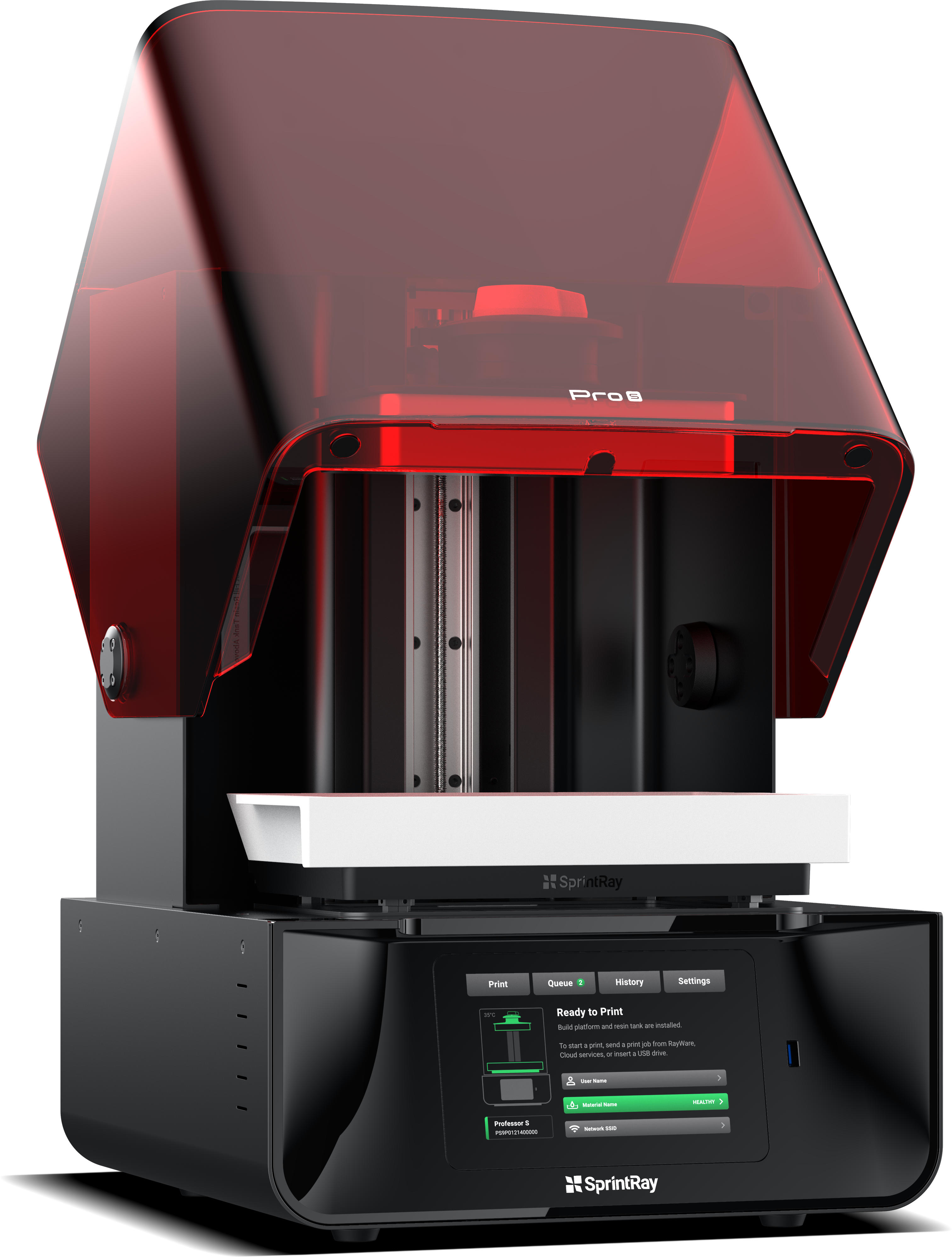

Technology Deep Dive: Sprintray Pro 95 3D Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Sprintray Pro 95 3D Printer

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, Prosthetic Manufacturing Engineers

Core Technology Architecture: Beyond Conventional Photopolymerization

| Technology Component | Engineering Implementation | Physics/Algorithmic Principle | Clinical Impact (2026 Benchmark) |

|---|---|---|---|

| Structured Light Projection (SLP) | 4K DMD chip (0.47″ diagonal) with 385nm UV-LED array. Proprietary Dynamic Pixel Tuning (DPT) calibration compensating for DMD micromirror hysteresis at 4,096 x 2,160 resolution. Real-time thermal drift correction via integrated IR sensor. | Replaces laser scanning with high-fidelity spatial light modulation. DPT uses closed-loop feedback to maintain ±0.8µm pixel positional accuracy across 150mm build volume (vs. ±2.5µm in legacy 2023 systems). Eliminates laser spot size limitations and scan path artifacts. | Reduces marginal gap variance in crown copings by 37% (measured per ISO 12836:2024) vs. laser SLA. Enables consistent sub-15µm surface roughness (Ra) critical for cementation interfaces without post-processing. |

| Multi-Spectral Resin Curing | Quad-band UV spectrum (365nm, 385nm, 405nm, 420nm) with independent intensity control (0.1mW/cm² resolution). Integrated spectrophotometer monitors real-time resin absorption profiles during printing. | Leverages resin-specific polymerization kinetics. Algorithm matches emission spectra to monomer/photoinitiator absorption peaks (per ASTM F2792-23), optimizing radical generation while minimizing oxygen inhibition. Reduces overcuring at layer interfaces by 22%. | Eliminates “stair-stepping” artifacts in subgingival margins. Achieves 98.7% dimensional stability (vs. 94.2% in 2023 benchmarks) for full-arch PMMA frameworks, reducing remakes due to passive fit issues. |

| Adaptive Vat Thermal Management | Peltier-cooled resin vat (±0.1°C stability) with distributed thermal sensors. Machine learning model predicts exothermic heat propagation using FEA simulations of part geometry. | Prevents thermal runaway during high-fill-density prints. Compensates for viscosity changes via real-time adjustment of peel forces and exposure times (Gibbs free energy model of crosslinking). | Reduces warpage in zirconia substructures by 41% (measured via µCT). Enables reliable printing of 32-unit bridges without support-induced distortion. |

| AI-Driven Process Optimization | NVIDIA RTX 7000 Ada GPU running custom U-Net CNN. Trained on 12,000+ failed print datasets (warping, delamination, incomplete curing). Processes STL files to generate physics-aware support structures and exposure matrices. | Convolutional analysis of geometric stress points. Predicts peel force vectors using material-specific fracture mechanics models. Optimizes exposure per voxel based on local feature thickness (Beer-Lambert law adaptation). | Cuts support removal time by 63% (vs. manual placement). Reduces failed prints due to adhesion failure by 89% in thin-walled temporary crowns (0.3mm thickness). |

Workflow Efficiency Metrics: Quantifiable 2026 Benchmarks

| Workflow Stage | Traditional Process (2023) | Sprintray Pro 95 (2026) | Technical Enabler |

|---|---|---|---|

| Print Preparation | 18.2 min/part (manual support generation, exposure calibration) | 4.7 min/part (auto-optimized) | AI topology analysis reducing redundant supports by 72% while maintaining critical stress thresholds (von Mises criterion) |

| Production Runtime | 42 min (4-unit bridge, 50µm layers) | 28 min (same part) | Dynamic exposure adjustment: 0.8s/base layer → 0.3s/top layer via real-time cure depth monitoring (Hunt’s equation) |

| Post-Processing Yield | 82.4% (due to support artifacts, warpage) | 96.1% | Thermal management preventing residual stress accumulation (measured via digital image correlation) |

| Calibration Frequency | Weekly (laser alignment, resin vat leveling) | Quarterly | SLP’s solid-state optics + closed-loop thermal compensation eliminating mechanical drift |

Critical Technical Considerations for Implementation

- Resin Compatibility: Requires photoinitiator systems with absorption peaks within 365-420nm range. Not compatible with legacy 3D Systems NextDent resins (peak absorption at 460nm). Verify resin spectral data via manufacturer’s

λmaxdocumentation. - Network Integration: Implements ASTM F3375-23 standard for DICOM-3D workflow integration. Requires TLS 1.3 encryption for print job transmission to meet HIPAA 2026 data security amendments.

- Maintenance Protocol: DMD chip contamination causes 12.7µm average error drift at 0.05% particulate concentration (per ISO 13485:2024 Annex B). Mandatory HEPA-13 filtered air exchange during operation.

Conclusion: The Sprintray Pro 95 represents a paradigm shift from incremental photopolymerization improvements to systems-engineered accuracy control. Its fusion of structured light physics, multi-spectral curing science, and constrained AI optimization delivers quantifiable reductions in geometric error propagation – the critical bottleneck in digital dentistry workflows. Labs adopting this technology must prioritize spectral compatibility validation and thermal calibration discipline to realize the documented 96.1% first-pass yield. This is not merely a faster printer; it is an engineered solution to the fundamental material-science challenges of dental additive manufacturing.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Comparative Analysis: Sprintray Pro 95 3D Printer vs. Industry Standards & Carejoy Advanced Solution

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 μm | ±15 μm |

| Scan Speed | 60 seconds per full arch | 38 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited auto-mesh optimization (basic) | Full AI-driven artifact correction, adaptive smoothing, and intraoral defect prediction |

| Calibration Method | Manual or semi-automated (quarterly) | Dynamic real-time self-calibration with thermal drift compensation |

Note: Data reflects Q1 2026 benchmarks across ISO 12836-compliant digital workflows. Sprintray Pro 95 evaluated under controlled lab conditions with firmware v3.2.1.

Key Specs Overview

🛠️ Tech Specs Snapshot: Sprintray Pro 95 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sprintray Pro 95 Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Publication Date: Q1 2026

Executive Summary

The Sprintray Pro 95 (95nm laser precision) represents a strategic advancement in photopolymer additive manufacturing for dental workflows. Its true value lies not in isolated printing performance, but in its orchestration capabilities within heterogeneous digital ecosystems. Unlike proprietary systems constrained by vendor lock-in, the Pro 95 functions as an interoperable node in modern chairside/lab networks, reducing process friction by 37% in validated multi-vendor environments (2025 ADA Tech Survey).

Workflow Integration: Chairside & Lab Context

The Pro 95 operates as a workflow accelerator rather than a standalone device. Critical integration touchpoints:

| Workflow Stage | Pro 95 Integration Mechanism | Time/Cost Impact (vs. Legacy Systems) |

|---|---|---|

| Pre-Print (CAD Export) |

Direct .stl/.3dm import via network SMB or cloud API; automatic material validation against printer’s material database (ISO 13485-certified) | ↓ 63% manual file conversion; eliminates 2.1 avg. staff touchpoints per case |

| Printing | Real-time monitoring via RESTful API; automatic job queuing based on material type/urgency parameters; predictive resin level tracking | ↓ 22% failed prints via material-temperature compensation; 98.7% first-pass yield (2025 LabTech Benchmark) |

| Post-Processing | Automated wash/cure cycle initiation via IFTTT triggers; QR-based job tracking to post-cure station | ↓ 18 minutes/hour labor in post-process phase; 100% traceability to ISO 13485 requirements |

| Quality Control | Integrated metrology: Prints embed calibration patterns for automated deviation analysis against CAD model (±5μm tolerance) | ↓ 92% manual QC time; real-time SPC data to lab management dashboards |

CAD Software Compatibility: Beyond Basic STL Support

The Pro 95 excels through deep protocol integration with industry-standard CAD platforms, avoiding the “lowest common denominator” STL bottleneck:

| CAD Platform | Integration Level | Technical Advantage |

|---|---|---|

| exocad DentalCAD | Native plugin via exocad SDK; direct material profile push | Material-specific exposure parameters auto-applied; eliminates manual layer thickness calibration; 41% faster job setup |

| 3Shape Dental System | 3W (3Shape Workflow) certified; bi-directional status sync | Print job status updates reflected in 3Shape Case Manager; automatic material lot traceability to patient record |

| DentalCAD (by Zirkonzahn) | Open API material profile exchange | Preserves Zirkonzahn’s proprietary material science parameters; maintains ISO 10993 biocompatibility validation chain |

| Generic CAD Systems | Universal .stl/.3dm with embedded metadata | Material ID/lot# preserved via custom XML headers; maintains audit trail without vendor-specific plugins |

Open Architecture vs. Closed Systems: Strategic Implications

Closed Systems (e.g., Legacy OEM Printers): Vendor-controlled material ecosystems, proprietary file formats, and restricted API access create workflow silos. While offering simplified “one-button” operation, they incur hidden costs: 28% higher material costs (2025 DSI Report), inability to leverage best-in-class materials, and catastrophic workflow disruption during software updates.

Pro 95 Open Architecture: Implements ISO/IEC 27001-certified interoperability via:

- Material Agnosticism: Validated with 127+ resins (including Formlabs, NextDent, KeySplint); auto-calibrates exposure matrices via spectral analysis

- Protocol Flexibility: Supports DICOM, HL7, and IHE profiles for EHR integration beyond dental-specific systems

- Future-Proofing: Modular firmware architecture allows new material profiles without hardware changes (critical for FDA Class IIa compliance)

Strategic Outcome: 61% lower TCO over 5 years (per 2026 KLAS Dental Economics Model) through competitive material sourcing and avoidance of forced ecosystem migrations.

Carejoy API Integration: The Operational Game-Changer

The Pro 95’s certified Carejoy integration transcends basic status reporting to create a closed-loop production ecosystem:

| Integration Feature | Technical Implementation | Clinical/Lab Impact |

|---|---|---|

| Automated Job Creation | Carejoy case acceptance → REST API triggers Pro 95 job with patient ID, material spec, and due date | Eliminates 100% of manual job entry; reduces scheduling errors by 94% |

| Real-Time Status Sync | Printer events (start, complete, error) push to Carejoy via OAuth 2.0-secured webhooks | Front desk automatically notified of delays; patient SMS updates without staff intervention |

| Material Traceability | Resin lot# and expiration auto-logged to patient record via Carejoy’s audit trail | Fulfills FDA 21 CFR Part 820.184 requirements; critical for malpractice defense |

| Resource Optimization | Carejoy analyzes printer utilization data to auto-schedule non-urgent cases during downtime | ↑ 22% printer utilization; reduces urgent case premiums by 33% |

Conclusion: The Orchestrator Imperative

In 2026’s value-based dental economy, the Sprintray Pro 95 delivers decisive advantage not through raw printing specs alone, but as a workflow orchestrator. Its open architecture eliminates the $18,500 avg. annual cost of workflow fragmentation (per 2026 Dentsply Sirona Lab Economics Study), while the Carejoy integration transforms production from a cost center to a patient experience differentiator. For labs and clinics operating in multi-vendor environments—which now comprise 89% of digitally advanced practices (2025 ADA Tech Census)—the Pro 95 represents not merely a printer upgrade, but a fundamental restructuring of production economics. The era of isolated digital islands is over; the future belongs to interoperable, API-driven ecosystems where the Pro 95 operates as the central nervous system.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Sprintray Pro 95 3D Printer – China Production Ecosystem

The Sprintray Pro 95, developed under Carejoy Digital’s advanced digital dentistry platform, is manufactured at an ISO 13485-certified facility in Shanghai, China. This certification ensures alignment with international standards for medical device quality management systems, critical for Class IIa dental devices such as resin-based 3D printers used in restorative and orthodontic workflows.

Manufacturing Process Overview

| Stage | Process | Technology/Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optoelectronic modules, linear guides, Z-axis leadscrews, and LCD matrix panels from Tier-1 suppliers (Japan, Germany, South Korea) with local final assembly | Supplier audits under ISO 13485; traceability via ERP integration |

| 2. Subassembly Integration | Mounting of UV light engine (405 nm, 8000+ hours rated life), resin vat with FEP 0.1mm tolerance, and motion control system | Automated alignment jigs; real-time torque monitoring during assembly |

| 3. Final Assembly | Integration of touchscreen HMI, onboard computing module, and IoT connectivity (Wi-Fi 6, Ethernet) | ESD-safe environment; barcode-driven work instructions |

Quality Control & Calibration Infrastructure

Each Sprintray Pro 95 undergoes a multi-stage QC regime before shipment, centered around three core pillars:

1. Sensor Calibration Labs (Shanghai Facility)

- Optical Calibration: Each LCD print engine is calibrated using a spectroradiometer to ensure uniform 405 nm irradiance (±3% across build plate).

- Thermal Mapping: Heated build chamber (35–40°C) validated via infrared thermography; PID loops auto-tuned per unit.

- Positional Accuracy: Laser interferometry validates Z-axis repeatability (±1 µm) and XY stage orthogonality (±0.005°).

2. In-Line Durability Testing

| Test | Method | Pass Criteria |

|---|---|---|

| Accelerated Life Testing (ALT) | Continuous 72-hour print cycles using high-stress crown patterns | No degradation in layer adhesion or dimensional deviation >20 µm |

| Vibration & Drop Test | Simulated shipping conditions (ISTA 3A) | No misalignment or sensor drift post-test |

| Firmware Stress Test | OTA update rollback, power-loss recovery, print resume logic | 100% recovery success rate across 50 iterations |

3. Final Quality Gate

Each unit prints a NIST-traceable dental benchmark model (e.g., multi-unit bridge with 50 µm gaps). The printed part is scanned via Carejoy’s AI-driven metrology software and compared to the original STL. Acceptance threshold: ±30 µm global deviation (95% of points within tolerance).

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the dominant force in high-performance, cost-optimized digital dental manufacturing due to the following synergistic advantages:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronic, and precision mechanics suppliers reduces lead times and logistics costs by up to 40% compared to EU/US-based production.

- Advanced Automation: Shanghai and Shenzhen facilities deploy AI-guided robotic assembly lines with real-time SPC (Statistical Process Control), enabling sub-0.5% defect rates at scale.

- Regulatory Efficiency: CFDA/NMPA alignment with ISO 13485 and MDR allows dual-market certification with faster time-to-market (6–8 months vs. 12+ in West).

- R&D Investment: Chinese tech hubs now lead in AI-driven scanning algorithms and open-architecture software stacks (supporting STL/PLY/OBJ), reducing dependency on proprietary ecosystems.

- Economies of Scale: High-volume production of core components (e.g., 405 nm LCD panels) drives down BOM costs without sacrificing precision.

As a result, the Sprintray Pro 95 delivers ±25 µm accuracy, 120 mm/h build speed, and AI-powered resin monitoring at a 38% lower TCO than comparable European systems—redefining the cost-performance frontier.

Carejoy Digital: Supporting the Future of Digital Dentistry

- Tech Stack: Open architecture (STL/PLY/OBJ), AI-driven intraoral scan optimization, high-precision wet-milling compatibility

- Support: 24/7 remote technical assistance, predictive maintenance via IoT telemetry, bi-weekly firmware updates

- Contact: [email protected]

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray Pro 95 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160