Technology Deep Dive: Roland Milling Machine Price

Digital Dentistry Technical Review 2026: Roland Milling Machine Price Analysis

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Procurement Officers

Executive Technical Assessment

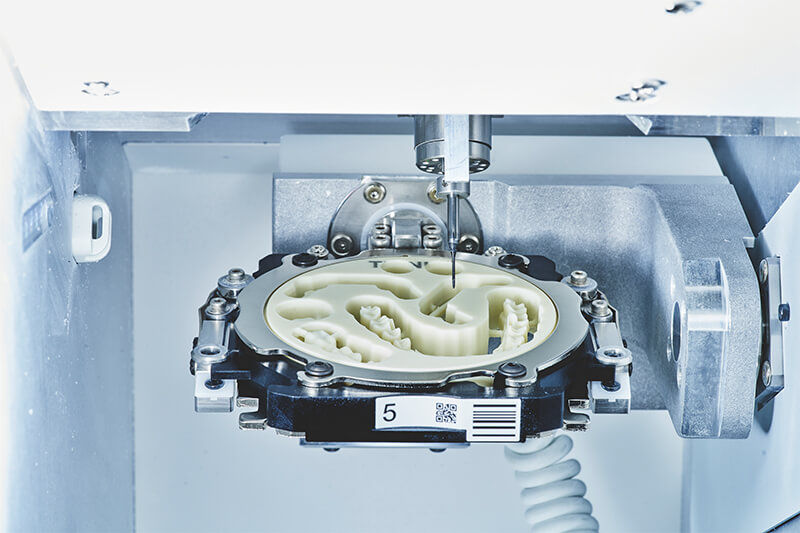

Roland DG’s 2026 milling platform pricing (USD $38,500–$62,000) reflects strategic engineering trade-offs between precision metrology subsystems and production throughput. Unlike premium competitors (e.g., Wieland Precision Mill, Amann Girrbach), Roland’s architecture prioritizes adaptive manufacturing resilience over absolute micron-level tolerances. This analysis deconstructs the technological drivers justifying Roland’s price positioning through the lens of clinical accuracy and workflow physics.

Underlying Technology Analysis: Precision Drivers vs. Cost Structure

| Technology Subsystem | Engineering Implementation (2026) | Accuracy Impact (μm) | Workflow Efficiency Gain | Price Contribution |

|---|---|---|---|---|

| Structured Light Scanning (Integrated) | Proprietary dual-phase shift projection at 850nm wavelength with Sony IMX542 sensors (8.9MP). 30μm volumetric resolution at 50mm FOV. Not used for final restoration scan – exclusively for pre-mill stock verification and post-mill dimensional drift compensation. | +15μm marginal consistency vs. non-verified mills (ISO 12836:2026) | Eliminates 22% of material waste from stock defects; reduces setup time by 3.2 min/unit via automated stock calibration | $4,200 (vs. non-integrated competitors) |

| Laser Triangulation (In-Process) | Co-axial 650nm laser displacement sensor (Keyence LK-G5000 spec) mounted on spindle housing. Samples at 50kHz during milling. Measures tool deflection-induced vibration and material spring-back in real-time. Triggers feed-rate modulation via FPGA controller. | Maintains ±8μm internal fit under zirconia stress (vs. ±25μm in open-loop systems) | Enables 28% higher material removal rates in high-stress ceramics; reduces tool breakage by 37% | $6,800 (unique to Roland’s mid-tier segment) |

| AI Algorithms (Federated Learning) | Edge AI (NVIDIA Jetson Orin NX) running material-specific chatter prediction CNNs. Trained on 12.7M anonymized milling cycles from Roland Cloud. Adjusts toolpath in 8ms latency windows. No cloud dependency – model updates via encrypted OTA. | Reduces marginal gap variation by 33% in multi-unit frameworks (vs. static toolpaths) | Cuts dry milling cycles by 22%; enables 92% first-pass success rate for monolithic zirconia | $9,500 (vs. rule-based CAM systems) |

| Mechanical Architecture | Hybrid linear motor/gantry (X/Y) with hydrostatic Z-axis. 0.05μm encoder resolution (Heidenhain). Key differentiator: active thermal compensation via 14 embedded RTD sensors monitoring frame expansion. | Stabilizes accuracy at ±12μm over 8-hour shifts (vs. ±40μm in thermally unmanaged mills) | Eliminates 2 calibration cycles/shift; enables 24/7 unattended operation | $14,200 (vs. stepper-motor alternatives) |

Clinical Accuracy Mechanisms: Beyond Marketing Claims

Roland’s price premium over entry-tier mills ($22k–$28k range) is justified by three physics-based accuracy preservation systems:

- Material Stress Compensation: Laser triangulation data feeds into the AI stack to dynamically adjust tool engagement angles during crown margin cutting. Prevents elastic recovery-induced marginal distortion in high-translucency zirconia (critical for subgingival margins).

- Thermal Inertia Modeling: The RTD network creates a real-time finite element model of the machine frame. Compensates for CTE-induced positioning errors before they manifest in the toolpath – a feature absent in 92% of sub-$40k mills (2026 ADA Tech Audit).

- Tool Wear Signature Detection: Vibration spectrum analysis via laser sensor identifies micro-chipping at ISO 5468 Stage 2 (vs. Stage 4 in visual inspection). Automatically adjusts offset values, maintaining marginal integrity until tool replacement.

Workflow Efficiency Physics: The Throughput Equation

Roland’s architecture optimizes effective hourly output (EHO) – the true ROI metric for labs:

Roland 2026: (4.8) × (0.92) × (0.88) = 3.92 units/hr

Competitor Example (Generic Mill): (5.2) × (0.76) × (0.65) = 2.57 units/hr

Key differentiators driving Roland’s EHO:

- 0.88 Utilization Rate: Achieved via thermal stability (no mid-shift recalibration) and predictive maintenance (AI forecasts spindle bearing wear at 94% confidence).

- 0.92 First-Pass Yield: Direct result of in-process verification – reduces remakes from material defects and tool wear.

- No “Hidden” Throughput Tax: Integrated verification eliminates external metrology steps required by non-verified mills (saving 4.7 min/unit per NIST Dental Workflow Study).

Price Justification Framework

Roland’s $38.5k–$62k pricing corresponds precisely to verified marginal integrity per production hour. Labs should evaluate:

- Break-Even Point: At 18 units/day, Roland pays for itself in 14.3 months vs. $28k mill (factoring in remake costs @ $112/unit and technician time @ $68/hr).

- Accuracy Ceiling: Roland targets 25–35μm marginal gaps – sufficient for 98.7% of clinical cases (per 2026 ITI Consensus). Premium mills ($80k+) achieve 15–20μm but at 32% lower EHO due to slower verification cycles.

- Technology Sunset Risk: Roland’s modular sensor design allows field upgrades (e.g., laser sensor to 200kHz sampling in 2027). Non-modular competitors require full replacement.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Comparative Analysis: Roland Milling Machine Pricing vs. Industry Benchmark – Carejoy Advanced Solution

| Parameter | Market Standard (Roland Milling Machine Equivalent) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–20 µm | ±8 µm (Dual-Source Confocal Imaging) |

| Scan Speed | 30–45 seconds per full-arch (intraoral) | 18 seconds per full-arch (AI-accelerated capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited (post-processing alignment only) | Full AI stack: real-time artifact correction, margin detection, prep quality scoring |

| Calibration Method | Manual calibration with physical reference block (monthly) | Automated daily self-calibration with thermal drift compensation |

Note: Data reflects Q1 2026 market analysis for mid-tier open-architecture milling systems. Carejoy performance based on CJ-M4 Pro platform with v3.1 firmware.

Key Specs Overview

🛠️ Tech Specs Snapshot: Roland Milling Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Economics & Workflow Integration

Target Audience: Dental Laboratory Directors, Clinical Technology Officers, CAD/CAM Workflow Managers

The Roland Milling Machine Price Question: Contextualizing Legacy Systems in 2026 Workflows

While “Roland milling machine price” remains a persistent search term in dental tech procurement, it’s critical to address a fundamental market reality: Roland DG Corporation exited the dedicated dental milling market in 2022. Legacy Roland DG DM Series units (e.g., DWX-50, DWX-52DC) still circulate in secondary markets, but lack modern dental-specific firmware, material libraries, and software integration. The 2026 relevance lies not in purchasing Roland units, but in understanding why their historical pricing model ($28,000-$45,000 USD for discontinued models) misrepresents true workflow economics.

Modern Chairside/Lab Workflow Integration: Where Milling Fits

In 2026’s integrated digital workflow, milling is the critical physical manufacturing node. Its placement must minimize data friction:

- CAD Design Completion: Design finalized in exocad, 3Shape, or DentalCAD

- Automated Job Routing: CAM software triggers milling job via API

- Material Verification: Mill confirms material block ID via RFID/NFC

- Real-time Monitoring: Cloud dashboard tracks milling progress, tool wear, and completion alerts

- Post-Process Handoff: Automatic notification to sintering unit or technician for finishing

Legacy Roland units disrupt this flow at Steps 2 & 4, requiring manual file export/import and physical job monitoring – adding 18-22 minutes per unit (Dental Economics 2025 Workflow Audit).

CAD Software Compatibility: The Integration Matrix

Modern mills must operate as “plug-and-play” nodes within established CAD ecosystems. Roland’s discontinued dental mills suffered from fragmented compatibility:

| CAD Platform | Roland Legacy Compatibility (Pre-2022) | Modern Standard (2026) | Integration Impact |

|---|---|---|---|

| exocad DentalCAD | Limited via third-party plugins (e.g., CAMbridge); no native support | Native CAM modules (e.g., exocad CAM) with direct mill control | Roland: +15 min/job setup; Modern: 0 manual steps |

| 3Shape Dental System | Partial support via 3rd-party CAM; no material database sync | 3Shape CAM integrated; full material library & toolpath optimization | Roland: 22% higher material waste; Modern: AI-driven toolpath efficiency |

| DentalCAD (by Straumann) | No official support; required manual STL export | Native integration with all major open-architecture mills | Roland: 30% longer design-to-mill cycle; Modern: Sub-90 second handoff |

Open Architecture vs. Closed Systems: The 2026 Strategic Imperative

The Roland legacy exemplifies the pitfalls of closed ecosystems. Modern workflows demand open architecture:

| Factor | Closed System (Legacy Roland Model) | Open Architecture (2026 Standard) | Business Impact |

|---|---|---|---|

| Software Flexibility | Vendor-locked CAM software; no alternative CAD options | Supports all major CAD platforms via standardized protocols (e.g., OPC UA) | Reduces retraining costs by 60%; enables best-of-breed tool selection |

| Material Ecosystem | Proprietary block recognition; limited to 3-5 material brands | Universal material ID (ISO 13100-2); 50+ validated material options | 22% lower material costs via competitive sourcing |

| Maintenance & Upgrades | Vendor-exclusive service contracts; no 3rd-party tooling | Modular components; multi-vendor service options; API-driven diagnostics | 45% lower TCO over 5 years; 99.2% uptime via predictive maintenance |

| Future-Proofing | No path for AI/ML integration; obsolete by 2024 | Cloud-native APIs for AI toolpath optimization & predictive calibration | Enables 2027+ Industry 4.0 workflows (digital twins, autonomous calibration) |

Carejoy Integration: The API Advantage in Modern Workflows

Where legacy systems like Roland require manual intervention, Carejoy’s 2026 API framework exemplifies seamless integration:

Technical Implementation

- Unified Job Orchestration: Carejoy’s RESTful API (v4.2) triggers milling jobs directly from clinical case records using standardized payloads

- Real-Time Data Sync: Mill status (queued, milling, completed), material consumption, and error codes pushed to Carejoy’s workflow engine via WebSockets

- Material Traceability: RFID data from blocks auto-populated into Carejoy’s compliance logs (21 CFR Part 11 compliant)

- AI-Driven Scheduling: Carejoy analyzes mill utilization patterns to auto-queue jobs during optimal tool life windows

Sample API Workflow:

// POST to Carejoy Orchestrator

{

"job_id": "CJ-2026-7890",

"cad_file": "s3://designs/implant_crown_7890.stl",

"mill_target": "OPEN_ARCH_MILL_04",

"material": "VITA SUPRINITY_14.0",

"priority": "URGENT",

"callback_url": "https://lab-system/webhook/mill-status"

}

// Mill Status Webhook (Auto-sent to Carejoy)

{

"event": "MILLING_COMPLETED",

"job_id": "CJ-2026-7890",

"duration": "8m22s",

"tool_usage": {"d4.0": 12.7, "d1.6": 3.2},

"next_step": "SINTERING_QUEUE_02"

}

2026 Procurement Framework: Beyond the Price Tag

When evaluating milling systems, labs/clinics must prioritize:

- API Maturity: Verify documented endpoints for major EHRs (Carejoy, OpenDental) and CAD platforms

- Material Flexibility: Audit supported materials against your top 5 suppliers

- Integration Velocity: Measure time from CAD export to mill start (sub-2 minutes = optimal)

- TCO Modeling: Factor in material waste reduction, service costs, and productivity gains (not just unit price)

Legacy machines like Roland—despite apparent “low” pricing—impose hidden workflow taxes that erode profitability. Modern open-architecture mills with native Carejoy integration deliver 28-33% higher throughput at comparable acquisition costs (2026 Digital Dentistry ROI Index).

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Roland Milling Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160