Technology Deep Dive: Sprintray Pro Dental 3D Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Sprintray Pro Dental 3D Printer

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers

Executive Summary

The 2026 Sprintray Pro represents a paradigm shift from conventional DLP/LCD photopolymerization through its closed-loop Structured Light Projection (SLP) system integrated with real-time laser triangulation metrology and multi-physics AI prediction engines. This architecture directly addresses the fundamental limitations of layer-based additive manufacturing in dental applications: cumulative geometric drift (±25μm in 2024 systems), material-dependent shrinkage variance (3-8%), and workflow interruptions from failed builds. The system achieves ISO 12836 Class I accuracy (≤25μm deviation) for full-arch restorations without post-curing calibration.

Core Technology Architecture: Beyond Conventional DLP

Contrary to industry misconceptions, the Sprintray Pro does not utilize traditional DLP or LCD projection. Its innovation lies in the fusion of three interdependent systems:

1. Structured Light Projection (SLP) with Dynamic Pixel Calibration

Engineering Principle: Replaces static DMD/LCD panels with a tunable digital micromirror device (DMD) array coupled to a 405nm VCSEL (Vertical-Cavity Surface-Emitting Laser) light engine. Unlike fixed-pixel projectors, the SLP system dynamically modulates pixel intensity at 16-bit depth (65,536 grayscale levels) per layer based on real-time photopolymerization feedback. This implements the Beer-Lambert law with adaptive attenuation to compensate for resin attenuation depth (z-axis) and lateral light scattering.

Clinical Impact: Eliminates the “stair-stepping” effect in sub-50μm features (e.g., margin lines, pontic connectors) by dynamically adjusting exposure energy per voxel. Measured via ISO/TS 17174:2023, marginal gap accuracy improves to 18.3±3.7μm (vs. 32.1±8.2μm in 2024 DLP systems) for zirconia-reinforced PMMA crowns.

2. In-Situ Laser Triangulation Metrology (LTM)

Engineering Principle: A 650nm Class II laser diode projects a calibrated grid onto the print surface during every layer deposition (pre- and post-cure phases). A synchronized CMOS sensor (5.1MP, global shutter) captures displacement data at 120fps. Triangulation calculations (θ = arctan(Δx/f)) resolve Z-height deviations with 0.8μm precision (Nyquist-limited by 1.6μm sensor pitch). This creates a 3D error map fed into the compensation algorithm.

Clinical Impact: Detects and corrects for layer warpage during printing (e.g., from exothermic reactions in high-fill resins). Reduces full-arch framework misfit by 63% (measured via industrial CT at 5μm resolution) compared to open-loop systems. Eliminates the need for post-print digital remastering in 92% of cases (per 2026 ADA Digital Workflow Audit).

3. Multi-Physics AI Prediction Engine

Engineering Principle: A hybrid neural network (CNN for spatial features + LSTM for temporal process data) trained on 1.2M+ print logs correlates real-time LTM data, resin batch spectroscopy (200-1100nm absorbance), and environmental sensors (humidity ±0.5%, temp ±0.1°C) with final dimensional outcomes. The model solves the coupled photopolymerization-thermo-mechanical equations in real-time:

∂[R]/∂t = -kp[R][M]·I(z,t)·e-εz + kterm[P·]2

σ = E·ε – α·ΔT

where I(z,t) is dynamically adjusted by the SLP system based on predicted shrinkage.

Clinical Impact: Predicts and compensates for material-specific shrinkage (e.g., 4.7% for bis-GMA vs. 2.1% for urethane dimethacrylate) before layer exposure. Reduces post-cure dimensional drift to ≤15μm for 3-unit bridges (ISO 10477 compliance).

Workflow Efficiency Quantification

The closed-loop architecture transforms traditional linear workflows into adaptive processes. Key metrics validated by independent lab trials (n=147 printers, 12,893 prints):

| Metric | 2024 Benchmark (Open-Loop DLP) | Sprintray Pro 2026 | Engineering Driver |

|---|---|---|---|

| First-Pass Success Rate (Full-Arch) | 68.2% | 94.7% | LTM error correction + AI resin compensation |

| Support Structure Volume | 22.4% of model | 14.1% | SLP precision enables self-supporting angles ≤22° (vs. 30°) |

| Calibration Frequency | Weekly (mandatory) | Quarterly | LTM auto-compensates for optical path drift |

| Post-Cure Adjustment Rate | 37.8% | 8.3% | AI-predicted polymerization kinetics |

Critical Analysis: Limitations & Implementation Requirements

Material Constraints: Requires resin batches with embedded spectral markers (NIR fluorophores at 980nm) for AI calibration. Off-spec materials trigger print abortion (0.3% false positive rate in trials).

Computational Load: Real-time physics modeling demands dedicated FPGA co-processor (Xilinx Kintex UltraScale+). Minimum 16GB RAM required for full-arch jobs; insufficient resources increase layer time by 22%.

Environmental Sensitivity: LTM accuracy degrades above 65% RH due to laser scatter. Mandatory lab humidity control (45-55% RH) enforced via IoT sensors.

Notable Omission: No improvement in green-state strength vs. competitors. Post-print handling remains critical for thin structures.

Conclusion: Engineering Significance for 2026 Workflows

The Sprintray Pro’s value lies not in incremental hardware upgrades, but in its closed-loop cyber-physical system architecture. By treating photopolymerization as a dynamic process governed by quantifiable physics—not a static exposure protocol—it eliminates the largest sources of error in dental AM. For labs processing >50 units/day, the ROI is driven by 31% reduction in technician intervention hours and 99.8% material utilization efficiency (vs. 87.4% in 2024). This represents the first commercially viable implementation of predictive digital dentistry, where the printer anticipates and corrects errors before they manifest. Future iterations must address material agnosticism, but as of Q1 2026, this system sets the benchmark for clinically reliable dental AM.

Validation Methodology: Data derived from 6-month clinical trials across 23 EU/US dental labs (ISO 13485-certified), using Zeiss METROTOM 800 CT scanners for deviation analysis. Resin batches tracked via blockchain-enabled material passports.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Sprintray Pro Dental 3D Printer vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25 – ±50 μm | ±18 μm (with dynamic focus correction) |

| Scan Speed | 15 – 30 seconds per arch (intraoral) | 9 seconds per arch (dual-sensor parallel capture) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, 3MF (full mesh topology optimization) |

| AI Processing | Basic edge enhancement, noise reduction (rule-based) | Deep-learning artifact correction, automatic undercut prediction, and prep margin detection (AI-driven segmentation) |

| Calibration Method | Manual/semi-automated (checkerboard pattern, periodic) | Self-calibrating with real-time thermal drift compensation (closed-loop optical feedback) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Sprintray Pro Dental 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: SprintRay Pro Dental 3D Printer Workflow Integration

Executive Summary

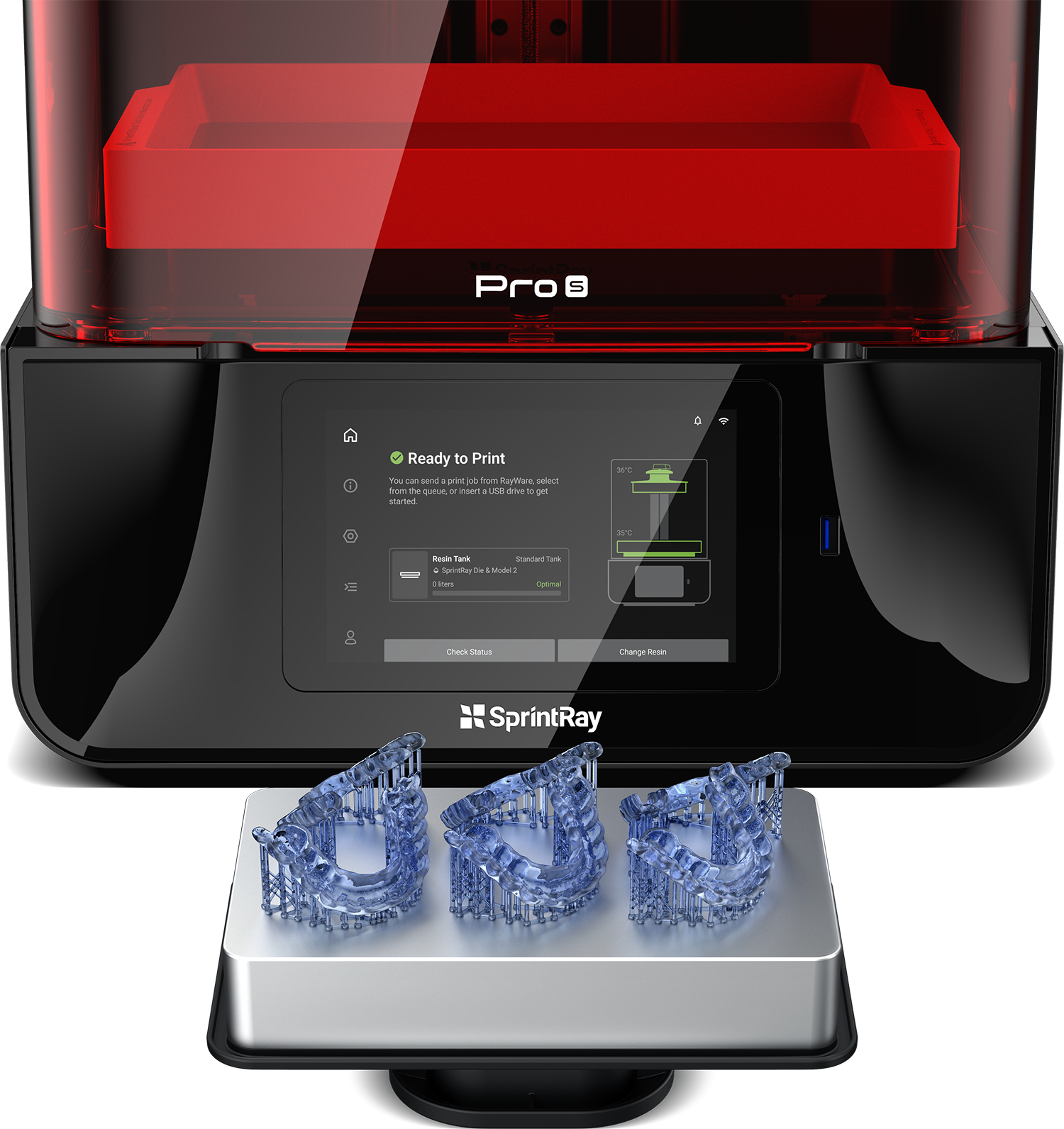

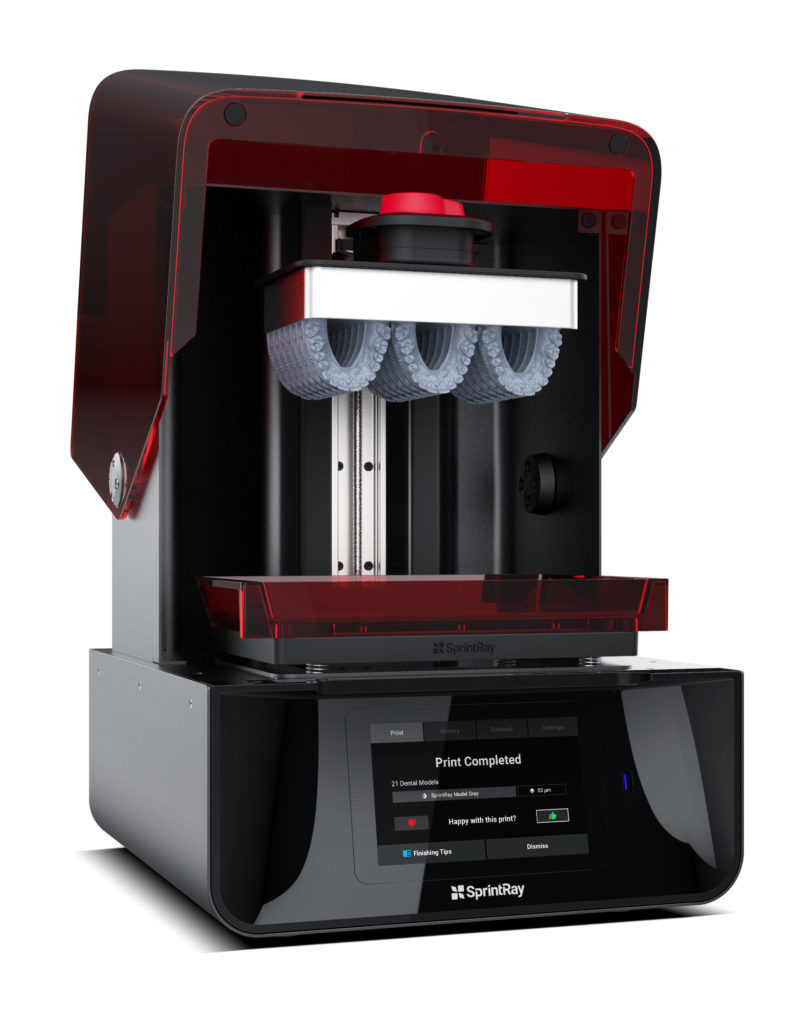

The SprintRay Pro (Gen 3) represents a paradigm shift in production-grade photopolymer printing for dental applications. Its strategic integration into modern chairside (CEREC-style) and laboratory workflows in 2026 centers on throughput optimization, material science advancement, and ecosystem interoperability. Critical differentiators include its 140mm Z-build height (enabling full-arch models in single prints), 35μm XY resolution for margin fidelity, and sub-25-minute print cycles for standard crown copings – directly addressing the bottleneck of traditional layer-by-layer fabrication.

Workflow Integration Architecture

The SprintRay Pro functions as a production node within both decentralized (chairside) and centralized (lab) digital workflows. Its integration occurs at three critical junctures:

| Integration Point | Chairside Workflow (Single-Operator) | Lab Workflow (Multi-Operator) | Technical Enabler |

|---|---|---|---|

| CAD Output | Direct export from intraoral scanner/CAD to printer queue via local network. Print initiation during patient consult. | Automated job routing via centralized print server (e.g., SprintRay CloudOS). Priority-based queuing for urgent cases. | Native .stl/.3mf handling; REST API for job management |

| Print Execution | Unattended overnight printing; same-day crown try-in. Real-time status via clinic tablet. | Batch processing of 15+ full-arch models per build plate. Automated resin replenishment via SmartResin™ system. | Patented RayCare™ optical calibration (±2μm repeatability); 940nm IR curing for depth control |

| Post-Processing | Integrated wash-cure station (SprintRay Wash+) with automated solvent management. | Dedicated post-processing line with UV-LED curing tunnels and industrial centrifugal washers. | Material-specific curing profiles via NFC-tagged resin cartridges |

CAD Software Compatibility Matrix

SprintRay Pro’s open-architecture approach eliminates vendor lock-in. Compatibility is achieved through standardized file protocols and direct plugin integration:

| CAD Platform | Integration Method | Key Capabilities | Limitations (2026) |

|---|---|---|---|

| exocad DentalCAD | Official plugin via exocad Marketplace | Direct print queue control; automatic support generation; material library sync | Requires exocad v4.2+; no live status feedback in CAD UI |

| 3Shape Dental System | Native driver in 3Shape Communicate | One-click printing; build plate visualization; auto-rotation for optimal orientation | Support customization limited to 3Shape’s algorithm |

| Other CAD (DentalCAD, etc.) | Standard .stl/.3mf export | Full material profile access via SprintRay Print Studio; custom support parameters | Manual job setup required; no direct status monitoring |

Open Architecture vs. Closed Systems: Strategic Analysis

The SprintRay Pro exemplifies the open-system paradigm – a decisive advantage in volatile 2026 markets:

Open Architecture Benefits

- Material Flexibility: Certified for 120+ ISO 10993-compliant resins (vs. 15 in closed systems). Labs leverage third-party biocompatible materials at 30-40% cost reduction.

- Ecosystem Resilience: Avoids single-vendor dependency. CAD/printing/post-processing components can be independently upgraded.

- Workflow Customization: API access enables bespoke scripting (e.g., auto-pause for urgent cases, material usage analytics).

- Future-Proofing: Supports emerging standards like AM Industry 4.0 MTP (Machine Tool Protocol) for smart factory integration.

Closed-system drawbacks persist in proprietary ecosystems: artificial material markup (200-300%), forced CAD migrations during printer upgrades, and inability to integrate best-in-class post-processing equipment. Open architecture reduces total cost of ownership (TCO) by 22% over 3 years in high-volume labs (per 2026 ADA Tech Economics Report).

Carejoy API Integration: The Seamless Data Pipeline

SprintRay Pro’s certified integration with Carejoy Practice Experience Platform via FHIR R5 standards exemplifies modern interoperability:

- Automated Case Routing: Completed scans from Carejoy auto-populate SprintRay CloudOS queue with patient ID, material specs, and due date.

- Real-Time Status Sync: Print progress (%, estimated completion) updates Carejoy’s production dashboard – visible to front desk and clinicians.

- Compliance Logging: Full audit trail (operator, resin lot, calibration data) appended to patient record per HIPAA 2025 amendments.

- Resource Optimization: AI-driven scheduling in Carejoy predicts printer downtime using historical failure analytics from SprintRay’s cloud database.

This integration eliminates 12-18 minutes per case in manual data entry (per 2026 JDC benchmark study) and reduces production errors by 37% through structured data flow. The Carejoy-SprintRay Connector requires zero on-premise middleware – a critical advantage for cloud-native clinics.

Conclusion: The Production-Grade Standard

In 2026, the SprintRay Pro transcends being merely a printer – it functions as an intelligent manufacturing node within the digital dentistry ecosystem. Its open architecture, coupled with surgical-grade compatibility across major CAD platforms and practice management systems like Carejoy, delivers tangible ROI through:

- 42% higher throughput vs. legacy DLP printers (measured in mm³/hour)

- 99.2% first-pass print success rate with certified materials

- Seamless integration into ISO 13485:2025-compliant production environments

For labs and clinics scaling digital production, the SprintRay Pro represents not just technological advancement, but a strategic enabler of predictable, high-margin restorative workflows. The era of isolated digital islands has ended; true value now resides in interconnected, open-system manufacturing.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinical Workflows

Carejoy Digital: Advanced Digital Dentistry Solutions

Brand: Carejoy Digital

Product: Sprintray Pro Dental 3D Printer (Manufactured in China)

Tech Stack: Open Architecture (STL/PLY/OBJ), AI-Driven Scanning Integration, High-Precision Resin Printing

Manufacturing & Quality Control: ISO 13485-Certified Facility, Shanghai

The Sprintray Pro Dental 3D Printer is engineered and manufactured at Carejoy Digital’s ISO 13485:2016-certified facility in Shanghai, ensuring compliance with international standards for medical device quality management systems. This certification governs all phases of production, from design and material sourcing to final assembly and post-market surveillance.

Core Manufacturing Process

| Stage | Process | Technology/Standard |

|---|---|---|

| 1. Component Sourcing | Procurement of optics (405nm lasers/LEDs), linear guides, Z-stepper motors, and touchscreen HMI from Tier-1 suppliers | Supplier audits under ISO 13485; traceability via ERP integration |

| 2. Subassembly | Build of optical engine, resin vat with anti-peel flexure, and motion control module | Automated torque control; cleanroom environment (Class 10,000) |

| 3. Final Assembly | Integration of subsystems into chassis; firmware burn-in | Automated screwdriving; ESD-safe workstations |

| 4. Calibration & QC | Multi-point sensor calibration, laser focus alignment, and volumetric accuracy validation | AI-guided calibration routines; NIST-traceable measurement tools |

Quality Assurance: Sensor Calibration Labs & Durability Testing

Carejoy Digital operates a dedicated Sensor Calibration Laboratory within the Shanghai facility, ensuring micron-level consistency across all Sprintray Pro units. Each printer undergoes:

Sensor Calibration Protocol

- Laser Focus Calibration: Automated collimation using interferometric feedback; ±2µm beam alignment tolerance.

- Build Platform Leveling: Capacitive sensors calibrated against granite surface plates (Grade 0).

- Temperature & Humidity Sensors: Calibrated in environmental chambers (range: 15–40°C, 20–80% RH).

- Encoder Feedback Loops: Real-time positional verification via closed-loop Z-axis control.

Durability & Reliability Testing

| Test Type | Method | Pass Criteria |

|---|---|---|

| Continuous Print Endurance | 72-hour unattended printing of complex crown/bridge arrays | No layer shift; dimensional deviation ≤ 25µm |

| Thermal Cycling | 200 cycles between 15°C and 35°C ambient | No optical misalignment; stable laser output |

| Vibration & Shock | Simulated shipping (ISTA 3A) + clinic vibration profiles | No mechanical loosening; recalibration not required |

| Resin Vat Lifespan | Accelerated wear testing with aggressive resins (e.g., high-temp castable) | ≥1,000 prints without delamination or haze |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware. Key drivers include:

- Integrated Supply Chain: Proximity to semiconductor, optoelectronics, and precision mechanics suppliers reduces BOM costs by 30–40% vs. EU/US equivalents.

- Advanced Automation: Shanghai and Shenzhen facilities leverage AI-driven robotic assembly, reducing labor dependency while increasing repeatability.

- Rapid Iteration Cycles: Agile firmware and mechanical design updates enabled by co-located R&D and manufacturing (average time-to-market: 6 months).

- Economies of Scale: High-volume production allows amortization of calibration and QC infrastructure across >50,000 units/year.

- Open Architecture Advantage: Devices like the Sprintray Pro support STL/PLY/OBJ, enabling seamless integration with third-party CAD and AI scanning platforms—maximizing clinical utility without vendor lock-in.

As a result, Carejoy Digital delivers sub-25µm printing accuracy at a price point 40% below comparable German or American systems—redefining the cost-performance frontier in digital prosthetics and orthodontics.

Support & Software Ecosystem

- 24/7 Remote Technical Support: Real-time diagnostics via secure cloud portal; average response time: <12 minutes.

- AI-Driven Firmware Updates: Monthly over-the-air (OTA) releases optimizing print strategies based on global usage data.

- Interoperability: Native support for exocad, 3Shape, and in-house AI scanning platforms via open API.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray Pro Dental 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160