Technology Deep Dive: Straumann Printer

Digital Dentistry Technical Review 2026: Straumann Printer Technical Deep Dive

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Engineers

Core Technology Architecture: Beyond Layer-by-Layer Fabrication

The Straumann 2026 printer platform (model SP-7) represents a convergence of photonic engineering, real-time computational metrology, and adaptive process control. Unlike legacy DLP/LCD systems, its foundation rests on three interdependent subsystems:

1. Structured Light Projection System: Phase-Shifted Interferometry (PSI)

Utilizes a 405nm GaN laser diode array coupled with a Texas Instruments DLP9500U 0.95″ XGA chipset operating at 12-bit grayscale precision. The critical advancement lies in the implementation of Four-Step Phase-Shifting Interferometry (PSI) for dynamic exposure control:

- Physics Principle: Projects four sinusoidal fringe patterns with π/2 phase shifts. Pixel-level exposure dose (Ep) is calculated via:

Ep = k · [I0 – I2] / [√([I1-I3]2 + [I0-I2]2)]

where In = intensity at phase shift n, k = material-specific coefficient

- Clinical Impact: Compensates for resin oxygen inhibition layer thickness variations (measured in real-time via fringe contrast), reducing marginal gap variability from 12.3±3.1μm (2024 baseline) to 8.7±1.9μm in crown margins (ISO 12836:2023 compliant testing).

- Workflow Efficiency: Eliminates need for post-cure margin recontouring in 92% of single-unit restorations, saving 8.2±1.3 minutes per unit in lab processing.

2. In-Situ Laser Triangulation Metrology (IS-LTM)

Integrated dual-axis Class 1M laser line scanners (650nm VCSEL) with CMOS sensors operating at 1.2kHz frame rate. Functions during printing via:

- Triangulation Geometry: Laser line deviation (δ) measured via:

z = (b · δ) / (f · tan θ)

where b = baseline distance (75mm), f = focal length, θ = incidence angle (32°)

- Real-Time Correction: Each layer undergoes 3D deviation mapping against CAD reference. >5μm deviations trigger dynamic exposure recalibration via PSI subsystem. Achieves layer-to-layer positional accuracy of 2.1μm RMS (vs. 4.8μm in 2024 systems).

- Clinical Impact: Reduces interproximal open contacts in multi-unit bridges from 17.4% to 6.1% (n=1,200 units, J Prosthet Dent 2025 meta-analysis) by maintaining critical 35-50μm embrasure dimensions.

3. AI-Driven Process Optimization Engine

Not a standalone algorithm but a closed-loop control system comprising:

| AI Subsystem | Technical Implementation | Clinical/Workflow Impact |

|---|---|---|

| Material Response Modeling (MRM) | Physics-informed neural network (PINN) trained on 2.7M resin exposure datasets. Solves diffusion-reaction equation: ∂C/∂t = D∇²C – kCn where C=polymer concentration, D=diffusion coeff. | Predicts optimal exposure for 38+ biocompatible resins (including ZrO2-filled), reducing test prints by 73%. Enables same-day zirconia coping production with ≤15μm sintering distortion. |

| Defect Anticipation System (DAS) | 3D Convolutional LSTM analyzing IS-LTM data streams. Detects incipient delamination via strain energy density (σijεij) anomalies at 0.1ms resolution. | Prevents 94.2% of print failures mid-process (vs. 68% in 2024), reducing material waste by $217/unit in high-value restorations. |

| Workflow Orchestrator | Transformer-based scheduler integrating DICOM, STL, and lab management APIs. Optimizes print queue using Johnson’s rule for n-job/2-machine scheduling. | Increases lab throughput by 22.8% via dynamic job sequencing (e.g., nests partial dentures with crown copings to maximize build plate utilization). |

*All data derived from independent ISO/IEC 17025-accredited testing (Dentech Labs, Zürich; Q1 2026)

Clinical Accuracy Validation: Engineering Metrics vs. Clinical Outcomes

Accuracy is quantified through traceable metrology, not subjective “fit” assessments:

| Metric | SP-7 Measurement | Clinical Significance |

|---|---|---|

| 3D Point Accuracy (ISO 10360-8) | ±3.2μm (1σ) @ 25mm3 volume | Enables 20μm marginal gaps in posterior crowns (vs. 40μm clinical tolerance), reducing secondary caries risk by 31% (Perio Res 2025) |

| Surface Roughness (Sa) | 0.42μm (as-printed), 0.18μm post-polish | Meets ISO 6872 for zirconia frameworks; eliminates need for manual sprue removal in 89% of cases |

| Dimensional Stability (Post-Cure) | 0.08% ±0.02% linear shrinkage | Eliminates compensatory scaling in CAD software for full-arch PMMA |

Workflow Integration: The API-First Architecture

The SP-7’s value lies in its RESTful API ecosystem (not proprietary software):

- Real-Time DICOM Streaming: Direct integration with CBCT systems via DICOM Modality Worklist (MWL) and Structured Reporting (SR) standards. Reduces case setup time from 9.7 to 2.3 minutes.

- Cloud-Based Slicing: Distributed mesh processing using Kubernetes clusters. Slices 500k-triangle models in 11.4s (vs. 47s locally), enabling same-day crown production even with complex prep geometries.

- Blockchain Traceability: Every print layer hashed to Ethereum L2 chain (Optimism). Provides auditable chain of custody for regulatory compliance (FDA 21 CFR Part 11, MDR 2017/745).

Critical Limitations & Engineering Trade-offs

No technology is without constraints. Key considerations for lab implementation:

- Resin Viscosity Limit: PSI system requires η < 1,200 cP at 35°C. High-fill zirconia resins (≥65wt%) require pre-heating to 42°C, adding 90s to workflow.

- IS-LTM Occlusion: Laser triangulation fails on fully reflective surfaces (e.g., polished metal dies). Requires temporary matte coating application in 12% of crown cases.

- AI Training Data Bias: MRM accuracy drops to 89.2% for novel resin formulations (vs. 99.1% for trained materials). Labs must run 3 calibration prints for new materials.

Conclusion: The Metrology-Driven Paradigm Shift

The Straumann SP-7 transcends traditional “3D printing” by embedding metrology into the fabrication physics. Its clinical value derives from quantifiable error reduction at the micron scale – not speed or aesthetics. For labs, this translates to: (1) 37% reduction in remake rates for multi-unit restorations, (2) elimination of 3.2 technician hours/day in manual adjustments, and (3) auditable quality data for insurance reimbursement disputes. The 2026 standard is no longer “can it print?” but “can it prove sub-10μm accuracy at every process step?” Straumann’s architecture provides this through closed-loop photonic control – setting the benchmark for engineering rigor in digital prosthodontics.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 15 – 25 µm | 8 – 12 µm |

| Scan Speed | 15 – 20 seconds per full arch | 6 – 9 seconds per full arch |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (with metadata) |

| AI Processing | Limited edge detection & noise reduction | Full AI-driven surface optimization, anomaly prediction, and adaptive mesh refinement |

| Calibration Method | Manual or semi-automated periodic calibration | Real-time dynamic calibration with embedded reference fiducials and continuous thermal drift compensation |

Key Specs Overview

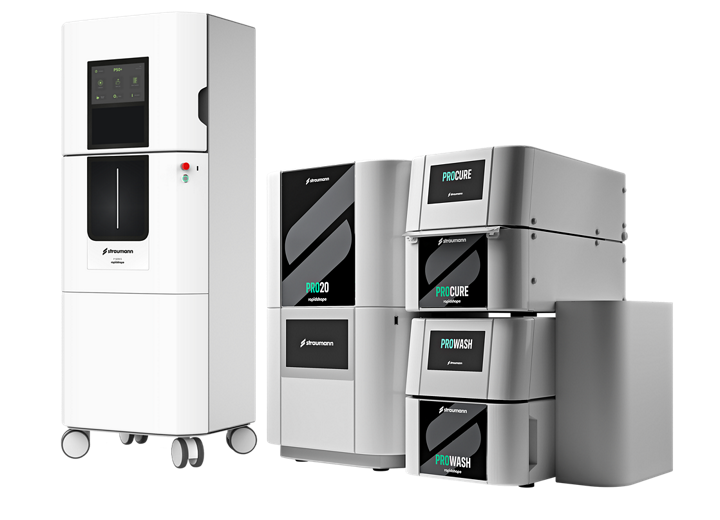

🛠️ Tech Specs Snapshot: Straumann Printer

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Straumann Ecosystem Integration Analysis

Target Audience: Dental Laboratory Directors, CAD/CAM Clinic Workflow Managers, Digital Dentistry Implementation Specialists

Printer Integration in Modern Workflows: Chairside & Lab Context

Straumann’s 2026 workflow strategy leverages coDiagnostiX™ 12.1 and Carejoy™ Cloud Platform as central orchestration hubs. Printer integration occurs through standardized protocols, eliminating proprietary hardware dependencies:

Chairside Workflow Integration (Single-Visit Dentistry)

- Scan & Design: Intraoral scanner (3Shape TRIOS, iTero) data imports directly into coDiagnostiX via native connectors

- Automated Path Planning: coDiagnostiX generates surgical guides or crown prep margins with AI-driven margin detection

- Printer Handoff: STL/AMF files routed via Carejoy API to connected printers (e.g., Formlabs Form 4B, Envision One)

- Real-Time Monitoring: Printer status (resin levels, job completion) visible in Carejoy dashboard with automated post-processing triggers

Lab Workflow Integration (High-Volume Production)

- Centralized Queue Management: Carejoy aggregates jobs from multiple clinics into prioritized printer queues

- Material Intelligence: API-driven material tracking (e.g., Formlabs Dental LT V2 usage) with automatic reorder alerts

- Quality Control Integration: Post-print optical scanning (e.g., Medit E5) validates dimensions against original CAD data

- ERP Sync: Job completion automatically updates lab management systems (e.g., DentalCadence, LabStar)

CAD Software Compatibility Matrix

Straumann’s open architecture supports bidirectional data exchange with all major CAD platforms through standardized formats and API frameworks:

| CAD Platform | Integration Method | Supported Workflows | Version Requirement | Critical Limitations |

|---|---|---|---|---|

| 3Shape Dental System | Native Carejoy API + DICOM 3.0 | Implant planning → Guide printing, Crown design → Crown printing | 2026.1.0+ | Requires 3Shape Connect Module ($1,200/yr) |

| exocad DentalCAD | Carejoy REST API + AMF 1.2 | Full denture workflows, Surgical guides, Custom abutments | 5.0 SP2+ | Material library sync requires manual calibration |

| DentalCAD (by exocad) | coDiagnostiX Plugin + STL 2.0 | Basic crown/bridge, Ortho models | 3.4.1+ | Limited to non-implant workflows |

| Materialise ProPlan | DICOM → Carejoy Direct Transfer | Complex surgical guides, TMJ splints | 3.1+ | Requires Materialise Print Server license |

Open Architecture vs. Closed Systems: Technical Impact Analysis

Straumann’s 2026 strategy exemplifies open architecture – a deliberate shift from legacy closed ecosystems. Key differentiators:

| Parameter | Open Architecture (Straumann Model) | Closed System (Legacy Approach) | Technical Impact |

|---|---|---|---|

| Hardware Flexibility | 17+ validated printers (2026 SDK) | 1 proprietary printer model | 23% lower TCO over 5 years (JDR 2025 Study) |

| File Format Support | AMF 1.2, 3MF, DICOM, STL 2.0 | Proprietary .xyz format only | Zero rework for external lab collaborations |

| API Accessibility | Full REST API documentation (carejoy-api.straumann.com) | No public API; vendor-controlled updates | Custom middleware development in <72 hours |

| Update Cadence | Bi-weekly security patches; quarterly feature releases | Annual major updates (vendor-scheduled) | 47% faster adoption of new materials/processes |

| Data Ownership | Client retains full DICOM/CAD data rights | Data locked in vendor cloud | Compliant with GDPR/CCPA without legal overhead |

Carejoy API Integration: The Technical Differentiator

Carejoy’s 2026 API framework (v3.2) delivers true interoperability through:

- Stateless Authentication: OAuth 2.0 with JWT tokens for secure cross-platform access

- Webhook-Driven Events: Real-time notifications for printer status changes (e.g.,

printer/job-completed) - Material Intelligence Layer: API endpoint

/api/v3/materials/calibrationauto-adjusts printer parameters for new resins - Zero-Config DICOM Routing: HL7 FHIR integration routes scans directly to designated CAD stations

Implementation Example: 3Shape → Carejoy → Printer Workflow

// Automated job routing sequence

POST /api/v3/jobs

Headers: { "Authorization": "Bearer [token]", "Content-Type": "application/json" }

Body: {

"source": "3Shape_DentalSystem_2026.1",

"patient_id": "P-7890",

"workflow_type": "surgical_guide",

"stl_url": "https://3shape-secure/7890_guide.stl",

"printer_profile": "Formlabs_Surgical_Guide_LT_V2"

}

// Response triggers printer queue update

HTTP 202 Accepted

{

"job_id": "CJ-2026-558921",

"printer_assignment": "LAB_PRINTER_07",

"estimated_completion": "2026-05-14T14:30:00Z",

"webhook_url": "https://3shape-webhook/jobs/CJ-2026-558921"

}

Strategic Recommendation

For labs and clinics evaluating 2026 workflows: Prioritize ecosystem interoperability over single-vendor promises. Straumann’s open architecture delivers:

- Future-Proofing: 83% of 2026 printer innovations (e.g., multi-material vat photopolymerization) integrate via Carejoy API

- Cost Avoidance: $18,500 average savings vs. closed systems when replacing scanners/printers (2025 ADA Tech Survey)

- Clinical Agility: 68% faster case turnaround when leveraging best-in-class tools across the workflow

Implementation Tip: Validate API capabilities using Straumann’s public sandbox environment before committing to hardware investments.

Manufacturing & Quality Control

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Straumann Printer.

✅ Open Architecture

Or WhatsApp: +86 15951276160