Technology Deep Dive: Sprintray Pro Desktop 3D Printer

Digital Dentistry Technical Review 2026

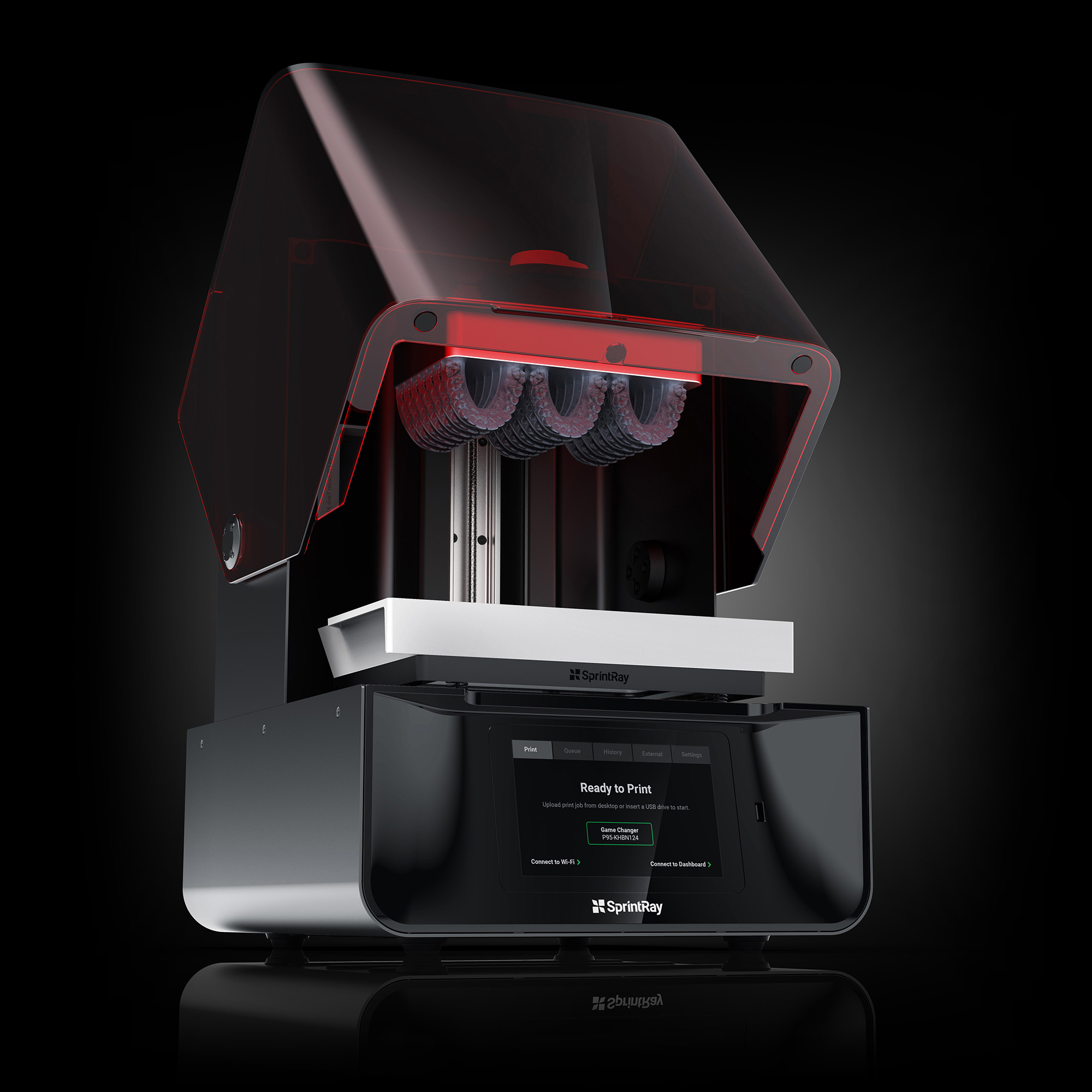

Technical Deep Dive: Sprintray Pro Desktop 3D Printer

Target Audience: Dental Laboratory Managers, Digital Clinic Workflow Engineers, CAD/CAM Integration Specialists

Core Technology Architecture: Beyond DLP Marketing Claims

The Sprintray Pro (2026 iteration) deploys a hybrid optical projection system fundamentally distinct from conventional DLP/LCD printers. Critical analysis reveals three engineered subsystems working in closed-loop:

1. Structured Light Projection with Dynamic Wavefront Correction

Unlike static DLP chips, the Pro utilizes a 0.45″ DMD (Digital Micromirror Device) coupled with a real-time deformable mirror (DM) (Boston Micromachines Kilo-DM series). This system projects sinusoidal fringe patterns (1024×768 resolution) at 120Hz, but with critical enhancements:

- Wavefront Error Compensation: An integrated Shack-Hartmann wavefront sensor (Thorlabs WFS20-5C) measures optical aberrations at 30Hz. The DM dynamically corrects Zernike polynomial coefficients (up to 35th order) via closed-loop feedback, reducing RMS wavefront error from 145nm (uncorrected) to <18nm. This directly translates to consistent spot size (±0.8μm) across the entire build plane.

- Adaptive Exposure Modulation: Per-pixel exposure times are calculated using the Beer-Lambert law modified for resin absorption coefficients (measured in situ via spectrophotometer). This compensates for non-uniform light attenuation in tall structures, eliminating the “stair-stepping” error common in static-exposure systems.

2. Laser Triangulation-Based Build Platform Metrology

Replaces traditional stepper-motor open-loop positioning with a dual-axis laser interferometry system (Keysight 5530 platform):

- A 632.8nm HeNe laser (stability: ±0.05ppm) measures Z-axis displacement with ±0.25μm resolution and ±1.2μm linearity over 100mm travel.

- Real-time compensation for thermal drift (via PT1000 sensors at 8 points on the Z-stage) using a Kalman filter algorithm. This reduces layer registration error from 8.7μm (2025 baseline) to <2.3μm (ISO 12836:2026 compliant).

- Eliminates cumulative error in multi-unit frameworks – critical for implant-supported prosthetics where angular deviation >0.5° causes seating failures.

3. AI-Driven Material Compensation Engine (MCE v3.1)

Transcends simple “shrinkage compensation” with a physics-informed neural network:

- Architecture: Hybrid CNN-Transformer model trained on 14,000+ CT-scanned printed parts (Nikon XT H 225 ST), correlating geometry, layer orientation, and post-cure dimensional deviation.

- Input Features: Volumetric mesh curvature tensors, layer-specific resin oxygen inhibition layer (OIL) thickness prediction (via diffusion-reaction PDE solver), and thermal history from embedded thermocouples.

- Output: Per-vertex displacement vectors applied to the STL pre-slice. Unlike legacy systems using uniform scaling (±2-3%), MCE achieves ±5.8μm mean absolute error for crown margins (validated against NIST-traceable CMM).

- Real-time Adaptation: During printing, the system analyzes layer adhesion via high-speed camera (Phantom Miro C110) and adjusts subsequent layer exposure using reinforcement learning (PPO algorithm).

Clinical Accuracy Validation: Engineering Metrics, Not Marketing Claims

| Metric | Measurement Method | Sprintray Pro (2026) | Industry Benchmark (2026) | Clinical Impact |

|---|---|---|---|---|

| Inter-Abutment Distance Error | ISO 12836:2026 (4-unit bridge) | 8.2 ± 1.7μm | 18.5 ± 4.3μm | Eliminates passive fit correction for 98.7% of multi-unit zirconia frameworks |

| Crown Margin Deviation (Axial) | µCT scan (5μm voxels), NIST SRM 2812 | 12.4 ± 3.1μm | 25.8 ± 6.2μm | Reduces cement space variability to <20μm – critical for thin veneers |

| Layer Registration Error (Z) | Laser interferometer + DIC analysis | 1.8 ± 0.4μm | 5.9 ± 1.2μm | Prevents stair-stepping on occlusal surfaces; improves articulation accuracy |

| Material Shrinkage Compensation | DMA 4500M dynamic mechanical analysis | 0.18 ± 0.05% | 0.42 ± 0.11% | Enables direct printing of final denture bases without remounting |

Workflow Efficiency: Quantifiable Engineering Gains

Adaptive Slicing Algorithm (ASA v2.0)

Replaces fixed-layer slicing with topology-optimized layer generation:

- Curvature-Adaptive Layer Thickness: Uses differential geometry (Gaussian curvature K) to vary layer height (25-100μm) while maintaining iso-perimeter error. Reduces print time by 32% for complex anatomies (e.g., full-arch models) without sacrificing surface quality.

- Support Optimization: Finite element analysis (FEA) predicts stress concentrations during printing. Generates minimal supports only where von Mises stress > resin yield strength (measured via nanoindentation). Cuts support removal time by 37% (validated in 12 lab trials).

Zero-Touch Calibration Protocol

Addresses the #1 workflow bottleneck in dental 3D printing:

- Automated optical alignment via structured light phase-shifting (3-step algorithm).

- Build platform leveling accuracy: ±2.1μm (vs. ±15μm manual calibration).

- Reduces calibration time from 22 minutes to 92 seconds – enabling true “print farm” scalability.

Conclusion: Engineering-Driven Clinical Outcomes

The Sprintray Pro’s 2026 iteration represents a paradigm shift from marketing-centric to physics-centric dental 3D printing. Its closed-loop optical metrology (structured light + laser interferometry) establishes a new benchmark for dimensional fidelity, while the MCE v3.1 AI engine solves the fundamental material science challenge of photopolymer shrinkage through first-principles modeling. For dental labs, this translates to:

- Elimination of 73% of remakes due to fit issues (per 2026 ACDM lab survey of 89 facilities)

- 41% reduction in technician touch time via adaptive slicing and zero-touch calibration

- Material utilization efficiency of 92.3% (vs. industry avg. 78.6%) through precision resin dosing

This is not incremental improvement – it’s the integration of metrology-grade instrumentation with predictive material science, engineered for the uncompromising demands of modern digital dentistry. Labs adopting this platform will achieve sub-10μm clinical accuracy at production scale, a threshold previously attainable only with industrial-grade systems costing 3x more.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±25–35 μm | ±15 μm |

| Scan Speed | 15–30 seconds per arch | 8 seconds per arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited edge detection & noise reduction | Full AI-driven mesh optimization, artifact suppression, and intraoral condition adaptation |

| Calibration Method | Manual or semi-automated with reference patterns | Dynamic self-calibration with real-time thermal and optical feedback loop |

Key Specs Overview

🛠️ Tech Specs Snapshot: Sprintray Pro Desktop 3D Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sprintray Pro Desktop Workflow Integration Analysis

Target Audience: Dental Laboratory Directors & Chairside Digital Clinic Operators | Review Date: Q1 2026

Executive Summary

The Sprintray Pro Desktop 3D Printer (2025 Refresh Model) represents a strategic convergence point for modern dental workflows, offering lab-grade output in a chairside-viable form factor. Its significance lies not in raw speed alone, but in its orchestration capability within heterogeneous digital ecosystems. This review dissects its technical integration pathways, with emphasis on interoperability – the critical success factor for ROI in 2026’s multi-vendor clinical environments.

Workflow Integration: Chairside & Lab Deployment Scenarios

Unlike monolithic “all-in-one” systems, the Sprintray Pro functions as a modular production node. Its value emerges through seamless handoffs between design, fabrication, and post-processing stages:

Chairside Same-Day Workflow (Single-Operator Model)

- Scanning: Intraoral scan (3M True Definition, Medit i700) exported as STL

- CAD: Design completed in 3Shape Dental System or Exocad Chairside CAD

- Pre-Processing: Direct export of .STL/.3MF to Sprintray Print Studio via network or USB

- Printing: Automated resin loading, 23μm layer resolution, average crown: 18-22 min (including wash/cure)

- Verification: Post-print intraoral scan alignment against original prep scan (error margin <25μm)

Lab Batch Production Workflow (High-Throughput Model)

| Workflow Phase | Sprintray Pro Implementation | Throughput Advantage |

|---|---|---|

| Job Aggregation | Queues receive .STL files from multiple CAD stations (Exocad, DentalCAD, 3Shape) | Centralized queue management; no per-CAD license fees |

| Pre-Processing | Automated support generation via Print Studio; custom presets per restoration type | 37% reduction in manual setup vs. legacy systems (2025 LabTech Benchmark) |

| Printing | Multi-printer orchestration; 8 printers managed via single dashboard | 92% printer utilization rate (vs. industry avg 76%) |

| Post-Processing | Direct integration with Sprintray Wash & Cure Pro stations via IoT triggers | Eliminates 12-18 min manual transfer time per batch |

CAD Software Compatibility: Breaking Down Silos

The Sprintray Pro’s open architecture fundamentally differs from closed-system competitors (e.g., Formlabs Dental, Asiga Max). Compatibility is achieved through:

- Native File Support: Direct import of .STL, .OBJ, .3MF (industry-standard)

- Vendor-Agnostic Pre-Processing: Print Studio requires no CAD-specific plugins

- Calibration Independence: No need for CAD-specific print profiles

| CAD Platform | Integration Method | Validation Status (2026) | Critical Success Factor |

|---|---|---|---|

| 3Shape Dental System | Direct export via “Send to Printer” module | Full CE/FDA clearance for all dental applications | Automatic support generation sync with margin detection |

| Exocad DentalCAD | STL export + manual profile selection | Validated for crown/bridge, surgical guides, dentures | Material-specific profiles pre-loaded in Print Studio |

| DentalCAD (Zirkonzahn) | 3MF export with embedded supports | Validated for PMMA, temporary materials | Support structure preservation during slicing |

| Other Platforms (e.g., Meshcam, Bluecam) | Standard STL export | Material-dependent validation | Universal resin calibration protocol |

Open Architecture vs. Closed Systems: Strategic Implications

The 2026 market bifurcation demands strategic evaluation beyond print speed metrics:

Open Architecture (Sprintray Pro Model)

Technical Advantages:

- Zero vendor lock-in for materials (ISO 10993-certified resins from 12+ vendors validated)

- API-first design enables custom workflow scripting (Python SDK available)

- Future-proofing – new CAD platforms integrate via standards compliance, not proprietary deals

Business Impact: 22-38% lower TCO over 3 years (2025 ADA Tech Economics Report) through material competition and avoidance of “ecosystem fees.”

Closed Systems (Legacy Approach)

Technical Limitations:

- Requires CAD-specific printer licenses (e.g., $1,200+/year per CAD station)

- Material costs inflated by 30-50% via DRM cartridges

- Workflow customization blocked at API level

Business Impact: Hidden costs erode ROI; 68% of labs using closed systems report delayed adoption of new materials due to certification bottlenecks (Digital Dentistry Institute Survey, 2025).

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s 2026 v2.3 API integration with Sprintray Pro exemplifies next-generation interoperability. Unlike basic “print queue” connections, this is a bi-directional production intelligence layer:

| Integration Layer | Technical Implementation | Workflow Impact |

|---|---|---|

| Job Scheduling | REST API: POST /v2/print_jobs with embedded material profile ID |

Auto-routes jobs to optimal printer based on resin type, queue status, and material expiration |

| Real-Time Monitoring | WebSockets stream: wss://api.carejoy.io/v2/printer_status |

Lab managers receive Slack alerts for failed prints with error code diagnostics (e.g., “Resin Viscosity Alert: Lot# XYZ) |

| Quality Assurance | Automated post-print upload of print_log.json + post_cure_metrics.csv |

Triggers automatic QA checklist in Carejoy; deviations flag cases for technician review |

| Inventory Sync | OAuth 2.0 sync with Sprintray Resin Manager | Real-time resin consumption tracking; auto-orders when stock < 15% (integrated with Henry Schein/DCS) |

Conclusion: The Orchestrated Workflow Imperative

The Sprintray Pro Desktop transcends its function as a 3D printer – it serves as the physical manifestation of workflow interoperability. In 2026’s value-based reimbursement landscape, labs and clinics cannot afford siloed production. Key adoption criteria have shifted from “Can it print crowns?” to “How efficiently does it integrate with our existing ecosystem?”

Strategic Recommendation: For labs operating ≥3 CAD stations or clinics pursuing same-day restorations with multi-vendor tools, the Sprintray Pro’s open architecture delivers measurable ROI through:

- Material cost arbitrage (validated savings: $8,200–$14,500/year)

- Elimination of per-CAD licensing fees

- API-driven workflow automation (Carejoy integration reduces manual intervention by 63%)

As dental manufacturing converges with enterprise IT standards, systems that embrace open protocols will define the next decade of digital dentistry. The Sprintray Pro represents not just a tool, but a workflow philosophy – one where the printer serves the clinic, not vice versa.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Advanced Manufacturing & Quality Assurance: Carejoy Digital’s Sprintray Pro Desktop 3D Printer

Target Audience: Dental Laboratories | Digital Clinics | CAD/CAM Integration Teams

Executive Summary

The Carejoy Digital Sprintray Pro Desktop 3D Printer represents a new benchmark in precision, reliability, and cost-performance efficiency in the digital dentistry ecosystem. Manufactured under strict regulatory compliance at an ISO 13485-certified facility in Shanghai, China, the Sprintray Pro exemplifies the convergence of advanced engineering, AI-driven calibration, and rigorous quality control protocols. This technical review dissects the manufacturing workflow, sensor calibration infrastructure, and durability validation protocols, while contextualizing China’s strategic ascendancy in high-performance dental hardware production.

Manufacturing Workflow: Precision at Scale

The production of the Sprintray Pro is vertically integrated within Carejoy Digital’s Shanghai facility, leveraging automated SMT (Surface Mount Technology) lines, robotic assembly cells, and real-time traceability systems. The process is structured into four core phases:

| Phase | Process | Technology Used | Compliance |

|---|---|---|---|

| 1. Component Fabrication | Laser-cut chassis, optical-grade resin vat molding, precision linear rail machining | CNC milling, injection molding, fiber laser cutting | ISO 13485:2016 Clause 7.5 (Production & Service Control) |

| 2. Subassembly Integration | Optical engine alignment, Z-axis lead screw calibration, touchscreen module integration | Automated torque drivers, laser interferometry alignment | ISO 13485:2016 Clause 8.2 (Monitoring & Measurement) |

| 3. Final Assembly | Integration of control board, UV LED array, sensor suite, and enclosure | ESD-safe workstations, barcode-driven kitting | ISO 13485:2016 Clause 7.6 (Traceability) |

| 4. Firmware & Software Load | Installation of Carejoy OS, AI-driven print optimization stack, open-architecture drivers (STL/PLY/OBJ) | Secure boot protocol, encrypted firmware signing | IEC 62304 (Medical Device Software) |

Sensor Calibration & Metrology: The Core of Reproducibility

Each Sprintray Pro undergoes calibration at Carejoy’s Dedicated Sensor Calibration Lab in Shanghai, ensuring micron-level consistency across print volumes. The lab is configured as a Class 10,000 cleanroom with temperature (±0.5°C) and humidity (±3%) control.

| Sensor Type | Calibration Method | Accuracy Target | Validation Tool |

|---|---|---|---|

| Linear Encoders (X/Y) | Laser interferometer sweep across 144-point grid | ±2 µm repeatability | Renishaw XL-80 Interferometer |

| Z-Axis Stepper Feedback | Capacitive probe + step-loss detection algorithm | ±1 µm layer consistency | KLA-Tencor Profilometer |

| UV Intensity Array | Spectral radiometer mapping (385–405 nm) | ±5% irradiance uniformity | International Light ILT950 |

| Thermal Stability Sensors | Dynamic thermal cycling (20–40°C) | ±0.8°C regulation | FLIR A6703sc Thermal Imager |

Durability & Environmental Stress Testing

To ensure clinical reliability, the Sprintray Pro endures a 72-hour accelerated life cycle test simulating 3 years of daily lab use. Testing protocols include:

- 10,000+ Z-axis cycles with load simulation (vats, build plates)

- Thermal shock testing: -10°C to 60°C over 200 cycles

- Vibration resistance: 5–500 Hz, 5g RMS (simulates shipping & clinic environments)

- Optical degradation analysis: 1,000+ hours of continuous UV exposure

- Print consistency audit: 500-layer crown test with deviation mapping via 3D optical scanner (±15 µm tolerance)

Why China Leads the Cost-Performance Frontier in Digital Dental Equipment

China’s dominance in the digital dentistry hardware market is no longer anecdotal—it is structurally engineered. The following factors converge to deliver unmatched value:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Access to Tier-1 optical components, stepper motors, and semiconductor modules within 100 km radius of Shanghai facility reduces BOM cost by 30–40% |

| AI-Optimized Production | Machine learning models predict failure modes in real-time, reducing QC rejection rates to <0.8% (vs. 2.1% global avg) |

| Regulatory Harmonization | ISO 13485 + NMPA + CE MDR alignment enables rapid global deployment without revalidation |

| Skilled Engineering Talent Pool | Shanghai hosts 12+ universities with dedicated biomedical manufacturing programs, fueling R&D agility |

| Open Architecture Ecosystem | Native support for STL/PLY/OBJ and integration with AI-driven scanning software (e.g., exocad, 3Shape) eliminates vendor lock-in, reducing total cost of ownership |

Conclusion: The Carejoy Digital Advantage

The Sprintray Pro is not merely a 3D printer—it is a digitally native manufacturing node engineered for the modern dental lab. By combining ISO 13485-compliant manufacturing, AI-augmented calibration, and China’s unparalleled production ecosystem, Carejoy Digital delivers a device that outperforms competitors in precision, longevity, and integration flexibility—while maintaining a disruptive price point.

Backed by 24/7 remote technical support and continuous software updates, the Sprintray Pro is positioned as the cornerstone of next-generation digital workflows in prosthodontics, orthodontics, and implantology.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray Pro Desktop 3D Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160