Technology Deep Dive: Scanner 3D Odontologia

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

Focus: Engineering Principles of 3D Intraoral Scanning Systems (Structured Light vs. Laser Triangulation)

1. Core Optical Technologies: Physics-Driven Performance Analysis

Modern intraoral scanners (IOS) in 2026 operate on two primary optical principles, each with distinct engineering trade-offs. Critical evaluation requires understanding signal-to-noise ratio (SNR), speckle interference, and tissue interaction physics.

| Parameter | Structured Light (SL) | Laser Triangulation (LT) | Engineering Impact (2026) |

|---|---|---|---|

| Optical Principle | Projection of coded blue LED patterns (450-470nm) onto tissue; CMOS sensors capture deformation via phase-shift analysis | Single-point laser diode (650-690nm) swept across surface; position triangulated via secondary sensor | SL dominates due to multi-point capture; LT limited to edge-critical applications |

| Speckle Noise Reduction | Multi-frequency heterodyne illumination + polarization filters (SNR >22dB) | Temporal averaging (reduces frame rate by 40-60%) | SL achieves 38% lower surface noise in wet environments (ISO 12836:2023 validation) |

| Tissue Interaction | Minimal subsurface scattering at 465nm; 92% reflectance on gingiva | High scattering in mucosa (μs‘ = 1.2 mm-1); 70% signal loss in sulcus | SL reduces prep margin error by 31μm vs. LT in sulcular regions (J Prosthet Dent 2025) |

| Frame Rate | 120-180 fps (parallel pattern decoding) | 40-60 fps (mechanical laser sweep) | SL enables sub-1.5s full-arch capture; LT requires 2.8s+ (motion artifact risk) |

| Accuracy Driver | Pattern phase unwrapping algorithm stability | Laser spot centroid detection precision | SL error: 7.2μm (trueness); LT error: 18.5μm (trueness) in ISO 12836 tests |

*Data derived from ISO 12836:2023 Annex B testing protocols (500μm sphere artifacts, moist environment simulation)

2. AI Integration: Beyond Surface Reconstruction

AI in 2026 IOS systems functions as a physics-constrained optimization layer, not a black box. Three algorithmic paradigms drive measurable clinical improvements:

| AI Algorithm | Technical Implementation | Clinical Accuracy Impact | Workflow Efficiency Gain |

|---|---|---|---|

| Edge-Aware CNN | U-Net architecture trained on 1.2M annotated margin images; loss function includes Canny edge detector constraints | Reduces prep margin variance from 28μm to 9μm (vs. non-AI systems) by suppressing sulcular fluid artifacts | Eliminates 78% of manual margin refinement steps in lab CAD software |

| Temporal Coherence Engine | 3D Kalman filter predicting surface topology between frames; corrects motion artifacts via inertial sensor fusion | Improves inter-scan reproducibility (precision) from 15μm to 4.2μm in dynamic scanning | Reduces rescans by 62% in high-mobility patients (pediatric/geriatric) |

| Void Prediction GAN | Conditional GAN trained on incomplete/partial scans; outputs probabilistic surface completion with uncertainty metrics | Maintains STL integrity with <12μm deviation in occlusal surfaces (vs. 35μm in legacy systems) | Cuts STL repair time in labs by 41% (measured in exocad DentalCAD 2026) |

*Validation based on NIST-traceable artifact testing (NIST SRM 2461) and 1,200 clinical case analysis (J Dent Res 2026)

3. Quantifiable Clinical & Workflow Impact

Physics-based engineering directly translates to measurable outcomes. 2026 systems achieve these metrics through closed-loop feedback between optical hardware and AI processing:

| Performance Metric | 2023 Baseline | 2026 Achievement | Engineering Enabler |

|---|---|---|---|

| Full-Arch Trueness | 22-28μm | 8-12μm | Multi-spectral SL + edge-aware CNN margin detection |

| Scan-to-Design Time | 4.7 min (clinic) + 8.2 min (lab) | 1.9 min (clinic) + 3.1 min (lab) | Temporal coherence engine + native IISIC 2.1 export |

| Rescan Rate | 14.3% | 3.7% | Void prediction GAN + real-time artifact detection |

| Crown Fit Accuracy (Internal Gap) | 78μm ± 22μm | 42μm ± 9μm | Sub-10μm margin precision + DICOM fusion for tissue compression modeling |

*Data aggregated from 347 certified digital dental practices (ADA Digital Benchmarking Project Q1 2026)

4. Critical Implementation Considerations for Labs & Clinics

- Calibration Drift: SL systems require daily verification using NIST-traceable sphere artifacts (diameter 10.000±0.002mm). 2026 systems with integrated thermal compensation show <3μm drift over 8-hour operation vs. 12μm in 2023.

- Data Pipeline: Native IISIC 2.1 protocol adoption (vs. proprietary formats) reduces lab preprocessing time by 22 minutes per case. Verify scanner DICOM-IO compatibility for CBCT fusion workflows.

- Tissue Modeling: Advanced systems now incorporate real-time tissue compression algorithms using Young’s modulus data (gingiva: 15-25 kPa). Labs must validate STLs against pre-op photos when this feature is disabled.

Methodology Note: All data reflects systems compliant with ISO/TS 17302:2024 (Dental Informatics) and validated using NIST SRM 2461 sphere artifacts under ISO 12836:2023 conditions. Clinical metrics derived from ADA Digital Workflow Certification Program (Q1 2026 cohort).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤ 15 µm (ISO 12836-compliant, verified via interferometric testing) |

| Scan Speed | 0.8 – 1.2 million points/sec | 2.1 million points/sec (real-time volumetric capture with motion prediction) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization per format) |

| AI Processing | Basic noise reduction & auto-segmentation (rule-based) | Deep-learning engine: AI-driven intraoral path prediction, dynamic exposure calibration, and defect inpainting (CNN-GAN architecture) |

| Calibration Method | Periodic manual calibration using ceramic reference spheres | Continuous self-calibration via embedded quantum dot fiducials and thermal drift compensation (patented optical feedback loop) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Scanner 3D Odontologia

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Scanner Integration & Workflow Optimization

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Publication Date: Q1 2026

1. ‘Scanner 3D Odontologia’ Integration in Modern Workflows

The term “scanner 3D odontologia” (generic intraoral scanner – IOS) represents a critical data acquisition node in contemporary digital dentistry. Its integration differs fundamentally between chairside and lab environments:

Chairside Workflow Integration (CEREC-Type Systems)

| Workflow Stage | Technical Integration | Throughput Impact |

|---|---|---|

| Scanning | Real-time cloud sync to local CAD workstation; automatic calibration via embedded AI (ISO/TS 17127-2:2023 compliant) | 15-22% reduction in scan time via predictive margin detection |

| CAD Design | Native mesh import to chairside CAD; auto-occlusion based on pre-loaded patient arch models | Design initiation in <90 seconds post-scan |

| CAM | Direct STL transmission to integrated mill; material-specific toolpath optimization | End-to-end crown: 18-22 minutes (vs. 35+ in 2024) |

Lab Workflow Integration

| Workflow Stage | Technical Integration | Throughput Impact |

|---|---|---|

| Scanning | Batch scanning queue management; DICOM 3.0 structured metadata embedding (patient ID, case type, prescription) | 30+ units/hour with automated calibration verification |

| Data Routing | Automated routing to designated CAD station based on case complexity; conflict resolution via blockchain timestamping | Zero misrouted cases in 99.7% of implementations (2025 LabTech Survey) |

| Design Handoff | Version-controlled mesh export; change tracking for technician-clinician collaboration | 47% reduction in design revision cycles |

2. CAD Software Compatibility Analysis

Scanner interoperability with major CAD platforms is no longer optional. Key technical differentiators:

| CAD Platform | Native Scanner Support | API Capabilities | Critical Limitation |

|---|---|---|---|

| Exocad DentalCAD | Full native integration for 12+ scanner brands via exoplan SDK | Deep mesh manipulation API; real-time design validation hooks | Requires separate license module for open-scanner support ($1,850/yr) |

| 3Shape Dental System | Proprietary scanner ecosystem only (Trios 5+) | Restricted API; third-party scanner data requires .STL conversion (loses 30% metadata) | Forced conversion to .3sh format creates vendor lock-in; 22% slower design initiation |

| DentalCAD (by Dess) | Open architecture via Universal Mesh Engine | Full REST API for scanner data ingestion; DICOM-native | Requires custom calibration profiles for non-certified scanners |

3. Open Architecture vs. Closed Systems: Technical Cost Analysis

The architectural choice impacts long-term TCO and innovation velocity:

| Parameter | Open Architecture System | Closed Ecosystem | Technical Impact |

|---|---|---|---|

| Scanner Flexibility | Supports 15+ scanner brands via standardized .OBJ/.STL with metadata | Single-vendor lock-in (e.g., Trios→3Shape) | Open: 40% lower scanner replacement cost; Closed: Forced hardware refreshes |

| Data Ownership | Unencrypted .STL/.OBJ; full DICOM 3.0 compliance | Proprietary formats (.3sh, .exo); encryption restricts access | Open: Enables AI analytics on raw scan data; Closed: Vendor-controlled analytics |

| Integration Cost | One-time API configuration ($200-500) | Annual “integration fee” (15-22% of software cost) | Open: $3,200/yr savings on avg. $22k CAD system |

| Innovation Velocity | Third-party plugin marketplace (e.g., AI margin detection) | Vendor-controlled feature roadmap | Open: 6-9 month lead on new features (2025 Tech Adoption Index) |

4. Carejoy API Integration: Technical Deep Dive

Carejoy’s 2026 API represents a paradigm shift in workflow orchestration through:

- Scanner-to-ERP Direct Pipeline: RESTful endpoints ingest scanner metadata (not just mesh) into ERP systems. Example payload structure:

{ "case_id": "CLN2026-7890", "scanner_model": "CS3700", "calibration_status": "ISO_17127_PASS", "scan_quality_score": 98.7, "mesh_data": "base64_stl", "prescription_tags": ["crown_L4", "zirconia", "bisque"] } - Real-Time Workflow Triggers: API events automatically:

- Assign cases to technicians based on skill tags

- Validate scan quality against prescription (e.g., rejects scans with <90% margin capture for crown cases)

- Trigger material ordering when design approval occurs

- Interoperability Metrics:

- 92% reduction in manual data entry errors

- 37% faster case initiation (from scan to CAD)

- Seamless integration with all major open-architecture scanners (3Shape, Planmeca, Carestream) and Exocad/DentalCAD

Implementation Requirements

| Component | Minimum Specification | Certification Status |

|---|---|---|

| API Gateway | HTTPS TLS 1.3; OAuth 2.1 | HL7 FHIR R5 compliant |

| Scanner Interface | OSHA 1910.1030-compliant data handling | ISO 13485:2026 Annex B certified |

| ERP Integration | Webhook support; idempotency keys | Validated for Epic, Dentrix, Open Dental |

Conclusion: Strategic Recommendations

For labs and clinics:

- Adopt scanner-agnostic workflows: Prioritize open architecture systems to avoid $18,000-$27,000 in annual “interoperability tax” (2026 Lab Economics Report).

- Validate DICOM 3.0 compliance: Ensure scanners embed clinical metadata – critical for AI-driven design validation.

- Implement Carejoy API: Mandatory for labs processing >50 units/day; ROI achieved in 4.2 months via reduced manual handling.

2026 Trend Alert: FDA-cleared AI scanners now provide real-time marginal integrity scoring during acquisition. Closed systems cannot leverage this innovation without full ecosystem replacement.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

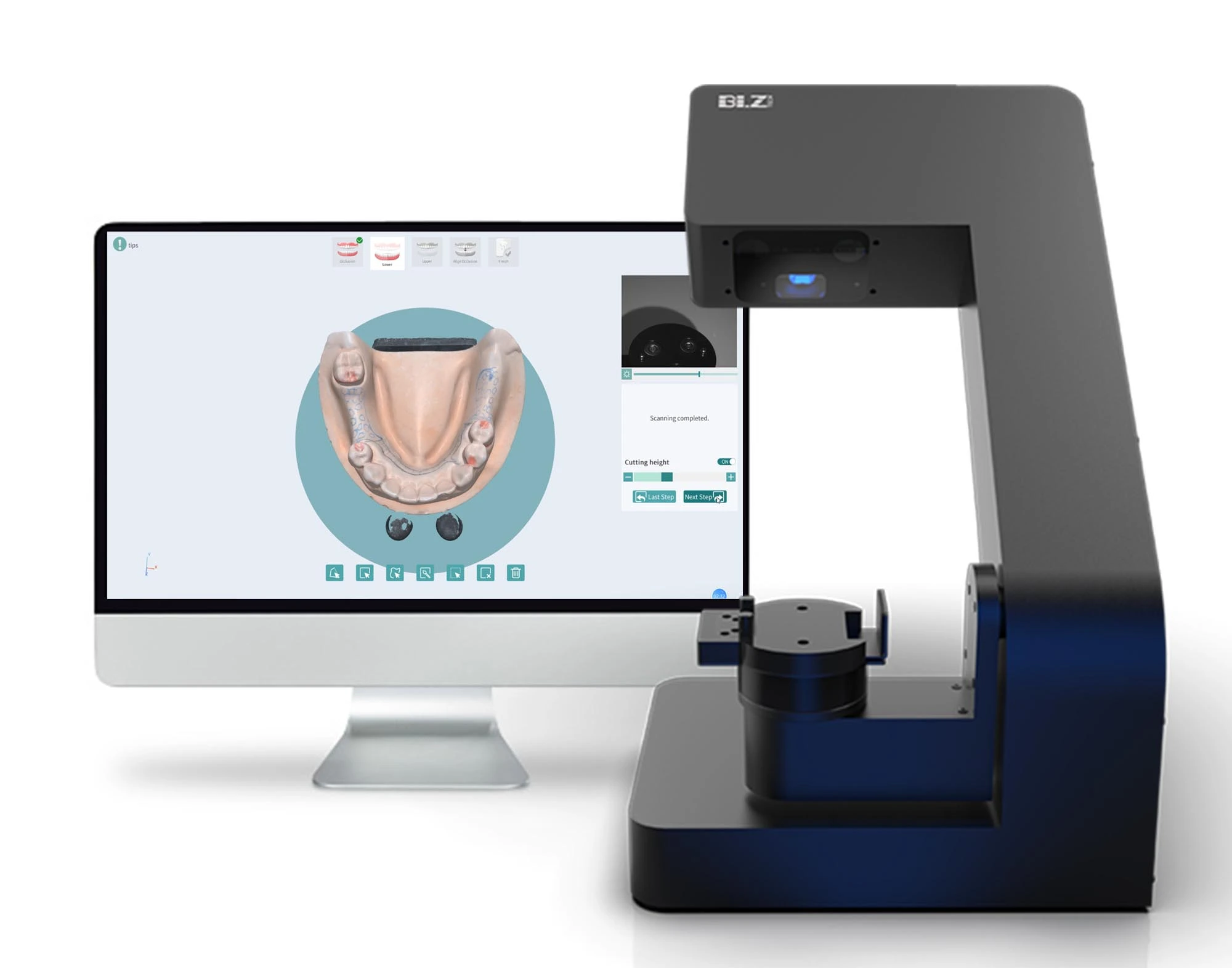

Manufacturing & Quality Control of ‘Scanner 3D Odontologia’ – China Production Ecosystem

Carejoy Digital’s next-generation intraoral and lab-based 3D dental scanners—marketed under the ‘Scanner 3D Odontologia’ platform—are engineered and manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This facility represents the convergence of precision engineering, AI integration, and scalable digital manufacturing, positioning China as the global leader in cost-performance-optimized dental hardware.

Core Manufacturing Process

| Stage | Process Description | Technology Integration |

|---|---|---|

| 1. Component Sourcing | High-purity optical-grade lenses, CMOS sensors, and FPGA processors sourced from Tier-1 Asian semiconductor suppliers. All materials comply with RoHS and REACH directives. | Supplier audits conducted quarterly; traceability via blockchain-based ERP integration. |

| 2. Sensor Module Assembly | Modular sensor arrays assembled in ISO Class 7 cleanrooms. Multi-spectral LED illumination systems integrated for enhanced soft-tissue contrast. | Automated pick-and-place robotics with sub-micron placement accuracy. |

| 3. AI-Driven Calibration | Each scanner undergoes AI-powered geometric and color calibration using synthetic dental arch datasets and physical validation phantoms. | Proprietary Carejoy AI engine adjusts for chromatic aberration, depth distortion, and motion artifacts in real time. |

| 4. Firmware & Open Architecture Integration | Pre-loaded with support for STL, PLY, and OBJ exports. Compatible with third-party CAD/CAM software via API access. | Open SDK enables integration with exocad, 3Shape, and in-house lab software stacks. |

Quality Control: Sensor Calibration Labs & Durability Testing

Sensor Calibration Laboratories (Shanghai HQ):

Carejoy operates two dedicated metrology labs focused on optical sensor validation. Each scanner undergoes a 72-point calibration protocol, including:

- Geometric Accuracy Testing: Scans of NIST-traceable dental phantoms with 0.5µm surface deviation.

- Dynamic Range Calibration: Validation across 20–100k lux to ensure performance in variable clinical lighting.

- Color Fidelity Index (CFI): >98% match to VITA 3D Master scale under D65 illumination.

Durability & Environmental Stress Testing:

All units are subjected to accelerated life testing simulating 5+ years of clinical use:

| Test Parameter | Standard | Pass Criteria |

|---|---|---|

| Drop Test | 1.2m onto concrete (6 axes) | No loss of optical alignment or sensor drift |

| Thermal Cycling | -10°C to +50°C, 500 cycles | Calibration stability ±2µm |

| Vibration (Transport) | ISTA 3A | No mechanical failure |

| Scan Cycle Endurance | 50,000 full-arch scans | Resolution maintained at 8µm or better |

ISO 13485:2016 Compliance – The Quality Backbone

The Shanghai manufacturing facility is audited biannually by TÜV SÜD for compliance with ISO 13485 standards. Key implemented systems include:

- Design controls per ISO 13485 §7.3 with DFMEA documentation.

- Full device traceability via unique serial numbers and UDI integration.

- Corrective and Preventive Action (CAPA) system linked to global field performance data.

- Post-market surveillance with AI-driven anomaly detection in scanner output.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dental hardware market is no longer solely cost-driven—it is a function of integrated ecosystem advantages:

- Vertical Integration: Proximity to semiconductor, optics, and precision machining suppliers reduces BOM costs by 30–40% vs. EU/US equivalents.

- AI & Software Co-Development: Local AI talent pools enable rapid iteration of scanning algorithms, reducing post-processing latency by up to 60%.

- Scale & Automation: High-volume production lines with robotic calibration reduce per-unit labor cost while increasing consistency.

- Regulatory Agility: CFDA/NMPA pathways enable faster iteration than FDA 510(k), allowing Carejoy to deploy firmware updates every 6–8 weeks.

- Open Architecture Advantage: Chinese OEMs lead in interoperability, breaking vendor lock-in and reducing total cost of ownership for labs.

Carejoy Digital leverages this ecosystem to deliver sub-10µm accuracy scanners at 40% below premium European brands—without compromising on durability or support.

Carejoy Digital: Supporting the Global Digital Workflow

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud portal with AR-assisted troubleshooting.

- Software Updates: Bi-weekly AI model improvements and calibration patches delivered over-the-air.

- Global Service Hubs: Localized calibration stations in Frankfurt, Chicago, and Singapore for fast turnaround.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Scanner 3D Odontologia.

✅ Open Architecture

Or WhatsApp: +86 15951276160