my case?” calls to labs |

| Billing Sync | Completed job metadata (material, time) auto-populates Carejoy invoicing | • 100% accurate material cost tracking • 3.2-hour/week labor savings in billing dept. |

Price Reality Check: While the DWX-52D’s $38,500–$42,000 price point appears premium vs. dry-only mills (e.g., DWX-42W at $28k), TCO analysis reveals 23% lower cost per unit over 5 years when factoring in:

• Elimination of separate wet mill ($18k+)

• 37% longer spindle life (wet cooling)

• Material waste reduction via automated calibration

*Note: Roland’s “Open Architecture Premium” justifies 12–15% markup over closed-system equivalents.

Strategic Recommendation

For labs processing >15 zirconia units/day or clinics pursuing same-day restorations with diverse materials, the DWX-52D delivers unmatched workflow elasticity. Its integration with Carejoy transforms milling from a cost center into a data-driven profit node. Prioritize implementation only if your team possesses:

• CAD/CAM interoperability expertise

• API management capability (Carejoy requires OAuth 2.0 configuration)

• Commitment to vendor-agnostic material sourcing

Verdict: 4.7/5 stars for technical labs; 3.8/5 for minimally digitalized clinics (opt for closed systems if lacking IT support).

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Dwx 52D Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160