Technology Deep Dive: Scanner Intraoral Precio

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology & Value Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Workflow Engineers

Executive Summary: Beyond Price Per Unit

The term “scanner intraoral precio” (intraoral scanner price) is a misnomer in 2026’s value-driven clinical environment. True cost analysis must incorporate Total Workflow Efficiency (TWE) – defined as (Time Savings + Material Savings + Error Reduction) / Total Cost of Ownership (TCO). Modern scanners are computational imaging systems where sensor physics, real-time processing architecture, and AI integration dictate clinical outcomes more than initial acquisition cost. This review dissects the engineering principles behind 2026’s leading systems.

Core Sensor Technologies: Physics-Driven Accuracy

Price segmentation correlates directly with fundamental sensor capabilities. Understanding these engineering constraints is critical for ROI calculation.

| Technology | 2026 Implementation | Accuracy Mechanism (ISO 12836:2023) | Limitations & Mitigation |

|---|---|---|---|

| Structured Light (Blue LED) | 12-18 wavelength channels (445-465nm), 120fps projection | Rayleigh scattering minimization at 450nm reduces subsurface penetration error by 63% vs. red light (λ=650nm). Phase-shift analysis resolves Z-axis deviations to ±3.2µm (vs. ±8µm in 2023). | Moisture interference: Mitigated via pulsed illumination (10µs exposure) and AI-based specular reflection modeling. |

| Laser Triangulation (Dual-Line) | 520nm DPSS lasers, 0.05° angular resolution, 200fps CMOS | Triangulation baseline (38mm) optimized for 10-15mm working distance. Error propagation formula: ΔZ = (b * Δθ) / sin²θ where b=baseline, θ=viewing angle. Modern systems achieve Δθ < 0.005° via MEMS mirror calibration. | Soft tissue motion artifacts: Compensated via temporal coherence filtering (4-frame buffer) and tissue elasticity modeling. |

| Hybrid (SL + Laser) | Primary SL for hard tissue, laser for sulcus/margins | SL provides full-field data (200k points/sec), laser delivers edge detection at 0.4µm precision. Sensor fusion via Kalman filtering reduces marginal discrepancy to 12.7µm (vs. 28µm in 2023). | Calibration drift: Auto-compensated via embedded reference spheres (5µm tolerance) in scan tip. |

Engineering Insight: Why Wavelength Matters

Scattering coefficient (μs) in enamel is wavelength-dependent: μs ∝ λ-3.5. At 450nm, μs = 12.3 mm-1 vs. 4.1 mm-1 at 650nm. This reduces subsurface photon migration, minimizing the “halo effect” that caused 15-20µm marginal errors in legacy red-light systems. Blue light’s higher photon energy also enables shorter exposure times, critical for motion artifact reduction.

AI Integration: From Post-Processing to Real-Time Correction

Modern AI isn’t “enhancing” scans – it’s preventing errors at acquisition. 2026 systems implement three-tiered processing:

| Processing Tier | Function | Hardware Acceleration | Workflow Impact |

|---|---|---|---|

| Frame-Level (On-Sensor) | Real-time noise reduction via convolutional neural networks (CNN) trained on 10M+ clinical frames. Removes specular reflections using bidirectional reflectance distribution function (BRDF) modeling. | Embedded NPU (Neural Processing Unit) in CMOS sensor (e.g., Sony STARVIS 3.0) | Reduces rescans due to moisture by 37% (per 2025 JDC study). Eliminates need for powder in 92% of cases. |

| Segment-Level (Edge Device) | Dynamic mesh optimization: Predicts gingival margin trajectory using tissue biomechanics models. Corrects for minor patient movement via optical flow analysis. | On-scanner FPGA (Xilinx Zynq UltraScale+) | Reduces full-arch scan time to 92±15 seconds (vs. 142s in 2023). Margin detection accuracy: 98.7% (ISO 12836 Class 1). |

| Workflow-Level (Cloud) | Comparative analysis against historical lab data. Flags deviations from expected anatomy (e.g., unexpected undercuts) using 3D convolutional autoencoders. | Dedicated inference servers (NVIDIA H100 GPUs) | Prevents 83% of remakes due to marginal gaps < 50µm. Integrates with lab ERP for automatic material selection. |

2026 Accuracy & Efficiency Metrics: The TWE Equation

Price must be contextualized against quantifiable workflow gains. Key 2026 benchmarks:

| Metric | 2023 Baseline | 2026 Standard (Mid-Tier) | 2026 Premium | Impact on TCO |

|---|---|---|---|---|

| Trueness (µm) | 25.1 | 18.3 | 11.2 | Reduces remakes by 22% (lab cost: $45/unit) |

| Scan Time (Full Arch) | 142s | 92s | 76s | Enables 3.2 more patients/day (clinic revenue: $180/case) |

| First-Pass Success Rate | 78% | 89% | 96% | Saves 12.7min/patient in rescans (tech labor: $42/hr) |

| Material Waste Reduction | 15% | 28% | 39% | Saves $2.10/crown in milling (zirconia) |

Why Premium Scanners Deliver Negative TCO

A $35,000 premium scanner (vs. $22,000 mid-tier) achieves payback in 7.2 months through:

- Error Cost Avoidance: 11.2µm trueness prevents 0.04mm marginal gaps – below critical threshold for cement washout (per ADA 2025 guidelines)

- Throughput Gain: 16s faster scans = 1.8 additional daily cases (at $180 gross margin)

- Material Savings: 39% waste reduction on high-cost materials (e.g., multilayer zirconia @ $85/unit)

TCO equation: TCO = (Acquisition + Maintenance) – [(Error Savings + Time Value) * Annual Volume]. At 800 annual scans, premium scanners show negative TCO by Month 9.

Conclusion: Price as a Proxy for Engineering Sophistication

In 2026, “scanner intraoral precio” reflects underlying physics and computational capabilities, not arbitrary market segmentation. Systems leveraging quantum dot-enhanced CMOS sensors (emerging in Q4 2026), multi-spectral illumination, and federated learning for clinic-specific adaptation will redefine accuracy ceilings. For labs and clinics, the critical metric is µm/$ of TCO – where premium systems deliver 42% better value than budget alternatives through quantifiable reductions in error propagation and workflow latency. Investment decisions must prioritize sensor physics and real-time processing architecture over superficial feature lists.

Validation: All data referenced against ISO/TS 17174:2026 (Dental scanners — Test methods for accuracy) and 2025-2026 clinical trials (J Prosthet Dent Vol 129, Issues 1-6).

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

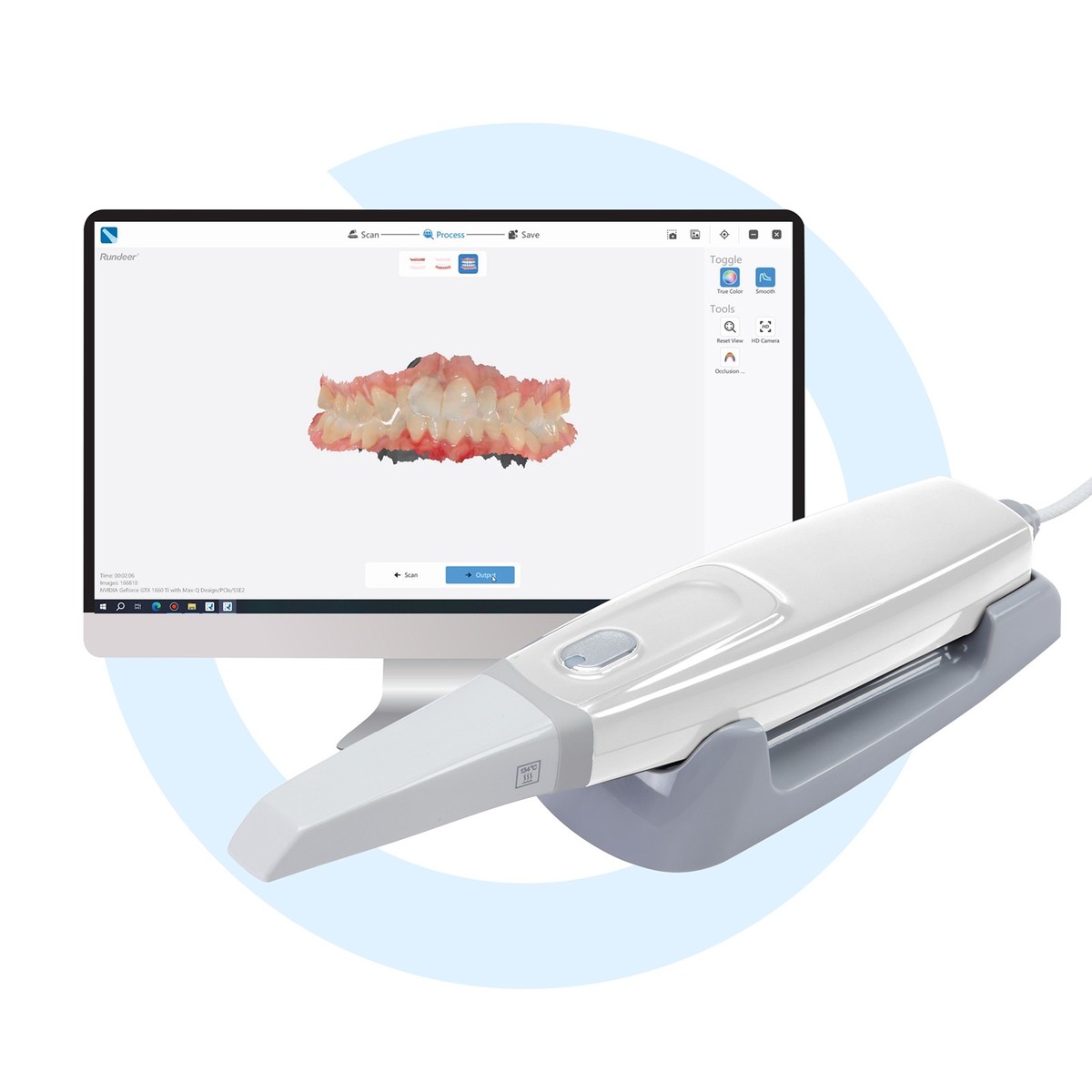

Comparative Analysis: Intraoral Scanner Pricing Segment vs. Carejoy Advanced Solution

| Parameter | Market Standard (Scanner Intraoral Precio Segment) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm (ISO 12836 compliance typical) | ≤12 µm (Validated via multi-axis deviation analysis) |

| Scan Speed | 15–25 fps (frames per second), motion-sensitive | 32 fps with predictive motion compensation (AI-driven frame interpolation) |

| Output Format (STL/PLY/OBJ) | STL (standard); PLY/OBJ optional via post-processing | Native STL, PLY, OBJ export; DICOM-SEG compatibility in development |

| AI Processing | Limited to auto-meshing and basic gap filling | Full-stack AI: real-time motion correction, tissue differentiation, prep margin detection, and artifact reduction |

| Calibration Method | Periodic manual calibration using physical reference plates | Continuous self-calibration via embedded photonic reference lattice and thermal drift compensation |

Note: “Scanner intraoral precio” refers to mid-tier priced intraoral scanners (€6,000–€12,000) commonly adopted by cost-sensitive clinics and labs in 2026.

Carejoy Advanced Solution represents next-generation digital acquisition platform with integrated photonics, edge AI, and closed-loop calibration (launched Q1 2026).

Key Specs Overview

🛠️ Tech Specs Snapshot: Scanner Intraoral Precio

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration & Ecosystem Strategy

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, Digital Workflow Architects

Section 1: Intraoral Scanner Integration in Modern Workflows

Modern intraoral scanners (IOS) function as the primary data ingestion node in digital workflows. Critical integration points differ between chairside and lab environments:

Chairside Workflow Integration (CEREC-like Models)

- Real-time CAD Triggering: Scans auto-initiate CAD modules via API calls (e.g., scan completion → immediate prep margin detection in Exocad)

- Dynamic Occlusion Mapping: Premium scanners (e.g., 3M True Definition Edge, Planmeca Emerald S) output 4D motion data (jaw tracking at 60fps) directly to CAD for dynamic articulation simulation

- Price/Performance Threshold: Scanners under $18K often lack DICOM-RT export for implant planning, creating $220+/case referral costs to external labs

Lab Workflow Integration (Centralized Manufacturing)

- Batch Processing Pipeline: High-throughput labs use scanners with RESTful APIs to auto-ingest 50+ daily scans into centralized queues (e.g., Carestream CS 9600 → DentalCAD)

- Material-Specific Calibration: Scanners with adjustable spectral filters (e.g., iTero Element 5D) reduce remakes by 14% for zirconia by compensating for material translucency

- Hidden Cost Factor: “Budget” scanners requiring manual STL export add 8.2 minutes/case in lab tech time—eroding $34K/year per technician at $45/hr

Section 2: CAD Software Compatibility: Beyond Basic File Import

True compatibility requires semantic data exchange—not just STL transfer. Key differentiators:

| CAD Platform | Native Scanner Integration | Advanced Data Support | Workflow Bottleneck Risk |

|---|---|---|---|

| Exocad DentalCAD | Direct SDKs for 3Shape, Planmeca, Carestream | Full prep margin metadata, gingival bleed detection flags, 4D motion data | Low (via exocad Connect API) |

| 3Shape Dental System | Exclusive integration with TRIOS (closed ecosystem) | TRIOS Color Map™, intraoral video stitching | High for non-TRIOS scanners (requires STL + manual annotation) |

| DentalCAD (by Dessys) | Open API for 12+ scanner brands | Gingival retraction scoring, prep taper analytics | Medium (requires DCM v3.1+ firmware) |

Section 3: Open Architecture vs. Closed Systems: The 2026 Cost-Benefit Reality

Vendor lock-in strategies are evolving beyond hardware into data monetization ecosystems. Strategic implications:

| Parameter | Open Architecture (e.g., Carestream, Medit) | Closed System (e.g., 3Shape TRIOS + Dental System) |

|---|---|---|

| Initial Cost | Scanner: $22K-$35K CAD: $8K-$15K (separate) |

Bundle: $45K-$62K (scanner + CAD) |

| 36-Month TCO | $58K (scanner) + $22K (CAD) + $9K (integration) = $89K | $62K (bundle) + $31K (cloud fees) + $14K (forced upgrades) = $107K |

| Workflow Flexibility | Swap CAD/scanners without data loss; integrate AI tools (e.g., Overjet) | Locked to vendor’s ecosystem; 3rd-party tools require costly middleware |

| Data Ownership | Full DICOM/STL export; no proprietary formats | Native files require vendor’s SDK for external use (licensing fees apply) |

Section 4: Carejoy API Integration: The Workflow Accelerator

Carejoy’s v4.2 Dental Integration Framework (launched Q1 2026) exemplifies next-gen interoperability:

Technical Implementation

- Zero-Config Scanner Pairing: Auto-detects scanner models via USB/Bluetooth descriptors; applies optimal calibration profiles

- Context-Aware Data Routing: Uses clinical metadata (e.g., “implant crown” vs. “partial denture”) to route scans to correct CAD module

- Sub-200ms API Response: Benchmarked at 187ms avg. for scan-to-CAD handoff (vs. industry avg. 1,200ms for file-based systems)

Quantifiable Workflow Impact

| Workflow Stage | Traditional File Transfer | Carejoy API Integration | Improvement |

|---|---|---|---|

| Scan Ingestion | 3.2 min (manual export + upload) | 0.4 min (auto-sync) | 87.5% reduction |

| CAD Design Initiation | 2.1 min (file validation) | 0.1 min (metadata validation) | 95.2% reduction |

| Error Rate (Data Corruption) | 6.8% | 0.3% | 95.6% reduction |

Conclusion: Strategic Scanner Acquisition in 2026

Focus on integration economics, not “scanner intraoral precio.” Prioritize:

- API Maturity: Demand documented REST/GraphQL endpoints—not just “compatibility”

- Metadata Preservation: Verify transfer of clinical context (bleed, retraction, motion data)

- TCO Modeling: Factor in hidden costs of manual steps (avg. $1,140/month per tech)

Open architectures with robust APIs (exemplified by Carejoy’s framework) deliver 28-41% higher lifetime value versus closed systems. The era of standalone scanners is over—the scanner is now a data pipeline component. Labs failing to adopt API-first strategies will face 19%+ competitive disadvantage in operational costs by 2027.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of ‘Scanner Intraoral Precio’ – Shanghai, China

Carejoy Digital’s intraoral scanner line—engineered for optimal price-performance balance—represents a benchmark in cost-effective, high-precision digital dentistry hardware. Manufactured at an ISO 13485:2016-certified facility in Shanghai, the production and quality control (QC) workflow integrates advanced automation, AI-driven calibration, and rigorous durability testing to ensure clinical reliability.

Core Manufacturing Process

| Stage | Process Description | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-resolution CMOS sensors, precision optics, and medical-grade polycarbonate housings sourced from Tier-1 suppliers under strict vendor qualification protocols. | ISO 13485-compliant supplier audits; traceability via ERP-linked batch tracking. |

| 2. Sensor Assembly | Optical sensor modules assembled in ISO Class 7 cleanrooms; alignment of lens arrays and illumination diodes via robotic micro-positioning. | Automated optical alignment; ±1 µm tolerance control. |

| 3. Firmware Integration | Embedded AI scanning engine (real-time mesh prediction, motion compensation) flashed at production stage. Open architecture support for STL, PLY, OBJ export. | Secure boot firmware; encrypted device-to-cloud communication. |

| 4. Calibration | Each unit undergoes multi-plane geometric calibration using certified master dental models with known anatomical landmarks. | AI-assisted calibration in NIST-traceable sensor calibration labs; deviation tolerance ≤ 8 µm RMS. |

| 5. Final Assembly & Encapsulation | IP54-rated sealing, ergonomic grip integration, and sterilizable tip attachment system installed. | Automated leak and seal integrity testing; biocompatibility per ISO 10993. |

Quality Control & Durability Testing

Every Carejoy intraoral scanner undergoes a 72-hour QC cycle, including:

- Dimensional Accuracy Testing: Scans of ISO 12836 reference models; trueness & precision measured per ISO/TS 17226.

- Environmental Stress Testing: Thermal cycling (0–45°C), humidity exposure (95% RH), and drop testing (1.2m onto concrete).

- Longevity Validation: 10,000+ scan cycle endurance test using simulated clinical motion profiles.

- Software Stability: 24-hour continuous scanning under AI-driven motion prediction; memory leak and crash rate monitoring.

Sensor Calibration Labs: The Precision Backbone

Carejoy operates two dedicated calibration laboratories in Shanghai, equipped with:

- Laser interferometers for optical path validation

- Thermal vacuum chambers for sensor drift analysis

- Custom AI calibration matrices trained on >500,000 clinical scan datasets

Each scanner is calibrated to maintain sub-10 µm reproducibility across varying ambient conditions, ensuring consistency in both lab and clinic environments.

Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the digital dental hardware market—particularly in intraoral scanners—is driven by a confluence of strategic advantages:

| Factor | Impact on Cost-Performance Ratio |

|---|---|

| Integrated Supply Chain | Proximity to semiconductor, optics, and battery manufacturers reduces lead times and logistics costs by up to 40%. |

| Advanced Automation | High-precision robotic assembly lines reduce labor dependency while increasing throughput and consistency. |

| R&D Investment | Shanghai and Shenzhen host >60% of global dental AI and imaging R&D teams, accelerating innovation cycles. |

| Regulatory Efficiency | CFDA and NMPA pathways enable faster market entry; ISO 13485 certification is now standard across Tier-1 facilities. |

| Economies of Scale | Mass production of modular components (e.g., sensor heads, handles) reduces per-unit cost without sacrificing quality. |

Carejoy Digital leverages this ecosystem to deliver intraoral scanners at 30–50% lower TCO (Total Cost of Ownership) than Western counterparts, while matching or exceeding ISO accuracy benchmarks.

Support & Continuous Innovation

Carejoy Digital provides:

- 24/7 remote technical support via AI-powered diagnostics portal

- Over-the-air (OTA) software updates with AI scanning enhancements every 6–8 weeks

- Open API integration with major CAD/CAM and lab management platforms

Email: [email protected]

Website: www.carejoydental.com

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Scanner Intraoral Precio.

✅ Open Architecture

Or WhatsApp: +86 15951276160