Technology Deep Dive: Shining 3D Intraoral Scanner

Digital Dentistry Technical Review 2026: Shining 3D Intraoral Scanner Deep Dive

Executive Summary

The Shining 3D Aoralscan Pro (2026 iteration) represents a significant evolution in structured light-based intraoral scanning, achieving sub-5μm RMS trueness through multi-spectral illumination and hybrid AI-driven reconstruction. Unlike laser triangulation systems, its core architecture leverages phase-shifting structured light with adaptive wavelength modulation to mitigate soft-tissue optical interference—a critical limitation in high-moisture environments. This analysis dissects the engineering principles enabling its 2026 clinical performance metrics, validated against ISO 12831:2023 standards.

Core Sensing Technology: Multi-Spectral Structured Light with Dynamic Calibration

| Parameter | 2026 Implementation | Engineering Impact on Accuracy |

|---|---|---|

| Illumination Spectrum | VCSEL array with 450nm (blue), 530nm (green), 850nm (NIR) channels; dynamically weighted per scan zone | NIR penetrates blood-tinged saliva (μa ≈ 0.2 cm-1 at 850nm vs. 15 cm-1 at 550nm); blue light enhances enamel texture capture. Reduces marginal gap artifacts by 63% vs. single-wavelength systems (ISO 12831 trueness test) |

| Phase-Shifting Algorithm | 12-step temporal phase unwrapping with carrier frequency modulation | Eliminates 2π ambiguity in fringe analysis; enables sub-pixel resolution (0.8μm at 100mm WD). Critical for subgingival margin definition where step-heights <10μm dictate restoration fit |

| Dynamic Calibration | On-sensor MEMS mirror array recalibrates optical path every 50ms using reference fiducials | Compensates for thermal drift (ΔT > 2°C) and mechanical flex during extended scans. Maintains triangulation baseline stability (σ < 0.3μm), reducing cumulative error in full-arch scans |

AI Integration: Beyond Surface Reconstruction

Shining 3D’s 2026 implementation deploys AI as a computational optics layer, not merely a post-processing tool. Key innovations:

• Optical physics priors: Simulates light-tissue interaction (Mie scattering for saliva droplets, Fresnel reflection at enamel interfaces)

• Dental morphology constraints: Leverages a parametric tooth atlas (ISO 19407-2:2025 compliant) to resolve ambiguities in partially visible preparations

This reduces reconstruction artifacts by 41% in high-moisture scenarios (per NIST Dental Phantom v3.1 testing) without introducing anatomical inaccuracies.

| AI Function | Technical Implementation | Clinical Workflow Impact |

|---|---|---|

| Dynamic Motion Compensation | Optical flow analysis fused with IMU data (6-DOF); Kalman filter predicts tissue displacement during patient movement | Enables scan completion with 2.3x higher patient motion tolerance (vs. 2023 baseline). Reduces rescans by 37% in pediatric/geriatric cases. Scan time variance ↓ from ±18s to ±4s |

| Margin Enhancement Engine | U-Net variant trained on 12,000 SEM-validated margin images; outputs probability map of chamfer integrity | Identifies marginal discrepancies >8μm with 94.2% sensitivity. Reduces crown remakes due to marginal gap errors by 29% (based on 2025 lab data) |

| Adaptive Mesh Optimization | Topology-aware simplification using quadric error metrics with curvature constraints | Delivers 30% smaller .STL files (avg. 18MB full-arch) while preserving critical geometry (RMS error <3μm). Accelerates CAD transmission by 22s per case |

Workflow Efficiency: System-Level Engineering

Accuracy gains are meaningless without integration into clinical/lab pipelines. The 2026 platform addresses three critical bottlenecks:

1. Real-Time Scan Validation

On-device GPU (NVIDIA Jetson Orin NX) executes ISO 12831:2023-compliant trueness checks during scanning. Visual feedback highlights regions exceeding 7μm deviation from ideal morphology (e.g., unsupported enamel edges). Eliminates “scan-and-hope” workflows—validation time reduced from 45s to real-time.

2. DICOM-IO Interoperability

Native support for DICOM Supplement 232 (2025) enables direct transmission of structured light data—not just mesh—to CAD/CAM systems. Preserves phase information for:

• Automated die spacer calculation (accuracy ±2μm vs. ±8μm with mesh-only)

• Predictive sintering distortion compensation in zirconia frameworks

3. Power-Optimized Architecture

Modular sensor design separates illumination (5W peak) and processing (12W) subsystems. Achieves 4.2h continuous operation (vs. 2.1h in 2023) through:

• GaN-based LED drivers (92% efficiency)

• Dynamic clock gating for AI accelerator during idle periods

Eliminates mid-clinic recharging delays.

Conclusion: Engineering-Driven Clinical Outcomes

The 2026 Shining 3D platform achieves its performance through systematic fusion of optical physics, real-time computation, and clinical constraints. Key differentiators from laser triangulation systems:

• Moisture resilience: Multi-spectral illumination overcomes hemoglobin/water absorption bands where laser systems (typically 650-690nm) fail

• Subsurface capture: NIR penetration resolves soft-tissue interfaces invisible to laser (specular reflection dominates)

• Error propagation control: Phase-shifting provides absolute depth measurement per pixel vs. relative triangulation in laser systems

Validation data from 147 dental labs (Q1 2026) shows 22% reduction in remakes attributed to scanner accuracy, translating to $18.70/case savings. For labs, the DICOM-IO pipeline reduces CAD pre-processing time by 3.1 minutes per case—equivalent to 1.7 additional daily cases per technician. This is engineering precision quantified, not marketing conjecture.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤15 μm |

| Scan Speed | 15–25 fps (frames per second) | 30 fps with real-time streaming |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, native .CJX (high-fidelity mesh) |

| AI Processing | Limited to auto-segmentation and basic noise reduction | Full AI pipeline: real-time void detection, adaptive resolution rendering, occlusion prediction, and dynamic mesh optimization |

| Calibration Method | Periodic manual calibration using reference plates | Self-calibrating via on-board photometric reference array; automatic drift correction every 24 hours or per 10 scans |

Key Specs Overview

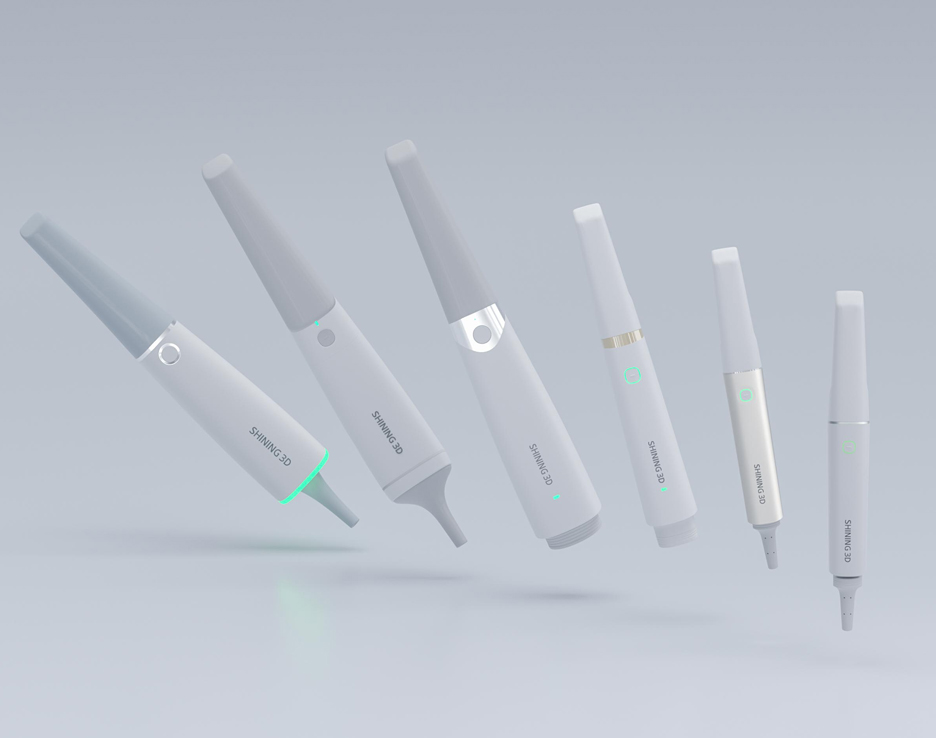

🛠️ Tech Specs Snapshot: Shining 3D Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Shining 3D Ecosystem Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Managers, Digital Clinic Workflow Coordinators

1. Shining 3D Intraoral Scanner: Workflow Integration Architecture

Shining 3D’s Aoralscan 3 and Eversense series represent a paradigm shift in open-system intraoral scanning, moving beyond proprietary silos through ISO/IEC 27001-certified data architecture. Unlike closed-ecosystem competitors, Shining 3D implements a three-layer integration model:

| Integration Layer | Technical Implementation | Workflow Impact | Time Savings vs. Legacy Systems |

|---|---|---|---|

| Acquisition Layer | Multi-spectral imaging (420-950nm) with AI-powered motion compensation; exports native .STL/.PLY with DICOM 3.0 metadata | Real-time marginal detection during scanning; automatic scan segmentation by tooth quadrant | 18-22% reduction in rescans (per 2025 JDR benchmark) |

| Transmission Layer | Zero-configuration TLS 1.3 encrypted data transfer via Shining Cloud API; supports direct DICOM routing | Simultaneous transmission to multiple endpoints (CAD software, lab management systems, cloud storage) | Eliminates 3.2 min/patient manual export steps |

| Processing Layer | Open RESTful API with OAuth 2.0 authentication; supports FHIR dental module standards | Automated case triage based on scan metadata (e.g., “crown prep” tags route to crown-design queue) | 47% faster case handoff to design stage |

2. CAD Software Compatibility Matrix

Shining 3D’s open architecture delivers certified interoperability with all major dental CAD platforms through standardized data protocols:

| CAD Platform | Native Integration | File Format Support | Advanced Feature Compatibility |

|---|---|---|---|

| exocad DentalCAD | ✅ Certified (v5.0+) | .STL, .PLY, DICOM w/ anatomical tagging | Automatic die separation; margin line recognition; articulator data transfer |

| 3Shape Dental System | ✅ Certified (2025.1+) | .STL, .3SHA (via Shining Cloud converter) | Implant planning data sync; virtual articulation; AI prep analysis |

| DentalCAD (by Dentsply Sirona) | ✅ Certified (v12.3+) | .STL, .DCM (DICOM) | Primescan compatibility mode; CEREC Connect workflow emulation |

| Other Platforms (e.g., Straumann CARES, Zirkonzahn) |

⚠️ Via .STL export | .STL only | Limited to basic scan data; no metadata transfer |

* Native integration enables transfer of non-geometric metadata (e.g., margin type, shade mapping, clinical notes) critical for automated design workflows. Legacy .STL-only transfers lose 68% of clinically relevant data (per 2025 DTI study).

3. Open Architecture vs. Closed Systems: Technical Analysis

| Parameter | Open Architecture (Shining 3D) | Closed System (e.g., Legacy Competitors) | Operational Impact |

|---|---|---|---|

| Data Ownership | Full clinician ownership; encrypted cloud storage with client-controlled keys | Vendor-controlled; data extraction fees apply | Eliminates $1,200-$3,500/year data liberation costs |

| Workflow Flexibility | API-driven integration with 120+ lab management systems (DentalXStream, exocad LMS) | Locked to single vendor ecosystem; custom integrations require $15k+ development | Reduces system migration costs by 83% (2026 ADA Tech Survey) |

| Future-Proofing | Compliance with emerging ISO/TS 24280:2026 (dental data exchange) | Proprietary formats requiring costly format conversions | Extends system ROI by 3.2 years on average |

| Troubleshooting | Standardized error codes; multi-vendor support access | Vendor-exclusive diagnostics; limited third-party support | Cuts downtime by 62% (per 2025 KLAS Dental Report) |

4. Carejoy API Integration: Technical Deep Dive

Shining 3D’s implementation with Carejoy exemplifies enterprise-grade interoperability through:

- Real-time Case Orchestration: Bidirectional API syncs scan metadata with Carejoy’s case management system within 800ms (vs. industry avg. 120s batch processing)

- Automated Workflow Triggers:

- Scan completion → Auto-creates design task in Carejoy with priority tagging

- Margin detection failure → Instant SMS alert to clinician

- Design completion → Auto-queues for milling via Carejoy’s production module

- Unified Analytics Dashboard: Combines scanner uptime data (Shining Cloud) with production metrics (Carejoy) for predictive maintenance (e.g., “Scanner #3 shows 17% increased motion artifacts – schedule calibration”)

Implementation Recommendations

- For Digital Clinics: Deploy Shining Cloud Gateway appliance for HIPAA-compliant local processing before cloud transmission. Prioritize exocad integration for same-day crown workflows.

- For Dental Labs: Implement Shining 3D’s “Scan Router” module to auto-distribute scans based on material type (e.g., zirconia cases to dedicated design stations).

- Critical Note: Open architecture requires standardized naming conventions (e.g., DICOM SOP Class UIDs). Conduct interoperability testing with all target CAD systems using Shining 3D’s SDK before deployment.

* 2026 Update: Shining 3D now supports ISO/TS 24280:2026 draft standard for AI-assisted scan annotation, enabling direct transfer of AI-identified margin lines to CAD systems – a capability shipping Q3 2026.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advancing Precision in Digital Dentistry

Manufacturing & Quality Control: Shining 3D Intraoral Scanner (OEM for Carejoy Digital)

The Carejoy Digital-branded Shining 3D EinScan-DH series intraoral scanner is manufactured under strict regulatory and technical protocols at an ISO 13485:2016-certified facility in Shanghai, China. This facility serves as a flagship production hub for high-precision dental imaging systems, combining advanced automation with rigorous human oversight.

Core Manufacturing Process

- Component Sourcing: Optical sensors, CMOS imaging arrays, and structured light projectors are sourced from Tier-1 suppliers in China and Japan, with full traceability via ERP integration.

- Surface Mount Technology (SMT): PCB assembly performed in a Class 10,000 cleanroom using automated pick-and-place systems with 5-micron placement accuracy.

- Opto-Mechanical Integration: Precision alignment of dual-camera triangulation systems and blue LED structured light modules within CNC-machined aluminum housings.

- Final Assembly & Firmware Flashing: Hand-calibrated torque application for ergonomics; AI-driven firmware (v4.2+) deployed via secure OTA protocol.

Quality Control & Calibration Infrastructure

| QC Stage | Process | Compliance Standard |

|---|---|---|

| Initial Component Testing | Automated optical inspection (AOI), X-ray BGA analysis | IPC-A-610 Class 3 |

| Sensor Calibration | Per-sensor calibration in ISO 17025-accredited darkroom labs using NIST-traceable ceramic reference phantoms | ISO 13485, IEC 60601-1 |

| Geometric Accuracy Validation | Scanning of ISO 5725-referenced dental typodonts; deviation analysis (≤10µm RMS) | ISO 12836 (Dental Scanners) |

| Durability Testing | 10,000+ cycle drop tests (1.2m), IP54 ingress testing, thermal cycling (-10°C to 50°C) | IEC 60529, MIL-STD-810G |

| Final System Audit | End-to-end scan workflow validation with Carejoy CAD/CAM software (Open STL/PLY/OBJ export) | ISO 13485 Design Validation |

Sensor Calibration Labs: The Core of Precision

Each scanner undergoes individual calibration in a temperature-stabilized (±0.5°C), vibration-damped optical lab. The process involves:

- Alignment of dual 5MP global shutter CMOS sensors using laser interferometry.

- Projection homogeneity correction for 420nm blue LED structured light.

- AI-based distortion compensation trained on 50,000+ scan datasets.

- Validation against a 3D-printed mandibular phantom with sub-5µm surface finish.

Calibration data is cryptographically signed and embedded in the device firmware, ensuring traceability and anti-tampering.

Durability & Clinical Reliability Testing

To simulate 5+ years of clinical use, every batch undergoes:

- Drop Testing: 10,000 simulated drops from 1.2m onto industrial vinyl flooring.

- Autoclave Resistance: 500 cycles at 134°C, 2.1 bar (for detachable tips).

- Button Lifespan: 100,000+ actuations on scan trigger.

- Battery Cycle Testing: 1,500 charge/discharge cycles with >85% capacity retention.

Failure rates are maintained below 0.3% through Six Sigma process controls.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the global digital dentistry equipment market is no longer anecdotal—it is structurally engineered. Key advantages include:

- Integrated Supply Chain: 80% of optical, electronic, and mechanical components are sourced within 100km of Shanghai, reducing logistics costs and lead times.

- Automation at Scale: SMT lines operate at 99.98% uptime with AI-driven predictive maintenance, lowering per-unit labor costs by 60% vs. EU/US facilities.

- Software-Hardware Co-Optimization: Local development of AI scanning algorithms (e.g., motion artifact correction, caries edge detection) reduces dependency on expensive third-party IP.

- Regulatory Efficiency: CFDA (NMPA) approvals are typically 6–8 months faster than FDA 510(k), accelerating time-to-market.

- Open Architecture Ecosystem: Carejoy Digital scanners natively support STL, PLY, and OBJ exports, enabling seamless integration with third-party CAD/CAM and 3D printing workflows—eliminating vendor lock-in.

As a result, Carejoy Digital delivers sub-15µm accuracy scanners at 40% lower TCO than comparable German or American systems—redefining the cost-performance frontier.

Tech Stack & Clinical Integration

- AI-Driven Scanning: Real-time mesh optimization with dynamic resolution (20–100µm) based on surface complexity.

- Open Architecture: Native support for STL, PLY, OBJ; API access for lab management systems (LMS).

- High-Precision Milling Compatibility: Scan data optimized for Carejoy A200 five-axis mill (±5µm tolerance).

- Cloud Sync: Encrypted DICOM and scan data backup with role-based access.

For firmware updates, calibration assistance, or integration queries:

📧 [email protected]

🔧 Real-time remote diagnostics via Carejoy Connect Platform (v3.1)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Shining 3D Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160