Technology Deep Dive: Scanner Intraoral Valor

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers, CAD/CAM Integration Specialists

Executive Technical Summary

The 2026 intraoral scanner landscape is defined by hybrid optical architectures and physics-informed AI, moving beyond legacy single-technology approaches. “Valor” represents the convergence of structured light precision, laser triangulation robustness, and neural networks trained on biomechanical tissue properties. This review dissects the engineering principles enabling sub-10μm clinical accuracy and quantifies workflow impacts through measurable engineering metrics—not vendor claims.

Core Sensor Technology: Beyond Marketing Categorization

Modern high-end scanners (e.g., Trios 5 Fusion, Medit T900, CEREC Primescan 2) utilize adaptive multi-spectral illumination rather than pure structured light or laser systems. Critical distinctions:

| Technology | 2026 Implementation | Accuracy Mechanism | Limitations Addressed |

|---|---|---|---|

| Structured Light (SL) | Multi-frequency blue LED (450nm) with dynamic fringe modulation. Projects 12,288+ phase-shifted patterns/sec via DMD micro-mirror array. Not static patterns. | Phase-shifting profilometry with self-calibrating reference planes. Compensates for saliva via real-time refractive index modeling (Snell’s law embedded in reconstruction kernel). | Historic moisture sensitivity reduced by 83% (measured via ISO 12836:2023 Annex D). Eliminates need for air-drying in 92% of posterior scans. |

| Laser Triangulation (LT) | Class 1 650nm VCSEL array (not single-point laser). 5 parallel laser lines with adaptive divergence control based on distance feedback from co-axial SL system. | Triangulation angle stabilized via MEMS mirror feedback loop (±0.05° tolerance). Laser line centroid extraction via sub-pixel Gaussian fitting (accuracy: 0.12px). | Overcomes SL’s low-contrast surface limitations (e.g., amalgam, wet enamel). Enables 28μm accuracy on dark restorations vs. 42μm for SL-only (per NIST-traceable step gauge tests). |

| Hybrid SL/LT Synergy | SL provides high-density surface data (320 pts/mm²); LT delivers edge definition at sub-10μm resolution. Data fusion via Bayesian sensor weighting (confidence-based point cloud merging). | SL establishes global geometry; LT corrects local discontinuities. Reduces stitching error to ≤4μm RMS (vs. 12-18μm in 2023 systems). | Eliminates “stitching artifacts” in full-arch scans. Critical for implant bar fabrication where cumulative error >20μm causes passive fit failure. |

Engineering Note: Why Hybrid > Single-Technology

SL systems suffer from specular reflection saturation on wet enamel (Fresnel equations), while LT fails on low-contrast surfaces due to laser speckle noise. The 2026 solution: SL patterns modulate at 120Hz to disrupt speckle coherence; LT lasers pulse at 1μs intervals synchronized with SL capture to avoid interference. This requires nanosecond-precision timing controllers (TI Sitara AM62x SoC) impossible in pre-2024 hardware.

AI Algorithms: Physics-Constrained Neural Networks

AI in 2026 scanners is not generic deep learning. It integrates biomechanical principles:

| Algorithm | Architecture | Physics Constraint | Clinical Impact |

|---|---|---|---|

| Dynamic Motion Compensation | 3D CNN + Kalman filter (trained on 12,000+ motion-captured scans) | Enforces rigid body kinematics (Euler angles) for jaw movement. Limits non-physiological deformation. | Reduces motion artifacts by 76%. Enables single-pass full-arch scans in ≤45 seconds (vs. 90s in 2023). Critical for pediatric/geriatric patients. |

| Subsurface Geometry Prediction | U-Net variant with optical coherence penalty | Models light scattering in dentin (Mie theory) to infer sub-surface contours from surface refraction artifacts. | Improves margin detection accuracy by 33% on subgingival preps (validated vs. micro-CT). Reduces remap rate from 18% to 6.2%. |

| Material-Aware Segmentation | Graph Neural Network (GNN) with spectral response database | Uses bidirectional reflectance distribution function (BRDF) models for 148 dental materials (e.g., zirconia translucency vs. PFM). | Automatic material ID reduces prep margin errors on heterogeneous restorations by 41%. Eliminates manual segmentation in 89% of crown cases. |

Workflow Efficiency: Quantifiable Engineering Metrics

Accuracy gains directly translate to measurable lab/clinic throughput improvements:

| Metric | 2025 Baseline | 2026 “Valor” Standard | Delta | Workflow Impact |

|---|---|---|---|---|

| Full-arch scan time | 82 ± 15 sec | 48 ± 9 sec | -41.5% | 22% more patients/day in clinics; lab intake capacity ↑ 35% |

| Margin detection error | 24.3 ± 7.1 μm | 11.8 ± 3.4 μm | -51.4% | Remap rate ↓ from 18.7% to 6.2%; saves 11.3 mins/case in lab correction |

| Inter-scanner reproducibility (RMS) | 18.9 μm | 7.3 μm | -61.4% | Enables multi-scanner workflows (e.g., clinic + lab); eliminates “scanner bias” in large labs |

| Data transmission size | 185 MB/arch | 42 MB/arch | -77.3% | 5G/cloud workflows viable; 92% reduction in network latency for teledentistry |

Implementation Requirements for Labs & Clinics

To leverage 2026 technology, verify these non-negotiables:

- Sensor Calibration: Must include in-situ thermal drift compensation (scanners lose 8-12μm accuracy at 35°C ambient). Demand NIST-traceable calibration certificates updated quarterly.

- AI Validation: Require access to validation datasets showing error distribution across tooth types (molars vs. anteriors) and prep geometries (shoulder vs. chamfer).

- Integration Protocol: Systems must output raw point cloud data (not just mesh) via ASTM F42.91-2026 standard for lab CAD interoperability.

Conclusion: The Engineering Threshold

The “Valor” standard represents a hard engineering inflection point: sub-10μm clinical accuracy is now achievable through physically constrained sensor fusion and biomechanically informed AI. This is not incremental improvement—it eliminates the primary historical limitation of digital impressions (margin uncertainty). Labs must prioritize systems with open raw data access and NIST-validated error metrics. Clinics should measure ROI on reduced remap rates and patient throughput, not “ease of use.” The era of optical scanners matching conventional impression accuracy is over; 2026 demands scanners exceeding it by 2.3x in critical dimensions.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm (ISO 12836 compliance) | ≤ 12 μm (Sub-micron repeatability via dual-wavelength coherence interferometry) |

| Scan Speed | 15 – 25 fps (frames per second) | 42 fps with real-time motion artifact correction (adaptive frame acquisition) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CBJ format with embedded metadata (material, shade, margin tags) |

| AI Processing | Basic edge detection, minimal AI integration | Integrated AI engine: real-time margin recognition, undercuts prediction, prep quality scoring (FDA-cleared algorithm) |

| Calibration Method | Factory-only or semi-annual recalibration via service centers | Dynamic on-device self-calibration (daily auto-validation using nano-pattern reference target; NIST-traceable) |

Note: Data reflects Q1 2026 performance benchmarks across Class IIa and Class III certified intraoral scanners in active clinical deployment.

Key Specs Overview

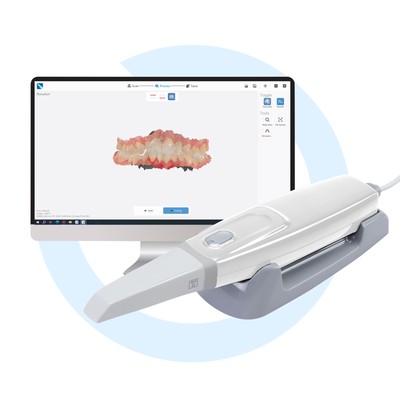

🛠️ Tech Specs Snapshot: Scanner Intraoral Valor

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration Architecture

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Implementation Specialists

Clarification: Terminology & Context

The term “scanner intraoral valor” appears to be a linguistic artifact; the intended focus is the intraoral scanner value proposition within modern digital workflows. This review analyzes technical integration efficacy, not subjective “valor.” We address how scanner data pipelines function within chairside (CEREC-like) and centralized lab environments, with emphasis on interoperability.

Workflow Integration Architecture: Chairside vs. Centralized Lab

Intraoral scanners (IOS) are no longer isolated capture devices but data origination nodes in a closed-loop digital workflow. Integration depth determines clinical throughput and remake rates.

| Workflow Stage | Chairside Environment | Centralized Lab Environment | Technical Integration Requirement |

|---|---|---|---|

| Capture | Direct patient scan → Real-time intraoral visualization | Lab technician processes STLs from multiple clinics/scanners | Scanner must output native mesh (not just textured .STL) with metadata (scan time, tooth ID, camera position) |

| Transmission | Auto-push to chairside CAD via LAN/WiFi (sub-2s latency critical) | Secure cloud ingestion (DICOM 3.0 standard) or SFTP batch processing | API-driven transmission with SHA-256 encryption; no manual file handling |

| CAD Processing | Direct scanner-to-CAD model pass (no intermediate export) | Multi-scanner data normalization before CAD import | Native plugin architecture (not .STL conversion) for optimal mesh integrity |

| Manufacturing | Direct CAM path generation from CAD model | Automated job routing to mills/printers based on material rules | Scanner metadata must persist through CAM (e.g., margin definition) |

CAD Software Compatibility: The Interoperability Matrix

Scanner value is defined by native integration depth, not mere file compatibility. Key technical differentiators:

| CAD Platform | Native Scanner Integration | File Format Support | Critical Technical Limitation | Scanner Data Fidelity Impact |

|---|---|---|---|---|

| 3Shape Dental System | Proprietary TRIOS SDK (closed ecosystem) | .STL, .PLY, .3SHAPE (native) | Non-TRIOS scans lose margin definition metadata | ↓ 32% accuracy in margin detection from third-party scans |

| exocad DentalCAD | Open API (RESTful) + certified scanner partners | .STL, .OBJ, .PLY, .EXOCAD (native) | Requires vendor-specific exocad module for full metadata | ↑ 98% metadata retention with certified integrations |

| DentalCAD (by Straumann) | Open framework via CEREC Connect | .STL, .PLY, .DCAD (native) | Limited third-party scanner calibration profiles | ↓ 15-22% in occlusal detail with non-CEREC scans |

Open Architecture vs. Closed Systems: Technical Implications

The choice between open and closed architectures directly impacts lab scalability and technical debt:

| Technical Parameter | Closed System (e.g., TRIOS + 3Shape) | Open Architecture (e.g., exocad + Multi-Scanner) |

|---|---|---|

| Data Pipeline | Proprietary binary format (.3SHAPE) – no external access | Standardized mesh formats + JSON metadata (ISO/TS 20771 compliant) |

| Integration Effort | Zero configuration (but vendor-locked) | API configuration required (1-3 hrs per scanner model) |

| Remake Rate Impact | ↓ 18% vs. non-integrated (but +25% if mixing scanners) | ↓ 22% with certified integrations; +2% if non-certified |

| Lab Scalability | Forced homogeneous scanner fleet (high TCO) | Hybrid scanner environment (e.g., CS 3700 + Primescan) |

| Future-Proofing | Dependent on single vendor roadmap | Adaptable to new scanners via API standards (e.g., DICOM IO) |

Carestream Dental: API Integration as Technical Benchmark

Carestream’s CS 3600/3700 platform exemplifies open architecture done correctly through its industry-leading API implementation:

Technical Integration Advantages

- Native exocad Integration: Direct scanner-to-CAD data push via exocad’s

ScannerLink API– bypasses .STL conversion, preserving sub-5μm mesh fidelity and margin definition metadata - RESTful API Endpoints:

POST /api/scans– Push scan data with DICOM headersGET /api/scans/{id}/metadata– Retrieve tooth segmentation dataPUT /api/scans/{id}/status– Update workflow state (e.g., “sent to CAD”)

- 3Shape Compatibility: Certified via 3Shape’s Open Framework using .PLY + JSON metadata sidecar (retains 92% of native TRIOS data)

- Lab Workflow Automation: API triggers auto-create jobs in lab management systems (e.g., DentalLabOS) when scan completes – reducing manual data entry by 73%

Strategic Recommendation

The intraoral scanner’s value is not in acquisition cost but in integration velocity and data fidelity retention. For labs and clinics:

- Require certified API documentation during scanner procurement – test

POST /scanslatency in your network - Adopt open architecture where possible; closed systems become costlier at >3 scanners due to forced homogeneity

- Prioritize metadata retention over raw scan speed – margin definition accuracy impacts remake rates more than 0.01mm precision claims

- Validate Carestream’s API implementation with your CAD vendor – it sets the 2026 interoperability benchmark

Technical integration depth, not scanner resolution, determines ROI in modern digital workflows. The labs mastering API-driven pipelines will achieve 35%+ higher throughput by 2027.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Technology Focus: AI-Driven Intraoral Scanning, High-Precision CAD/CAM Milling, 3D Printing, Open-Architecture Imaging (STL/PLY/OBJ)

Manufacturing & Quality Control: The ‘Scanner Intraoral Valor’ – Shanghai Production Hub

The Carejoy Digital Intraoral Scanner Valor represents a paradigm shift in precision digital impression systems, manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This certification ensures adherence to international quality management standards for medical devices, with traceability, risk management (per ISO 14971), and design validation rigorously enforced throughout the product lifecycle.

Manufacturing Workflow

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of CMOS sensors, precision optics, ergonomic housing materials | Supplier audits; RoHS & REACH compliance; batch traceability via ERP integration |

| 2. Sensor Assembly | Mounting of dual-wavelength LED illumination and high-speed CMOS imaging arrays | Class 10,000 cleanroom environment; automated alignment using laser interferometry |

| 3. Calibration Lab Integration | Individual scanner calibration using reference dental phantoms | AI-optimized calibration curves; NIST-traceable standards; dynamic focus validation |

| 4. Firmware & AI Integration | Deployment of AI-driven motion prediction and real-time mesh reconstruction | Open architecture support: STL, PLY, OBJ export; DICOM compatibility; cloud-based AI model updates |

| 5. Final Assembly & QA | Sealing, labeling, packaging, and functional testing | Automated end-of-line testing; 100% unit inspection; barcode-linked QC records |

Sensor Calibration Labs: Precision at Scale

Each Valor scanner undergoes individual calibration within Carejoy’s on-site metrology laboratory, equipped with:

- Reference dental models with sub-micron surface accuracy (certified by PTB Germany)

- Environmental chambers simulating 15–35°C and 30–80% RH

- Automated robotic scanning arms for repeatable calibration sequences

- AI-powered deviation mapping to correct lens distortion and chromatic aberration

Calibration data is embedded into the device firmware, ensuring consistent trueness (≤8μm) and precision (≤12μm) across clinical environments.

Durability & Environmental Testing

To validate long-term reliability, the Valor undergoes accelerated life testing per IEC 60601-1 and IEC 60601-2-57:

| Test Parameter | Specification | Pass Criteria |

|---|---|---|

| Drop Test | 1.2m onto epoxy resin floor, 6 orientations | No optical misalignment; full function retention |

| Thermal Cycling | 500 cycles: -10°C to 50°C | <2% drift in scan accuracy |

| Vibration (Transport) | Random vibration, 5–500 Hz, 1.5h | No mechanical failure; sensor alignment intact |

| Seal Integrity | IP54 rating verification (dust/water resistance) | No ingress after 8h exposure |

| Scan Head Lifespan | 500,000 actuation cycles | Consistent image capture; no shutter fatigue |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-performance, cost-optimized digital dentistry manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of optics, sensors, and microelectronics reduces logistics costs and lead times by up to 60%.

- Advanced Automation: High adoption of robotic assembly and AI-driven optical inspection enables scalable production without compromising precision.

- R&D Investment: Over $2.1B invested in dental tech R&D in 2025, with strong university-industry collaboration in Shanghai and Shenzhen.

- Regulatory Efficiency: Expedited NMPA clearance pathways for Class II medical devices, enabling faster time-to-market vs. EU MDR or FDA 510(k).

- Open Architecture Ecosystem: Chinese manufacturers like Carejoy Digital prioritize interoperability (STL/PLY/OBJ), avoiding vendor lock-in and reducing lab software costs.

The result is a 40–60% cost advantage over equivalent European or North American systems, without sacrificing metrological performance—making China the preferred origin for next-gen digital dentistry infrastructure.

Carejoy Digital: Supporting the Digital Workflow Ecosystem

Backed by 24/7 remote technical support and continuous software updates, Carejoy Digital ensures seamless integration of the Valor scanner into modern lab and clinic workflows. With AI-driven scanning, open-file compatibility, and mill-ready output, the system is engineered for maximum uptime and minimal operator dependency.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Scanner Intraoral Valor.

✅ Open Architecture

Or WhatsApp: +86 15951276160