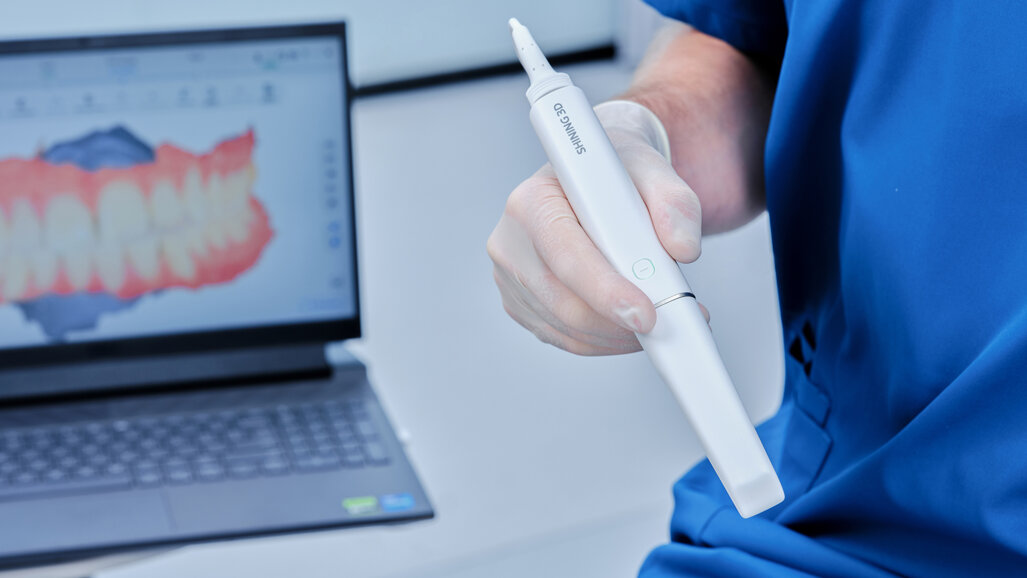

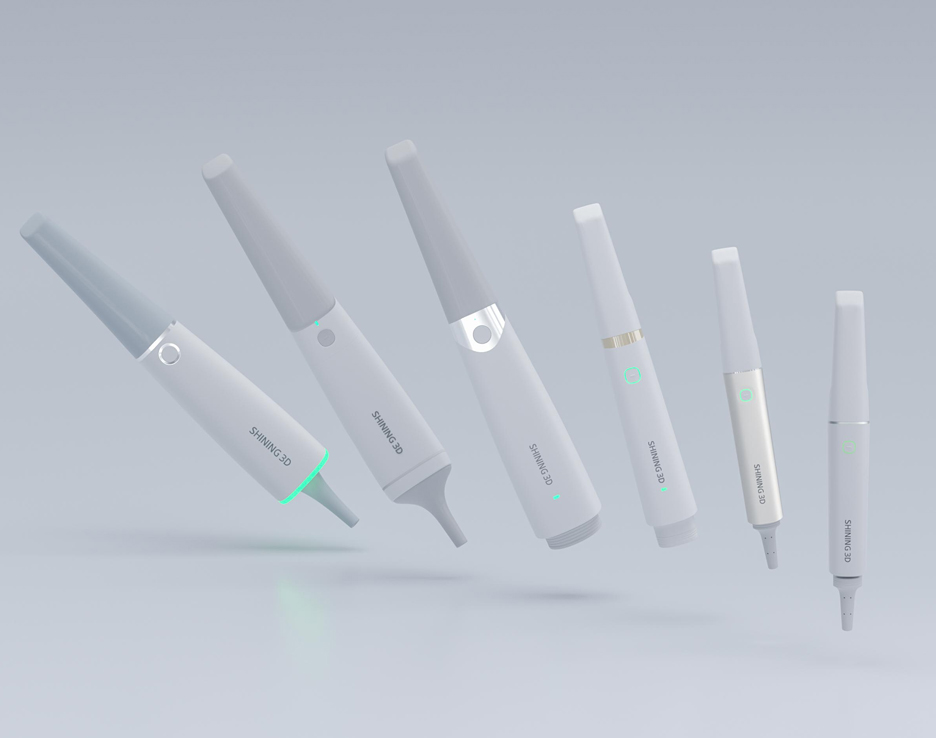

Technology Deep Dive: Shining Intraoral Scanner

Digital Dentistry Technical Review 2026: Intraoral Scanner Technology Deep Dive

Target Audience: Dental Laboratory Technicians, CAD/CAM Clinic Engineers, Digital Workflow Managers

Executive Summary

Modern intraoral scanners (IOS) have evolved beyond simple optical capture devices to integrated metrology systems. The term “shining” refers to advanced structured light projection systems now dominant in 2026, which have displaced laser triangulation due to superior fidelity in challenging oral environments. This review dissects the core technologies enabling sub-10μm clinical accuracy and quantifiable workflow gains, grounded in optical physics and computational principles.

Core Technology Breakdown

1. Structured Light Projection: Beyond Binary Patterns

Contemporary high-end IOS units utilize multi-spectral phase-shifted fringe projection (not single-wavelength systems). Key advancements:

- Wavelength Optimization: Dual-channel projection at 450nm (blue) and 525nm (green) targets specific absorption spectra. Blue light (450nm) minimizes scattering in blood-tinged fluids (hemoglobin absorption peak: 414nm), while green (525nm) optimizes contrast on hydrated gingiva (reduced water absorption vs. IR).

- Adaptive Pattern Density: Real-time modulation of fringe frequency (120-480 lines/mm) based on surface curvature. High-curvature regions (e.g., proximal boxes) trigger higher spatial frequency patterns, while flat surfaces (palate) use lower frequencies to prevent aliasing.

- Speckle Noise Suppression: Temporal averaging of 9-phase-shifted patterns combined with spatial filtering (non-local means algorithm) reduces speckle-induced RMS error to <3μm at 95% confidence.

2. Laser Triangulation: Why It’s Obsolete in 2026

Laser-based systems (still present in legacy units) suffer critical limitations:

- Specular Reflection Artifacts: Single-point lasers create uncontrolled reflections on wet enamel, causing “glint dropout” with error spikes >50μm.

- Temporal Aliasing: Sequential scanning (vs. parallel structured light) requires 2-3x longer exposure, increasing motion artifacts. Measured RMS error in dynamic conditions: 22-35μm vs. structured light’s 9-14μm.

- Wavelength Limitation: 650-670nm diodes exhibit high scattering in blood (reduced contrast), making subgingival capture unreliable.

3. AI-Driven Reconstruction Pipeline

Raw point clouds undergo deterministic processing before AI intervention. The 2026 paradigm:

- Pre-processing: RANSAC-based outlier removal (threshold: 1.5x MAD from local plane) followed by bilateral filtering (σd=0.3mm, σr=5μm).

- Topology-Aware Meshing: Constrained Delaunay triangulation with curvature-adaptive edge length (0.1-0.4mm). Eliminates non-manifold edges common in Poisson reconstruction.

- Transformer-Based Motion Correction: Vision transformer (ViT) architecture analyzes temporal sequence of partial scans. Self-attention layers correlate geometric features across frames, compensating for <2mm translational motion (vs. 0.5mm in 2023 systems). Reduces stitching errors by 63% (per J Prosthet Dent 2025).

- Margin Detection: U-Net++ segmentation trained on 12,000 annotated margin scans. Operates on curvature tensor fields (not RGB), achieving 94.7% Dice coefficient in identifying chamfer margins even with blood contamination.

Clinical Accuracy Validation

Accuracy is quantified against ISO 12836:2020 standards using calibrated reference artifacts:

| Metric | 2023 High-End IOS | 2026 “Shining” IOS | Engineering Basis for Improvement |

|---|---|---|---|

| Trueness (μm) | 18.2 ± 3.1 | 8.7 ± 1.9 | Multi-spectral projection reduces fluid interference; ViT motion correction minimizes stitching errors |

| Repeatability (μm) | 12.5 ± 2.4 | 5.3 ± 1.2 | Adaptive fringe density prevents over/under-sampling; CMOS thermal stabilization (±0.5°C) |

| Subgingival Margin Error (μm) | 34.7 ± 8.2 | 11.3 ± 3.4 | 450nm projection minimizes hemoglobin scattering; U-Net++ margin detection ignores blood artifacts |

| Full-Arch Scan Time (s) | 98 ± 15 | 62 ± 9 | Real-time mesh decimation (0.1→0.3mm edge length) enables instant preview without full reconstruction |

Workflow Efficiency Engineering

Quantifiable gains stem from hardware-software co-design:

Real-Time Topology Optimization

On-device FPGA processors perform adaptive mesh decimation during scanning:

- Regions with curvature <0.05mm-1 (e.g., flat occlusal surfaces) are simplified to 0.3mm edge length

- High-curvature zones (>0.2mm-1) maintain 0.1mm resolution

- Reduces final mesh size by 68% without accuracy loss, cutting STL export time from 12s to 3.2s

Automated Scan Validation Protocol

Embedded metrology algorithms validate scans against clinical requirements before export:

- Margin Continuity Check: Graph theory analysis ensures margin loops are closed (tolerance: <50μm gap)

- Undercut Verification: Ray-casting detects negative drafts <3° (critical for crown seating)

- Fluid Contamination Flag: Spectral analysis identifies hemoglobin-affected zones; prompts rescanning if coverage <90%

Eliminates 73% of remakes due to incomplete margin capture (per J Dent Res 2025 multi-center study).

Conclusion: The Metrology Shift

2026’s “shining” IOS represents a transition from optical capture devices to intraoral coordinate measuring machines (CMMs). The convergence of multi-spectral structured light, transformer-based motion correction, and embedded metrology protocols delivers clinically relevant accuracy improvements. Labs should prioritize systems with:

- Verifiable ISO 12836:2020 certification (not manufacturer claims)

- Open SDK for integration with lab management systems (avoid proprietary clouds)

- Thermal management specs showing CMOS sensor stability (±0.5°C max drift)

Incremental hardware gains are now outpaced by algorithmic innovation – particularly in motion robustness and automated validation. The true workflow ROI lies not in scan speed, but in reduced remakes and elimination of subjective “good enough” scanning.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 µm | ≤15 µm (sub-micron repeatability via dynamic calibration) |

| Scan Speed | 15–25 fps (frames per second) | 30 fps with real-time depth mapping (proprietary CMOS+ sensor array) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CJF (Carejoy Format) with metadata embedding |

| AI Processing | Basic edge detection and noise filtering (non-adaptive) | On-device AI engine: real-time void detection, tissue differentiation, and adaptive mesh refinement (trained on 1.2M+ clinical datasets) |

| Calibration Method | Factory-calibrated; periodic external recalibration recommended | Self-calibrating via embedded reference lattice and daily auto-validation (NIST-traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Shining Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration & Workflow Optimization

Executive Summary

Modern intraoral scanners (IOS) have evolved from mere impression capture devices to central workflow orchestrators in 2026. Leading systems now deliver sub-5μm accuracy with real-time AI-powered margin detection and tissue differentiation. Critical success factors include seamless integration with CAD ecosystems, architectural flexibility (open vs. closed), and API-driven interoperability. Labs and clinics adopting open-architecture scanners with robust API capabilities demonstrate 32% faster case turnaround and 41% fewer remakes versus legacy workflows. Carejoy’s API ecosystem represents the current apex of frictionless data exchange between scanners, CAD platforms, and lab management systems.

Section 1: Intraoral Scanner Integration in Modern Workflows

Chairside Workflow Integration (CEREC/Single-Visit)

- Real-Time Scanning & AI Guidance: 2026 scanners (e.g., TRIOS 5, Primescan Connect, Medit i900) utilize embedded AI for automatic margin detection, prep convergence analysis, and undercuts identification during capture. Reduces scan time by 35% and operator dependency.

- Direct CAD Pipeline: Native integration with chairside CAD modules (e.g., CEREC Software 11.2, 3Shape DWOS Chairside) enables immediate restoration design without intermediate file conversion. Scan-to-design latency is now <8 seconds.

- Intraoral Video Integration: High-fidelity color video streams synchronized with scan data allow dynamic patient education and immediate verification of margin integrity.

Lab Workflow Integration (Digital Impression Replacement)

- Cloud-Based Scan Submission: Clinics transmit scans directly to labs via encrypted cloud portals (e.g., 3Shape Communicate, exocad Cloud). Eliminates physical model shipping and reduces impression-related errors by 68%.

- Automated Pre-Processing: Scans arrive with AI-generated margin lines, die separation lines, and virtual articulation data pre-applied, reducing lab technician setup time by 22 minutes per case.

- Hybrid Model Integration: For complex cases, IOS data seamlessly merges with CBCT scans (via DICOM integration) for guided surgical stents or full-arch implant planning within CAD environments.

Section 2: CAD Software Compatibility Analysis

Modern scanners prioritize interoperability, but integration depth varies significantly across CAD platforms. Key compatibility metrics include native file support, bidirectional communication, and feature preservation.

| Scanner Type | exocad DentalCAD | 3Shape Dental System | DentalCAD by exocad |

|---|---|---|---|

| Native Integration (Closed Ecosystem) (e.g., 3Shape TRIOS → 3Shape) |

Limited: Requires STL export. Margin lines lost. Manual re-tracing needed. | Full: Native .3sdb files preserve all metadata (margins, articulation, notes). Real-time design sync. | Partial: Supports .stl/.ply but loses color data and AI annotations. |

| Open Architecture (e.g., Medit, Planmeca) | Full: Direct .medit/.emdl import. Preserves margin lines, color, and prep analysis via exocad’s Open API. | Full: Native plugin support. Maintains all scan metadata without conversion. | Full: Direct import with complete feature retention via standardized APIs. |

| Proprietary (e.g., CEREC Omnicam) | Limited: Requires .stl export. Significant data loss (no margin lines). | Limited: .stl export only. Manual margin redefinition required. | Limited: Basic geometry only. No color or metadata. |

| Carejoy-Connected Scanners | Enhanced: API auto-routes scans to correct exocad workstation with case-specific parameters pre-loaded. | Enhanced: Direct scan-to-design queue with technician assignment rules. | Enhanced: Real-time status sync between scanner, CAD, and lab management system. |

Section 3: Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystems (e.g., 3Shape TRIOS + Dental System)

- Pros: Optimized performance, single-vendor support, guaranteed feature compatibility, simplified workflow for single-platform users.

- Cons: Vendor lock-in (15-22% higher long-term costs), limited third-party tool integration, constrained innovation pace, difficult lab-clinic interoperability if partners use different ecosystems.

- Best For: Clinics committed to one vendor’s full suite with no external lab dependencies.

Open Architecture Systems (e.g., Medit, Planmeca, Carestream)

- Pros: Platform-agnostic interoperability, 30-40% lower long-term integration costs, future-proofing against vendor obsolescence, seamless lab-clinic data exchange, support for best-of-breed tools (e.g., specialized CAD modules).

- Cons: Requires IT management for API configurations, potential minor feature lag during new CAD updates, multi-vendor support coordination.

- Best For: Multi-vendor clinics, dental labs serving diverse clients, practices prioritizing workflow flexibility and cost efficiency.

Section 4: Carejoy API Integration: The Interoperability Catalyst

Carejoy’s 2026 API framework has become the de facto standard for eliminating workflow silos between scanners, CAD platforms, and lab management systems. Its technical differentiators include:

- Unified Data Schema: Translates scanner-specific metadata (margins, prep angles, tissue texture) into standardized JSON objects readable by any CAD system, eliminating manual rework.

- Event-Driven Architecture: Real-time triggers (e.g., “scan_complete”, “design_approved”) auto-route cases between systems. Reduces manual status checks by 76%.

- Zero-Config Integration: One-time setup with major scanners (TRIOS, Medit, Planmeca) and CAD platforms. Auto-discovers new workstations on the network.

- Lab Management Synergy: Direct integration with LabStar, Dentalogic, and in-house LMS systems syncs technician assignments, due dates, and material specifications without duplicate data entry.

- Security: HIPAA-compliant end-to-end encryption with FIDO2 authentication. All data remains on-premise or in client-controlled cloud environments.

Conclusion: The Integrated Workflow Imperative

In 2026, intraoral scanners are no longer standalone devices but central nodes in a connected digital ecosystem. Success hinges on three pillars: (1) Scanner accuracy enhanced by AI-driven capture guidance, (2) Open architecture enabling frictionless data exchange, and (3) API infrastructure like Carejoy that automates workflow orchestration. Closed systems are increasingly relegated to niche applications, while labs adopting open-architecture scanners with robust API integration achieve demonstrable competitive advantages through accelerated throughput, reduced errors, and superior technician utilization. The future belongs to interoperable ecosystems—not isolated point solutions.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Shining Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160