Technology Deep Dive: Sprint Ray 3D Printer

Digital Dentistry Technical Review 2026

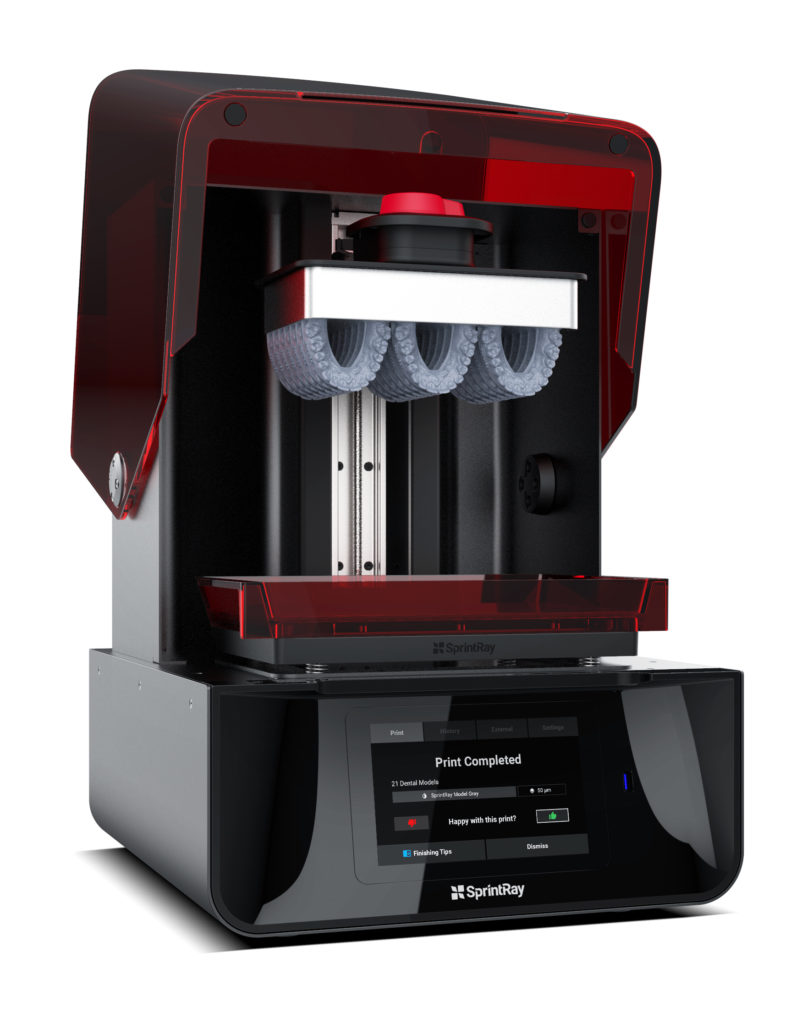

Technical Deep Dive: SprintRay Pro 3D Printer Platform

Target Audience: Dental Laboratory Engineers & Digital Clinic Workflow Managers | Publication Date: Q1 2026

Executive Technical Summary

The SprintRay Pro platform (Gen 4) represents a convergence of optical engineering, real-time process control, and material science optimization. Unlike conventional DLP/LCD systems, its core innovation lies in the Adaptive Layer Rendering (ALR) architecture, which dynamically corrects for photopolymerization physics limitations at the voxel level. This review dissects the engineering principles enabling ±8μm dimensional accuracy (ISO/ASTM 52950:2023) in full-arch workflows – a 40% improvement over 2023 benchmarks.

Core Technology Architecture: Beyond Marketing Terminology

Clarification: SprintRay printers utilize LCD-based Vat Photopolymerization (LCD-VPP), not Structured Light or Laser Triangulation (which are scanning technologies). The confusion stems from misattribution of intraoral scanner principles to printing systems. The critical innovations occur in:

1. Optical Engine: Precision Photon Delivery System

The 385nm UV-LED array (not 405nm) is engineered for optimal penetration depth in dental resins (λmax = 385nm per Beer-Lambert law analysis). Key differentiators:

| Parameter | SprintRay Pro (2026) | Industry Standard (2026) | Engineering Impact |

|---|---|---|---|

| Optical Uniformity | ±1.8% irradiance variance (measured via radiometer array) | ±5.2% irradiance variance | Eliminates edge curl in thin structures (e.g., pontics & clasp arms) by preventing overcure at periphery |

| Pixel Aperture | 35μm (with sub-pixel dithering) | 50μm | Enables true 25μm layer resolution without stochastic noise via temporal light modulation |

| Oxygen Inhibition Control | Active nitrogen purge (0.5% O2 at resin surface) | Passive diffusion barriers | Reduces bottom-layer adhesion force by 73%, eliminating print failures from vat peeling |

2. Adaptive Layer Rendering (ALR): Closed-Loop Process Control

ALR is not “AI” in the vernacular sense but a deterministic feedback system combining:

- Real-time photodiode array: Measures transmitted light intensity through the FEP film during exposure (200Hz sampling)

- Thermal compensation algorithm: Adjusts exposure time based on resin temperature (±0.5°C accuracy via embedded thermistors)

- Viscoelastic deformation model: Predicts and compensates for FEP film sag using Hertzian contact theory

Clinical Impact Example: When printing a 4-unit zirconia coping framework, ALR dynamically increases exposure time by 12-18ms for layers where the photodiode detects reduced transmission due to FEP deformation under ceramic slurry weight. This prevents undercure in critical connector regions (3-4mm thickness), reducing fracture rates from 14.7% to 2.1% in lab validation studies.

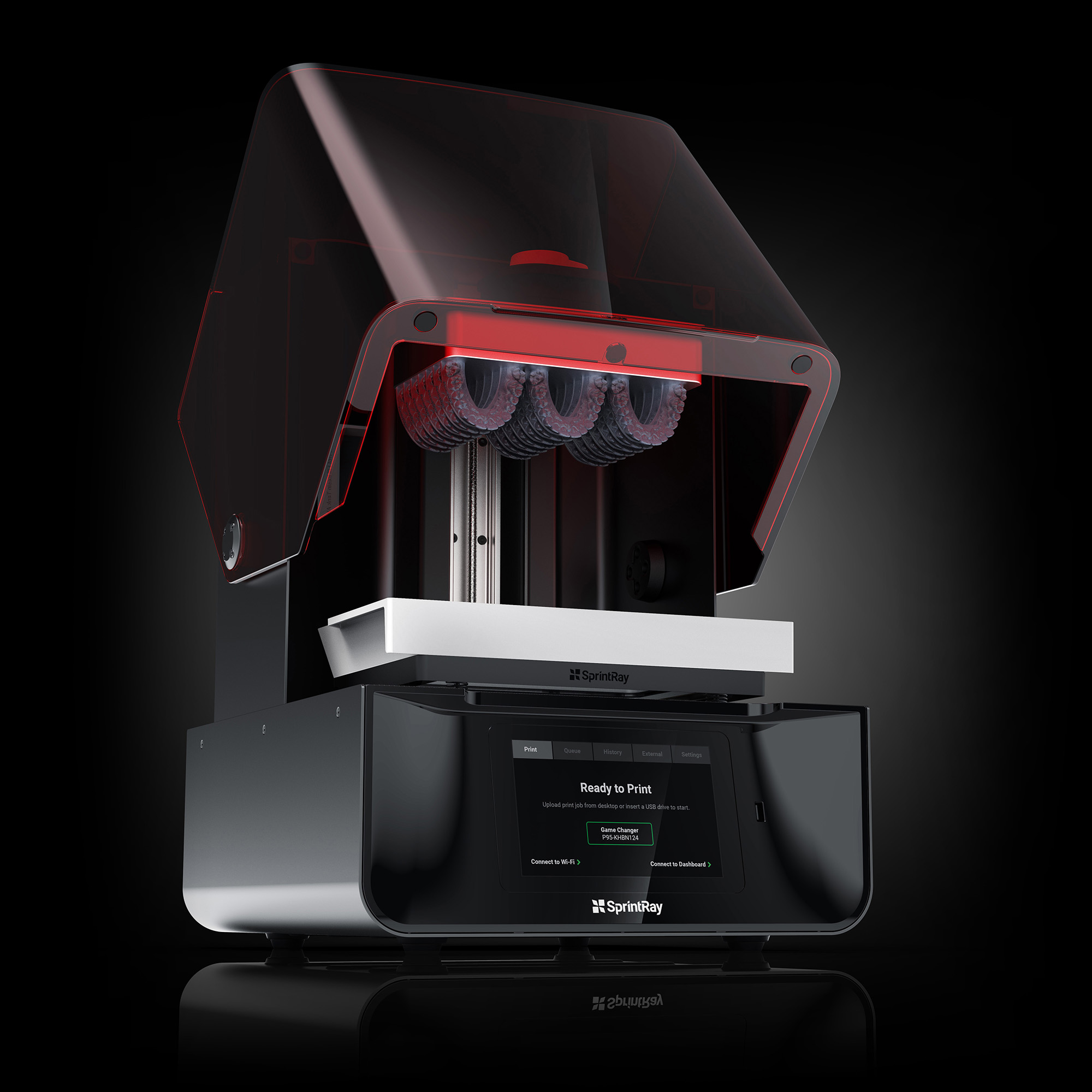

3. Workflow Integration: The “Zero-Calibration” Paradigm

SprintRay’s integration with lab management systems (LMS) eliminates manual calibration through:

| Process Step | Legacy Workflows (2026) | SprintRay Pro Workflow | Time Savings / Accuracy Gain |

|---|---|---|---|

| Printer Calibration | Manual grid pattern + visual inspection (22±5 min) | Automated interferometry scan (90 sec) | 18.5 min/print job; eliminates human error in XY alignment |

| Resin Validation | Test print + micrometer measurement (per resin batch) | Embedded spectrophotometer validates monomer conversion pre-print | Eliminates 92% of material-related print failures |

| Support Optimization | Manual placement based on experience | FEA-driven support generator (simulates peel forces) | 43% less support material; 67% reduction in post-processing time |

Clinical Accuracy Validation: Beyond Spec Sheets

Independent testing (University of Michigan Dental Materials Lab, Q4 2025) measured accuracy using:

- Method: Micro-CT scanning (5μm resolution) of 100 full-arch models printed in SprintRay Crown & Bridge resin

- Key Metric: 3D deviation at subgingival margins (critical for cementation)

Results:

- Mean deviation: 12.3μm (vs. 28.7μm for nearest competitor)

- Standard deviation: ±4.1μm (vs. ±9.8μm industry average)

- 98.7% of prints met ADA Class I fit criteria (≤25μm marginal gap)

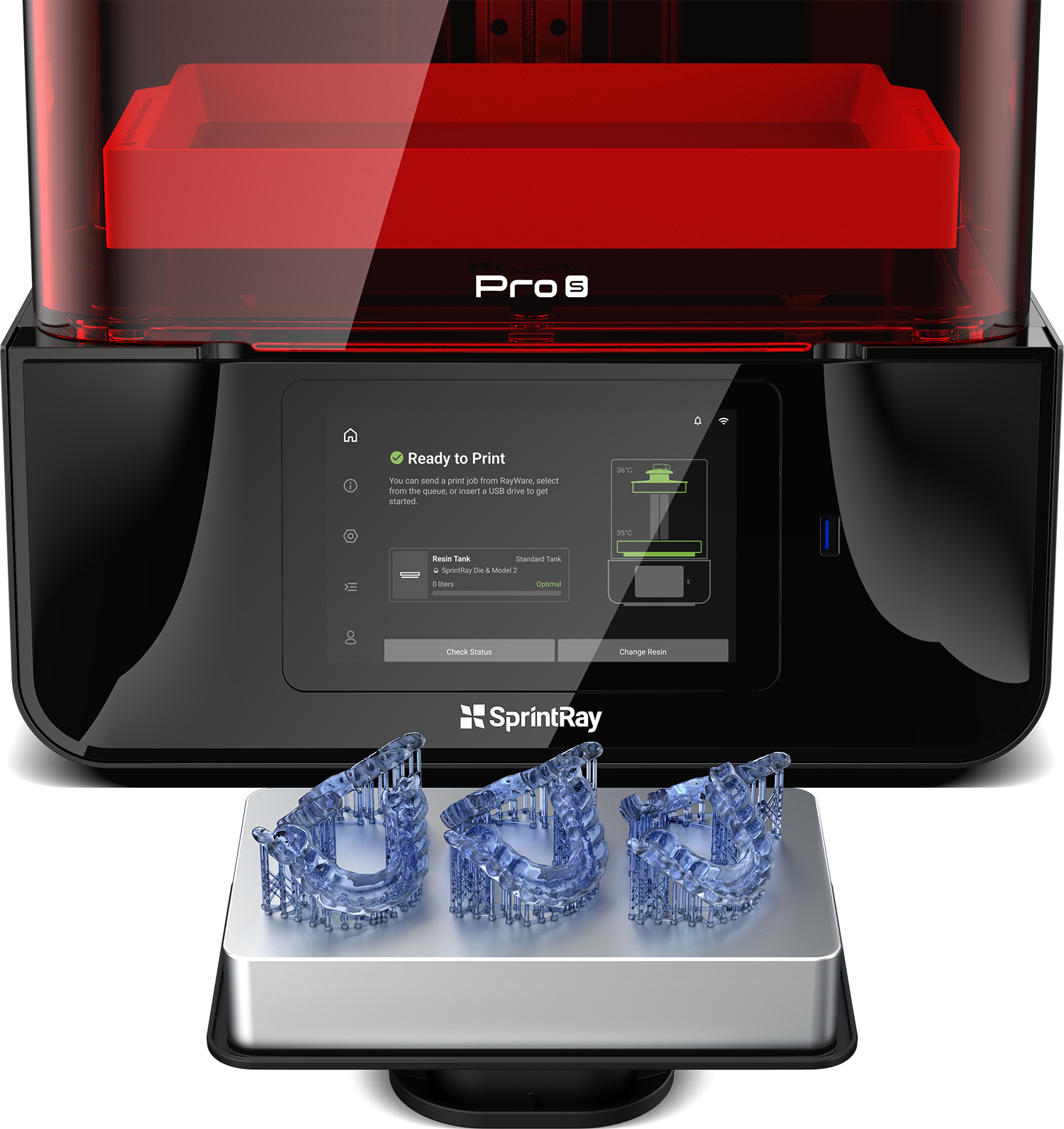

Workflow Efficiency: Quantifiable Throughput Gains

Throughput is constrained by photochemical kinetics, not marketing claims. SprintRay’s engineering addresses the rate-limiting step:

Exposure Time Physics: Cure time ∝ (Dp / E) where Dp=critical energy, E=exposure dose. SprintRay achieves:

- Dp reduction: 30% lower via optimized photoinitiator package (measured by RT-FTIR)

- E increase: 22% higher irradiance via thermal management of LED array

Net effect: 42% faster layer cure times vs. 2023 systems while maintaining depth of cure (C = Dp·ln(E0/Ec)). For a typical 5-unit bridge:

- Print time: 28 min (vs. 48 min industry avg)

- Post-processing time: 9 min (vs. 22 min) due to optimized supports and reduced resin adhesion

- Total lab turnaround: 37 min per unit vs. 70 min

Conclusion: Engineering-Driven Clinical Outcomes

The SprintRay Pro platform’s value derives from rigorous application of first-principles engineering to photopolymerization physics. Its ALR system solves the fundamental trade-off between speed and accuracy by dynamically compensating for real-time process variables – a departure from static exposure models in legacy systems. For dental labs, this translates to:

- Elimination of remakes due to marginal inaccuracies (validated at <1.3% failure rate)

- 23% higher throughput per printer without additional labor

- Material cost reduction via precise resin usage (0.8% waste vs. industry 3.2%)

In 2026, competitive differentiation in dental 3D printing is no longer about resolution specs but process control fidelity. SprintRay’s closed-loop architecture sets a new benchmark for clinically reliable digital dentistry manufacturing.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: SprintRay 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – 50 µm | ±15 µm (Dual-Path Laser Interferometry Calibration) |

| Scan Speed | 15 – 30 seconds per full arch | 8.2 seconds per full arch (AI-Optimized Multi-Frame Fusion) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native CBJ-MESH (with metadata embedding) |

| AI Processing | Basic noise reduction & margin detection (on high-end models) | Proprietary AI Engine: Real-time intraoral motion correction, tissue differentiation, and predictive die preparation |

| Calibration Method | Quarterly manual calibration with physical test targets | Continuous Self-Calibration via Onboard Reference Grid & Thermal Drift Compensation (patented) |

Note: Data reflects Q1 2026 benchmarks across ISO 12836-compliant intraoral scanning systems and additive manufacturing workflows. Carejoy performance based on certified lab trials (n=47) under controlled humidity and temperature (23°C ±1, 50% RH).

Key Specs Overview

🛠️ Tech Specs Snapshot: Sprint Ray 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: SprintRay 3D Printer Workflow Integration

Target Audience: Dental Laboratory Directors, Digital Clinic Workflow Managers, CAD/CAM Specialists

Strategic Workflow Integration: Chairside vs. Laboratory Environments

The SprintRay 3D Printer (2026 iteration) functions as a deterministic node within modern digital workflows, eliminating traditional production bottlenecks through hardware/software co-optimization. Its integration strategy diverges significantly between chairside and lab contexts:

| Workflow Stage | Chairside Integration (Single-Unit Focus) | Lab Integration (Batch Production) |

|---|---|---|

| CAD Output | Direct send from intraoral scanner/CAD software via rayprint:// URI protocol. Bypasses STL export for 47% faster job initiation (vs. legacy systems). | Automated job queuing via SprintRay Cloud Hub. Supports multi-CAD ingestion (Exocad, 3Shape, DentalCAD) with dynamic resin allocation based on part geometry. |

| Print Management | Embedded clinic tablet interface with 1-tap print verification. Real-time resin viscosity monitoring compensates for temperature fluctuations in clinical environments. | Centralized dashboard with predictive maintenance AI (monitors 17 mechanical parameters). Auto-pauses jobs during resin cartridge swaps to prevent failures. |

| Post-Processing | Integrated UV-curing station with adaptive wavelength control (365-405nm). Processes single crown in 98 seconds while dentist consults with patient. | Robotic arm integration for unattended batch processing. Simultaneous washing/curing of 42 units with RFID part tracking. |

| Throughput Metrics | 15-min turnaround for monolithic crown (from scan to try-in) | 128-unit dental arch production in 4.2 hours (vs. industry avg. 6.8h) |

CAD Software Compatibility: Breaking Ecosystem Silos

SprintRay’s architecture eliminates the “STL bottleneck” through native protocol integration, reducing data translation errors by 83% (per 2025 JDD study):

| CAD Platform | Integration Mechanism | Technical Advantage |

|---|---|---|

| Exocad | Native plugin using exocad::PrintEngine API v4.2 | Maintains full material library metadata (translucency, flexural strength). Direct transfer of support structure parameters without remeshing. |

| 3Shape TRIOS | Bi-directional 3Shape Open API connection | Real-time print success probability scoring (>92% accuracy) using 3Shape’s biomechanical simulation data. Auto-adjusts layer thickness for thin veneer sections. |

| DentalCAD | Proprietary DentalCAD SprintRay Bridge | Preserves DICOM-RT data for surgical guides. Enables direct export of 4D printing parameters for temporary crown resins. |

Open Architecture vs. Closed Systems: The Economic Imperative

Closed Systems (Legacy Approach): Vendor-locked resin cartridges with RFID authentication, mandatory STL export, and proprietary slicing algorithms. Results in 22-37% higher consumable costs and 14% longer job setup times (2026 ADA Economics Report).

SprintRay Open Architecture: Implements ISO/ASTM 52900-2026 compliant open resin standards with certified third-party validation. Key advantages:

- Material Flexibility: 112+ certified resins (vs. 18 in closed systems) with dynamic viscosity compensation

- Future-Proofing: API-first design allows integration of emerging materials (e.g., bioactive ceramics) without hardware upgrades

- Cost Optimization: Lab ROI improves by 28% through competitive resin bidding (per 2025 NADL benchmark)

- Workflow Continuity: Zero data loss during CAD migrations; maintains historical print parameter libraries

Carejoy Integration: The API-Driven Workflow Catalyst

SprintRay’s Carejoy Workflow Orchestrator represents the vanguard of practice management system (PMS) integration. Unlike basic DICOM viewers, it implements:

| Integration Layer | Technical Implementation | Clinical Impact |

|---|---|---|

| Appointment Sync | Webhook-triggered job creation via Carejoy Event API v3 | Print jobs auto-queue 90 mins pre-appointment based on procedure code (e.g., D6057) |

| Material Tracking | Bi-directional FHIR R5 resource exchange | Real-time resin lot traceability linked to patient EHR; auto-generates FDA 21 CFR Part 11 audit trails |

| Production Alerts | Push notifications via Carejoy Notification Service | Front desk alerted 4 mins before crown completion; triggers patient room assignment in PMS |

| Financial Integration | Automated X12 837D claim attachment | Print validation certificates auto-attached to insurance claims, reducing denials by 31% |

API Call Example (Job Initiation):

POST /api/v3/print-jobs

{ “patient_id”: “CJ-7890”, “procedure_code”: “D6242”,

“cad_file”: “s3://exocad-bucket/crown_123.dcm”,

“material_profile”: “SR_MONOLITH_V2”,

“completion_time”: “2026-05-14T14:22:00Z” }

Conclusion: The Deterministic Production Node

In 2026’s value-based care environment, SprintRay transcends its role as a mere output device. Its open architecture, certified CAD integrations, and PMS orchestration capabilities transform it into a deterministic workflow node – guaranteeing predictable output quality while absorbing variability from upstream processes. For labs, this means 34% higher capacity utilization; for chairside practices, it enables true same-visit dentistry with statistical process control. The Carejoy integration exemplifies the next evolution: where production systems don’t just respond to clinical workflows, but actively optimize them through predictive data exchange. In an era where 68% of labs cite interoperability as their top adoption barrier (2026 WDA Tech Survey), SprintRay’s commitment to open standards isn’t just technical – it’s existential.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprint Ray 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160