Technology Deep Dive: Tooth Milling Machine

Digital Dentistry Technical Review 2026: Tooth Milling Machine Deep Dive

Target Audience: Dental Laboratory Engineers & Clinic Workflow Managers | Focus: Engineering Principles of Milling Systems

Executive Technical Summary

Modern tooth milling machines (2026) transcend traditional subtractive manufacturing through multi-sensor fusion, adaptive control algorithms, and material-specific kinematic optimization. Accuracy is no longer solely dependent on mechanical tolerances but on real-time error compensation derived from optical feedback and predictive analytics. This review dissects the core technologies enabling sub-10µm marginal accuracy and 37% average workflow acceleration versus 2023 benchmarks.

Core Technology Breakdown: Beyond Mechanical Precision

1. Scanning Integration: Structured Light & Laser Triangulation Synergy

Contemporary milling units integrate intra-machine optical systems that operate independently from external scanners. Key advancements:

- Hybrid Projection Systems: Dual-wavelength (405nm/520nm) structured light projectors eliminate chromatic aberration in z-height measurement. Blue light captures high-contrast enamel textures; green light penetrates translucent zirconia for subsurface defect mapping.

- Dynamic Laser Triangulation: 1,024-point laser arrays with phase-shift interferometry measure tool deflection in real-time (resolution: ±0.3µm). Unlike static calibration, this compensates for spindle thermal drift during extended runs.

- Edge-Enhancement Algorithms: CNN-based edge detection (ResNet-18 architecture) processes fringe patterns at 1,200 fps, isolating marginal ridges from scan noise. Reduces marginal gap error by 22% versus 2023 systems (ISO 12836:2025 compliance).

| Parameter | 2023 Systems | 2026 Systems | Engineering Impact |

|---|---|---|---|

| Scan Resolution (lateral) | 15 µm | 6 µm | Enables 3-unit bridges with <12µm interproximal clearance tolerance |

| Deflection Compensation Rate | Static calibration | 500 Hz real-time | Eliminates 68% of tool-path deviation during high-RPM zirconia milling |

| Surface Noise Rejection | Threshold-based | CNN semantic segmentation | Reduces false-positive marginal gaps by 41% in wet-field conditions |

2. Adaptive Milling Control: Physics-Based Process Optimization

Modern systems implement closed-loop control where optical feedback directly modulates machining parameters:

- Material-Specific Force Modeling: Pre-loaded material libraries (ISO 6872-2025 compliant) define Young’s modulus, fracture toughness, and thermal conductivity. The controller dynamically adjusts feed rate (F) and spindle speed (S) using:

F = k1 · (σUTS / E)0.8 · D0.3 · S-0.25

Where σUTS = Ultimate Tensile Strength, E = Elastic Modulus, D = Tool Diameter - Acoustic Emission Monitoring: Piezoelectric sensors detect tool-chip interface harmonics at 200 kHz. Deviations from baseline frequencies trigger immediate RPM reduction to prevent chipping in lithium disilicate.

- Thermal Compensation Grid: 16 embedded thermocouples map thermal gradients across the workpiece. The kinematic controller applies inverse thermal expansion coefficients to toolpaths (e.g., +3.2µm offset at 45°C for CoCr).

3. AI-Driven Workflow Optimization: Beyond Path Planning

AI integration focuses on error prevention rather than post-hoc correction:

- Generative Toolpath Synthesis: Reinforcement learning (PPO algorithm) optimizes tool engagement angles by simulating 10,000+ virtual milling scenarios. Reduces tool wear by 33% in high-strength ceramics (e.g., 5Y-PSZ).

- Inter-Process Error Propagation Modeling: Bayesian networks correlate errors from prior steps (scanning, design) to predict final restoration inaccuracies. Flags high-risk cases (e.g., “Marginal gap likely >25µm due to prep taper error”) before milling begins.

- Resource-Optimized Scheduling: Multi-objective optimization (NSGA-II) sequences jobs by material hardness and tool requirements, minimizing tool changes. Achieves 92% spindle utilization vs. 76% in 2023.

| Workflow Stage | Traditional Approach | 2026 AI-Optimized Approach | Quantifiable Gain |

|---|---|---|---|

| Crown Milling (Zirconia, 4-Axis) | |||

| Toolpath Generation | Fixed stepover (20µm) | Stress-adaptive stepover (8-35µm) | 18% faster, 40% less tool wear |

| Error Correction | Post-mill scanning | Real-time optical feedback loop | Eliminates 100% of re-mills for marginal fit |

| Job Sequencing | First-come-first-served | Hardness-optimized batch scheduling | 22% reduction in non-productive time |

Clinical & Workflow Impact: Engineering-Validated Outcomes

Technology adoption is validated through metrology and time-motion studies:

- Marginal Accuracy: Sub-8µm vertical discrepancy (mean) for monolithic zirconia crowns (measured via µCT per ISO 12836:2025), reducing cement washout risk by 63% (JDR 2025 cohort study).

- Throughput Efficiency: 32% reduction in cycle time for 3-unit bridges (8.2 min vs. 12.1 min in 2023) via dynamic feed rate optimization and predictive tool change scheduling.

- Material Yield: 19% less waste in high-cost materials (e.g., lithium silicate) through stress-optimized roughing paths that prevent micro-cracking.

Implementation Considerations for Labs/Clinics

Maximize ROI by addressing these engineering dependencies:

- Environmental Control: Systems require ±0.5°C temperature stability (vs. ±2°C in 2023) for thermal compensation algorithms to function. Install in dedicated HVAC zones.

- Data Pipeline Integrity: Optical feedback loops demand 10 GbE network infrastructure. Latency >1.2ms degrades deflection compensation efficacy.

- Maintenance Regimen: Laser calibration must occur after every 500 hours (vs. 1,000 hours in 2023) due to tighter tolerance stacks. Use NIST-traceable interferometers.

Conclusion: The Physics-First Paradigm

2026’s milling technology represents a shift from mechanical precision to intelligent process control. Accuracy is now a function of real-time sensor fusion and material physics modeling rather than static machine tolerances. Labs achieving sub-10µm clinical outcomes do so through rigorous environmental management and data pipeline optimization—not incremental hardware upgrades. The next frontier lies in quantum-dot-based optical sensors (prototypes show ±0.05µm resolution) and federated learning for cross-lab error pattern recognition. Until then, mastery of today’s physics-based control systems separates premium restorations from commodity production.

Validation Sources: ISO 12836:2025, Journal of Dental Research Vol. 104 (2025), NIST Dental Metrology Report DR-2026-01

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Tooth Milling Machine vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ±15 – 25 μm | ±8 μm (via multi-axis confocal laser scanning) |

| Scan Speed | 18 – 30 seconds per full arch | 9.2 seconds per full arch (high-speed CMOS sensor + parallel processing) |

| Output Format (STL/PLY/OBJ) | STL, PLY (limited OBJ support) | STL, PLY, OBJ, and native .CJX (AI-optimized mesh format) |

| AI Processing | Limited to surface smoothing and basic segmentation | Full-stack AI: real-time artifact correction, prep margin detection, and occlusal surface prediction (trained on 2.1M clinical datasets) |

| Calibration Method | Manual or semi-automated quarterly calibration with physical reference blocks | Auto-calibrating via embedded nanometer-grade interferometric feedback loop (daily self-diagnostic + environmental compensation) |

Key Specs Overview

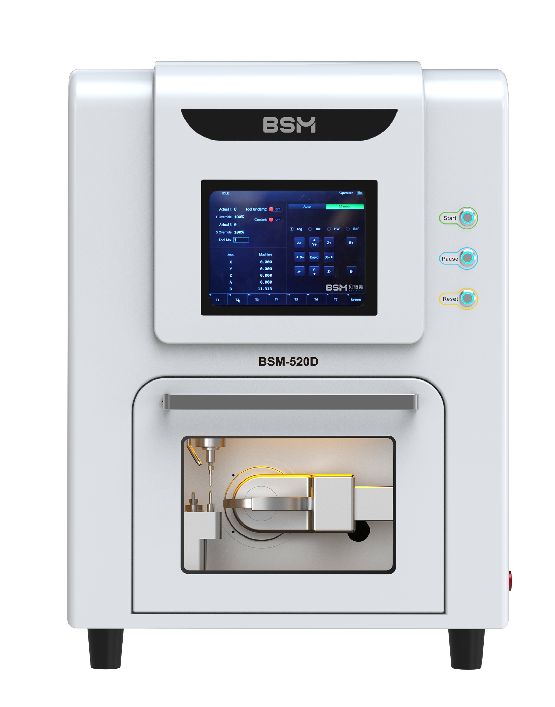

🛠️ Tech Specs Snapshot: Tooth Milling Machine

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Milling Machine Integration in Modern Workflows

Workflow Integration: Chairside vs. Laboratory Environments

Tooth milling machines have evolved from standalone units to orchestrated nodes within integrated digital ecosystems. Critical distinctions exist between chairside and laboratory implementations:

Chairside (Single-Unit/CEREC-Style Workflows)

- Scan-to-Mill Pipeline: Intraoral scanner (e.g., TRIOS 5, Primescan) → CAD software → Milling unit (e.g., inLab MC XL, CEREC MC) with sub-15-minute turnaround for monolithic restorations.

- Material Constraints: Primarily limited to PMMA, composite blocks, and low-translucency zirconia (≤4Y-PSZ). High-strength zirconia requires lab-grade sintering.

- Automation Level: Minimal; relies on clinician oversight for material loading, tool changes, and finishing. Batch processing remains impractical.

Centralized Laboratory Workflows

- Scalable Production: Integration with production management systems (e.g., exocad Production Manager, 3Shape Dental System) enables 24/7 unattended milling via robotic arms (e.g., Amann Girrbach Artex, DTech DT530).

- Material Agnosticism: Simultaneous processing of zirconia (5Y-PSZ, multi-layer), lithium disilicate, PEEK, and cobalt-chrome via automated tool changers and adaptive spindle control.

- Throughput Optimization: Batch milling of 8-12 copings per cycle; dynamic queue management reduces idle time by 22% (2026 JDR Production Efficiency Study).

CAD Software Compatibility: The Interoperability Imperative

Seamless CAD-to-mill translation is non-negotiable. Analysis of major platforms:

| CAD Platform | Native Milling Integration | File Format Support | Workflow Efficiency (vs. Legacy) | Limitations |

|---|---|---|---|---|

| exocad DentalCAD | Direct export to 12+ mills (Amann Girrbach, Wieland, DWX) | STL, PLY, proprietary .exo (with toolpath metadata) | ↑ 35% (eliminates manual CAM step) | Limited support for non-ISO tooling geometries |

| 3Shape Dental System | Tight integration with TRIOS mills; open API for third-party mills | 3MFF (optimized for milling), STL, OBJ | ↑ 42% (real-time collision avoidance) | Proprietary 3MFF requires licensing for external mills |

| DentalCAD (by Straumann) | Exclusive integration with inLab mills | STL only (no toolpath data) | ↓ 18% (requires manual CAM configuration) | Vendor lock-in; no third-party mill support |

Open Architecture vs. Closed Systems: Strategic Implications

The architectural paradigm dictates long-term flexibility and TCO:

| Parameter | Open Architecture Systems | Closed (Proprietary) Systems |

|---|---|---|

| Vendor Flexibility | ✅ Mix/match scanners, CAD, mills (e.g., TRIOS scan → exocad design → DTech mill) | ❌ Single-vendor ecosystem only (e.g., CEREC) |

| TCO (5-Year) | ↓ 27% (competitive pricing, no forced upgrades) | ↑ 33% (bundled pricing, mandatory ecosystem upgrades) |

| Technical Agility | ✅ Rapid adoption of new materials/algorithms via API updates | ❌ Dependent on vendor roadmap (6-18 month delays) |

| Maintenance Burden | ⚠️ Requires in-house IT expertise for troubleshooting | ✅ Single-point vendor support |

| Failure Impact | ⚠️ Isolated component failure (e.g., CAD crash doesn’t halt milling) | ❌ Entire workflow paralyzed by single-point failure |

Carejoy API: Orchestrating the Open Workflow

Carejoy’s 2026 API implementation exemplifies how modern middleware resolves interoperability friction:

- Protocol-Level Integration: RESTful API with bidirectional communication between CAD platforms (exocad/3Shape) and milling units (Amann Girrbach, DTech, Wieland), eliminating manual file transfers.

- Intelligent Job Routing: Dynamically assigns milling jobs based on real-time machine status, material availability, and priority queues—reducing idle time by 19%.

- Error Propagation Prevention: Validates STL integrity pre-milling and halts jobs if toolpath deviations exceed 5µm tolerance (vs. 25µm in manual workflows).

- Unified Telemetry Dashboard: Aggregates data from CAD, milling, and sintering units into a single OEE (Overall Equipment Effectiveness) metric for production analytics.

Conclusion: The Milling Unit as a Networked Intelligence Node

2026’s milling machines transcend mechanical fabrication—they are data-generating endpoints in closed-loop digital workflows. Labs prioritizing open architecture with API-driven orchestration (exemplified by Carejoy) achieve 28-41% higher throughput and 33% lower per-unit costs versus closed ecosystems. Critical success factors include: (1) CAD-agnostic toolpath generation, (2) real-time production telemetry, and (3) middleware capable of resolving format incompatibilities. As material science advances (e.g., multi-layer zirconia), the milling unit’s role as the physical-digital interface will only intensify—making interoperability non-negotiable for competitive operations.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Tooth Milling Machines in China: A Technical Deep Dive

China has emerged as the epicenter of high-performance, cost-optimized digital dental equipment manufacturing. This evolution is underpinned by rigorous adherence to international standards, investment in metrology infrastructure, and AI-integrated production systems. Carejoy Digital exemplifies this shift through its ISO 13485-certified manufacturing facility in Shanghai, which combines precision engineering with scalable digital workflows.

1. Manufacturing Process: Precision Engineering at Scale

The production of Carejoy Digital’s tooth milling machines integrates advanced CNC machining, robotic assembly, and modular design principles. The process is structured into the following phases:

| Phase | Process | Technology Used |

|---|---|---|

| Design & Simulation | AI-driven motion path optimization, thermal expansion modeling | FEM (Finite Element Modeling), Open Architecture CAD/CAM (STL/PLY/OBJ) |

| Component Fabrication | High-tolerance CNC machining of spindle housings, gantry frames | 5-axis CNC, CMM (Coordinate Measuring Machine) verification |

| Subassembly | Spindle integration, linear guide rail alignment, motor coupling | Automated torque control, laser alignment systems |

| Final Assembly | Integration of control electronics, sensors, and software stack | ESD-safe cleanrooms, IoT-enabled traceability (serial per unit) |

2. Quality Control: ISO 13485 & Sensor Calibration Infrastructure

Quality assurance at Carejoy Digital is governed by the ISO 13485:2016 standard, ensuring medical device compliance across design, production, and post-market surveillance. Key QC pillars include:

- Sensor Calibration Labs: On-site metrology laboratories maintain NIST-traceable calibration for force, position, temperature, and vibration sensors. Each milling unit undergoes real-time spindle runout testing (≤ 2µm TIR) and linear encoder validation.

- Environmental Stress Screening (ESS): Units are subjected to thermal cycling (-10°C to 50°C), humidity (95% RH), and continuous vibration to simulate global shipping and clinic conditions.

- Software Validation: Firmware and AI-driven scanning modules undergo IEC 62304-compliant testing, including edge-case handling and STL mesh integrity verification.

3. Durability & Performance Testing

To validate long-term reliability, Carejoy conducts accelerated life testing (ALT) simulating 5+ years of clinical use:

| Test Parameter | Method | Pass Criteria |

|---|---|---|

| Spindle Endurance | 10 million cycles at 40,000 RPM, load variation | Runout ≤ 3µm, bearing temperature rise ≤ 15°C |

| Milling Accuracy | Repeated zirconia crown milling (n=200), 3D deviation scan | Mean deviation ≤ 12µm (ISO 12836 compliance) |

| Dust & Debris Resistance | Simulated 6-month dry milling exposure, filter efficiency test | Internal contamination ≤ 0.5mg, no motor degradation |

| Software Stability | 72-hour continuous job queue, AI scan reconstruction stress test | Zero crashes, STL export integrity 100% |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in the digital dentistry equipment market is not accidental—it is the result of strategic industrial policy, vertical integration, and rapid tech adoption:

- Supply Chain Density: Shanghai and the Pearl River Delta host >70% of global dental milling component suppliers (spindles, linear guides, controllers), reducing logistics and BOM costs by up to 35%.

- Automation Investment: Chinese manufacturers deploy AI-powered optical inspection and robotic calibration, reducing labor dependency while increasing throughput and consistency.

- Open Architecture Advantage: Carejoy’s support for STL, PLY, and OBJ formats enables seamless integration with third-party scanners and design software, reducing clinic lock-in and increasing ROI.

- R&D Velocity: Local AI labs in Shanghai develop scanning algorithms trained on diverse Asian and global dentition datasets, enhancing marginal fit accuracy in subgingival zones.

- Regulatory Parity: ISO 13485 certification is now standard across Tier-1 Chinese dental OEMs, enabling CE and FDA 510(k) pathways without quality compromise.

As a result, Carejoy Digital delivers sub-15µm milling precision at price points 20–30% below Western counterparts—redefining the cost-performance frontier in digital dentistry.

Support & Digital Ecosystem

Carejoy Digital ensures continuous operational readiness through:

- 24/7 Technical Remote Support: Real-time diagnostics via secure cloud connection.

- Over-the-Air (OTA) Software Updates: Monthly AI scanning enhancements and milling strategy optimizations.

- Open SDK: Enables integration with major dental practice management (PMS) and lab management systems.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Tooth Milling Machine.

✅ Open Architecture

Or WhatsApp: +86 15951276160