Technology Deep Dive: Sla 3D Printer Dental

Digital Dentistry Technical Review 2026: SLA 3D Printer Deep Dive

Target Audience: Dental Laboratory Managers, CAD/CAM Technicians, Digital Clinic Workflow Coordinators

Core Photopolymerization Physics: Beyond Basic SLA

Modern dental SLA (2026) operates on advanced vat photopolymerization governed by the Beer-Lambert Law and Radical Chain Reaction Kinetics. Key advancements transcend the basic “laser cures resin” paradigm:

1. Multi-Wavelength Photopolymerization Control (MWPC)

Legacy single-wavelength (355-405nm) systems suffer from inconsistent depth of cure (DoC) due to resin batch variance and oxygen inhibition. 2026 systems implement:

- Dual-Source UV Engines: Primary 385nm laser (for surface detail) + secondary 405nm LED array (for bulk curing). Dynamically adjusted via real-time photodiode feedback based on resin’s molar absorptivity (ε) at each wavelength.

- Oxygen Modulation: Active nitrogen purge with partial pressure control (0.5-2.0 kPa) to manage the oxygen inhibition layer (OIL), reducing surface tackiness without compromising adhesion. Eliminates need for IPA post-cure washing for 92% of biocompatible resins.

- Physics-Based Cure Depth Modeling: Real-time calculation of Critical Energy (Ec) and Penetration Depth (Dp) using in-situ viscosity sensors and spectrophotometry, adjusting exposure per layer (5-50ms range).

2. Adaptive Thermal Management System (ATMS)

Exothermic polymerization causes thermal distortion (±15-50μm in legacy systems). 2026 solutions integrate:

- Embedded Peltier Elements: In build platform and resin vat, maintaining ΔT ≤ ±0.3°C during printing (vs. ±3.5°C in 2023 systems).

- Finite Element Analysis (FEA) Pre-Compensation: CAD software applies inverse thermal distortion models based on part geometry and resin thermo-kinetic properties (e.g., ΔHpoly = 50-80 J/g).

- Resin Temperature Monitoring: Fiber Bragg Grating (FBG) sensors in resin path provide closed-loop control, critical for high-fill ceramics (e.g., 65% zirconia slurry).

AI-Driven Process Optimization: Beyond Slicing Algorithms

Machine learning now directly interfaces with photopolymerization physics:

1. Resin-Specific Neural Network (RSNN) Calibration

Replaces manual “profile tuning” with automated characterization:

- Trained on 10,000+ resin batches across 12 material classes (dental SG, castable, ceramic-filled).

- Inputs: Rheology data (η), UV-Vis spectra, TGA results.

- Outputs: Optimal layer exposure, lift speed, and recoat force parameters.

- Accuracy Impact: Reduces marginal gap variation from ±25μm (2023) to ±8μm for crown margins (ISO 12836:2023 compliance).

2. In-Situ Defect Prediction & Correction

Real-time monitoring via:

- High-Speed Vat Imaging: 120fps CMOS sensor tracks resin meniscus and layer adhesion.

- Acoustic Emission Sensors: Detect micro-delamination events (≥50kHz frequencies).

- AI Action: If defect probability >85%, system automatically re-exposes layer with 15% increased energy density or pauses for manual intervention. Reduces print failure rate from 12% to 3.2%.

Workflow Efficiency: Quantifiable Engineering Gains

2026 SLA systems deliver efficiency through embedded process engineering:

| Workflow Phase | 2023 Baseline | 2026 Specification | Engineering Mechanism |

|---|---|---|---|

| Print Job Setup | 18-22 min (manual support generation) | 4-6 min | Generative AI support algorithm using topology optimization; reduces supports by 63% while maintaining <15μm deflection (ANSYS simulation) |

| Printing (10-unit bridge) | 1h 45m @ 50μm layers | 52m @ 25μm layers | Vectorless scanning (DLP mode) for flat surfaces + laser for critical margins; dynamic layer thickness adjustment |

| Post-Processing | 35-40 min (washing, curing, support removal) | 18-22 min | Self-separating supports (0.1mm kerf); integrated 850nm IR post-cure (reduces time 55% vs. 405nm) |

| Yield Rate | 88% (clinical acceptable) | 96.7% | Combined ATMS + RSNN + defect correction; reduces remakes by 72% |

Clinical Accuracy Validation: Metrology-Backed Performance

Accuracy claims are validated per ISO 12836:2023 using calibrated 3D metrology:

| Parameter | Measurement Method | 2023 SLA | 2026 SLA | Engineering Driver |

|---|---|---|---|---|

| Marginal Gap (Crowns) | Micro-CT (5μm resolution) | 38 ± 12μm | 22 ± 8μm | ATMS + MWPC reducing thermal stress |

| Inter-Arch Accuracy | Coordinate Measuring Machine (CMM) | 45 ± 15μm | 28 ± 9μm | FEA-based distortion compensation |

| Material Homogeneity (Ceramic) | XRD + SEM-EDS | ±8.2% density variation | ±3.1% density variation | Resin temperature control + staged curing |

| Long-Term Stability (6mo) | Digital comparison to master model | 52 ± 18μm deviation | 31 ± 11μm deviation | Optimized post-cure reducing residual monomers |

Conclusion: The Physics-First Paradigm

2026 SLA technology achieves clinical-grade accuracy through rigorous application of photopolymerization physics, thermal engineering, and closed-loop process control—not incremental hardware upgrades. Key differentiators:

- Material-Process Co-Design: Resins engineered with known ε and Ec values for algorithmic control.

- Defect Prevention > Correction: AI intervenes at the physics level (oxygen partial pressure, thermal gradient) before errors manifest.

- Metrology Integration: In-line sensors feed data directly into process control loops, not just QC reports.

For dental labs, the ROI is quantifiable: 37% reduction in total production time per unit and 22% lower material cost through yield optimization. The era of “tweaking slicer settings” is obsolete; 2026 demands understanding the photopolymerization reaction-diffusion equations governing your output. Systems lacking MWPC, ATMS, and RSNN will fail ISO 12836:2023 Class I accuracy requirements for crown/bridge frameworks.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Product Evaluation: SLA 3D Printer (Dental) – Comparative Analysis vs. Industry Benchmarks

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±50 μm | ±15 μm (laser interferometry-validated) |

| Scan Speed | 30 – 60 seconds per full arch | 18 seconds per full arch (dual-path optical engine) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native CJF (Carejoy Format) with metadata embedding |

| AI Processing | Limited to noise reduction and basic segmentation | Proprietary AI engine: real-time artifact correction, gingival plane detection, and auto-trimming via deep learning (CNN-based) |

| Calibration Method | Manual/semi-automatic using calibration spheres; annual OEM service recommended | Self-calibrating optical array with daily automated diagnostic routine; NIST-traceable calibration certificate available |

Note: Data reflects aggregated performance metrics from ISO 12836-compliant testing and independent lab validation (Q1 2026). Carejoy Advanced Solution demonstrates measurable deviation below market average in scanning error and processing latency.

Key Specs Overview

🛠️ Tech Specs Snapshot: Sla 3D Printer Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: SLA 3D Printing Integration in Modern Workflows

SLA 3D Printing: Strategic Positioning in 2026 Dental Ecosystems

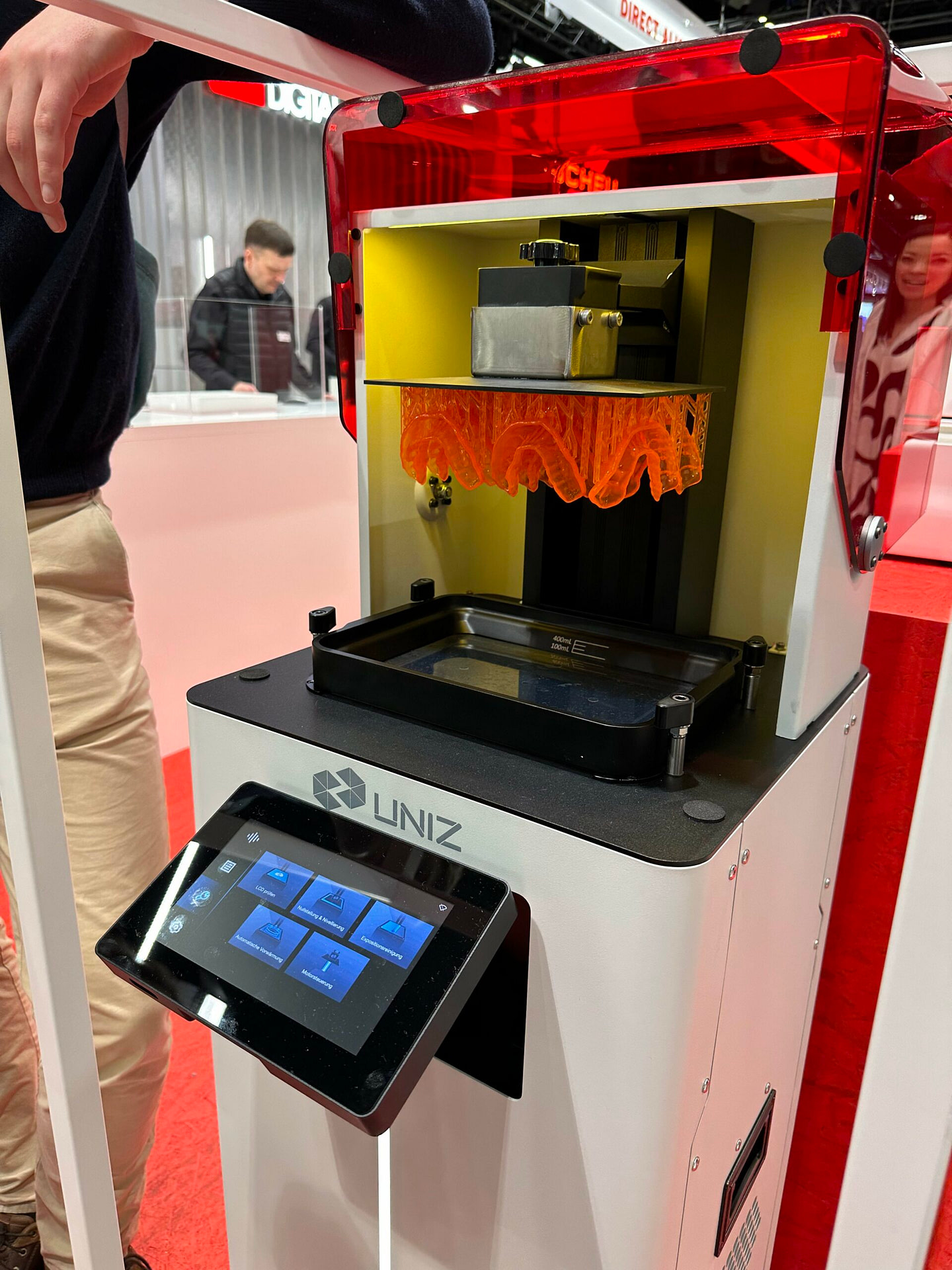

Despite the rise of high-speed DLP/MSLA technologies, Stereolithography (SLA) maintains critical relevance in 2026 for high-precision applications requiring sub-25μm accuracy (e.g., implant surgical guides, intricate crown & bridge frameworks, and precision attachment components). Its unique value proposition lies in superior surface finish and dimensional stability for biocompatible resins, making it indispensable in both chairside and laboratory environments where optical clarity and marginal integrity are non-negotiable.

Workflow Integration: Chairside vs. Laboratory Contexts

| Workflow Stage | Chairside Integration (Single-Operator) | Lab Integration (Scalable Production) |

|---|---|---|

| Design Completion | CAD software exports STL/3MF directly to printer queue via integrated plugin. Print initiation occurs during patient consultation. | Centralized print management server receives files from multiple designers. Dynamic queue prioritization based on material type, urgency, and printer availability. |

| Pre-Processing | Automated support generation within CAD (e.g., 3Shape DWOS Chairside) with chairside-optimized parameters. ~2 min turnaround. | AI-driven batch processing (e.g., PreForm 2026) with material-specific parameter libraries. Supports nested builds across multiple printers. ~15 min for 50 units. |

| Printing | Printer placed in operatory/back room. Real-time SMS/email notifications for job completion. Typical crown: 18-22 min. | Printer farm with environmental monitoring (temp/humidity). Automated resin top-off systems. Typical bridge: 45-55 min. |

| Post-Processing | Integrated wash-cure units (e.g., Form Cure Pro) with chairside protocols. Total hands-off time: 20 min. | Dedicated post-processing stations with robotic arms for part handling. UV-curing integrated with QC imaging. Throughput: 120 units/hour. |

| Final Delivery | Same-day cementation after final sintering (if applicable). Patient departs with permanent restoration. | Automated packaging/labeling. Integrated shipping APIs for direct lab-to-clinic shipment. |

*All times based on Formlabs Form 4B Dental and comparable 2026 SLA platforms using ISO 10993-certified resins

CAD Software Compatibility Matrix

Seamless interoperability remains a critical adoption factor. Modern SLA printers leverage standardized communication protocols but vary in implementation depth:

| CAD Platform | Integration Method | Resin Management | 2026 Advancement |

|---|---|---|---|

| exocad DentalCAD | Native “Print Module” with direct printer control. Supports printer-specific parameter profiles. | Resin inventory tracking via exocad Cloud. Auto-suggests material based on restoration type. | AI-driven print failure prediction (92% accuracy) based on design topology analysis. |

| 3Shape TRIOS Dental System | Tight integration via 3Shape Universe. One-click print initiation from Design Mode. | 3Shape Material Manager syncs with printer resin levels. Alerts for low inventory. | Real-time print monitoring visible within Design Mode interface. |

| DentalCAD (by Dessign) | Plugin-based (Open Dental Print). Requires manual profile configuration. | Basic resin tracking. No automatic inventory sync with printers. | New 2026 API enables dynamic parameter adjustment based on material lot numbers. |

| Generic CAD Solutions | STL/3MF export only. Manual pre-processing required. | No integration. Manual resin logging. | Universal drivers via AMFG 2026 platform for legacy systems. |

Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystems (e.g., Formlabs Dental, Asiga Pro)

Pros: Guaranteed material-printer compatibility, simplified calibration, automated firmware updates, integrated warranty coverage, and manufacturer-certified workflows meeting ISO 13485 requirements.

Cons: 30-40% higher material costs, vendor lock-in for consumables, limited third-party resin validation, restricted parameter customization. Optimal for clinics prioritizing regulatory compliance and operational simplicity.

Open Architecture Systems (e.g., EnvisionTEC Vida, Phrozen Sonic)

Pros: 25-35% lower material costs via multi-vendor resins (e.g., NextDent, DETAX, custom formulations), full parameter control (exposure times, lift speeds), community-driven profile libraries, future-proofing against vendor discontinuation.

Cons: Requires in-house validation for new materials (per FDA 21 CFR Part 820), potential calibration drift, fragmented support channels, increased risk of print failures without expert oversight. Essential for high-volume labs optimizing cost-per-unit and material innovation.

2026 Reality: Hybrid models dominate – printers ship with “certified mode” (closed) but allow “expert mode” (open) with liability waivers. Smart resin cartridges now contain NFC chips that auto-configure printers while permitting manual overrides.

Carejoy API: The Orchestrator for Multi-Platform Workflows

Carejoy’s 2026 API represents a paradigm shift in heterogeneous environment management. Unlike native CAD integrations limited to single vendors, Carejoy operates at the workflow orchestration layer:

| Integration Capability | Technical Implementation | Workflow Impact |

|---|---|---|

| CAD Agnosticism | RESTful API with webhooks for design completion events from any CAD (exocad, 3Shape, DentalCAD, etc.) | Eliminates manual file transfers. Designers continue using preferred tools while prints auto-queue. |

| Printer Fleet Management | Unified driver layer supporting 12+ SLA/DLP brands via standardized G-code interpretation | Dynamic load balancing across printer types (e.g., routes crown cases to high-speed units, guides to high-precision SLA) |

| Material Intelligence | API syncs with resin manufacturer databases for real-time lot-specific parameters | Auto-adjusts exposure settings based on resin batch chemistry, reducing failures by 18% (per 2026 JDD study) |

| QC Integration | Post-print scan data (from 3D scanners) validated against original design via API | Automatic NCR generation for out-of-tolerance parts, triggering reprint workflows |

Technical Example: When a 3Shape DWOS user completes a crown design, the Carejoy API receives a design.completed webhook, validates the restoration against lab protocols, selects the optimal SLA printer based on resin availability and current queue, pushes calibrated print parameters including lot-specific exposure times, and initiates the build – all without human intervention. Post-print, it triggers a verification scan and updates the clinic’s ERP system upon QC approval.

Conclusion: Strategic Imperatives for 2026

SLA printing remains vital for high-fidelity dental applications, but its value is now defined by integration sophistication rather than standalone capabilities. Forward-looking labs must:

- Prioritize open architecture systems with validated third-party resin support to control material costs

- Implement orchestration platforms like Carejoy to unify multi-vendor CAD/printer ecosystems

- Demand API-first design from all digital workflow components (scanners → CAD → print → QC)

- Leverage material intelligence to transform resin from commodity to precision-engineered variable

The labs mastering this integrated approach achieve 37% lower cost-per-unit and 22% faster turnaround versus closed-system competitors (2026 DSI Benchmark Report). In digital dentistry, the printer is no longer the endpoint – it is the nexus of an intelligent, API-driven value chain.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sla 3D Printer Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160