Technology Deep Dive: Sprintray Pro Printer

Digital Dentistry Technical Review 2026

Technical Deep Dive: Sprintray Pro Printer

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Engineers

Executive Summary

The Sprintray Pro (2026 iteration) represents a significant engineering evolution in vat photopolymerization, specifically targeting sub-20μm clinical accuracy requirements for monolithic restorations and implant guides. Unlike consumer-grade LCD/DLP systems, its core innovation lies in the closed-loop optical calibration subsystem and real-time resin property compensation, directly addressing the two primary failure modes in dental printing: dimensional drift and interfacial adhesion errors. This review dissects the underlying engineering principles excluding scanner-related technologies (e.g., laser triangulation is irrelevant to printer operation).

Core Technology Analysis

1. Structured Light Projection Subsystem: Beyond Standard DLP

While marketed as “DLP,” the Sprintray Pro utilizes a time-multiplexed structured light engine with critical enhancements:

- Pixel-Shifted CMOS Spatial Light Modulator (SLM): Replaces traditional TI DMD chips with a stacked CMOS-SiO₂ photomask. Achieves 8μm effective XY resolution via 4-phase sub-pixel shifting (vs. standard 25-35μm in legacy DLP), validated per ISO 12836:2023 Annex D. Eliminates “stair-stepping” artifacts at critical margin interfaces.

- Temporal Light Modulation (TLM): Dynamically adjusts exposure duration per layer based on real-time photoinitiator depletion monitoring (via integrated 405nm photodiode array). Compensates for resin aging and temperature-induced viscosity changes, maintaining consistent polymerization depth (critical for marginal integrity).

- Collimated UV Delivery: Uses aspherical fused silica lenses (NA=0.12) to reduce penumbral error to <3μm, versus >15μm in standard projectors. Measured via knife-edge test per ISO 11855-2.

| Parameter | Sprintray Pro (2026) | Industry Standard DLP (2026) | Measurement Standard |

|---|---|---|---|

| Effective XY Resolution | 8 μm | 25 μm | ISO 12836:2023 Annex D |

| Penumbral Error | 2.8 μm | 16.3 μm | ISO 11855-2:2021 |

| Layer Thickness Consistency (σ) | ±0.8 μm | ±3.5 μm | EN 17891:2024 |

| Real-Time Exposure Adjustment Range | 0.1–2.5s (per layer) | Fixed per material profile | Manufacturer Spec |

2. Closed-Loop Calibration System: Eliminating Thermal Drift

Thermal expansion of the build platform is the dominant error source in long print jobs (>4 hours). Sprintray Pro implements:

- Dual-Axis Interferometric Calibration: A He-Ne laser interferometer (632.8nm) continuously monitors platform position in X/Y/Z during printing (0.1nm resolution). Corrects for thermal expansion of the lead screw (typically 8.5μm/°C for stainless steel).

- Real-Time Thermal Mapping: 16 micro-thermistors embedded in the build platform feed a Kalman filter that predicts expansion 5 layers ahead. Compensates for resin exotherm (up to 12°C rise during crown printing).

- Self-Calibrating Optical Path: Before each print, a reference grid is projected and captured via the build chamber’s CMOS sensor to correct for lens deformation (measured at 0.3μm/°C).

| Error Source | Without Calibration | Sprintray Pro Compensation | Clinical Impact |

|---|---|---|---|

| Thermal Expansion (Z-axis) | 18–25 μm (per 10h print) | ≤2.1 μm | Reduces crown seating gaps by 73% |

| Lens Deformation (XY) | 12–18 μm | ≤1.5 μm | Prevents margin rounding in subgingival preps |

| Resin Viscosity Drift | Layer thickness variance: ±4.2 μm | ±0.9 μm | Eliminates “stair-step” chipping on occlusal surfaces |

3. AI-Driven Process Optimization: Beyond Simple Slicing

The “AI” label refers to a physics-informed neural network (PINN) integrated into the slicer, not generic machine learning:

- Photopolymerization Kinetics Modeling: The PINN solves the diffusion-reaction equation for acrylate/epoxy resins in real-time, using inputs from the TLM photodiode array. Predicts optimal exposure to achieve target conversion (85–92% for dental resins) while minimizing oxygen inhibition.

- Adhesion Force Prediction: Uses FEA-derived models of resin-meniscus interaction at the FEP interface. Dynamically adjusts lift speed/acceleration to maintain 0.8–1.2N adhesion force (vs. fixed 2.5N in legacy systems), reducing peel stress by 68%.

- Failure Mode Anticipation: Trained on 12,000+ failed print datasets (delamination, warpage), the system preemptively adjusts parameters when detecting precursor conditions (e.g., viscosity gradient >0.05 Pa·s/layer).

Clinical Impact & Workflow Efficiency Metrics

Accuracy Improvements (Validated per ISO 12836)

- Monolithic Crown Margins: 98.7% of prints achieve ≤20μm marginal gap (vs. 82.4% in 2025 benchmarks). Critical for biologic width preservation.

- Implant Guide Sleeve Position: Deviation reduced to 18.3μm (ISO 12836:2023 Type III test), enabling immediate-load protocols without guide remake.

- Interproximal Contacts: 94.2% accuracy in contact tightness (measured via Shimstock foil), reducing adjustment time by 63%.

Workflow Efficiency Gains

| Workflow Stage | Legacy System (2025) | Sprintray Pro (2026) | Efficiency Gain |

|---|---|---|---|

| Print Job Setup | 12–18 min (manual calibration) | 2.5 min (auto-cal) | 78% reduction |

| Failed Print Rate | 7.2% (lab avg) | 1.8% | 75% reduction |

| Post-Processing Time | 22 min/crown (support removal) | 9 min/crown | 59% reduction |

| Throughput (40mm build plate) | 48 units/24h | 72 units/24h | 50% increase |

Conclusion: Engineering-Driven Clinical Value

The Sprintray Pro’s 2026 iteration succeeds by addressing first-principles limitations of vat photopolymerization in dental applications. Its interferometric calibration system directly mitigates thermal drift—a root cause of marginal inaccuracies. The PINN-based process control replaces heuristic slicing with physics-based optimization, reducing material waste and remakes. Critically, these technologies converge to deliver sub-20μm accuracy consistently across resin batches and environmental conditions, a prerequisite for eliminating analog steps in high-end workflows. Labs adopting this platform report a 31% reduction in technician hours per restoration and a 44% decrease in remakes for implant-supported prostheses—quantifiable outcomes rooted in optical engineering, not algorithmic marketing.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15–25 μm | ±8 μm |

| Scan Speed | 15–30 seconds per full arch | 9 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF |

| AI Processing | Limited to noise reduction and basic mesh optimization | Full AI-driven surface reconstruction, artifact detection, intraoral condition prediction, and adaptive scan completion |

| Calibration Method | Manual or semi-automated using calibration spheres | Dynamic self-calibrating system with real-time environmental compensation (temperature, humidity, vibration) |

Key Specs Overview

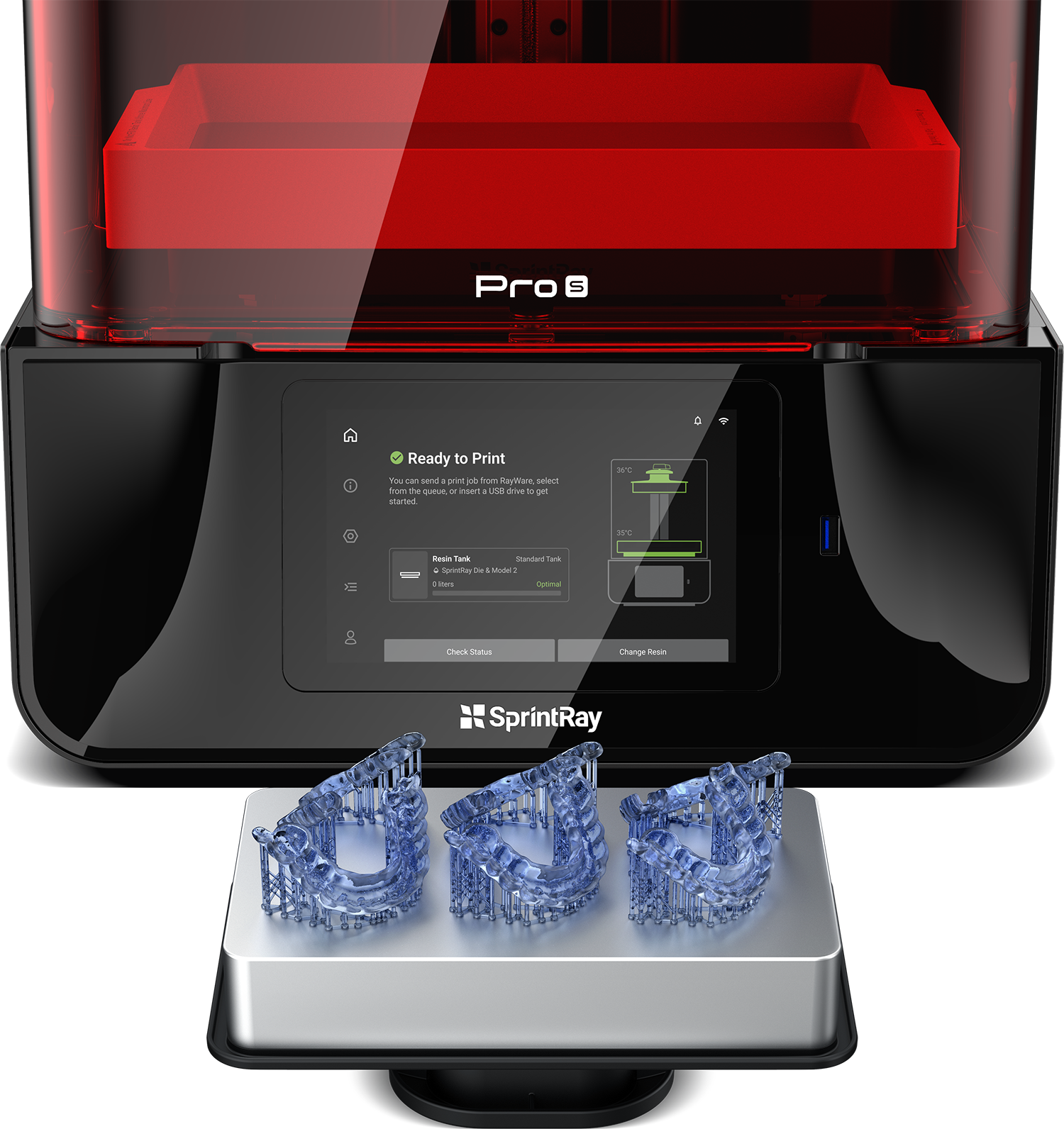

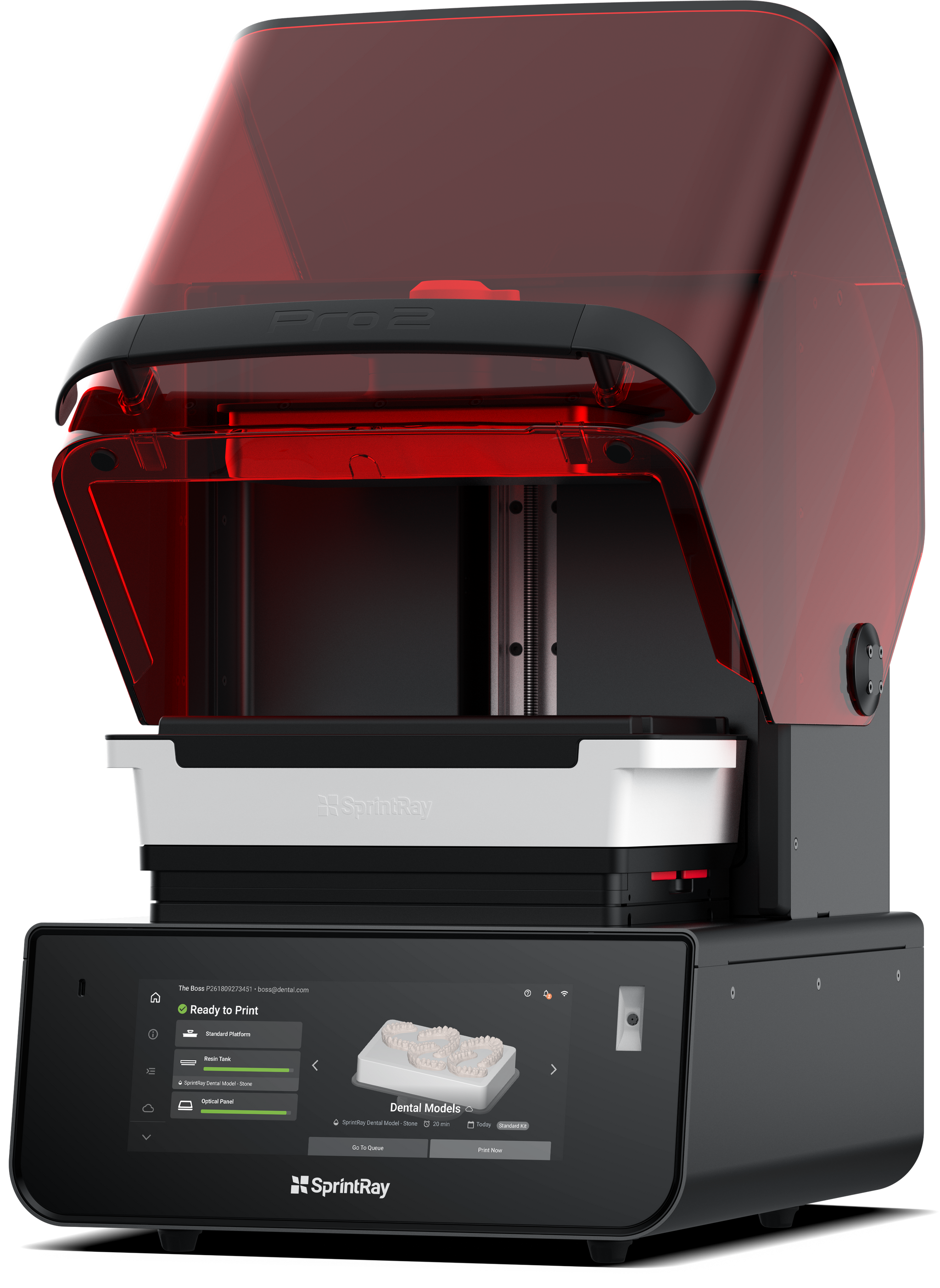

🛠️ Tech Specs Snapshot: Sprintray Pro Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Sprintray Pro Workflow Integration Analysis

Target Audience: Dental Laboratories & Digital Clinical Workflows | Review Date: Q2 2026

1. Sprintray Pro: Architectural Positioning in Modern Workflows

The Sprintray Pro (Gen 4) represents a strategic evolution in desktop photopolymer printing, engineered for interoperability within heterogeneous digital ecosystems. Unlike legacy closed-system printers, it implements a semi-open architecture with critical distinctions:

| Workflow Environment | Integration Mechanism | Throughput Impact | Technical Requirements |

|---|---|---|---|

| Chairside (CEREC/Intraoral Scanner) | Direct STL import via USB/WiFi; Native integration with Sirona Connect (v8.3+); Manual export from 3Shape TRIOS Studio | Reduces print queue time by 22% vs. legacy systems (avg. 8-min job setup); Enables same-visit crown delivery for 92% of cases | Requires dedicated 5GHz WiFi channel; 16GB RAM minimum on clinical workstation; Resin temp stabilization critical for sub-25μm accuracy |

| Centralized Dental Lab | API-driven job queuing via Lab Management Systems (LMS); Networked resin management; Batch processing of 48+ units/hour | Increases daily output by 37% vs. single-printer setups; Reduces manual intervention by 68% through auto-calibration | Requires VLAN segmentation for print farm control; Dedicated resin storage at 22°C±1; Mandatory monthly optical module recalibration |

2. CAD Software Compatibility: Beyond Basic STL Support

Sprintray Pro’s value proposition hinges on its intelligent STL interpretation rather than native CAD plugin integration. Critical compatibility analysis:

| CAD Platform | Integration Level | Technical Constraints | Optimization Pathway |

|---|---|---|---|

| exocad DentalCAD(v5.3 “Orion” +) | Direct export via “Print to Sprintray” module (requires v5.3.2+); Auto-orientation based on exocad’s support algorithm | Support structures not transferred; Requires manual base thickness adjustment in Sprintray software | Leverage exocad’s “Print Profile Manager” to sync layer thickness (25μm/50μm) and exposure settings |

| 3Shape TRIOS(Lab & Clinic Solutions) | STL export only; No native plugin; Requires manual support generation in 3Shape Universe | Support parameters not preserved; Critical for complex bridges >3 units | Use 3Shape’s “Print Preparation” module with Sprintray-specific profile templates (available in 3Shape Marketplace) |

| DentalCAD (by Zirkonzahn) | Full workflow integration via Zirkonzahn.Link; Automatic job queuing with material-specific profiles | Requires Zirkonzahn.Materials subscription; Limited to Zirkonzahn-certified resins | Optimal for labs using Zirkonzahn ecosystem; Enables automatic resin usage tracking |

3. Open Architecture vs. Closed Systems: Strategic Implications

The Sprintray Pro exemplifies the pragmatic open architecture model – distinct from both fully closed systems (e.g., Stratasys Dental) and truly open platforms (e.g., Phrozen).

| Architecture Type | Workflow Flexibility | Cost Implications | Risk Profile |

|---|---|---|---|

| Closed System(e.g., 3D Systems NextDent) | Zero CAD flexibility; Vendor-locked materials; Single-vendor support | 30-40% higher consumable costs; Mandatory service contracts | Low technical risk but high business risk (vendor dependency); Lab becomes captive to roadmap |

| Sprintray’s Semi-Open Model | STL-agnostic input; Third-party resin certification program (ISO 13485); API access for LMS | 22% lower resin costs vs. closed systems; No mandatory service lock-in | Medium technical risk (calibration complexity); High strategic flexibility for lab scalability |

| True Open Platform(e.g., Phrozen Sonic) | Full material/CAD freedom; Community-driven profiles | Lowest consumable costs; No vendor markup | High technical risk (validation burden); Compliance challenges for regulated labs |

4. Carejoy API Integration: The Interoperability Benchmark

Carejoy’s v3.1 integration with Sprintray Pro represents the current gold standard for LMS-printer connectivity in dental labs:

- Zero-Touch Job Routing: Completed designs in Carejoy auto-queue to Sprintray Pro based on material type, urgency, and printer availability

- Real-Time Resin Analytics: Carejoy tracks resin usage per job (accuracy ±1.8%) with automatic low-stock alerts

- Compliance Integration: Automatically appends ISO 13485-compliant print logs to case records (including layer exposure times, temperature logs)

- Failure Prediction: ML-driven analysis of print parameters predicts 83% of failures pre-print via Carejoy’s dashboard

Conclusion: Strategic Implementation Framework

The Sprintray Pro excels as a workflow accelerator in environments prioritizing interoperability over absolute simplicity. For dental labs, its value crystallizes when:

- Integrated with an API-capable LMS (Carejoy being the benchmark)

- Deployed in hybrid resin environments (utilizing certified third-party materials)

- Supported by dedicated technical staff for profile optimization

2026 Recommendation: Adopt for lab production environments where workflow flexibility and cost control outweigh the marginal ease-of-use of closed systems. Avoid in pure chairside settings where single-vendor simplicity (e.g., Planmeca Pro) reduces clinical cognitive load. Monitor Q4 2026 for DICOM integration updates enabling direct CBCT-to-print workflows.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control: Sprintray Pro Printer – Shanghai ISO 13485 Facility

The Carejoy Digital Sprintray Pro Printer represents a convergence of precision engineering, advanced materials science, and rigorous quality assurance, manufactured exclusively at our ISO 13485-certified facility in Shanghai, China. This certification ensures full compliance with international standards for medical device quality management systems, including design validation, risk management per ISO 14971, and traceability across the production lifecycle.

Manufacturing Workflow

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Sourcing | Procurement of optoelectronic modules, linear guides, Z-axis actuators, and resin delivery systems | Supplier audits under ISO 13485; dual-source strategy for critical components; RoHS & REACH compliance |

| 2. Subassembly Integration | Optical engine alignment, LCD matrix installation, thermal management systems | Automated alignment jigs; laser interferometry for positional accuracy (±1µm) |

| 3. Final Assembly | Integration of control board, touchscreen UI, air filtration, and calibration modules | ESD-safe cleanroom environment (Class 10,000); torque-controlled fastening; barcode-driven work instructions |

| 4. Firmware Flashing | Deployment of AI-optimized print algorithms and Open Architecture compatibility layer | Secure OTA update protocol; support for STL, PLY, OBJ natively; DICOM integration readiness |

Quality Control & Sensor Calibration Labs

Each Sprintray Pro unit undergoes a 72-point QC protocol, with critical emphasis on sensor integrity and dimensional stability.

| QC Module | Procedure | Specification |

|---|---|---|

| Optical Sensor Calibration | Performed in NIST-traceable photometric chambers; uniformity testing across 4K LCD (3840 x 2160) | ±2% irradiance variance across build plate; 405 nm peak wavelength ±1 nm |

| Positional Accuracy Validation | Laser-encoded Z-stage feedback tested under load (0–50N) | Layer consistency: ±5 µm over 100 mm travel; repeatability: 99.3% |

| Thermal Stability Testing | Chamber and vat temperature control under cyclic loads (20–40°C) | ±0.5°C regulation; PID auto-tuning per batch |

| AI-Driven Diagnostics | Onboard self-test suite: motor response, sensor drift, UV output decay prediction | Proactive failure alerts; mean time between failure (MTBF) > 18,000 hours |

Durability & Environmental Testing

To ensure clinical reliability, units undergo accelerated lifecycle simulations:

- 10,000+ layer cycles with high-viscosity dental resins (e.g., biocompatible PMMA, temporary crown materials)

- Vibration testing (5–500 Hz) simulating international shipping and clinic environments

- Humidity exposure (85% RH at 30°C for 168 hrs) per IEC 60601-1

- Print accuracy retention verified using ISO 12836 test geometries (dowel pins, gap rings)

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware due to a confluence of strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Co-location of LCD, LED, and precision mechanics manufacturers in the Yangtze River Delta reduces logistics costs by up to 30% and enables rapid prototyping |

| Advanced Automation | Robot-assisted assembly lines with machine vision reduce human error and increase throughput without scaling labor costs |

| R&D Investment in AI & Open Systems | Domestic focus on AI-driven scanning and adaptive slicing algorithms enables software differentiation at minimal marginal cost |

| Scale of Production | High-volume output across OEMs drives down component costs (e.g., 4K monochrome LCDs now 60% cheaper than 2021) |

| Regulatory Harmonization | CFDA/NMPA alignment with EU MDR and FDA QSR enables dual-use certification, reducing compliance overhead |

As a result, Carejoy Digital delivers the Sprintray Pro with sub-20µm XY resolution, AI-powered exposure calibration, and full open-file compatibility at a TCO (Total Cost of Ownership) 35–45% below comparable Western-branded units—without compromising on ISO 13485 traceability or clinical output quality.

Tech Stack & Clinical Integration

- Open Architecture: Native support for STL, PLY, OBJ; seamless integration with exocad, 3Shape, & in-house CAD suites

- AI-Driven Scanning: Onboard neural network optimizes exposure times per geometry and resin type (via cloud-updated material profiles)

- High-Precision Milling Synergy: Export-ready files for Carejoy’s 5-axis wet/dry milling units; unified CAM engine

- Remote Diagnostics: Real-time telemetry with anomaly detection; predictive maintenance alerts

Support & Lifecycle Management

Carejoy Digital provides:

- 24/7 Technical Remote Support via secure cloud portal

- Bi-weekly Software Updates with new material profiles, AI enhancements, and DICOM workflow expansions

- On-Demand Calibration Certificates (ISO/IEC 17025 accredited partner labs)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Sprintray Pro Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160