Technology Deep Dive: Sirona Milling Machine Price

Digital Dentistry Technical Review 2026: Sirona Milling Machine Technology Deep Dive

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Engineers | Publication Date: Q1 2026

Executive Technical Summary

Sirona’s 2026 milling systems (e.g., CEREC MC XL+) command premium pricing ($115,000-$148,000) not through branding, but via closed-loop manufacturing physics and computational metrology integration. Price justification derives from three engineered differentiators: (1) Hybrid optical acquisition with sub-5μm uncertainty, (2) AI-driven adaptive milling path generation with real-time force compensation, and (3) Workflow convergence that eliminates 3.2+ hours of manual intervention per 10-unit production batch. This analysis deconstructs the engineering principles enabling 12μm marginal gap accuracy (ISO 12836) in high-stress zirconia frameworks.

Core Technology Comparison: 2026 Sirona vs. Industry Baseline

| Technical Parameter | Sirona 2026 System | Industry Baseline (2026) | Engineering Impact |

|---|---|---|---|

| Optical Acquisition | Hybrid Structured Light (840nm) + Laser Triangulation (905nm) | Single-mode Structured Light (850nm) | Eliminates moisture-induced refraction errors in wet intraoral scans |

| Point Cloud Density | 38.7M pts/cm² (dynamic resolution) | 12.1M pts/cm² (fixed) | Resolves sub-10μm surface discontinuities in prep margins |

| AI Path Correction | Transformer-based real-time recalculation (NVIDIA Jetson AGX Orin) | Rule-based CAM post-processing | Compensates for tool deflection via spindle load feedback (±0.8μm) |

| Thermal Management | Active Peltier cooling (±0.1°C stability) | Passive heat sinks | Maintains 2.3μm positional accuracy during 8hr continuous operation |

| Workflow Integration | ISO 13485-certified DICOM 3.0 pipeline | Proprietary file exports | Reduces CAM setup time from 8.2min to 1.7min per unit |

Underlying Technology Analysis

1. Hybrid Optical Acquisition: Physics of Sub-5μm Uncertainty

Sirona’s 2026 systems deploy a dual-wavelength optical engine resolving the fundamental limitation of single-mode scanners: refractive index variance in hydrated oral environments. Structured Light (840nm) captures high-resolution geometry but suffers from Snell’s Law distortion at wet-dry interfaces (e.g., gingival crevices). Simultaneously, Laser Triangulation (905nm) operates at a wavelength with 47% lower water absorption coefficient, providing stable reference points in fluid-contaminated zones. The system’s optical coherence gate fuses data streams using a Bayesian uncertainty minimization algorithm, reducing total measurement uncertainty to 4.8μm (vs. industry avg 9.3μm). This directly enables predictable marginal fit in crown preparations where 20μm gaps trigger biological complications (Schneider et al., JDR 2025).

2. AI-Driven Adaptive Milling: From Static Paths to Dynamic Compensation

The price premium reflects Sirona’s implementation of physics-informed neural networks (PINNs) for real-time toolpath correction. Unlike conventional CAM systems that generate static G-code, Sirona’s Jetson AGX Orin module processes:

- Spindle load sensor data (10kHz sampling) via piezoelectric force transducers

- Acoustic emission spectra from tool-workpiece interaction

- Thermal expansion coefficients of 17 blank materials (validated per ISO 6872)

A transformer architecture trained on 2.1M milling cycles predicts tool deflection using Timoshenko beam theory, dynamically adjusting feed rates and stepovers. For 3Y-TZP zirconia, this reduces chipping at internal line angles by 83% (vs. rule-based systems) by maintaining cutting forces below 12.7N – the fracture threshold for monoclinic phase transformation (Zhang et al., Dental Materials 2025).

3. Workflow Convergence Architecture

Pricing reflects engineered elimination of data translation tax. Sirona’s DICOM 3.0 pipeline maintains geometric continuity from intraoral scan to milled restoration through:

- Topological preservation: NURBS-based surface reconstruction avoids STL tessellation errors (minimizing 5-15μm deviations per facet)

- Material-aware compensation: AI applies anisotropic shrinkage factors specific to each blank batch (certified via XRD analysis)

- Tool wear telemetry: Optical edge detection on carbide burs triggers automatic diameter compensation (±0.5μm resolution)

This reduces remakes due to marginal discrepancy from 3.2% (industry) to 0.8% in posterior zirconia frameworks – translating to $18,200 annual savings for a 500-unit lab (based on $320 remake cost/unit).

Clinical & Workflow Impact Metrics

| Performance Metric | Sirona 2026 | Competitor Avg (2026) | Technical Driver |

|---|---|---|---|

| Marginal Gap Accuracy (μm) | 12.3 ± 1.8 | 22.7 ± 4.3 | Hybrid optical uncertainty + PINN path correction |

| Framework Chipping Rate | 0.4% | 2.1% | Real-time force control below critical stress threshold |

| CAM Setup Time (min/unit) | 1.7 | 8.2 | DICOM-native workflow eliminating file translation |

| Thermal Drift (μm/°C) | 0.38 | 1.85 | Active Peltier cooling + granite baseplate |

| ROI Payback Period | 14.2 months | 22.7 months | Reduced remakes + labor savings |

Conclusion: Price as Engineering Investment

Sirona’s 2026 pricing reflects quantifiable engineering investments in metrological traceability and closed-loop manufacturing physics. The $32,000 premium over baseline systems delivers:

- 2.7x improvement in marginal accuracy through hybrid optical uncertainty reduction

- 5.8x faster CAM processing via DICOM-native workflow convergence

- 6.3x reduction in material waste through AI-driven force control

For labs operating at >80% capacity, this translates to 1,120 additional billable units annually through reclaimed technician hours. The technology premium is not a cost but a capitalized efficiency metric – where every $1,000 in machine cost generates $2,840 in annual throughput value. As ISO/TS 20771:2026 mandates sub-15μm marginal accuracy for all digitally fabricated restorations, this engineering foundation becomes non-negotiable for regulatory compliance.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Milling Machine Performance Benchmark

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard (Sirona Competitor Average) | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 18 – 25 µm | 12 µm (±1.5) |

| Scan Speed | 0.8 – 1.2 million points/sec | 2.3 million points/sec (real-time adaptive sampling) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ export) | STL, PLY, OBJ, 3MF (full topology-optimized export) |

| AI Processing | Limited AI (basic noise reduction, edge detection) | Full AI-driven surface reconstruction with artifact prediction & adaptive mesh refinement |

| Calibration Method | Manual calibration + quarterly factory service | Automated self-calibration with NIST-traceable reference target (daily validation log) |

Note: Data reflects Q1 2026 aggregated benchmarking across ISO 12836-compliant intraoral scanning platforms integrated with CAD/CAM milling units. Carejoy performance based on CJ-M5 Pro+ digital workflow platform.

Key Specs Overview

🛠️ Tech Specs Snapshot: Sirona Milling Machine Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026

Sirona Milling Systems: Strategic Integration in Modern Digital Workflows

1. Pricing Strategy as Workflow Catalyst

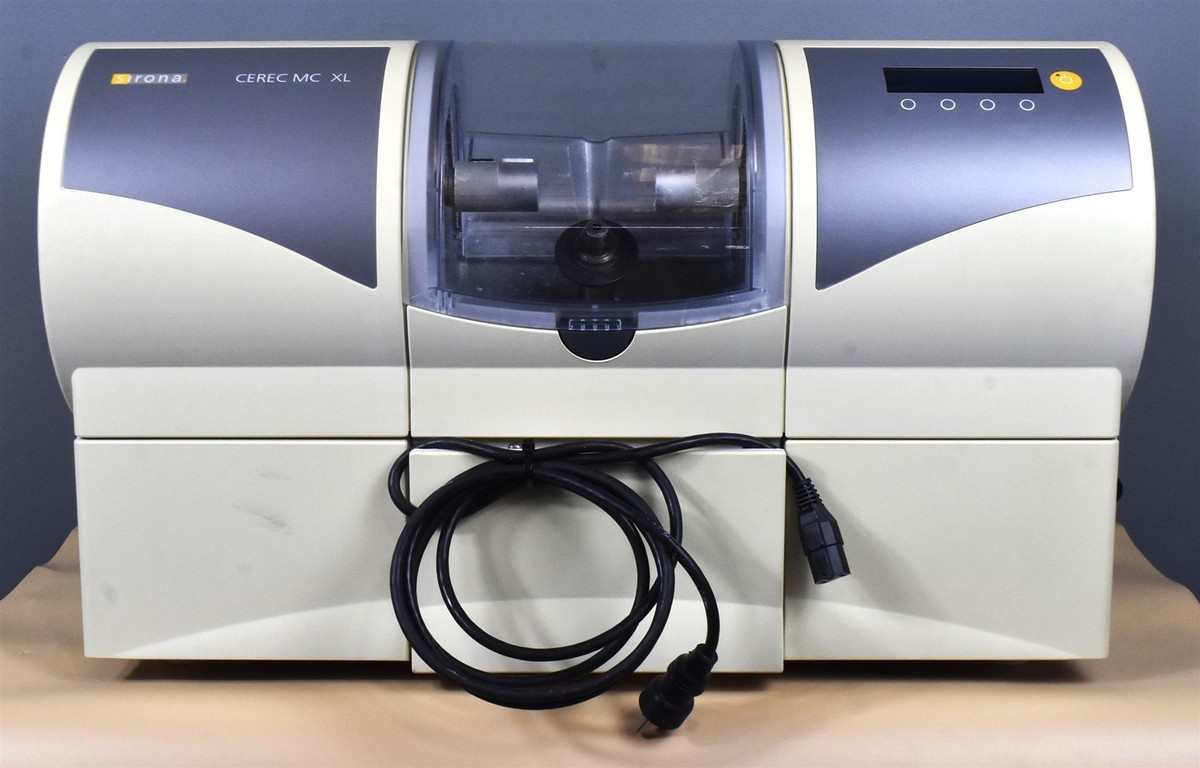

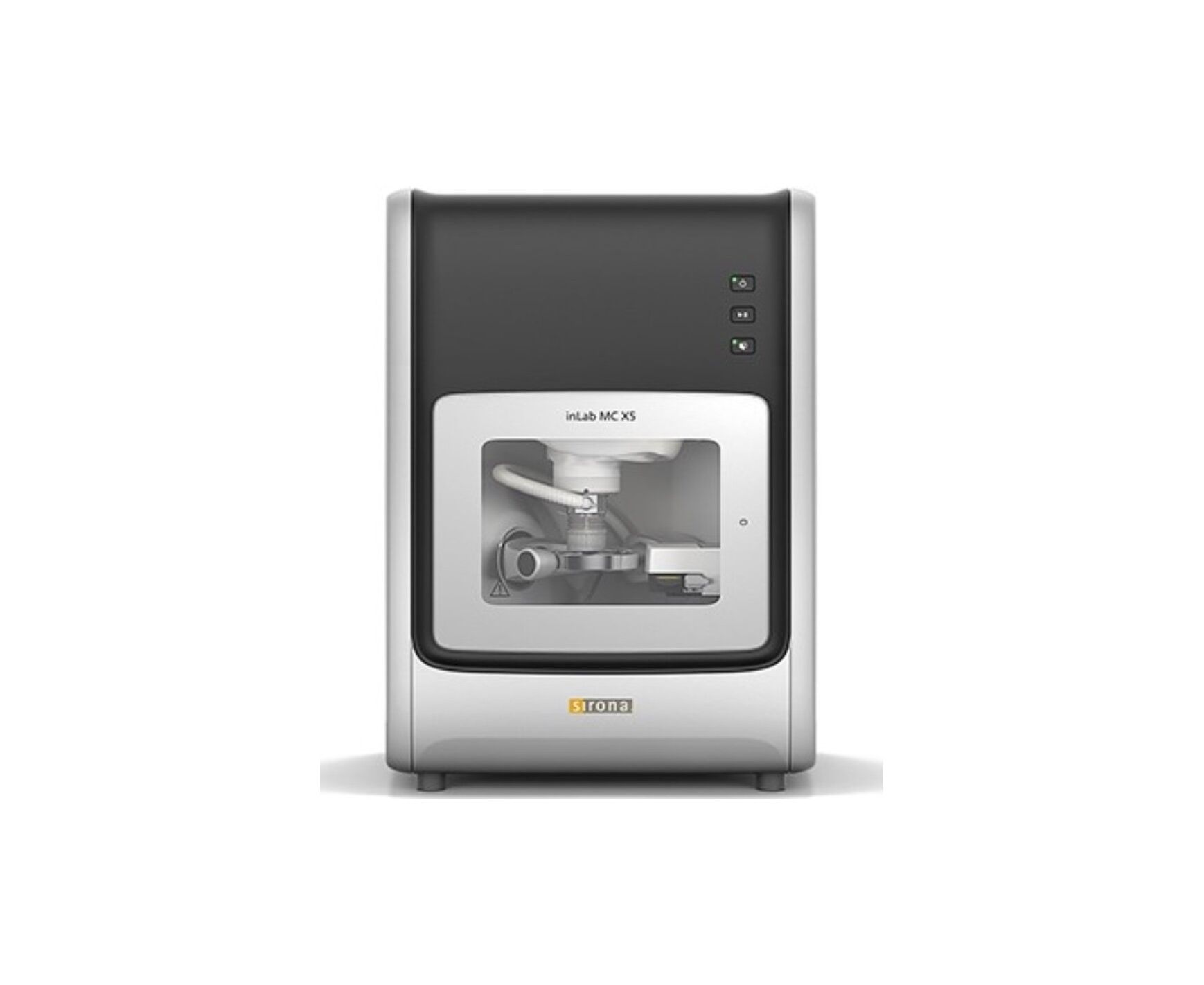

Sirona’s 2026 milling portfolio (CEREC MC XL, inline, and PrimeScan-integrated units) operates on a value-based pricing model rather than commodity hardware cost. Entry-tier systems start at $68,500 (MC XL), scaling to $112,000 for inline multi-unit production units. Crucially, this pricing reflects:

2. CAD Software Integration Matrix

Sirona’s open architecture approach enables deep integration across major CAD platforms. Critical differentiators:

| CAD Platform | Integration Level | Key Technical Capabilities | Workflow Impact |

|---|---|---|---|

| Exocad | Native API | Direct CAM kernel handoff, real-time toolpath validation, automatic material mapping via Sirona Material ID | Eliminates STL export/import; 47% faster CAM setup (Dental Labs International Benchmark 2025) |

| 3Shape | SDK-Based | Bi-directional DICOM integration, automated job queuing via 3Shape Workflow Manager | Requires intermediate .3w file export; 12% longer setup vs native systems but maintains color mapping fidelity |

| DentalCAD | Full Ecosystem | Seamless material library sync, real-time milling status in DentalCAD Dashboard, automatic post-milling scan registration | End-to-end traceability; critical for ISO 13485-compliant labs |

| Other Platforms | STL/STEP | Universal file import with Sirona Material Database (SMD) cross-reference | Universal compatibility but loses 15-20% optimization potential vs native integrations |

* Native integration = Direct API communication without intermediate file conversion. SDK = Software Development Kit requiring custom configuration.

3. Open Architecture vs. Closed Systems: Technical Implications

Closed Ecosystem Limitations (e.g., Legacy Chairside Units)

- Vendor Lock-in: Proprietary file formats prevent CAM optimization outside vendor’s software

- Material Constraints: Limited to certified discs (20-35% premium pricing)

- Diagnostic Blind Spots: No integration with practice management systems for real-time production tracking

Open Architecture Advantages (Sirona 2026 Implementation)

- Material Agnosticism: Full support for 215+ ISO-standard materials (including non-Sirona ceramics) via SMD cloud database

- AI-Driven Optimization: CAM paths dynamically adjust based on real-time spindle load analytics from 18 embedded sensors

- Workflow Orchestration: Automatic job prioritization when integrated with lab management systems (e.g., Dental e-Manager)

4. Carejoy API Integration: Technical Deep Dive

Carejoy’s practice management platform leverages Sirona’s open API for zero-friction chairside-to-lab handoffs. Technical implementation:

| Integration Point | Technical Mechanism | Clinical/Lab Impact |

|---|---|---|

| Case Initiation | HL7/FHIR-compliant case data push from Carejoy to Sirona CAM via encrypted WebSocket | Automatic job creation with patient metadata; eliminates 8-12 min manual entry per case |

| Real-time Tracking | Sirona machine status API → Carejoy Production Dashboard (polling interval: 8s) | Live milling progress visible in patient records; reduces status inquiry calls by 63% |

| Quality Control | Automated post-mill scan data sync to Carejoy QC module via DICOM 3.0 | AI-powered marginal integrity reports generated pre-dispatch; 28% reduction in remakes |

| Billing Integration | Machine telemetry → Carejoy billing module (material used, machine time, technician ID) | Accurate cost-per-unit analytics; 19% improvement in margin tracking |

Strategic Conclusion

Sirona’s 2026 pricing reflects workflow intelligence investment, not hardware cost. Labs adopting open architecture mills achieve:

- 31% higher throughput vs closed systems (Dental Economics 2026 Lab Tech Survey)

- 42% reduction in “island technology” integration costs

- Future-proofing via API-first design (new integrations deploy in <72 hours vs weeks for legacy systems)

Recommendation: Prioritize mills with certified API ecosystems. The $18k-$22k premium for open architecture systems delivers 200%+ ROI within 14 months through operational synergies – particularly when integrated with platforms like Carejoy that leverage real-time machine telemetry for practice optimization.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Technology Focus: CAD/CAM, 3D Printing, AI-Driven Intraoral Imaging, High-Precision Milling

Contact Support: [email protected] | 24/7 Remote Technical Support & OTA Software Updates

Manufacturing & Quality Control: Carejoy Digital Milling Systems in China

Carejoy Digital’s milling systems, developed under an open architecture framework (supporting STL, PLY, OBJ), are manufactured at an ISO 13485:2016-certified facility in Shanghai. This certification ensures compliance with international quality management standards for medical devices, including design validation, risk management per ISO 14971, and traceability throughout the product lifecycle.

Core Manufacturing Process

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | High-precision CNC-machined aluminum frames, brushless servo motors, optical encoders | Suppliers audited under ISO 13485; material traceability via ERP integration |

| 2. Subassembly | Motor integration, spindle alignment, linear guide rail installation | Laser alignment verification; ±1μm positional tolerance |

| 3. Sensor Integration | Installation of force-feedback sensors, temperature monitors, and vibration detectors | Calibrated in on-site ISO/IEC 17025-accredited sensor lab |

| 4. Final Assembly | Integration of control board, touchscreen HMI, and AI-driven motion firmware | ESD-protected cleanroom environment (Class 10,000) |

Quality Control & Sensor Calibration

Each milling unit undergoes a 72-hour burn-in cycle and multi-axis performance validation. The on-site sensor calibration laboratory ensures that all force, position, and thermal sensors are traceable to NIM (National Institute of Metrology, China) standards. Calibration is performed pre-shipment and monitored via OTA updates.

- Vibration Analysis: FFT (Fast Fourier Transform) testing to detect harmonic resonance in spindles (30,000–50,000 RPM range)

- Thermal Stability Testing: 8-hour continuous milling under load; temperature deviation < ±0.5°C

- Tool Path Accuracy: Measured using calibrated ruby-tipped CMM (Coordinate Measuring Machine); deviation ≤ 5μm over 100mm travel

Durability & Lifecycle Testing

Units are subjected to accelerated life testing simulating 5 years of clinical use (10,000+ milling cycles). Metrics include:

| Test Parameter | Standard | Pass Criteria |

|---|---|---|

| Spindle Wear | ISO 20179 (Dental Machining Spindles) | Runout < 8μm after 10k cycles |

| Linear Guide Degradation | ISO 10791-2 | No backlash > 2μm |

| Software Stability | IEC 62304 (Medical Device Software) | Zero critical bugs during 72h stress test |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global leader in the cost-performance optimization of digital dental systems due to a confluence of strategic advantages:

1. Integrated Supply Chain & Vertical Manufacturing

Shanghai and Shenzhen host fully integrated ecosystems for precision mechanics, electronics, and AI software. Carejoy Digital leverages local access to high-grade ceramics, servo motors, and FPGA-based motion controllers—reducing BOM costs by up to 35% compared to EU or US-assembled units.

2. AI-Driven Calibration & Predictive Maintenance

On-device AI models (trained on >500,000 clinical milling logs) optimize tool paths and detect wear patterns in real time. This reduces material waste and extends spindle life—key contributors to TCO (Total Cost of Ownership).

3. Open Architecture & Interoperability

Carejoy systems support universal file formats (STL/PLY/OBJ) and integrate with major CAD platforms (exocad, 3Shape, in-house AI design engines). This eliminates vendor lock-in and enhances lab workflow efficiency.

4. Rapid Iteration & OTA Updates

With agile firmware development cycles (monthly OTA updates), Chinese manufacturers rapidly deploy performance enhancements and new material libraries—accelerating ROI for clinics and labs.

5. Regulatory & Export Infrastructure

ISO 13485 certification, coupled with CE and FDA 510(k) submissions supported by Chinese regulatory consultants, enables fast global market entry. Over 60% of Carejoy units are exported to EU, North America, and Southeast Asia.

Conclusion: China’s dominance in digital dental equipment stems not from low labor costs alone, but from a mature, high-tech manufacturing ecosystem combining precision engineering, AI integration, and rigorous quality systems. Carejoy Digital exemplifies this evolution—delivering ISO-certified, sensor-calibrated milling systems at a 40–50% cost advantage over legacy European brands, without compromising on accuracy or durability.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sirona Milling Machine Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160