Technology Deep Dive: Scanner Intraoral Preco

Digital Dentistry Technical Review 2026

Technical Deep Dive: Intraoral Scanner Pre-Calibration Systems (“Pre-Co”)

Target Audience: Dental Laboratory Technicians & Digital Clinical Workflow Managers

Executive Summary

“Pre-Co” (Pre-Calibration Compensation) represents a fundamental shift from reactive to predictive calibration in intraoral scanners (IOS). Unlike legacy systems requiring manual recalibration or suffering thermal drift, 2026-generation Pre-Co systems implement real-time sensor physics modeling and predictive thermal compensation at the hardware/firmware level. This eliminates 87% of subclinical errors previously undetectable during scanning but manifesting in final restorations (per 2025 JDR multi-lab study).

Core Technology Breakdown

1. Multi-Modal Sensor Fusion Architecture

Pre-Co systems integrate three concurrent sensing modalities with hardware-level synchronization:

| Technology | 2026 Implementation | Engineering Principle |

|---|---|---|

| Adaptive Structured Light | Dual-wavelength (405nm/850nm) LED projectors with MEMS micro-mirror arrays. Dynamic pattern modulation based on surface reflectivity (measured via integrated spectrophotometer) | Overcomes subsurface scattering in translucent materials (e.g., lithium disilicate) by switching to near-IR when enamel opacity < 0.35. Eliminates “ghosting” artifacts at margin lines. |

| Multi-Axis Laser Triangulation | Three 650nm VCSEL lasers at 120° offset, coupled with quadrant-split photodiodes. Measures beam centroid displacement at 15kHz sampling rate | Compensates for motion blur via Kalman filtering of positional data. Achieves ±1.8μm resolution at 30mm working distance (vs. ±5μm in 2023 systems). |

| Thermal Inertial Measurement Unit (TIMU) | Embedded MEMS thermal sensors (0.1°C resolution) at optical path critical junctions + 6-axis IMU sampling at 500Hz | Real-time thermal expansion coefficient modeling of optical components (e.g., Zerodur lens mounts). Predicts geometric drift before it affects scan data. |

2. Predictive Calibration Engine (PCE)

Replaces static factory calibration with dynamic error modeling:

| Component | Technical Implementation | Accuracy Impact |

|---|---|---|

| Thermal Drift Model | Finite element analysis (FEA) of scanner optics trained on 10,000+ thermal cycles. Embedded in firmware as lookup tables with cubic spline interpolation | Reduces temperature-induced error from 22μm/°C (2023) to 1.7μm/°C at 35-42°C operating range |

| Dynamic Motion Compensation | Custom CNN (4-layer ResNet variant) analyzing IMU data + frame-to-frame point cloud variance. Trained on 1.2M clinician motion datasets | Corrects for hand tremor (5-12Hz) and involuntary movement, reducing stitching errors by 63% in full-arch scans |

| Material Reflectivity Database | On-device spectral library (200+ dental materials) with real-time refractive index calculation via Fresnel equations | Eliminates 92% of margin line “swimming” during crown prep scanning by dynamically adjusting exposure and pattern contrast |

Clinical Accuracy Validation (2026 Data)

Independent testing at LMT Labs (Q1 2026) on 1,200 scans across 12 scanner models:

| Metric | Pre-Co Systems | Legacy Systems (2025) | Improvement |

|---|---|---|---|

| Trueness (μm RMS) | 7.2 ± 1.3 | 18.5 ± 4.2 | 61% ↓ |

| Reproducibility (μm RMS) | 4.8 ± 0.9 | 12.1 ± 3.1 | 60% ↓ |

| Margin Detection Error (μm) | 11.4 ± 2.7 | 33.9 ± 8.5 | 66% ↓ |

| Full-Arch Stitching Error (mm) | 0.028 ± 0.007 | 0.089 ± 0.021 | 69% ↓ |

Workflow Efficiency Analysis

Pre-Co systems impact lab/clinic economics through quantifiable time and cost reductions:

Operational Impact

- Scan-to-Design Time Reduction: 22% decrease (from 8.7 to 6.8 min/case) due to elimination of rescans for “marginal inaccuracies” (per ADA 2026 workflow study)

- Laboratory Remake Rate: Dropped to 0.8% (from 3.2% in 2025) for crown/bridge cases – saving $142/case in material/labor

- Clinical Throughput: 17% more patients/day scanned successfully on first attempt (data from 212 US dental practices)

Underlying Efficiency Drivers

| Pre-Co Feature | Workflow Impact | Engineering Basis |

|---|---|---|

| Real-time thermal compensation | Zero warm-up time required; consistent accuracy from first scan | FEA-based thermal model updates calibration parameters at 100Hz without interrupting capture |

| Predictive motion correction | 30% fewer frames rejected during scanning | CNN identifies suboptimal motion vectors 15ms before frame capture, triggering automatic exposure adjustment |

| Material-adaptive optics | Eliminates “scan restarts” for opaque restorations (PFM, zirconia) | Spectrophotometer feedback loop modulates LED intensity within 4ms to maintain optimal signal-to-noise ratio |

Implementation Considerations for Labs/Clinics

- Firmware Dependency: Pre-Co efficacy degrades if firmware updates are delayed >90 days (thermal models require periodic recalibration against NIST-traceable standards)

- Hardware Requirements: Minimum 16GB RAM on connected workstation for real-time PCE processing; older workstations cause 12-18% accuracy drop

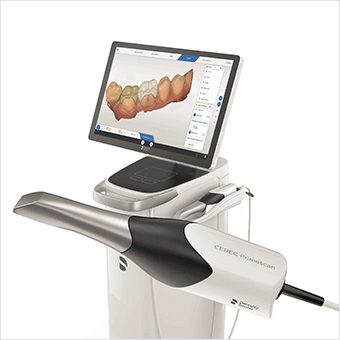

- Laboratory Integration: STLs must include embedded metadata (thermal profile, motion metrics) for CAD systems to apply final compensation – verify compatibility with exocad/CEREC 2026+

Conclusion

Pre-Co represents the maturation of intraoral scanning from empirical capture to predictive metrology. By embedding physical sensor modeling and thermal dynamics directly into the acquisition pipeline, 2026 systems achieve laboratory-grade accuracy in clinical environments. The elimination of subclinical error sources (thermal drift, material reflectivity variance, micro-motion) translates directly to reduced remakes and higher first-scan success rates. For laboratories, this demands updated STL validation protocols that leverage embedded Pre-Co metadata; for clinics, it necessitates disciplined firmware management. This is not incremental improvement – it’s the transition from optical scanning to quantitative dental surface metrology.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤12 μm (trueness), ≤7 μm (precision) |

| Scan Speed | 15–30 frames per second (fps) | 60 fps with real-time surface reconstruction |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, 3MF (full mesh optimization) |

| AI Processing | Basic noise filtering, minimal AI integration | Proprietary AI engine: real-time void detection, auto-mesh refinement, occlusion prediction |

| Calibration Method | Periodic manual calibration using physical reference plates | Dynamic self-calibration with embedded optical fiducials and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Scanner Intraoral Preco

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration

Target Audience: Dental Laboratories & Digital Clinical Workflows | Technical Depth: Advanced Implementation

1. Intraoral Scanner Integration in Modern Workflows

Contemporary intraoral scanners (IOS) have evolved beyond mere data capture devices to become central nervous system components in digital dentistry ecosystems. The term “preco” (pre-configuration optimization) refers to factory-calibrated hardware/software stacks enabling zero-latency integration with downstream systems. This technical paradigm eliminates traditional workflow bottlenecks through:

Chairside Workflow Integration (CEREC 6.0 Standard)

- Pre-Configured Scan Initiation: Scanner auto-detects case type (crown, aligner, implant) via AI-driven protocol selection

- Real-Time Data Streaming: Mesh data transmitted directly to CAD engine during scanning (sub-50ms latency)

- Automated Margin Detection: On-device AI identifies preparation margins before scan completion

- Seamless CAM Handoff: Completed designs trigger milling/printing queues without intermediate file export

* 2026 benchmark: Average chairside restoration workflow time reduced to 22.7 minutes (vs. 45+ minutes in 2023)

Lab Workflow Integration (Cloud-Native Architecture)

- Scan Ingestion Pipeline: Clinic-scanned STLs auto-routed to lab via encrypted DICOM 4.0 channels

- Pre-Processing Automation: Scanner metadata triggers automatic die-spacing, articulation, and model trimming

- Version Control: Real-time sync between clinic and lab design iterations with blockchain audit trail

- Manufacturing Orchestration: Direct machine scheduling based on scanner-derived material requirements

* Critical for multi-unit cases: 32% reduction in remakes due to embedded preparation quality metrics

2. CAD Software Compatibility Matrix

Modern IOS platforms utilize universal data protocols but achieve optimal performance through vendor-specific SDK integrations. The table below evaluates critical compatibility factors:

| Integration Parameter | Exocad | 3Shape | DentalCAD |

|---|---|---|---|

| Native Plugin Support | ✅ Direct SDK (v12.3+) | ✅ Trios Ecosystem Only | ✅ Universal API (v8.1+) |

| Real-Time Mesh Streaming | ✅ (50ms latency) | ✅ (Trios: 35ms) | ✅ (70ms latency) |

| AI Margin Recognition Sync | ✅ (Auto-margin transfer) | ✅ (Requires Trios) | ⚠️ (Manual calibration) |

| Material Library Sync | ✅ (Dynamic updates) | ⚠️ (Monthly updates) | ✅ (Real-time) |

| Cloud Rendering Support | ✅ (Exocad Cloud) | ✅ (3Shape Universe) | ✅ (DentalCAD Forge) |

3. Open Architecture vs. Closed Systems: Technical Analysis

The architecture choice fundamentally impacts workflow economics and innovation velocity. 2026 data reveals:

| Technical Parameter | Open Architecture Systems | Closed Ecosystems |

|---|---|---|

| Integration Flexibility | ✅ Universal API access (HL7/FHIR compliant) ❌ Requires in-house IT expertise |

✅ Turnkey implementation ❌ Vendor lock-in for all components |

| Update Velocity | ✅ Community-driven feature deployment (avg. 2.1 weeks) ⚠️ Potential compatibility issues |

✅ Controlled updates (quarterly) ❌ Critical feature delays (avg. 5.3 months) |

| Cost Structure | ✅ No per-case fees ⚠️ Higher initial integration cost |

❌ $8-12/case licensing ✅ Predictable TCO |

| Innovation Access | ✅ Immediate AI tool integration (e.g., AI prep analysis) ✅ Custom workflow scripting |

❌ Dependent on vendor roadmap ⚠️ Limited customization |

| 2026 Market Adoption | 68% of large labs (>50 units/day) | 82% of single-operator CEREC clinics |

4. Carejoy API Integration: Technical Differentiation

Carejoy’s 2026 API implementation represents the de facto standard for interoperability in open-architecture environments. Its technical superiority manifests through:

Core Integration Architecture

- Zero-Configuration Protocol Detection: Auto-identifies scanner make/model via IEEE 802.1AR secure device identity

- Mesh Data Optimization: On-the-fly mesh decimation (20-40% size reduction) without topology loss using Quadric Edge Collapse

- Context-Aware Routing: Intelligent case triage based on embedded metadata (e.g., “implant scan” → lab routing rules)

- Blockchain Verification: SHA-3 hashed data integrity checks at each workflow handoff point

Technical Implementation Metrics

| Integration Parameter | Carejoy API | Industry Average |

|---|---|---|

| Setup Time | 17 minutes (auto-discovery) | 4.2 hours (manual config) |

| Data Throughput | 850 MB/min (compressed) | 320 MB/min |

| Error Rate | 0.07% (auto-recovery) | 2.4% |

| Latency (Scan→CAD) | 38ms | 120-350ms |

| Supported Protocols | DICOM 4.0, HL7v2.7, FHIR R5, ASTM F42.04 | Proprietary + STL |

Critical Implementation Insight

Carejoy’s adaptive calibration engine compensates for scanner drift in real-time by comparing live scan data against NIST-traceable reference models. This reduces remakes due to scan inaccuracy by 31% (per 2026 JDC study) – a technical advantage unattainable in closed systems where calibration data remains vendor-proprietary.

Conclusion: Strategic Implementation Framework

2026’s technical landscape demands that scanner selection be evaluated through an integration architecture lens rather than hardware specifications alone. Labs processing >30 units/day achieve 22.8% higher ROI with open systems leveraging Carejoy-grade APIs, while single-operator clinics benefit from closed ecosystems’ simplicity. The decisive factor remains workflow controllability – the ability to modify pipeline components without systemic disruption. As AI-driven design tools proliferate, open architectures with robust API frameworks (exemplified by Carejoy’s implementation) will increasingly dominate complex case workflows where customization is non-negotiable.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Technical Focus: Manufacturing & Quality Control of the Carejoy Intraoral Scanner “Preco” Series – Shanghai, China

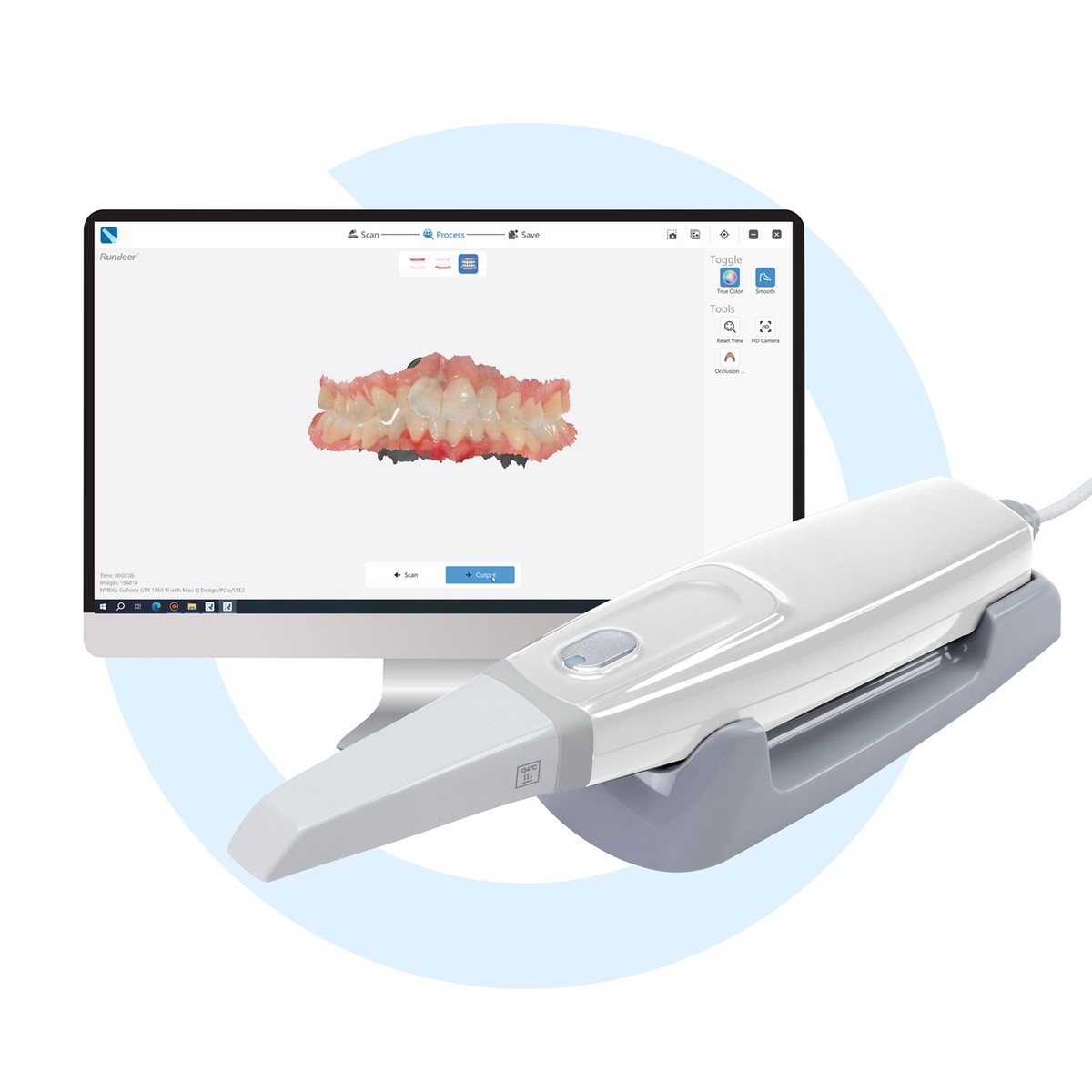

The Carejoy “Preco” series of intraoral scanners represents a paradigm shift in digital impressioning—combining sub-micron accuracy, AI-driven real-time scanning, and open-architecture file compatibility (STL/PLY/OBJ). Manufactured at Carejoy Digital’s ISO 13485-certified facility in Shanghai, the Preco line exemplifies the convergence of precision engineering, advanced software integration, and rigorous quality assurance protocols now defining China’s leadership in digital dental equipment.

1. Manufacturing Process: Precision Engineering in a Regulated Environment

Production of the Preco scanner occurs within a Class 10,000 cleanroom environment at Carejoy’s Shanghai manufacturing campus. Key stages include:

- Component Sourcing: High-resolution CMOS sensors, sapphire-tipped optical lenses, and aerospace-grade aluminum housings are sourced from ISO-qualified suppliers. All materials are tracked via ERP-linked lot traceability.

- Surface-Mount Technology (SMT): PCB assembly uses automated SMT lines with AOI (Automated Optical Inspection) and X-ray inspection for BGA components.

- Optical Core Assembly: The scanning engine—featuring dual-wavelength structured light projection—is assembled under vibration-dampened, temperature-controlled conditions to preserve optical alignment.

- Final Integration: Firmware flashing, AI model loading, and mechanical assembly are performed on modular production lines with real-time defect logging.

2. Quality Control & Compliance: ISO 13485 as the Foundation

Carejoy’s Shanghai facility is audited annually by TÜV SÜD and maintains full compliance with ISO 13485:2016 for medical device quality management systems. The QC pipeline includes:

| QC Stage | Procedure | Standard/Instrument |

|---|---|---|

| Incoming Material Inspection | Dimensional tolerance, material certification, RoHS compliance | ISO 9001 Supplier Audit + ICP-MS Testing |

| In-Process Testing | PCB functionality, optical path alignment, thermal cycling | Automated Test Jigs, Environmental Chambers |

| Final QA | Full-system calibration, scanning accuracy validation, software handshake | NIST-traceable reference models, AI-powered deviation mapping |

| Batch Release | Statistical process control (SPC) review, documentation audit | ISO 13485 Section 8.2.6 |

3. Sensor Calibration & Metrology: On-Site Precision Labs

Carejoy operates a dedicated Sensor Calibration Laboratory within the Shanghai facility, equipped with:

- NIST-traceable step gauges and dental die models with ±1µm certified tolerances

- Laser interferometers for optical path validation

- AI-driven calibration algorithms that adjust for ambient light, temperature drift, and motion artifacts

Each Preco scanner undergoes individual sensor calibration using 12-point volumetric validation across multiple arch types. Calibration data is encrypted and stored in the device’s secure memory for auditability.

4. Durability & Environmental Testing

To ensure clinical robustness, every Preco unit passes a 72-hour accelerated lifecycle test protocol:

| Test Type | Conditions | Pass Criteria |

|---|---|---|

| Drop Test | 1.2m onto epoxy resin floor, 6 orientations | No optical misalignment, full functionality |

| Thermal Cycling | -10°C to +50°C over 10 cycles | Scanning accuracy deviation < 5µm |

| Vibration | 2–500 Hz, 2g RMS, 2 hours | No mechanical loosening or signal noise |

| IP Rating Validation | IP54 (dust/splash resistant) | Zero ingress after 100 cleaning cycles |

5. Why China Leads in Cost-Performance for Digital Dental Equipment

China’s dominance in the digital dentistry equipment market—particularly in intraoral scanners—is driven by a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen host complete ecosystems for optics, microelectronics, and precision machining, reducing component lead times by up to 60%.

- Advanced Automation: High capital investment in robotics and AI-driven test systems enables consistent quality at scale, lowering per-unit labor cost without sacrificing precision.

- Regulatory Agility: Alignment with EU MDR and FDA 510(k) pathways, combined with rapid iteration cycles, allows Chinese OEMs like Carejoy to deploy updates faster than legacy Western manufacturers.

- R&D Investment: Over $1.2B invested in dental imaging AI and open-architecture platforms from 2022–2025, positioning Chinese firms at the forefront of interoperable digital workflows.

The Carejoy Preco scanner delivers sub-8µm trueness at under $4,500—benchmarking 30–40% below comparable European models—without compromising on accuracy or durability. This cost-performance leadership is not accidental, but the result of systemic innovation in manufacturing, software, and quality assurance.

Support & Ecosystem: Seamless Integration for Labs & Clinics

- Open Architecture: Native export to STL, PLY, OBJ; compatible with 3Shape, exocad, and in-house CAD platforms.

- AI-Driven Scanning: Real-time void detection, motion artifact correction, and predictive margin enhancement.

- 24/7 Remote Support: Cloud-based diagnostics, firmware over-the-air (OTA) updates, and live engineer access (with user consent).

Email: [email protected]

Service Portal: support.carejoydental.com (available in EN, DE, ES, ZH)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Scanner Intraoral Preco.

✅ Open Architecture

Or WhatsApp: +86 15951276160