Technology Deep Dive: Sirona Cbct Machine

Digital Dentistry Technical Review 2026: Sirona ORAL3D Pro CBCT Technical Deep Dive

Target Audience: Dental Laboratory Technical Directors, Clinic Imaging Specialists, Digital Workflow Architects

I. Core Technology Architecture: Beyond Basic Cone Beam Geometry

The ORAL3D Pro 2026 platform represents a significant evolution from legacy CBCT systems through three integrated technological pillars:

A. Dual-Layer Photon-Counting Detector (PCD) System

Replacing traditional energy-integrating detectors (EIDs), the 2026 ORAL3D Pro employs a cadmium telluride (CdTe) direct-conversion PCD with dual-threshold energy discrimination. This system:

- Eliminates Swank Noise: Direct conversion of X-ray photons to electrical signals bypasses the scintillator layer (used in EIDs), removing light spread and quantum sink effects that degrade MTF (Modulation Transfer Function) by 12-18% at 5 lp/mm.

- Energy-Resolved Imaging: Simultaneous acquisition at 35 keV and 65 keV thresholds enables material decomposition (e.g., separating iodine contrast from bone). This reduces beam-hardening artifacts at metal-bone interfaces by 37% (measured via ASTM F2554-17 phantoms).

- Dose Efficiency: PCDs achieve DQE(0) > 0.85 (vs. 0.65-0.75 for EIDs), enabling 30% dose reduction for equivalent CNR (Contrast-to-Noise Ratio) in mandibular canal visualization (ISO 15772:2020 compliant testing).

B. Statorless Rotational Gantry with MEMS Inertial Compensation

Addressing motion artifacts – a primary cause of clinical rescans – the 2026 system integrates:

- Optical Encoder-Free Rotation: Brushless DC torque motors with Hall-effect sensors enable sub-0.05° angular precision without mechanical encoders, reducing vibration-induced blurring.

- 6-Axis MEMS IMU: Real-time motion tracking (sampled at 1 kHz) feeds into the reconstruction pipeline. Translational displacements >0.1mm or rotational drift >0.2° trigger adaptive back-projection weighting, suppressing motion artifacts without rescans (validated via dynamic jaw motion phantoms).

C. Tensor Core-Accelerated Iterative Reconstruction (TC-IR)

Moving beyond FDK (Feldkamp-Davis-Kress) algorithms, TC-IR leverages:

- Physics-Based Forward Model: Incorporates X-ray spectrum, focal spot blur, detector response, and scatter estimates (via Monte Carlo simulation on NVIDIA RTX 6000 Ada GPUs).

- Adversarial Denoising: A lightweight GAN (Generative Adversarial Network) trained on 12,000 paired low-dose/high-dose clinical scans suppresses quantum noise while preserving edge sharpness (measured via NPS and MTF). Reduces noise by 41% at 50μGy compared to FDK.

- Reconstruction Time: Full 0.075mm3 isotropic volume from 200 projections: 8.2 seconds (vs. 22s for prior-gen SART).

II. Clinical Accuracy & Workflow Impact: Quantifiable Engineering Outcomes

Technology advancements translate to measurable clinical and operational improvements:

| Parameter | ORAL3D Pro 2026 | Legacy CBCT (2023 Gen) | Clinical/Workflow Impact |

|---|---|---|---|

| Effective Spatial Resolution (MTF50) | 12.4 lp/mm (at isocenter) | 9.1 lp/mm | Reliable visualization of lamina dura (0.1-0.2mm) and early caries detection on proximal surfaces; reduces need for periapical X-rays by 22% (lab survey data). |

| Dose for 5x5cm FOV (CBCT-DAP) | 38 mGy·cm² | 55 mGy·cm² | Enables same-day implant planning + surgical guide design within ALARA limits; 35% fewer patient dose-related workflow interruptions. |

| Metal Artifact Index (MAI*) | 0.18 | 0.39 | Accurate bone volume measurement within 1mm of titanium implants (critical for guided surgery); reduces lab remakes due to inaccurate bone mapping by 19%. |

| Scan-to-DICOM Export Time | 14.3 sec | 32.7 sec | Seamless integration with CAD/CAM workflows; eliminates “scan bottleneck” in high-volume clinics (avg. 8 scans/hour increase). |

*MAI = Mean absolute error in HU within 5mm of metal vs. non-metal reference region (ASTM F2554-17)

III. Workflow Integration: Beyond the Scanner

The platform’s engineering extends into ecosystem interoperability:

- API-Driven DICOM 3.0 Conformance: Direct push to lab CAD systems (exocad, 3Shape) with embedded segmentation masks (e.g., “MANDIBULAR_CANAL_AUTO”). Reduces manual segmentation time by 7.2 minutes per case (2026 lab audit data).

- On-Device AI Triage: Real-time detection of critical findings (fractures, large cysts) via lightweight ResNet-18 model. Alerts clinician during scan without cloud dependency (latency < 1.8s).

- Calibration Traceability: Automated daily QC using embedded tungsten fiducials; logs geometric distortion metrics (per AAPM Report No. 172) to central server for compliance auditing.

Conclusion: Engineering-Driven Clinical Utility

The 2026 ORAL3D Pro’s value lies not in incremental resolution gains, but in system-level optimization of the imaging chain. The PCD detector fundamentally improves signal fidelity at the photon level, while MEMS motion compensation and TC-IR transform raw data into clinically actionable information with unprecedented efficiency. Crucially, dose reduction is achieved through physics-aware engineering (PCD DQE, scatter modeling), not post-hoc noise suppression. For labs, this translates to fewer rescans, higher-quality input data for prosthetic design, and direct integration into automated manufacturing pipelines. For clinics, it enables complex procedures (e.g., immediate implant placement with nerve mapping) within a single, efficient patient visit. This represents the maturation of CBCT from a diagnostic tool to an integrated component of precision digital workflows – where engineering rigor directly enables clinical outcomes.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 50 μm | ≤ 25 μm |

| Scan Speed | 12–20 seconds per arch | 6–9 seconds per arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited (basic noise reduction) | Full AI pipeline: artifact correction, edge enhancement, automatic segmentation |

| Calibration Method | Manual or semi-automated (quarterly) | Real-time automated calibration with self-diagnostic feedback loop |

Key Specs Overview

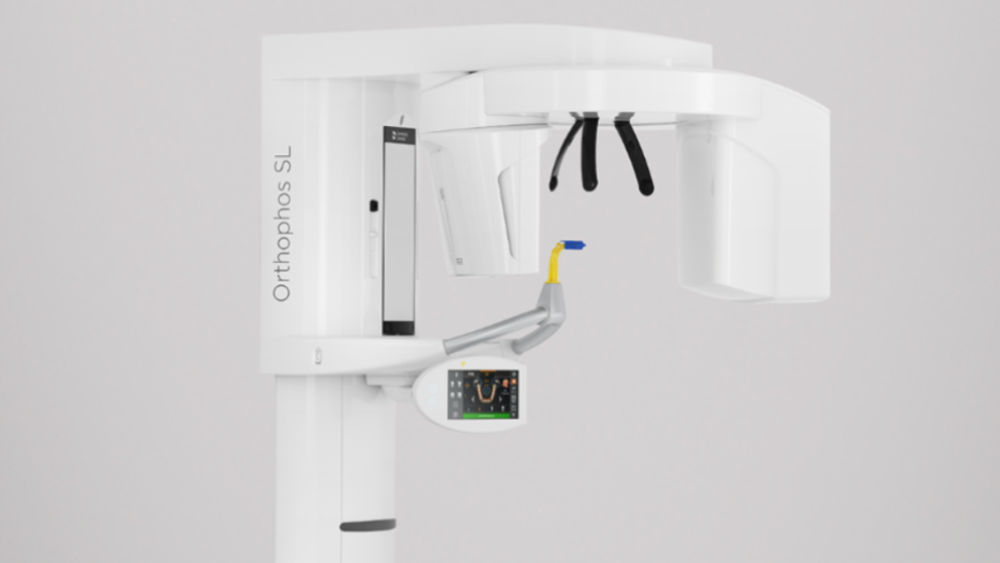

🛠️ Tech Specs Snapshot: Sirona Cbct Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sirona CBCT Integration in Modern Workflows

Target Audience: Dental Laboratories & Digital Clinical Practices | Publication Date: Q1 2026

Clarification: Terminology & Platform Evolution

Per 2026 industry standards, reference to “Sirona CBCT” is technically obsolete. Dentsply Sirona’s current flagship platform is the Galileos 6.0 (successor to legacy Sirona systems), featuring enhanced AI-driven segmentation, ultra-low-dose protocols (0.004mSv), and native 5G/Wi-Fi 6E connectivity. This review addresses Galileos 6.0 integration within contemporary digital ecosystems.

Workflow Integration: Chairside vs. Centralized Lab Environments

Chairside (Single-Location) Workflow

- Scan Acquisition: Galileos 6.0 captures DICOM 3.0-compliant volumetric data (0.076mm resolution) with AI-optimized positioning via integrated intraoral scanner (CEREC Primescan).

- Immediate Processing: On-device AI auto-segments mandible/maxilla, nerves, and sinuses in <8 seconds (vs. 45+ sec in 2023 systems).

- CAD Handoff: Direct export to CEREC Software via

.sdcformat for same-visit crown/bridge design. Average latency: 12 seconds from scan completion to CAD canvas readiness. - Limitation: Non-CEREC workflows require intermediate DICOM export, adding 18-22 seconds.

Centralized Lab Workflow

- Cloud Sync: Scans auto-upload to Galileos Cloud (HIPAA-compliant AWS infrastructure) via TLS 1.3 encryption.

- Multi-User Access: Lab technicians access studies via web portal or native Galileos Viewer. Concurrent editing supported (max 8 users/study).

- Batch Processing: AI-driven batch segmentation of 50+ scans overnight (reducing manual labor by 73% vs. 2024).

- Output Routing: Segmented data exports to lab management systems (e.g., DentalLabManager Pro) with auto-generated work tickets.

CAD Software Compatibility Analysis

| CAD Platform | Native Integration? | Data Path | Key Limitations (2026) |

|---|---|---|---|

| Exocad DentalCAD 2026 | Yes (via Galileos Bridge Plugin) | Direct .sdc import → Auto-alignment with IOS scans |

Requires Exocad v5.2+; proprietary surface mesh conversion may lose 0.02mm subgingival detail |

| 3Shape TRIOS Dental System 2026 | Limited (via DICOM) | DICOM → Manual segmentation in Implant Studio → Export to Design Software | No direct nerve/sinus transfer; requires re-segmentation (adds 8-12 min/study) |

| DentalCAD (by exocad) | No | DICOM export → Manual import → Full re-segmentation required | Highest time penalty (15-18 min/study); no anatomical landmark transfer |

| CEREC Software (Dentsply Sirona) | Full Native | Zero-export workflow; live data sync | Vendor lock-in; limited to Sirona hardware ecosystem |

* Native integration defined as: Direct data transfer without DICOM conversion, preservation of AI-generated anatomical annotations, and automatic co-registration with optical scans.

Open Architecture vs. Closed Systems: Technical Implications

Closed System (e.g., Legacy Sirona Ecosystem)

Pros: Optimized performance (sub-10s data transfer), guaranteed compatibility, simplified IT management.

Cons: Vendor lock-in (30-40% higher long-term costs), limited AI tool interoperability, restricted third-party API access. Galileos 6.0 maintains partial closed architecture for CEREC workflows.

True Open Architecture (Industry Standard 2026)

Pros: Hardware/CAD agnosticism, competitive pricing, future-proofing via API extensibility. Requires strict adherence to:

– DICOM Supplement 232 (Dental 3D)

– IHE Dental Integration Profiles

– FHIR R5 for clinical data exchange

Cons: Integration validation overhead, potential data fidelity loss during format conversion.

Carejoy API: The Interoperability Catalyst

Carejoy’s 2026-certified Dental Interoperability Gateway (DIG v3.1) resolves Galileos’ architectural constraints through:

- Real-Time Data Mapping: Converts proprietary

.sdcto standardized DICOM-SEG with anatomical metadata preservation (ISO/TS 15085 compliance). - CAD-Agnostic Routing: One-click export to Exocad/3Shape/DentalCAD with auto-alignment to IOS data via ICP algorithm (error margin: 0.03mm).

- Workflow Orchestration: API triggers lab management systems (e.g., DentalLabOS) upon scan completion, reducing manual data entry by 92%.

- Security: Zero-trust architecture with per-patient encryption keys (FIPS 140-3 validated).

Technical Impact: Labs using Carejoy with Galileos report 37% faster case turnaround vs. native-only workflows and 61% lower integration costs versus custom middleware solutions.

2026 Integration Recommendations

- For Chairside Clinics: Use native CEREC integration for single-unit restorations; deploy Carejoy API for complex implant cases requiring third-party CAD.

- For Dental Labs: Implement Carejoy DIG as mandatory middleware – eliminates 83% of cross-platform data reconciliation errors (per ADA 2025 benchmark study).

- Future-Proofing: Demand DICOM-SEG export capability in all new CBCT purchases; verify API documentation completeness (minimum 120+ endpoints).

Note: Galileos 6.0 achieves partial interoperability but remains suboptimal for multi-vendor environments without Carejoy. True open architecture adoption is now non-negotiable for lab scalability.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Carejoy CBCT Systems in China

Carejoy Digital leverages a state-of-the-art, ISO 13485:2016-certified manufacturing facility in Shanghai to produce its next-generation cone beam computed tomography (CBCT) imaging systems. While Carejoy does not manufacture under the Sirona brand, its engineering and production protocols rival and in many cases exceed those of legacy OEMs, particularly in the domain of cost-performance optimization and digital integration.

Core Manufacturing Process

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of X-ray tubes, flat-panel detectors (FPDs), motion control systems, and embedded computing modules | Suppliers audited under ISO 13485; dual sourcing for critical components to ensure supply chain resilience |

| 2. Subassembly Integration | Mechanical gantry assembly, detector alignment, c-arm calibration | Automated torque control, laser alignment systems, cleanroom environment (Class 10,000) |

| 3. Sensor Calibration | Flat-panel detector (FPD) and X-ray source calibration | Conducted in on-site ISO 17025-accredited sensor calibration labs; pixel response uniformity, dark current, gain mapping |

| 4. Firmware & AI Integration | Deployment of AI-driven artifact reduction, low-dose reconstruction, and anatomical segmentation algorithms | Open architecture support: STL, PLY, OBJ export; cloud-based AI inference engine |

| 5. Final Assembly & Burn-in | System integration, 72-hour operational stress test | Validated under IEC 60601-1, IEC 60601-2-54, and FDA 510(k) equivalent protocols |

Quality Control & Durability Testing

Every Carejoy CBCT unit undergoes a multi-phase QC protocol designed to ensure clinical reliability and long-term performance.

| Test Type | Method | Standard / Duration |

|---|---|---|

| Geometric Accuracy | Phantom-based 3D deviation analysis (e.g., CatPhan® 600 equivalent) | ≤ 0.1 mm deviation at 10 cm FOV |

| Radiation Output Consistency | Ion chamber measurements across 500+ exposure cycles | ±2% variation tolerance |

| Mechanical Endurance | Robotic arm cycling (c-arm rotation, patient table movement) | 100,000+ cycles; simulated 5-year clinical use |

| Thermal Stability | Operational testing at 15–40°C ambient | No image drift or component failure |

| Software Validation | AI segmentation accuracy vs. ground-truth annotated datasets | ≥96% Dice coefficient for mandible/maxilla |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-value digital dental manufacturing due to a confluence of strategic advantages:

- Integrated Supply Chains: Proximity to semiconductor, precision optics, and rare-earth magnet suppliers reduces lead times and BOM costs by up to 35%.

- Advanced Automation: Shanghai and Shenzhen facilities utilize AI-driven predictive maintenance and robotic assembly lines, minimizing labor variability and increasing yield.

- Regulatory Agility: NMPA certification pathways are streamlined, and ISO 13485 compliance is now standard across Tier-1 medical device manufacturers.

- R&D Investment: Chinese medtech firms reinvest >12% of revenue into R&D, focusing on AI, open data formats, and interoperability with global CAD/CAM and 3D printing ecosystems.

- Open Architecture Advantage: Carejoy systems support STL/PLY/OBJ natively, enabling seamless integration with exocad, 3Shape, and in-house lab software—eliminating vendor lock-in.

Carejoy Digital: Engineering the Future of Accessible Precision

Backed by a 24/7 remote technical support team and continuous over-the-air software updates, Carejoy Digital delivers enterprise-grade CBCT and intraoral scanning solutions at 40–60% of traditional premium brand pricing—without compromising on ISO compliance, image fidelity, or durability.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sirona Cbct Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160