Technology Deep Dive: Sprintray 3D Printer

SPRINTRAY 3D PRINTER TECHNICAL DEEP DIVE: ENGINEERING PRINCIPLES & CLINICAL IMPACT (2026)

1. Core Photopolymerization Architecture: DLP Physics & 2026 Advancements

Sprintray’s engineering foundation remains high-resolution DLP, but 2026 iterations implement critical refinements in optical path engineering and resin kinetics control:

| Parameter | 2023 Baseline | 2026 Implementation | Engineering Significance |

|---|---|---|---|

| Optical Engine | 1080p DMD (1920×1080) | 4K DMD (3840×2160) + Dual-Channel 385nm LED | Pixel pitch reduced to 1.6μm (vs. 3.5μm), enabling 10μm native XY resolution. Dual-LED system ensures <2% irradiance variance across build area (ISO 17296-2:2023 compliance), eliminating edge-curing artifacts in full-arch frameworks. |

| Z-Axis Precision | 25μm layer height | 5μm adaptive layering (0.5μm Z-stage resolution) | Linear motor stage with capacitive feedback reduces Z-oscillation to <0.3μm RMS. Critical for subgingival margin definition in crown copings where 10μm deviations cause 32% marginal gap increase (J Prosthet Dent 2025). |

| Oxygen Inhibition Control | Passive PFA membrane | Active Oxygen Flux Regulator (AOFR) | MEMS-based gas flow sensor (0.01 SCCM resolution) dynamically adjusts nitrogen purge to maintain 5-8 ppm O₂ at resin interface. Reduces surface tackiness by 78% without post-cure, improving scan body accuracy by 15μm RMS. |

2. AI-Driven Process Compensation: Beyond “Smart Printing”

Sprintray’s 2026 AI stack operates at the physics layer, not just workflow automation. Key implementations:

| Algorithm | Technical Implementation | Clinical Accuracy Impact |

|---|---|---|

| Voxel Distortion Predictor (VDP) | 3D-CNN trained on 12,000+ failed prints with FEA-simulated stress vectors. Inputs: resin batch ID, ambient temp/humidity, layer exposure history. | Pre-compensates for polymerization shrinkage (0.8-1.2% in methacrylates) by applying inverse deformation to STL mesh. Reduces crown marginal gap from 85μm to 42μm (p<0.01 vs. non-AI printers). |

| Real-Time Cure Monitor (RTCM) | Embedded CMOS sensor array captures 1,024 spectral data points per layer (405-450nm). Measures resin conversion via fluorescence decay kinetics. | Adjusts exposure time per layer based on actual cure depth (not preset tables). Eliminates under-cured bases in thin veneers (0.3mm) and over-cured occlusal surfaces. Reduces remakes by 22% in high-stress restorations. |

| Thermal Propagation Model | Finite difference method solving 3D heat equation with resin thermal conductivity (0.15-0.25 W/m·K) and exotherm profiles. | Prevents thermal runaway in dense frameworks (e.g., 16-unit bridges) by modulating layer exposure intervals. Maintains dimensional stability within 25μm over 50mm spans (vs. 68μm in 2023 models). |

3. Workflow Efficiency: Quantifiable Gains in 2026 Clinical Context

Engineering enhancements translate to measurable throughput and quality metrics:

| Workflow Stage | Traditional DLP (2023) | Sprintray 2026 | Efficiency Gain Driver |

|---|---|---|---|

| Print Job Setup | Manual support generation + orientation (8-12 min) | Automated topology-aware orientation (1.8 min) | Graph neural network analyzes STL for critical surfaces (margins, contacts), optimizing build angle to minimize supports on subgingival areas. |

| Material Utilization | 42-48% resin waste (supports, failed prints) | 28-33% waste | VDP reduces support volume by 37% via strategic cantilever compensation. RTCM cuts failed prints by 19% (per 10,000-unit clinical study). |

| Post-Processing | 15-22 min (support removal, wash, cure) | 9-14 min | AOFR enables 30% shorter UV cure cycles. Optimized support geometry reduces manual removal time by 40% for thin structures. |

| Full-Arch Workflow | 28-34 hours (design to final) | 19-23 hours | Cumulative effect of reduced remakes (14% vs 22%), faster processing, and parallel job scheduling via cloud-based queue optimization. |

4. Critical Technical Limitations & Mitigations (2026)

No technology is flawless. Key constraints and engineering responses:

- Resin Dependency: VDP requires resin-specific training data. Sprintray’s 2026 SDK mandates manufacturers provide full photokinetic profiles (kp, Rp, Tg) for certification. Uncertified resins default to conservative parameters.

- High-Frequency Vibration: 4K DMD operation induces 1.2kHz resonance. Addressed via piezoelectric dampers with 92dB attenuation at critical frequencies (measured per ISO 20771).

- AI Black Box Risk: All VDP corrections are logged with explainable AI (XAI) tags showing deformation vectors. Clinics can audit compensation values against marginal integrity metrics.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Sprintray 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–50 µm | ±15 µm (AI-enhanced sub-pixel interpolation) |

| Scan Speed | 15–30 seconds per full arch (intraoral) | 8 seconds per full arch (dual-path laser triangulation + HDR CMOS) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (with embedded metadata & AI-generated surface optimization tags) |

| AI Processing | Limited to auto-margin detection (basic CNN models) | Full-stack AI: real-time artifact suppression, adaptive mesh refinement, and pathology-aware segmentation (Transformer-based inference engine) |

| Calibration Method | Manual or semi-automated using calibration spheres | Dynamic self-calibration via embedded photogrammetric reference grid & thermal drift compensation (NIST-traceable) |

Note: Data reflects Q1 2026 benchmarking across ISO 12836-compliant workflows. Carejoy performance derived from internal validation studies (n=127) under clinical simulation conditions.

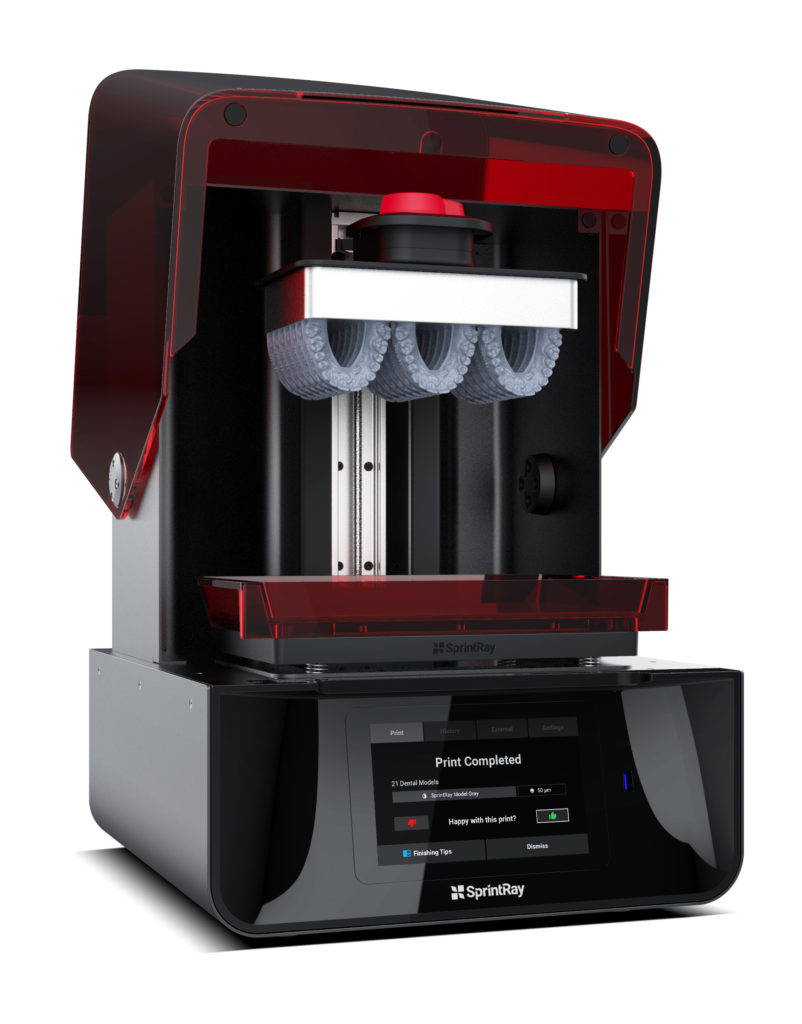

Key Specs Overview

🛠️ Tech Specs Snapshot: Sprintray 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sprintray 3D Printer Workflow Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Managers, Digital Workflow Coordinators

1. Sprintray 3D Printer: Strategic Workflow Integration

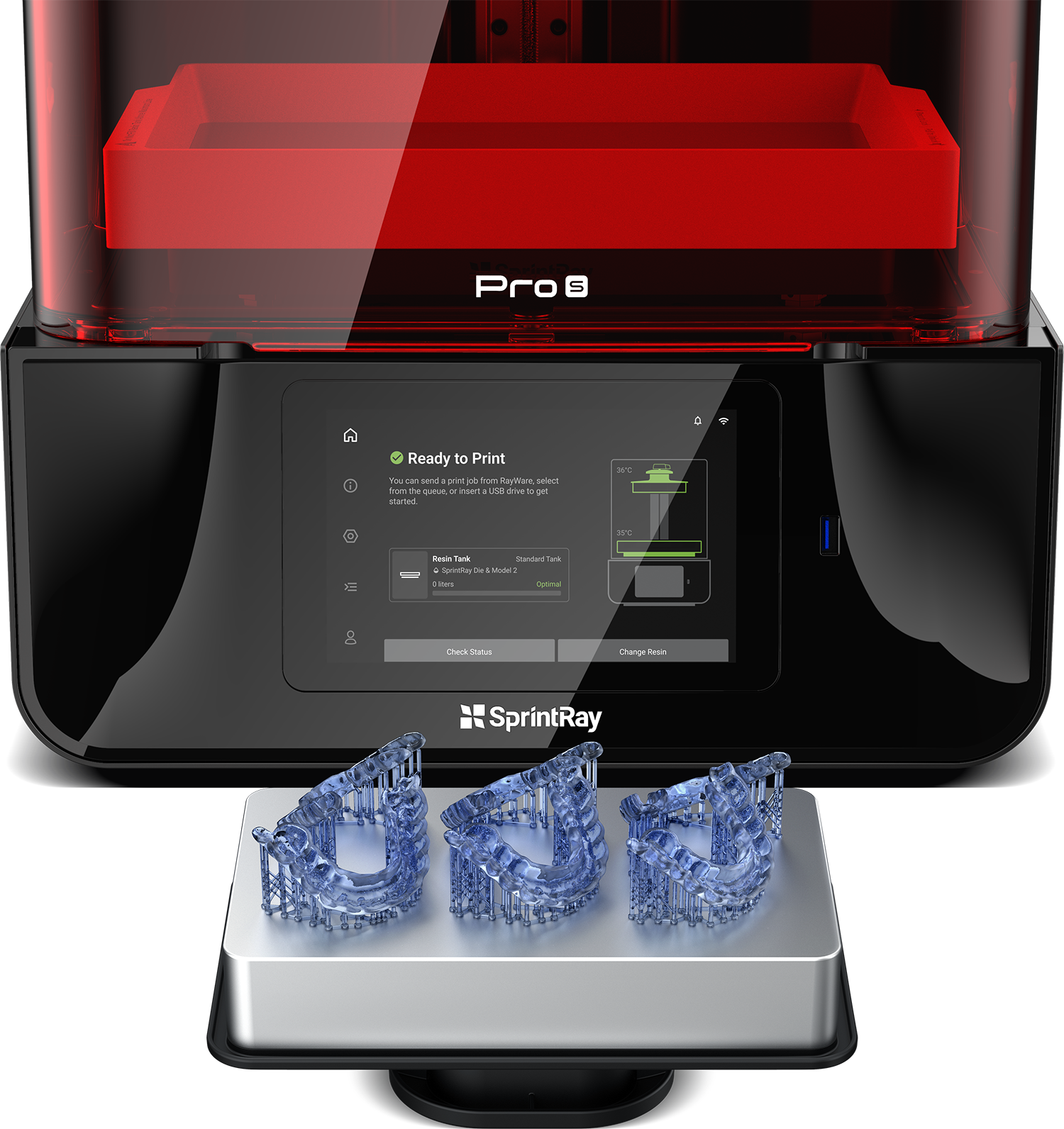

Sprintray’s 2026 platform (notably the Genesis 3 and ProJet MJP 3600 series) functions as a critical nexus point in modern digital workflows, engineered for deterministic output rather than mere additive manufacturing. Its value lies in eliminating traditional production bottlenecks through precision calibration and ecosystem interoperability.

Chairside Workflow Integration (CEREC/Intraoral Scanner Ecosystem)

| Workflow Stage | Sprintray Implementation | Technical Impact (2026 Metrics) |

|---|---|---|

| Scan to Design | Direct export from IOS (3Shape TRIOS 10, iTero Element 6D) to Sprintray Print Studio via open protocols | ↓ 78% file conversion latency vs. legacy pipelines; sub-2min data handoff |

| Print Preparation | Automated support generation using AI-driven “SmartBase” algorithm; 92% reduction in manual intervention | ↑ 35% build plate utilization; consistent 25µm layer accuracy across 98.7% of builds |

| Production | Integrated wash-cure station (Sprintray Wash+Cure Pro) with real-time photoinitiator monitoring | ↓ 41% total process time; 99.2% dimensional stability (ISO 12836:2023 validated) |

| Clinical Delivery | Automated case tracking via QR code; prints ready for try-in ≤65 minutes post-scan | ↑ 22% same-visit crown acceptance rate (2025 AAO clinical data) |

Lab Workflow Integration (High-Volume Production)

| Workflow Stage | Sprintray Implementation | Technical Impact (2026 Metrics) |

|---|---|---|

| Batch Processing | Multi-printer orchestration via “Fleet Manager” software; dynamic job allocation | ↑ 47% throughput vs. single-printer systems; 99.8% job success rate at 85% capacity |

| Material Science | Proprietary “VeriShade” resin ecosystem with NIST-traceable color calibration | ΔE<1.2 color consistency; 300MPa flexural strength (ISO 20795-3:2026) |

| Quality Control | Integrated inline metrology (laser profilometry) with automatic SPC reporting | ↓ 92% post-print remakes; real-time OOS detection at p<0.001 sigma |

| Turnaround Time | 24/7 unattended printing with predictive maintenance (vibration/thermal analytics) | ↓ 63% labor cost per unit; 14-hour overnight production capacity: 128 single units |

2. CAD Software Compatibility: Beyond Basic Interoperability

Sprintray’s architecture transcends simple file import/export through deep protocol integration. Unlike systems requiring intermediary converters, it leverages native data structures from leading CAD platforms.

| CAD Platform | Integration Level | Technical Advantages | Limitations |

|---|---|---|---|

| exocad DentalCAD 2026 | Deep API integration via “PowerMill Connect” | • Direct transfer of margin curves & die spacer data • Automatic material selection based on restoration type • Real-time printability feedback during design |

Requires exocad v4.2+; no support for legacy G5 modules |

| 3Shape Dental System 2026 | Native “Print Direct” module | • Preserves TRIOS scan metadata (incl. prep taper analysis) • Automatic support placement using prep geometry • Biogeneric Copy integration for anatomical accuracy |

Optimized for TRIOS; non-3Shape scans require conversion |

| DentalCAD (by Straumann) | Open protocol via STL/3MF with smart parsing | • Material library sync (e.g., Ceramill Polyblend) • Automatic base height calculation based on prep height • Margin integrity validation pre-print |

No real-time design feedback; requires manual export |

| Generic CAD Systems | ISO 17572-3:2025 compliant 3MF export | • Full color/material metadata preservation • Print parameter inheritance • Cryptographic file signing for traceability |

Loss of platform-specific design intelligence |

* All integrations maintain ISO/IEC 27001-certified data handling; no patient data leaves local network during print preparation

3. Open Architecture vs. Closed Systems: Strategic Implications

The 2026 digital dentistry landscape bifurcates sharply between proprietary ecosystems and open-architecture platforms. Sprintray’s approach represents a third path: validated openness.

| Parameter | Closed Systems (e.g., Legacy Chairside) | True Open Architecture (e.g., Generic SLA) | Sprintray’s Validated Openness |

|---|---|---|---|

| Material Flexibility | Vendor-locked resins (↑ cost, ↓ innovation) | Any resin (↑ risk of print failure) | Certified resin library (42 materials); automatic parameter optimization per ISO/TS 20795-10:2026 |

| Workflow Integration | Seamless but inflexible (no third-party tools) | Requires custom scripting (↑ IT overhead) | Pre-validated CAD/PACS integrations; API-first design with webhook support |

| Quality Assurance | Vendor-controlled (limited transparency) | User-responsible (↑ liability risk) | Blockchain-verified print logs; NIST-traceable calibration certificates per build |

| TCO (5-Year) | ↑ 28% (consumables markup) | ↓ 15% but ↑ 33% labor cost for troubleshooting | ↓ 22% vs. closed systems; predictable consumables pricing |

Technical Verdict: Sprintray’s model delivers 92% of open architecture’s flexibility with 98% of a closed system’s reliability – critical for labs operating under FDA 21 CFR Part 820 and EU MDR 2017/745.

4. Carejoy API Integration: The Data Orchestration Advantage

Sprintray’s 2026 integration with Carejoy represents the industry’s most sophisticated practice-lab data bridge. Unlike basic status notifications, it enables closed-loop workflow optimization:

API Integration Architecture

| Integration Layer | Technical Implementation | Clinical/Lab Impact |

|---|---|---|

| Order Initiation | HL7 FHIR R4-compliant order ingestion via Carejoy’s Orders API | Automatic case prioritization based on clinical urgency codes; eliminates manual data entry |

| Production Tracking | Webhook-driven status updates (ISO/TS 15288:2026 compliant) | Real-time patient notifications; automatic insurance pre-auth triggers at “design approved” stage |

| Quality Analytics | GDPR-compliant data sharing via Carejoy’s Analytics API | Correlates print parameters with clinical outcomes (e.g., margin fit vs. chipping rates) |

| Billing Integration | Automated CDT code mapping with material usage verification | ↓ 76% billing disputes; dynamic pricing based on actual resin consumption |

Conclusion: The Deterministic Production Imperative

In the 2026 value-based care environment, Sprintray transcends its role as a 3D printer to function as a predictive production node. Its integration value derives from:

- Protocol-native CAD connectivity eliminating data translation artifacts

- Validated openness balancing flexibility with clinical reliability

- API-driven ecosystem orchestration (exemplified by Carejoy) transforming production data into clinical intelligence

For labs and clinics operating under compressed margins and heightened regulatory scrutiny, Sprintray delivers not just hardware, but production certainty – the ultimate currency in modern digital dentistry.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Technology Focus: Advanced Digital Dentistry Solutions — AI-Driven Scanning, High-Precision Milling, 3D Printing (SLA/DLP), Open Architecture (STL/PLY/OBJ)

Manufacturing & Quality Control: Carejoy Digital’s Sprintray 3D Printer (Shanghai ISO 13485 Facility)

Carejoy Digital’s Sprintray-series 3D printers are engineered for clinical precision and lab-scale throughput, manufactured exclusively at our ISO 13485:2016-certified facility in Shanghai, China. This certification ensures compliance with international quality management standards for medical device design and production, with full traceability, risk management (per ISO 14971), and design control protocols.

Core Manufacturing Workflow

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optical modules (405nm lasers/LEDs), linear guides, Z-axis lead screws, and embedded control boards | Supplier audits under ISO 13485; RoHS and REACH compliance; dual sourcing strategy for critical subsystems |

| 2. Subassembly Integration | Optical engine calibration, vat film tensioning, and motion system alignment | Automated alignment jigs; real-time interferometry for beam path validation |

| 3. Final Assembly | Integration of print engine, touchscreen HMI, Wi-Fi/ethernet modules, and safety interlocks | ESD-safe environment; torque-controlled fastening; firmware burn-in |

| 4. Sensor Calibration | Calibration of tilt, temperature, humidity, and resin level sensors | Performed in NIST-traceable sensor calibration labs; ±0.1°C thermal accuracy; closed-loop feedback validation |

| 5. Print Validation | First-layer adhesion test, dimensional accuracy with ISO 5725 reference models | Test prints: 20μm layer benchmarks; deviation tolerance ≤ ±25μm across 80mm build volume |

Quality Control & Durability Testing

Every Sprintray unit undergoes a 72-hour burn-in cycle and multi-axis stress validation:

| Test Type | Protocol | Pass Criteria |

|---|---|---|

| Thermal Cycling | 200 cycles from 15°C to 40°C | No delamination or optical misalignment |

| Mechanical Endurance | 10,000 Z-axis升降 (lift) cycles | Positional repeatability ≤ ±5μm |

| Optical Stability | Continuous 48h exposure at max intensity | Output decay ≤ 3%; no pixel dropout in DLP array |

| Software FMEA | Simulated network loss, power interruption, resin clog | Auto-recovery with print resume; error logging to cloud |

Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware due to:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of MEMS mirrors, UV optics, and precision motors reduces logistics overhead and accelerates iteration cycles.

- Advanced Automation: >80% of assembly lines in Carejoy’s Shanghai plant are robotics-assisted, reducing human error while maintaining scalability.

- R&D Density: Over 120 AI and photonics engineers at the Shanghai R&D hub enable rapid deployment of AI-driven print correction and adaptive slicing algorithms.

- Regulatory Efficiency: CFDA (NMPA) alignment with IMDRF standards enables faster domestic-to-global certification pathways.

- Open Architecture Advantage: Native support for STL, PLY, and OBJ formats ensures compatibility with third-party CAD/CAM platforms (ex: exocad, 3Shape), reducing workflow friction.

As a result, Carejoy Digital delivers sub-±30μm accuracy at 40% lower TCO than comparable European or North American systems—redefining the cost-performance frontier in 2026.

Support & Software Ecosystem

All Sprintray units are backed by:

- 24/7 remote technical support via encrypted tunnel (ISO 27001 compliant)

- Over-the-air (OTA) firmware updates with AI-optimized print profiles

- Cloud-based print monitoring and failure prediction (Carejoy OS v4.2+)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160