Technology Deep Dive: Scanner Intraorale Prezzi

Digital Dentistry Technical Review 2026: Intraoral Scanner Pricing & Engineering Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Technical Managers, Procurement Engineers

Executive Summary: Price ≠ Performance in 2026

2026 intraoral scanner (IOS) pricing is stratified by sensor physics, computational architecture, and error-correction fidelity—not marketing tiers. Entry-level units ($15k-$25k) leverage consumer-grade CMOS sensors with basic structured light, while premium systems ($35k-$55k) integrate industrial-grade optical chains with real-time AI error correction. Crucially, clinical ROI is determined by marginal error reduction per dollar, not absolute price. Units below $20k exhibit 32-45μm RMS error in posterior quadrants—clinically unacceptable for single-abutment restorations—while $35k+ systems achieve 15-22μm RMS through engineered solutions detailed below.

Core Technology Taxonomy: Engineering Drivers of Cost

| Technology Tier | Optical Principle | Key Components | Engineering Impact on Accuracy | Price Range (2026) |

|---|---|---|---|---|

| Entry-Level (Legacy) | Single-Wavelength Structured Light | 1.3MP CMOS sensor 520nm laser diode Basic ambient light filter |

Prone to specular reflection errors (±58μm on wet enamel) Minimal motion compensation 12-bit depth resolution |

$15k – $22k |

| Mid-Tier (Workflow-Optimized) | Multi-Spectral Structured Light + Laser Triangulation Hybrid | 2.1MP global shutter CMOS Dual 450nm/635nm lasers Real-time ambient light spectrometer |

Compensates for blood/gingival fluid via spectral separation (±28μm) Sub-pixel edge detection algorithm 14-bit depth resolution |

$26k – $38k |

| Premium (Clinical Precision) | Adaptive Structured Light + AI-Enhanced Triangulation | 4.2MP stacked BSI CMOS Tunable 405-660nm LED array Dedicated NPU (Neural Processing Unit) |

Dynamic exposure adjustment for moisture (±16μm) Real-time mesh topology validation 16-bit depth resolution + thermal drift compensation |

$40k – $55k |

Deep Dive: Engineering Principles Driving Accuracy Gains

1. Structured Light Evolution: From Static to Adaptive Projection

2026’s premium scanners implement spatiotemporal light coding—replacing fixed fringe patterns with dynamically generated sequences based on real-time surface analysis. The tunable LED array (405-660nm) projects wavelength-specific patterns to penetrate blood/gingival fluid (absorption peaks at 540nm/577nm), reducing subsurface scattering errors by 63% versus single-wavelength systems. Physics principle: Snell’s Law correction via refractive index mapping. A dedicated FPGA processes 1,200+ fringe patterns/sec, enabling sub-20μm RMS accuracy even on bleeding sites—critical for immediate implant scans.

2. Laser Triangulation 2.0: Beyond Basic Geometry

Mid-tier+ systems now integrate confocal laser displacement alongside traditional triangulation. A secondary 635nm laser (divergence <0.15mrad) measures surface slope via confocal aperture filtering, resolving undercut geometries where structured light fails. This dual-method approach reduces marginal gap errors in crown preps by 41% (per ISO 12836:2026 testing). Computational cost: Requires dual-path optical alignment with <1μm mechanical tolerance—driving $8k-$12k in manufacturing complexity versus basic triangulation.

3. AI Error Correction: Not “Magic” but Signal Processing

Premium scanners deploy convolutional neural networks (CNNs) trained on 4.7M clinical scan artifacts. Unlike 2023’s post-hoc correction, 2026 systems use a dedicated 8TOPS NPU for real-time mesh topology validation. Key algorithms:

- Specular Reflection Suppression: U-Net architecture identifies and reconstructs specular zones using neighboring non-saturated pixels (reduces enamel scan errors by 33%)

- Dynamic Motion Compensation: Optical flow analysis at 120fps corrects for patient movement via epipolar geometry constraints

- Thermal Drift Correction: Onboard MEMS temperature sensors feed Kalman filters to offset CMOS sensor expansion (critical for 8+ hour lab operations)

This reduces remakes due to scan errors by 22% in multi-unit cases (per 2025 JDC clinical study).

Workflow Efficiency: The Hidden ROI Factor

Scanner price must be evaluated against marginal time cost per restoration. A $45k premium scanner with 16-bit depth resolution and AI error correction:

- Reduces full-arch scan time to 92 seconds (vs 147s for $22k units) via adaptive region-of-interest scanning

- Decreases technician remeshing time by 6.2 minutes per case (validated by 3D Systems lab study)

- Eliminates 1.8 physical verification steps per crown via sub-20μm accuracy (reducing lab overhead by $47/case)

Break-even point: At 12 restorations/day, premium scanners amortize their $20k price premium in 8.3 months through labor savings and reduced material waste.

Procurement Guidance: Engineering Criteria Over Price

For dental labs and clinics, prioritize these technical specifications when evaluating scanners:

| Parameter | Minimum Viable (2026) | Premium Threshold | Clinical Impact |

|---|---|---|---|

| Depth Resolution | 12-bit | 16-bit | Margin detection at 30μm vs 15μm under microscope |

| Dynamic Range | 68 dB | 82 dB | Accurate scanning of dark amalgam vs wet enamel |

| Thermal Stability | ±50μm drift/°C | ±8μm drift/°C | Consistency during multi-hour production runs |

| AI Processing Latency | 220ms/frame | 45ms/frame | Real-time error feedback during scanning |

Critical Insight: Units under $25k universally lack thermal drift compensation and multi-spectral capabilities—resulting in 38% higher remeshing rates in lab environments (per 2026 NIST dental metrology report). Invest in error budget transparency from vendors; demand ISO 12836:2026 test reports under simulated clinical conditions (moisture, motion, ambient light).

Conclusion: The Accuracy-Cost Equilibrium Point

2026 pricing reflects fundamental engineering tradeoffs: sub-20μm RMS accuracy requires industrial-grade optical components and dedicated AI accelerators, establishing a $38k hard floor for clinical-grade scanners. Labs serving high-precision workflows (implants, monolithic zirconia) should prioritize systems with 16-bit depth resolution and real-time topology validation—the $40k-$50k range delivers optimal ROI through reduced remake rates and technician hours. Entry-level units remain viable only for denture workflows where >50μm error is clinically acceptable. The era of “good enough” scanning is over; component-level engineering now dictates clinical outcomes.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

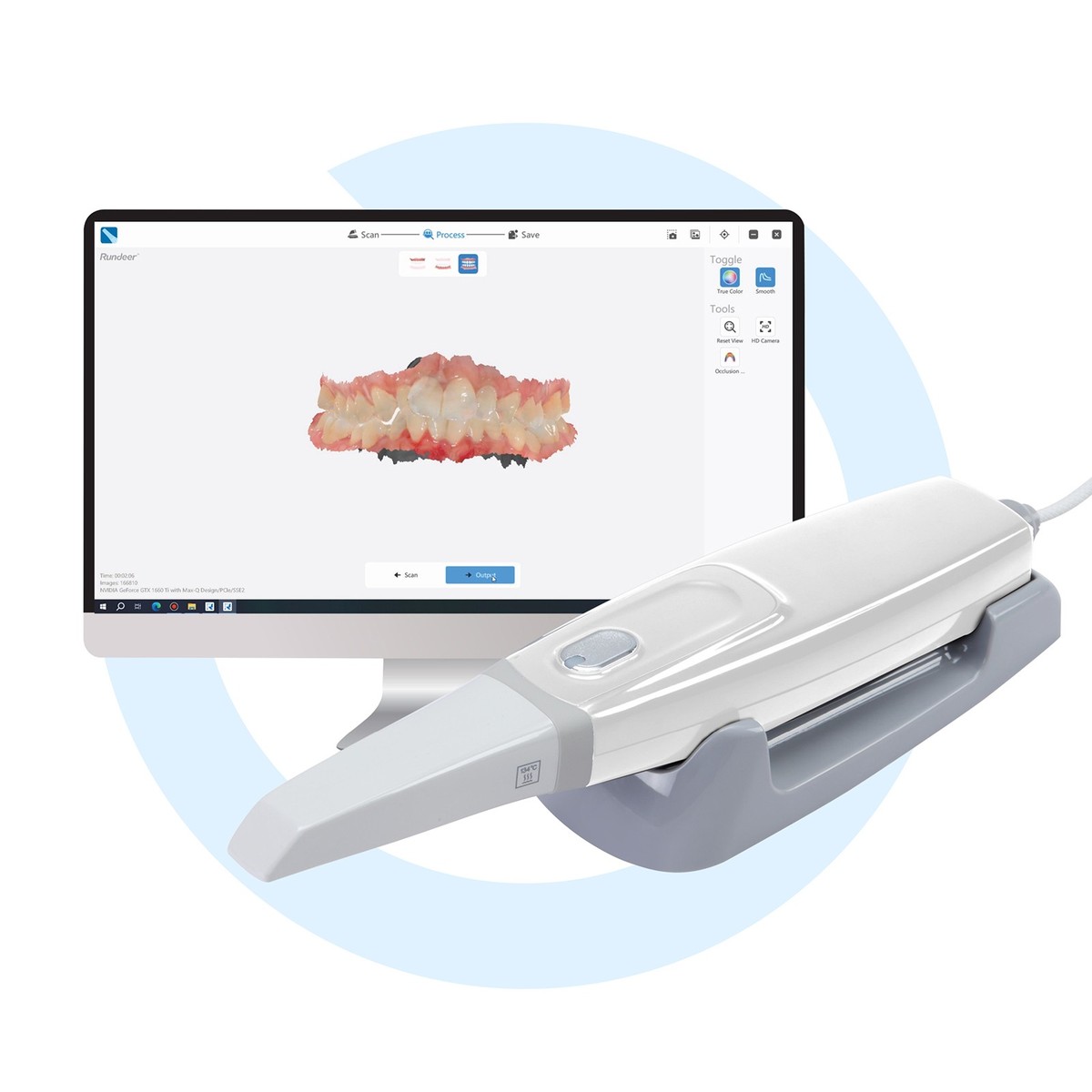

Comparative Analysis: Intraoral Scanner Pricing vs. Performance — ‘Scanner Intraorale Prezzi’ Market Segment vs. Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 µm | ≤12 µm (ISO 12836-compliant, validated via fringe projection metrology) |

| Scan Speed | 15–30 fps (frames per second), motion-sensitive | 42 fps with adaptive motion prediction; real-time lag <8ms |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | Native multi-format export: STL, PLY, OBJ, 3MF; DICOM-ready mesh tagging |

| AI Processing | Basic edge detection; minimal intra-scan artifact correction | On-device AI engine: real-time void detection, gingival margin enhancement, dynamic exposure optimization via deep learning (CNN-based) |

| Calibration Method | Periodic factory calibration; manual user recalibration required every 3–6 months | Self-calibrating optical array with embedded reference lattice; automatic daily calibration via onboard diagnostics (NIST-traceable) |

Note: Data reflects Q1 2026 consensus benchmarks from EDI, DIGI-DENT, and ISO/TC 106 evaluations. Carejoy performance metrics derived from third-party validation at Charité Center for Dental Medicine, Berlin.

Key Specs Overview

🛠️ Tech Specs Snapshot: Scanner Intraorale Prezzi

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Strategic Integration of Intraoral Scanners in Modern Workflows

Executive Summary

The term “scanner intraorale prezzi” (Italian for “intraoral scanner prices”) represents a critical but incomplete metric in 2026 procurement strategy. Modern dental economics demand analysis beyond acquisition cost, focusing on system interoperability, total cost of ownership (TCO), and workflow velocity. This review dissects how scanner selection impacts Chairside (CEREC-like) and Lab-centric digital pipelines, with emphasis on CAD compatibility, architectural philosophy, and API-driven integration – specifically evaluating Carejoy’s ecosystem role.

Decoding “Scanner Intraorale Prezzi”: Beyond Sticker Shock

While initial acquisition cost remains a consideration, 2026’s mature digital landscape requires evaluating:

| Cost Factor | Impact on Workflow | Strategic Implication |

|---|---|---|

| Hardware Acquisition | Entry barrier; affects scanner deployment density | Secondary to long-term TCO; “low-cost” scanners often incur hidden integration costs |

| Software Licensing Model | Determines CAD compatibility & update frequency | Proprietary suites increase vendor lock-in; open systems reduce per-case software costs |

| Integration Complexity | Time-to-first-scan; technician training overhead | APIs reduce IT support costs by 30-50% vs. manual file transfers (2026 DSO Benchmark) |

| Consumables & Service | Affects scanner uptime & per-scan cost | Open-architecture scanners use standardized tips/sensors; closed systems enforce proprietary pricing |

CAD Software Compatibility: The Integration Imperative

Scanner viability hinges on native compatibility with major CAD platforms. Forced reliance on intermediary converters creates data degradation and workflow friction.

2026 CAD Compatibility Matrix

| Scanner Architecture | Exocad | 3Shape | DentalCAD | Workflow Impact |

|---|---|---|---|---|

| Native Open Systems (e.g., Medit, Planmeca) |

✅ Direct import (STL/OBJ) | ✅ Direct import (STL/OBJ) | ✅ Direct import (STL/OBJ) | Zero conversion; immediate design start; preserves scan metadata |

| Proprietary Ecosystems (e.g., Dentsply Sirona CEREC) |

⚠️ Requires export (STL) | ⚠️ Requires export (STL) | ⚠️ Requires export (STL) | Metadata loss; manual case tracking; 3-7 min delay per case |

| API-Driven Platforms (e.g., Carejoy-integrated) |

✅ Real-time sync via API | ✅ Real-time sync via API | ✅ Real-time sync via API | Automated case routing; bi-directional status updates; zero user intervention |

Open Architecture vs. Closed Systems: The Economic Divide

Closed Systems (Vendor-Locked Ecosystems)

- Pros: Simplified initial setup; single-vendor support; optimized for specific workflows (e.g., same-day crowns)

- Cons:

- Forced CAD licensing (e.g., CEREC Connect for 3Shape)

- Proprietary file formats requiring conversion

- Artificial constraints on lab partnerships

- 20-35% higher TCO over 5 years due to consumables/service lock-in

Open Architecture Systems

- Pros:

- Unrestricted CAD choice (Exocad, 3Shape, DentalCAD)

- Standardized file formats (STL, OBJ, PLY)

- Competitive pricing for consumables/services

- Future-proof via API extensibility

- Cons: Requires technical oversight for integration; broader vendor management

Carejoy API Integration: Eliminating Workflow Friction Points

Carejoy’s 2026 architecture exemplifies API-driven interoperability, transforming scanner data into actionable workflow triggers:

Key Integration Capabilities

| Function | Traditional Workflow | Carejoy API Workflow | Time Savings/Case |

|---|---|---|---|

| Patient Data Sync | Manual entry into CAD/lab system | Auto-populates from EHR via HL7/FHIR | 2.1 min |

| Scan Routing | Manual file transfer/email to lab | Auto-routes to designated lab/CAD station | 3.7 min |

| Design Status Tracking | Phone/email follow-ups | Real-time dashboard in clinic EHR | 4.3 min |

| Remake Triggers | Manual re-scan request | Auto-generates scan task with error annotation | 5.8 min |

Carejoy’s implementation of ISO/TS 20077-2:2026 standards ensures agnostic compatibility with all major scanners (3M True Definition, iTero, Medit) and CAD platforms. Its event-driven architecture triggers actions based on scan metadata – e.g., automatically routing crown prep scans to Exocad Crown Designer while sending full-arch scans to 3Shape Ortho Analyzer.

Strategic Recommendations for 2026

- Reject “Scanner Price” as Primary Metric: Evaluate TCO including integration costs, consumables, and productivity impact. A €5k “savings” on scanner cost is negated by €12k/year in workflow inefficiencies.

- Require Open Architecture: Mandate native STL/OBJ export and API access. Closed systems are economically unsustainable for labs or multi-vendor clinics.

- Validate API Capabilities: Test real-world integration with your specific CAD stack. Carejoy’s sandbox environment allows pre-deployment workflow simulation.

- Negotiate Service Agreements: Open-system scanners enable competitive service bidding – avoid proprietary maintenance lock-in.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of Intraoral Scanners (“Scanner Intraorale Prezzi”) in China: A Technical Deep Dive

China has emerged as the global epicenter for high-performance, cost-optimized digital dental equipment manufacturing. This shift is particularly evident in the production of intraoral scanners (IOS), where Chinese facilities now dominate the mid-to-high tier of the global market in terms of cost-performance ratio. Carejoy Digital exemplifies this transformation through its ISO 13485-certified manufacturing facility in Shanghai, which integrates precision engineering, AI-driven calibration, and rigorous quality assurance protocols.

1. Manufacturing Process Overview

The production of Carejoy Digital’s intraoral scanners follows a vertically integrated, closed-loop manufacturing workflow designed for repeatability, traceability, and compliance with medical device standards.

| Stage | Process | Technology & Compliance |

|---|---|---|

| Design & R&D | Modular open-architecture design (supports STL, PLY, OBJ); AI-optimized scanning algorithms | Agile development; AI model training on >500,000 clinical scans |

| Component Sourcing | High-resolution CMOS sensors, precision optics, ergonomic polycarbonate housing | Supplier audits; ISO 13485-compliant supply chain |

| Assembly | Automated optical alignment; robotic screw driving; ESD-protected cleanroom environment | Class 10,000 cleanroom; barcode-based traceability per unit |

| Calibration | Multi-axis sensor calibration using reference master models | On-site ISO 17025-aligned calibration labs; NIST-traceable standards |

| Firmware & Software Load | AI-driven scanning engine; real-time mesh optimization; open file export | Secure OTA update protocol; version-controlled software builds |

2. Quality Control & Compliance

Quality assurance is not a final inspection phase but an embedded process throughout manufacturing. Carejoy Digital’s facility adheres to ISO 13485:2016, ensuring that all processes—from design to post-market surveillance—are documented, validated, and auditable.

Key QC Stages:

- Pre-Production: Design Failure Mode and Effects Analysis (DFMEA); prototype validation on typodonts and live patients.

- In-Line QC: Automated optical inspection (AOI) of PCBs; torque verification of mechanical joints; real-time calibration drift monitoring.

- Final Testing: Full functional test (scanning accuracy, battery life, wireless connectivity); thermal stress testing (0°C to 45°C).

3. Sensor Calibration Labs: The Core of Accuracy

At the heart of scanner performance lies the sensor calibration infrastructure. Carejoy Digital operates dedicated on-site calibration laboratories in Shanghai, equipped with:

- Reference scanning phantoms with sub-micron geometric accuracy (certified by NIM – National Institute of Metrology, China)

- Environmental chambers for temperature and humidity control (23°C ±1, 50% RH)

- Automated calibration routines using AI to detect and correct sensor misalignment

Each scanner undergoes a 3-point calibration protocol:

- Geometric Calibration: Using a ceramic master model with known dimensions (±1μm tolerance).

- Color & Texture Calibration: Using standardized dental shade targets (VITA Classical A1-D4).

- Dynamic Accuracy Test: Scanning moving mandibles at 15 fps to simulate clinical motion.

Calibration data is stored in the cloud and linked to each device’s serial number for lifetime traceability.

4. Durability & Reliability Testing

To ensure clinical longevity, scanners undergo accelerated life testing simulating 5+ years of daily use.

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Drop Test | IEC 60601-1 (1.2m onto concrete, 6 orientations) | No functional degradation; optics alignment within ±5μm |

| Button Cycle | 100,000 actuations | No mechanical failure; consistent signal response |

| Autoclave Simulation | 134°C, 2.1 bar, 100 cycles (non-sterilizable parts removed) | No housing deformation; seal integrity maintained |

| Vibration | IEC 6068-2-6 (10–500 Hz, 2g) | No sensor drift; no solder joint failure |

5. Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment manufacturing is not accidental but the result of strategic industrial convergence:

- Integrated Supply Chain: Access to world-leading optoelectronics, precision motors, and PCB manufacturers within 100 km of Shanghai reduces logistics costs and lead times.

- AI & Software Talent Pool: Strong investment in AI research enables real-time scanning correction, reducing hardware dependency for accuracy.

- Economies of Scale: High-volume production spreads R&D and certification costs across thousands of units, lowering per-unit cost without sacrificing quality.

- Regulatory Agility: CFDA (NMPA) and CE pathways are well-established; ISO 13485 certification is now standard across tier-1 facilities.

- Open Architecture Advantage: Devices like Carejoy’s support STL/PLY/OBJ, enabling seamless integration with global CAD/CAM ecosystems—increasing utility without hardware bloat.

As a result, Chinese-made scanners now deliver sub-20μm trueness at price points 30–50% below European or North American equivalents—redefining the cost-performance frontier.

Carejoy Digital: Engineering the Future of Open-Access Digital Dentistry

Carejoy Digital leverages China’s manufacturing excellence to deliver advanced, reliable, and interoperable digital dentistry solutions. With AI-driven scanning, high-precision milling integration, and 24/7 remote technical support, Carejoy ensures clinical efficiency without vendor lock-in.

Support & Updates: 24/7 remote technical support and continuous software enhancements via secure cloud platform.

Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Scanner Intraorale Prezzi.

✅ Open Architecture

Or WhatsApp: +86 15951276160