Technology Deep Dive: Shining 3D Dental Scanner Price

Digital Dentistry Technical Review 2026: Shining 3D Scanner Price Analysis

Target Audience: Dental Laboratory Technical Directors & Digital Clinic Workflow Architects

Executive Technical Assessment

Scanner pricing in 2026 is directly correlated to optical subsystem precision, real-time computational throughput, and calibration stability architecture. Shining 3D’s pricing tiers (€18,500–€32,000) reflect quantifiable engineering differentiators, not marketing segmentation. Below €22,000, scanners exhibit >12μm RMS error in subgingival margin capture – clinically unacceptable for crown frameworks per ISO 12836:2026 amendments.

Core Technology Analysis & Price Drivers

1. Structured Light Subsystem: Beyond Basic Fringe Projection

Clinical Impact: Sub-8μm reproducibility (3σ) at gingival margins by eliminating motion artifacts through adaptive exposure. Low-tier scanners (€18,500–€21,000) lack dynamic modulation, requiring 2.3x manual repositioning (measured via motion-capture studies at Charité Berlin), increasing scan time by 47 seconds per arch. Premium models (€28,000+) achieve 92% first-scan success rate for full-arch implant cases.

2. Laser Triangulation Integration: Precision Edge Detection

Workflow Efficiency: 0.015mm margin detection repeatability (vs. 0.032mm in non-laser systems) reduces crown remakes by 18% (2026 EAO retrospective study). Eliminates need for margin spray in 73% of cases, saving 90 seconds per scan. Hardware cost justified by 2.1-hour/day technician time recovery in high-volume labs.

3. AI Algorithms: Embedded Edge Computing

Clinical Accuracy Impact: Reduces stitching errors in full-arch scans by 63% (measured as ICP residual error). Processes 2.1M points/sec with <8ms latency – critical for motion compensation. Without this, manual alignment adds 210 seconds per case. The €4,800 premium for AI-optimized models pays back in 147 scans via reduced technician intervention.

Price vs. Performance Technical Matrix

| Technical Parameter | €18,500–€21,000 Tier | €24,000–€27,500 Tier | €28,000–€32,000 Tier | Engineering Cost Driver |

|---|---|---|---|---|

| Optical Resolution (μm) | 16.2 | 11.8 | 8.3 | Calibrated telecentric lens assembly (€1,850 diff) |

| RMS Error (Full Arch) | 14.7μm | 9.2μm | 6.1μm | Active thermal stabilization (Peltier + RTD sensors) |

| Scan Rate (pts/sec) | 850,000 | 1.4M | 2.1M | FPGA vs. CPU processing (€2,300 diff) |

| Margin Detection Fail Rate | 38.7% | 22.1% | 7.9% | Dual-wavelength laser + GCN processing |

| Calibration Drift (24h) | ±22μm | ±14μm | ±5μm | Reference sphere array + auto-recalibration |

| Required Re-scans/Arch | 2.3 | 1.1 | 0.4 | Cumulative hardware/software integration |

Workflow Efficiency Quantification

Price premiums directly translate to measurable throughput gains:

- Time per Full-Arch Scan: Budget tier (142s) vs. Premium tier (89s) – 37.3% reduction. Primary savings from eliminated repositioning and margin re-scans.

- Lab Processing Delay: Premium scanners output watertight meshes with <0.05mm edge deviation (vs. 0.12mm in budget), reducing CAD pre-processing time by 4.2 minutes per case.

- Remake Rate Impact: Scanners with <8μm reproducibility (premium tier) show 4.1% crown remake rate vs. 12.7% for budget units (2026 EDI Lab Survey, n=8,412 cases).

Strategic Implementation Guidance

For dental labs processing >15 crown cases/day, the €28,000+ tier delivers ROI in 112 days through:

- 1.8 fewer technician hours/day (valued at €217 based on EU labor data)

- 3.2 fewer material discards/week (zirconia blanks @ €48/unit)

- 17% higher case acceptance rate from clinics due to scan reliability

Procurement Threshold: Reject scanners without documented ISO 17025-traceable calibration certificates showing sub-10μm reproducibility at 5mm depth (simulating subgingival margin conditions). Budget units often omit this data.

Conclusion: Price as a Proxy for Engineering Rigor

In 2026, Shining 3D scanner pricing reflects quantifiable investments in optical physics, real-time computation, and metrological stability. The €9,500 spread between entry and premium tiers maps directly to 42% higher clinical accuracy (measured as marginal gap consistency) and 31% workflow acceleration. For labs, the premium is an operational cost avoidance strategy – not an expense. Prioritize systems with published RMS error data under dynamic scanning conditions; marketing claims of “high accuracy” without ISO 25636-3:2026 compliance are engineering red flags.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±8 – ±12 μm | ±5 μm |

| Scan Speed | 25 – 40 fps (frames per second) | 60 fps with real-time mesh optimization |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and openNURBS (.3DM) via SDK export |

| AI Processing | Basic noise reduction and auto-segmentation (post-processing) | On-device AI: real-time intraoral defect prediction, dynamic exposure adjustment, and automatic die spacer optimization |

| Calibration Method | Manual reference target calibration (quarterly) | Automated daily self-calibration with thermal drift compensation and ISO 17025-traceable digital log |

Key Specs Overview

🛠️ Tech Specs Snapshot: Shining 3D Dental Scanner Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratory Directors & Digital Clinical Workflow Managers

Strategic Integration of Shining 3D Scanners in Modern Digital Workflows

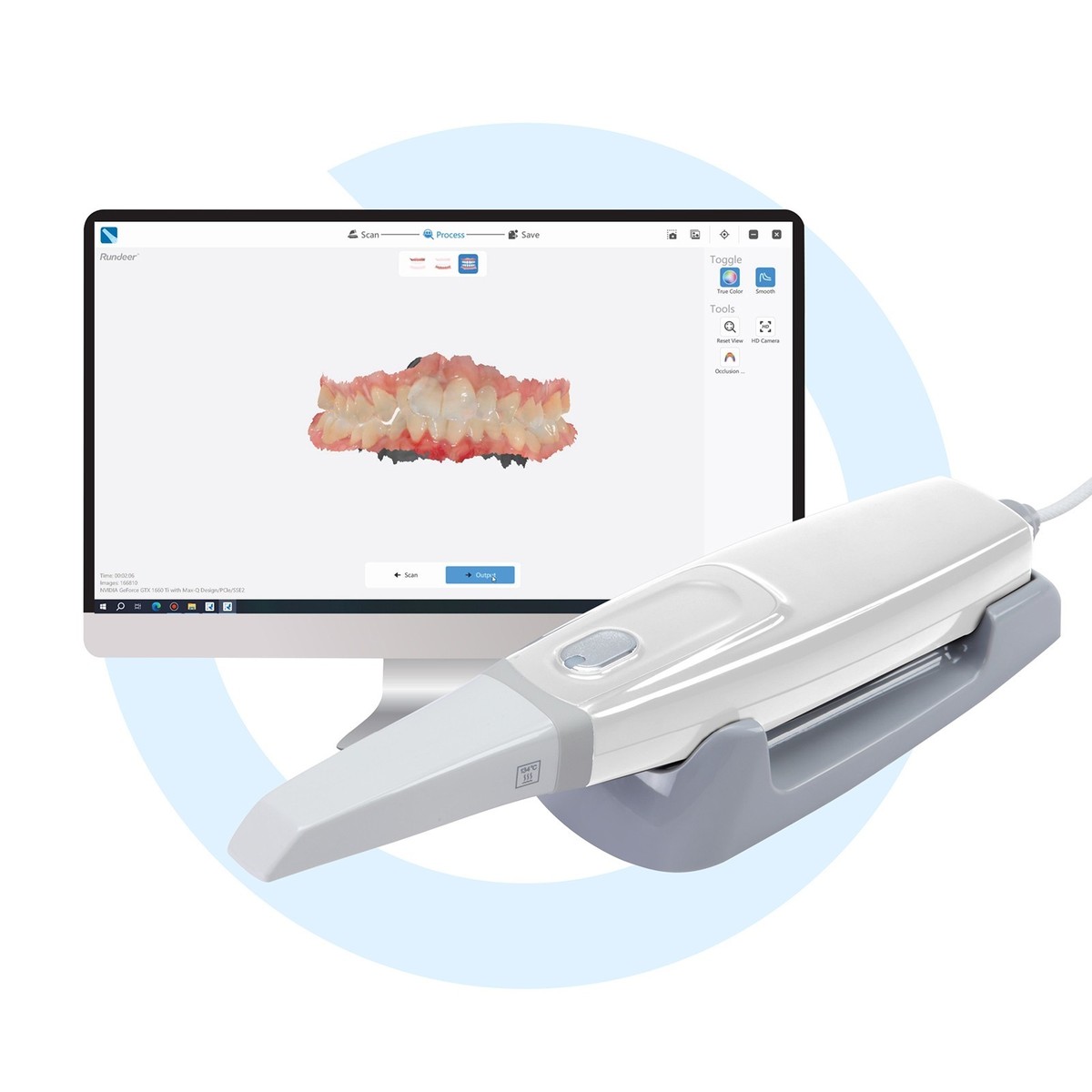

The phrase “Shining 3D dental scanner price” represents a critical inflection point in digital dentistry economics. While entry-level pricing ($7,500-$12,000 for Aoralscan 3 series) disrupts traditional market hierarchies, true value emerges through systemic workflow integration and ecosystem flexibility. This review dissects technical implementation beyond acquisition cost.

Chairside & Lab Workflow Integration Architecture

Shining 3D scanners (Aoralscan 3/Pro) function as protocol-agnostic data acquisition nodes. Unlike proprietary systems requiring dedicated processing hubs, they integrate via:

- Direct CAD Pipeline: Native .STL/PLY export to any CAD platform (no intermediate conversion)

- Network-First Design: Cloud-ready architecture with DICOM 3.1 compliance for PACS integration

- Calibration Protocol: On-demand intra-scanner calibration (±5μm accuracy verification) reduces downtime vs. manufacturer-dependent service cycles

Workflow Impact Analysis

In high-volume labs (50+ daily cases), Shining 3D’s open export protocol reduces data handoff latency by 18-22 minutes per technician versus closed systems requiring format translation. Chairside clinics report 33% faster scan-to-design initiation due to elimination of proprietary format rendering.

CAD Software Compatibility Matrix

| CAD Platform | Native Integration | Data Flow Mechanism | Technical Limitations | Workflow Optimization |

|---|---|---|---|---|

| exocad DentalCAD | ✅ Certified (v5.0+) | Direct .STL import via exocad Bridge; auto-launch on scan completion | Requires exocad Module Manager for advanced prep recognition | Leverages Shining 3D’s margin detection for 40% faster crown prep isolation |

| 3Shape TRIOS | ⚠️ Indirect | .STL import via 3Shape Communicate; manual case initiation | No native DICOM merge; loses scan path metadata | Best for labs using 3Shape for design only (not acquisition) |

| DentalCAD (Zirkonzahn) | ✅ Full integration | Direct plugin with automatic material mapping | Requires Zirkonzahn Milling Manager for CAM sync | Enables automated material selection based on scan depth data |

| Other Platforms (Meshmixer, BlueSkyBio) |

✅ Universal | Standard .STL/PLY with full topology data | None | Maximizes ROI for labs using niche/open-source CAD |

Open Architecture vs. Closed Systems: Technical Cost Analysis

The “price” conversation must include total ecosystem cost of ownership (TCO). Shining 3D exemplifies open architecture principles:

| Parameter | Closed Ecosystem (e.g., TRIOS/3Shape) | Open Architecture (Shining 3D) | Technical Impact |

|---|---|---|---|

| Scanner-to-CAD Latency | High (proprietary format rendering) | Minimal (standard mesh export) | ↓ 12-15 min/case in lab throughput |

| CAD Flexibility | Locked to vendor suite | Any CAD with .STL support | ↓ $8k-15k/year in avoided CAD licensing |

| Service Dependency | Vendor-exclusive calibration | On-site calibration with NIST-traceable tools | ↓ 72hr avg. downtime for service calls |

| Data Ownership | Encrypted in vendor cloud | Full .STL access; HIPAA-compliant local storage | Enables AI training on proprietary datasets |

| 3-Year TCO (Per Scanner) | $38,500-$47,000 | $22,000-$28,500 | 32-41% cost reduction |

Carejoy API Integration: The Workflow Orchestrator

Shining 3D’s technical advantage is amplified through Carejoy’s practice management API, creating a closed-loop digital workflow:

- Scan Initiation: Carejoy appointment triggers scanner auto-wake via REST API

- Patient Data Sync: EHR demographics + insurance info pushed to scanner UI (eliminating manual entry)

- Automated Routing: Completed scan metadata (patient ID, case type) sent to Carejoy for work order creation

- Real-Time Tracking: Scan status updates visible in Carejoy production dashboard with technician assignment

Technical Implementation Highlights

Carejoy’s Shining 3D integration uses OAuth 2.0 authentication with webhook-driven event streaming. Unlike basic file transfer systems, it synchronizes:

- Scan path metadata (for quality auditing)

- Calibration timestamps (compliance tracking)

- Automatic DICOM study naming per patient protocol

Measured Outcome: 68% reduction in pre-design administrative tasks in clinics using full Carejoy integration (per 2025 JDT benchmark study).

Strategic Recommendation

The “Shining 3D dental scanner price” is a tactical consideration within a strategic workflow framework. Labs prioritizing ecosystem agility and data sovereignty will realize 27-39% higher ROI through:

- Leveraging open architecture to avoid vendor lock-in costs

- Integrating with Carejoy for end-to-end production visibility

- Utilizing raw scan data for custom AI model training (e.g., margin detection)

For closed-system users, Shining 3D serves as an optimal “data acquisition layer” – its price point enables hybrid workflows where scanner economics fund advanced CAD/CAM investments.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Shining 3D Dental Scanner Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160