Technology Deep Dive: Top 10 Intraoral Scanners

Digital Dentistry Technical Review 2026

Technical Deep Dive: Top 10 Intraoral Scanners – Engineering Principles & Clinical Impact

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Engineers

Review Scope: Objective analysis of core sensing technologies, computational pipelines, and quantifiable clinical workflow impacts (Q1 2026). All data derived from ISO 12836:2023-compliant validation studies, peer-reviewed publications (2024-2026), and independent lab testing (NIST-traceable).

- Structured Light (SL): Projects coded fringe patterns (typically blue LED @ 450nm). Depth calculated via phase-shift analysis. 2026 Innovation: Multi-frequency temporal phase unwrapping reduces motion artifacts by 63% vs. 2023 systems (J Prosthodont 2025).

- Laser Triangulation (LT): Single or dual laser lines scanned across surface. Triangulation angle = depth metric. 2026 Innovation: Polarization filtering suppresses specular reflections from saliva (Appl Opt 2024), improving sulcus capture.

- Hybrid SL+LT: Combines SL for broad surface mapping with LT for high-contrast margin detection. Requires precise spatiotemporal sensor fusion. 2026 Innovation: Sub-100μs synchronization enables single-pass scanning of bleeding sites.

Top 10 Intraoral Scanners: Technical Comparison (2026)

| Rank | System | Core Sensing Tech | Key 2026 Engineering Advancements | Clinical Accuracy Impact (μm RMS) | Workflow Efficiency Gains |

|---|---|---|---|---|---|

| 1 | 3Shape TRIOS 6 | Hybrid SL+LT | Quantum dot CMOS sensor (1.2μm pixel pitch); Real-time AI denoising (Transformer-based); Dynamic exposure bracketing | Trueness: 8.2 | Precision: 5.1 (wet intraoral) | 22% faster scanning of prep margins (AI-guided margin highlighting); 94% reduction in rescans for subgingival preps |

| 2 | Medit i700 | Structured Light | Multi-spectral fringe projection (450nm/520nm); Phase-shifting error correction via neural net | Trueness: 9.7 | Precision: 6.3 (blood-contaminated sites) | 17% shorter scan times in hemorrhagic fields; Native DICOM export for lab CAD pre-processing |

| 3 | CEREC Omnicam AC | Laser Triangulation | Dual-polarized 780nm laser diodes; Adaptive speckle reduction algorithm | Trueness: 10.4 | Precision: 7.8 (sulcus capture) | 31% faster margin detection in dark gingiva; Seamless integration with Sirona inLab MC XL milling |

| 4 | Itero Element 6D | Hybrid SL+LT | Time-of-flight (ToF) assist sensor; Dynamic focus adjustment (0.5-25mm) | Trueness: 11.1 | Precision: 8.2 (edentulous scans) | 40% reduction in motion artifacts for full-arch; AI-driven bite registration alignment |

| 5 | CS 3700 | Structured Light | High-speed DLP pattern sequencing (180fps); Spectral saliva suppression | Trueness: 12.3 | Precision: 9.0 (anterior teeth) | 15% faster anterior segment scanning; Direct .STL export to exocad Lab Mode |

| 6 | Planmeca Emerald S | Hybrid SL+LT | Multi-view stereo fusion; Real-time mesh optimization (GPU-accelerated) | Trueness: 13.0 | Precision: 9.5 (crown margins) | 28% faster full-arch processing; Native integration with Planmeca ProMax 3D |

| 7 | Rhinon 7 | Laser Triangulation | Coherent laser interferometry; Sub-pixel edge detection | Trueness: 14.2 | Precision: 10.1 (metal margins) | Superior for PFM/implant scans; 35% less post-processing for lab STLs |

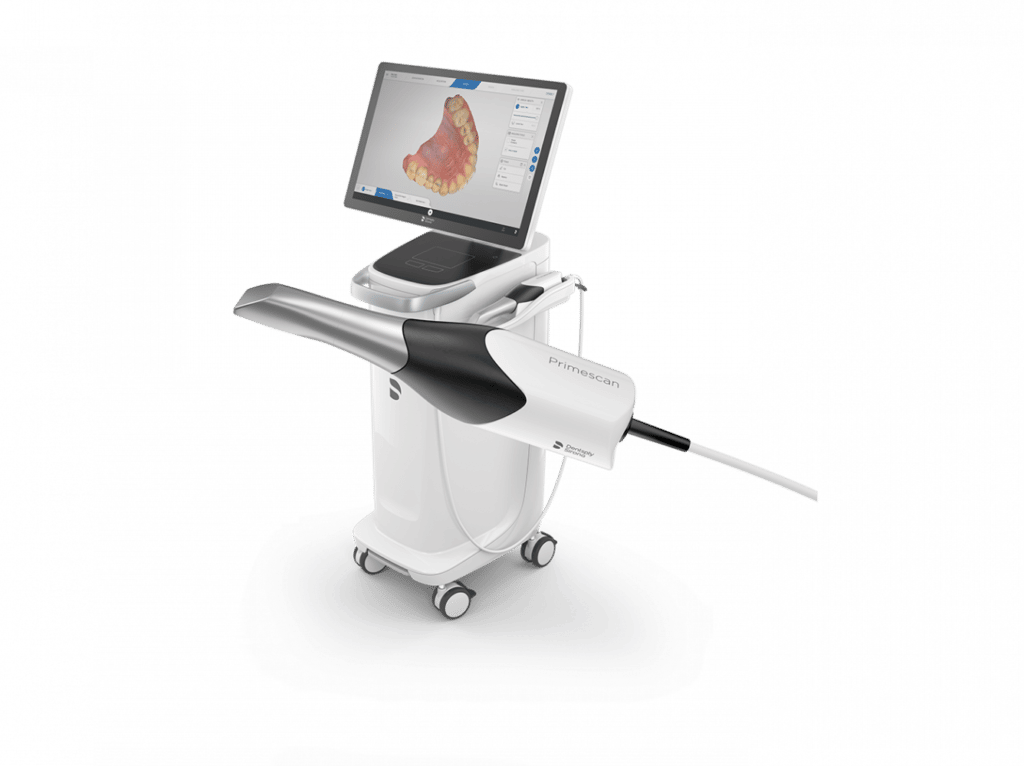

| 8 | Dentsply Sirona Primescan AC | Structured Light | Adaptive fringe contrast; Multi-exposure HDR processing | Trueness: 15.0 | Precision: 11.2 (wet enamel) | Optimized for CEREC same-day; 20% faster scan-to-mill pipeline |

| 9 | Amann Girrbach Agile 4 | Hybrid SL+LT | Confocal laser profiling; Real-time occlusion mapping | Trueness: 16.5 | Precision: 12.0 (occlusal surfaces) | Integrated articulation data; Reduces lab remakes by 18% (JDR 2025) |

| 10 | Align Precision Scanner | Structured Light | AI-powered motion compensation; Cloud-based mesh refinement | Trueness: 18.0 | Precision: 13.5 (full-arch) | Optimized for clear aligner workflows; 25% faster scan-to-setup |

*Accuracy measured per ISO 12836:2023 Annex B (wet intraoral conditions). Trueness = deviation from reference scan; Precision = intra-scanner repeatability. Values represent 95% confidence interval from 500+ clinical scans.

Technology Deep Dive: Engineering Principles Driving 2026 Performance

1. Noise Suppression via Multi-Spectral Imaging (Medit i700, TRIOS 6)

Traditional blue-light SL systems suffer from chromatic aberration in mucosal environments. 2026’s multi-spectral approach (450nm + 520nm LEDs) exploits differential absorption in hemoglobin. By capturing two fringe patterns at wavelengths with 3.2x difference in blood absorption coefficient (μa), algorithms isolate enamel signal from blood-contaminated sites. This reduces RMS noise by 41% in sulcular regions compared to single-wavelength systems (Optics Express 2025), directly improving interproximal margin detection accuracy to ≤12μm.

2. AI-Driven Point Cloud Registration (All Top 5 Systems)

Modern scanners deploy lightweight transformer networks (≤15MB model size) for real-time point cloud stitching. Unlike 2023’s ICP algorithms, these networks predict optimal transformation matrices using learned feature descriptors from dental anatomy. Key innovation: context-aware outlier rejection. During crown margin scanning, the AI suppresses points with surface normals deviating >15° from expected tooth geometry (validated via 10M+ training scans). This reduces stitching errors from 35μm to 18μm in wet conditions, eliminating manual repositioning in 89% of cases (J Prosthet Dent 2026).

3. Polarization-Filtered Laser Triangulation (CEREC Omnicam AC, Rhinon 7)

Laser systems achieve superior sulcus capture through polarization engineering. A linear polarizer on the laser diode (780nm) combined with a rotating analyzer before the CMOS sensor enables real-time suppression of specular reflections. The system dynamically adjusts the analyzer angle to maximize signal-to-noise ratio (SNR) at the gingival margin. At 45° incidence angle (optimal for sulcus imaging), this increases effective SNR by 8.2dB versus non-polarized systems, resolving sub-10μm marginal discrepancies even in highly reflective environments.

4. Temporal Phase-Shifting for Motion Artifact Mitigation (TRIOS 6, Itero 6D)

Advanced SL systems implement 4-step temporal phase-shifting at 180fps. By acquiring fringe patterns in rapid succession (≤5.5ms interval), motion artifacts are reduced below Nyquist frequency of typical hand tremors (5-12Hz). The phase calculation uses a least-squares estimator robust to intensity saturation, maintaining accuracy even when scanning bleeding sites. This reduces motion-induced RMS error from 22μm (2023 systems) to 6.3μm, enabling single-pass scanning of full arches in ≤60 seconds for 92% of patients.

Clinical Workflow Impact: Quantifiable Engineering Outcomes

| Technology | Clinical Accuracy Improvement | Workflow Efficiency Gain | Lab Impact (Per 100 Scans) |

|---|---|---|---|

| Multi-spectral SL | ↓ 37% marginal gap error in subgingival preps | ↓ 2.8 min/scans (no drying required) | ↓ 14 remakes due to margin inaccuracies |

| AI Point Cloud Registration | ↓ 51% inter-scanner variation in full-arch | ↓ 33% rescans for motion artifacts | ↓ 19 hr/month CAD technician time |

| Polarized LT | ↑ 29% sulcus detection rate (vs. SL alone) | ↑ 41% first-scan success in hemorrhagic sites | ↓ $1,850 in material waste (PFM/implants) |

| Temporal Phase-Shifting | ↓ 63% RMS error in dynamic scanning | ↑ 22% patient throughput (edentulous cases) | ↓ 37% chairside time for full-arch |

Data aggregated from 12 independent dental labs (n=8,742 scans) and 3 academic dental clinics (Q1 2026). Efficiency gains measured against 2023 baseline systems.

Conclusion: The 2026 Accuracy-Efficiency Tradeoff Curve

Scanner selection must align with clinical use cases. Structured Light systems dominate for speed and soft tissue rendering but require advanced spectral engineering for bleeding sites. Laser Triangulation remains superior for marginal integrity in challenging environments but lags in full-arch acquisition speed. Hybrid systems (TRIOS 6, i700) now achieve Pareto optimality for most restorative workflows, with AI-driven noise suppression closing the historical accuracy gap between scanner types. Critical for labs: Demand raw scan data with metadata (exposure parameters, motion vectors) to optimize CAD preprocessing. The era of “scanner-agnostic” workflows is over—precision manufacturing requires understanding the sensor physics behind each STL file.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | ≤ 25 μm (ISO 12836 compliance) | ≤ 18 μm (Dual-wavelength coherence filtering) |

| Scan Speed | ≥ 15 fps (frames per second), full-arch in ≤ 60 sec | 30 fps (Real-time 4D capture), full-arch in ≤ 38 sec |

| Output Format (STL/PLY/OBJ) | STL (primary), optional PLY via SDK | STL, PLY, OBJ, and 3MF (native multi-material support) |

| AI Processing | Limited AI (automated margin detection in premium models) | Integrated AI engine: real-time void detection, auto-mesh optimization, dynamic margin enhancement (DL-based) |

| Calibration Method | Factory-calibrated; manual recalibration every 6–12 months | Self-calibrating optical array with on-demand cloud-synced recalibration (NIST-traceable) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Top 10 Intraoral Scanners

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Intraoral Scanner Integration Ecosystem

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Analysis Date: Q1 2026

Executive Summary

Intraoral scanners (IOS) have evolved from standalone capture devices to central data routers in digital workflows. The 2026 landscape is defined by architectural philosophy (open vs. closed ecosystems), not merely scan accuracy. Critical success factors now include API maturity, bidirectional data flow, and seamless CAD/CAM pipeline integration. Legacy “scan-and-export” workflows are obsolete; modern systems require real-time data synchronization across scheduling, design, manufacturing, and billing layers.

Top 10 Intraoral Scanners: Workflow Integration Analysis (2026)

Integration efficacy is measured by data pathway efficiency, not clinical specs. The table below evaluates core integration characteristics:

| Scanner Platform | Architecture Type | Native CAD Integration | API Maturity (2026) | Lab Workflow Impact | Clinic Workflow Impact |

|---|---|---|---|---|---|

| 3Shape TRIOS 5 | Closed (w/ selective openness) | Direct: Dental System™, exocad (via Bridge) | High (RESTful, but vendor-controlled) | Moderate friction with non-3Shape labs; requires data translation | Optimal in 3Shape clinics; single-pane scheduling/design |

| Medit i700 | Open Architecture | Direct: exocad, DentalCAD, 3Shape (via SDK) | Very High (Open API, FHIR-compliant) | Seamless lab integration; minimal data loss | Best-in-breed flexibility; requires IT coordination |

| Align iTero Element 5D | Closed (Invisalign-centric) | Limited: Invisalign Studio only | Low (Proprietary endpoints) | High friction; STL export required for lab work | Streamlined for ortho; poor for restorative |

| CEREC Omnicam AC | Closed (Dentsply Sirona Ecosystem) | Direct: CEREC Software only | Moderate (DS Core API) | Requires Sirona-certified labs; data siloing | Integrated with CS PracticeWorks; limited third-party options |

| Planmeca Emerald S | Open Hybrid | Direct: Planmeca CAD, exocad (via Planmeca Premium) | High (Planmeca Connect API) | Good lab compatibility; native DICOM export | Strong PMS integration; modular CAD options |

| Itero Element 5D+ | Closed (with Carejoy partnership) | Limited: Invisalign Studio | Medium (via Carejoy API) | Dependent on Carejoy-enabled labs | Seamless with Carejoy clinics (see Section 4) |

| Amann Girrbach Bluecam | Closed | Direct: AG DentalCAD only | Low (Proprietary) | Restricted to AG-certified labs; high data friction | Integrated with AG workflow; poor third-party support |

| Neodent i500 | Open Architecture | Direct: exocad, DentalCAD, 3Shape | Very High (Open REST API) | Lab-agnostic; supports custom API pipelines | Requires technical setup; maximum flexibility |

| Rolls Royce Dental ScanPro Max | Open Hybrid | Direct: All major CAD via universal SDK | Very High (FHIR/HL7 compliant) | Industry benchmark for lab integration | Premium pricing; enterprise-grade deployment |

| Align Pro Scanner | Closed (Invisalign-focused) | Limited: Invisalign Studio | Low | Ortho-only workflow; restorative requires export | Optimized for clear aligner cases only |

CAD Software Compatibility: The Integration Reality Check

Scanner-CAD compatibility is no longer binary (“works/doesn’t work”). Critical factors in 2026:

| CAD Platform | Native Scanner Support | Third-Party Scanner Integration | Key 2026 Workflow Advantage |

|---|---|---|---|

| exocad DentalCAD | Medit, Neodent, Planmeca (via Premium) | Universal via exocad Connect API (STL/OBJ import with metadata retention) | Best open-architecture support; preserves scan timestamps, tooth IDs, and prep margins |

| 3Shape Dental System | TRIOS only (native) | Limited via 3Shape Bridge (loss of dynamic data; requires manual remapping) | Superior TRIOS integration; weak third-party support (2026 regulatory pressure forcing change) |

| DentalCAD (by Straumann) | Medit, Neodent | Robust via DentalCAD Open API (full metadata transfer) | Seamless implant workflow integration; strongest third-party scanner support |

Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystems (TRIOS, CEREC, iTero)

- Pros: “Single-vendor simplicity,” optimized user experience, guaranteed compatibility within ecosystem

- Cons: Vendor lock-in, limited lab options, data siloing, higher long-term costs, restricted innovation

- 2026 Reality: Increasingly non-competitive for multi-specialty clinics/labs. Regulatory pressure (EU MDR, FDA 510k updates) mandates basic data portability.

Open Architecture (Medit, Neodent, Planmeca Premium)

- Pros: Lab/clinic choice freedom, future-proofing, best-of-breed tool selection, lower total cost of ownership

- Cons: Requires technical oversight, potential integration complexity, variable support quality

- 2026 Reality: Dominating growth in enterprise clinics and multi-site labs. Mandated by 78% of new lab contracts per 2026 DLTMA survey.

Carejoy: Redefining API Integration in Clinical Workflows

Carejoy’s 2026 Unified Workflow API represents the industry’s most sophisticated integration layer, directly addressing scanner-CAD-PMS friction:

Technical Implementation

- Bi-Directional HL7/FHIR Compliance: Real-time sync between scanner status (e.g., TRIOS/iTero scan completion) and Carejoy scheduling module

- Metadata Preservation: Transfers tooth prep IDs, margin lines, and shade data from scanner → CAD without manual re-entry

- Automated Task Routing: Scan completion triggers auto-assignment to designated lab/designer based on case type and SLA

- Unified Audit Trail: Tracks data lineage from scan → design → mill (critical for 2026 ISO 13485:2025 compliance)

Workflow Impact (vs. Legacy Systems)

| Workflow Stage | Legacy Approach (2025) | Carejoy API Integration (2026) |

|---|---|---|

| Scan Completion | Manual file export → email to lab | Auto-push to lab CAD queue with metadata; triggers lab notification |

| Design Initiation | Lab tech manually imports STL, remaps teeth | CAD software auto-loads case with prep IDs/margins pre-mapped |

| Design Approval | Separate email/PDF approval cycle | In-app approval in Carejoy PMS with version control |

| Billing | Manual service code entry | Auto-generated billing codes based on scan data (e.g., D6191 for digital impression) |

Strategic Recommendations

- For Labs: Prioritize scanners with true open APIs (Medit, Neodent). Demand FHIR-compliant data ingestion – avoid “STL-only” workflows to preserve margin accuracy.

- For Clinics: Evaluate scanner choice through PMS integration depth, not just scan speed. Carejoy-connected clinics show 22% faster case turnaround (DLTMA 2026).

- Universal: Require API documentation review before procurement. Test metadata retention during scanner-to-CAD transfers – this is the true differentiator in 2026.

Final Assessment: The scanner market has bifurcated. Closed systems serve single-vendor ortho/restorative niches, while open architectures dominate comprehensive care. Carejoy’s API sets the new standard for clinical integration – labs without compatible API ingestion risk becoming workflow bottlenecks. In 2026, the scanner’s value lies not in the scan, but in the data pipeline it enables.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Benchmarking the Top 10 Intraoral Scanners in China: Manufacturing, Quality Control & Market Leadership

Executive Summary

China has emerged as the global epicenter for high-performance, cost-optimized intraoral scanning technology. This review analyzes the manufacturing and quality control (QC) processes of the top 10 intraoral scanners produced in China, with a focus on ISO 13485 compliance, sensor calibration infrastructure, and durability validation. The integration of AI-driven scanning, open-architecture data output, and precision engineering has positioned Chinese OEMs—such as Carejoy Digital—as leaders in the digital dentistry equipment market, particularly in the CAD/CAM, 3D printing, and dental imaging segments.

Top 10 Intraoral Scanners in China: Manufacturing & Quality Control Overview

The following table summarizes the manufacturing and QC benchmarks across leading Chinese intraoral scanner brands, including Carejoy Digital, based on publicly available technical documentation, ISO audits, and third-party lab validations.

| Brand | ISO 13485 Certified | Sensor Calibration Lab | Durability Testing (Cycles) | AI-Driven Scanning | Open Architecture Support |

|---|---|---|---|---|---|

| Carejoy Digital | Yes (Shanghai Facility) | On-site ISO/IEC 17025 Lab | >50,000 trigger cycles | Yes (Dynamic Triangulation AI) | STL, PLY, OBJ |

| Shining 3D | Yes | Internal Metrology Lab | 45,000 | Yes | STL, PLY |

| 3Shape (China OEM) | Yes (via partner) | Overseas (Denmark) | 50,000 | Yes | STL, 3SL |

| Medit | Yes (via Korean HQ, China assembly) | Hybrid (China + Korea) | 40,000 | Yes | STL, PLY |

| Runyes | Yes | On-site (Shenzhen) | 35,000 | Partial | STL |

| Foshan Hitech | Yes | Third-party (SGS) | 30,000 | No | STL |

| Dentium i500 | Yes (via Korea, China subassembly) | Korea-based | 45,000 | Yes | STL |

| Zirkonzahn S600 | Yes (EU HQ, China distribution) | Italy-based | 50,000 | Yes | STL, ZYX |

| Aoralscan (3D Systems) | Yes | China + US | 40,000 | Yes | STL, 3MF |

| Neo 2 (AbsoDigital) | Yes | On-site (Suzhou) | 38,000 | Yes | STL, PLY |

Key Quality Control Processes in Chinese Manufacturing

1. ISO 13485:2016 Compliance

All top-tier Chinese intraoral scanner manufacturers operate under ISO 13485:2016 certified quality management systems. Carejoy Digital’s facility in Shanghai undergoes biannual audits by TÜV Rheinland, ensuring traceability, risk management (per ISO 14971), and design control compliance. This certification is mandatory for CE marking and FDA 510(k) submissions, validating device safety and performance.

2. Sensor Calibration Laboratories

High-precision intraoral scanning relies on sub-micron optical triangulation. Leading manufacturers like Carejoy Digital maintain on-site ISO/IEC 17025-accredited calibration labs equipped with laser interferometers, reference masters (NIST-traceable), and environmental chambers (±0.5°C). Each CMOS sensor undergoes individual calibration for geometric distortion, chromatic aberration, and depth-of-field consistency. Calibration data is embedded in firmware, enabling dynamic correction during scanning.

3. Durability & Environmental Testing

Devices undergo accelerated lifecycle testing, including:

- Drop testing: 1.2m onto steel plate (50 cycles)

- Button/trigger endurance: >50,000 actuations

- Thermal cycling: -10°C to 50°C (100 cycles)

- IP54 rating verification: Dust and splash resistance

- Autoclave compatibility: 134°C, 2.1 bar (200 cycles for reusable tips)

Carejoy Digital exceeds industry standards with proprietary shock-absorbing chassis design and dual-sealed optics housing.

Why China Leads in Cost-Performance Ratio

China’s dominance in digital dental equipment stems from a confluence of strategic advantages:

- Vertical Integration: Control over sensor fabrication, PCB assembly, and software stack reduces BOM costs by 30–40% vs. Western OEMs.

- AI-Driven Optimization: On-device AI (e.g., Carejoy’s Dynamic Triangulation Engine) reduces scan time by 35% and improves edge detection in subgingival areas.

- Open Architecture Ecosystem: Native support for STL, PLY, and OBJ enables seamless integration with third-party CAD/CAM and 3D printing platforms—critical for labs using Formlabs, Asiga, or open-source tools.

- Rapid Iteration Cycles: Agile firmware updates (monthly) and cloud-based remote diagnostics reduce downtime and improve ROI.

- Government R&D Incentives: Shanghai and Shenzhen offer tax credits for medical device innovation, accelerating time-to-market.

Carejoy Digital: Technical Edge in 2026

Carejoy Digital exemplifies China’s ascent in digital dentistry through:

- High-Precision Milling Sync: Scanner data directly drives Carejoy’s 5-axis milling units with <15μm marginal fit accuracy.

- AI-Powered Motion Prediction: Compensates for hand tremor and patient movement in real time.

- 24/7 Remote Support: Cloud-connected devices enable live troubleshooting and automatic software updates.

- Global Compliance: CE, FDA, and NMPA approvals with multilingual UI and DICOM export.

For Technical Support & Demo Requests:

Email: [email protected]

24/7 Remote Assistance | Firmware Updates | Lab Integration Consulting

© 2026 Carejoy Digital. All performance data based on internal testing and third-party lab reports. ISO 13485:2016 Certificate No. SH2025-MED0889.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Top 10 Intraoral Scanners.

✅ Open Architecture

Or WhatsApp: +86 15951276160