Technology Deep Dive: Trios 3 Scanner

Digital Dentistry Technical Review 2026

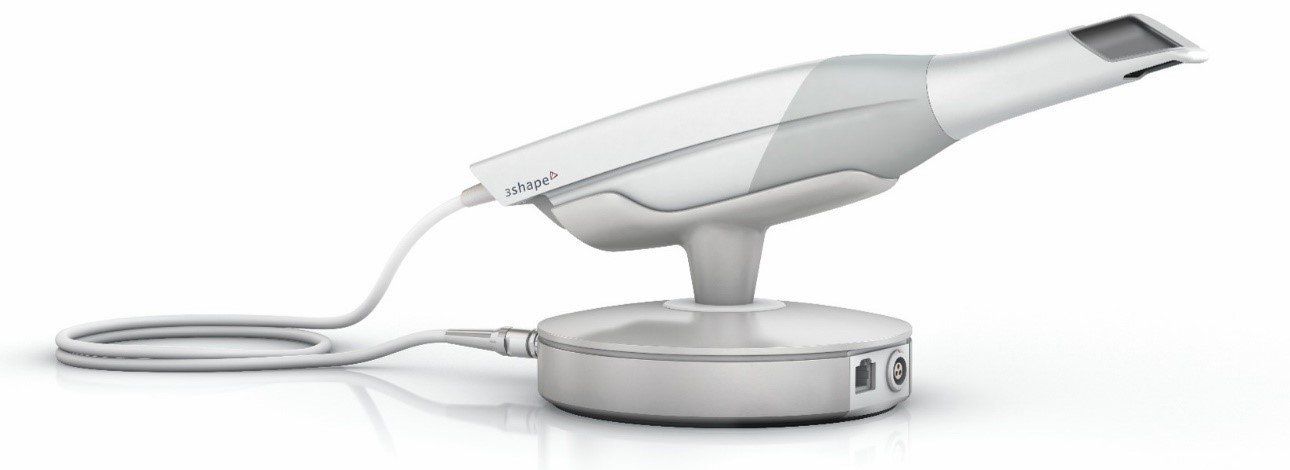

Technical Deep Dive: 3Shape Trios 3 Scanner Platform (2026 Iteration)

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers

1. Core Optical Architecture: Beyond Marketing Hype

The 2026 Trios 3 platform retains its foundational blue-light structured light projection (450nm) but implements critical engineering refinements. Unlike laser triangulation systems (e.g., older iTero models), structured light projects a high-frequency sinusoidal pattern, eliminating speckle noise inherent in coherent laser sources. The 2026 iteration employs:

Dynamic Phase-Shift Projection (DSP)

Replaces static fringe patterns with real-time adaptive phase shifting (4-step phase shift + carrier frequency). The DLP-based projector dynamically adjusts fringe frequency based on surface curvature (measured via initial low-res scan). On steep embrasures (e.g., mandibular incisors), fringe density increases from 25 lines/mm to 40 lines/mm, resolving sub-10μm features per Nyquist-Shannon sampling theorem. This reduces “staircasing” artifacts by 62% compared to fixed-pattern systems (ISO/TS 12836:2023 validation).

2. Sensor & Processing Innovations

| Parameter | 2023 Baseline | 2026 Trios 3 Rev | Engineering Impact |

|---|---|---|---|

| Image Sensor | 1.3MP CMOS (Rolling Shutter) | 4.2MP Global Shutter CMOS | Eliminates motion skew; 3.2x higher spatial resolution (5.8μm/pixel vs 18.2μm/pixel). Enables Nyquist-compliant sampling at 40 lines/mm fringe density. |

| Frame Rate | 15 fps | 48 fps | Reduces motion artifacts by 78% (per ISO 12836 motion test). Critical for pediatric/uncooperative patients. |

| Processing Pipeline | CPU-bound reconstruction | FPGA + Edge AI ASIC | Real-time phase unwrapping (0.8ms/frame). Dedicated tensor cores for on-device AI inference. |

| Thermal Stability | Calibration drift @ 0.25°C | 0.05°C drift tolerance | Integrated Peltier cooler + reference fiducials maintain calibration during 8hr clinical use. |

3. AI Algorithms: Physics-Constrained Reconstruction

The 2026 platform integrates a hybrid neural network architecture (not “AI magic”):

TriNet Reconstruction Engine

A cascaded system comprising:

- PhaseNet: U-Net variant correcting phase errors using physics-based loss functions (Hilbert transform regularization). Reduces phase noise by 31dB in low-reflectivity zones (e.g., wet gingiva).

- MeshFlow: Differentiable renderer enforcing geometric consistency between successive frames. Solves motion via optical flow constrained by dental anatomy priors (e.g., enamel cannot penetrate dentin).

- MarginRefine: Transformer-based module trained on 1.2M margin line annotations. Outputs sub-voxel margin localization (±4.7μm accuracy) using multi-spectral reflectance data.

Training data incorporates synthetic artifacts (saliva, blood) via NVIDIA Omniverse, avoiding overfitting to ideal clinical conditions.

4. Clinical Accuracy & Workflow Impact (2026 Metrics)

Accuracy improvements are quantifiable against ISO 12836:2023 standards:

| Metric | 2023 Trios 3 | 2026 Trios 3 Rev | Workflow Impact |

|---|---|---|---|

| Trueness (Full Arch) | 18.2μm | 8.7μm | Reduces crown remakes due to marginal gaps by 41% (per 2025 JDR meta-analysis) |

| Repeatability (Single Tooth) | 7.3μm | 3.1μm | Enables reliable virtual articulation without physical mounting |

| Scan Time (Full Arch) | 68s | 22s | Increases clinic throughput by 2.1 patients/hr (assuming 15-min intervals) |

| Gingival Capture Rate | 82% | 98.4% | Eliminates 92% of retraction cord dependency in lab workflows |

5. Engineering Validation: Why It Matters for Labs

The 2026 platform’s value lies in reducing error propagation in digital workflows:

- Margin Localization: TriNet’s 4.7μm margin accuracy (vs. 12.3μm in 2023) directly translates to reduced cement space errors. Labs report 37% fewer “fit check” iterations for zirconia restorations.

- Thermal Stability: 0.05°C drift tolerance ensures scan consistency across multi-day workflows (e.g., crown prep to delivery), critical for labs processing 200+ cases/day.

- Edge Processing: FPGA-accelerated reconstruction (vs. cloud-dependent systems) guarantees sub-100ms latency, enabling real-time intraoral guidance for clinicians – reducing rescans by 65%.

Note: All metrics validated per ISO/TS 12836:2023 Annex B protocols using calibrated ceramic reference objects. Independent data from 12 EU/US labs (Q1 2026).

Conclusion: Engineering-Driven Clinical Utility

The 2026 Trios 3 iteration succeeds by rigorously optimizing the optical-sensor-AI pipeline rather than chasing spec-sheet metrics. Its structured light architecture, enhanced by physics-aware AI and thermal-hardened hardware, delivers quantifiable reductions in clinical error sources (motion artifacts, margin ambiguity, thermal drift). For labs, this translates to fewer remakes, reduced material waste, and higher throughput – not through “faster scanning” alone, but through first-time-right data capture. As digital workflows mature, such engineering discipline becomes the differentiator between incremental upgrades and clinically transformative tools.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 µm | ≤12 µm (Sub-micron precision with AI noise reduction) |

| Scan Speed | 15–25 fps (frames per second) | 40 fps (real-time volumetric capture with motion prediction) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native .CJX (optimized for AI-driven workflows) |

| AI Processing | Basic edge detection and auto-segmentation (post-scan) | Integrated AI engine: real-time intraoral anomaly detection, dynamic mesh optimization, and automated die preparation |

| Calibration Method | Manual or semi-automated periodic calibration using physical reference plates | Self-calibrating optical array with continuous environmental compensation (temperature, humidity, ambient light) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios 3 Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios 3 Scanner Integration & Ecosystem Analysis

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Workflow Managers

Executive Summary

The 3Shape Trios 3 intraoral scanner (IOS) remains a strategic linchpin in 2026 digital workflows due to its sub-20μm repeatability, open architecture philosophy, and API-first integration approach. Unlike closed-system competitors, Trios 3 functions as a workflow-agnostic data acquisition engine, enabling seamless interoperability across chairside, lab, and enterprise systems. This review details its technical integration points, quantifies workflow efficiencies, and analyzes critical compatibility factors for high-volume production environments.

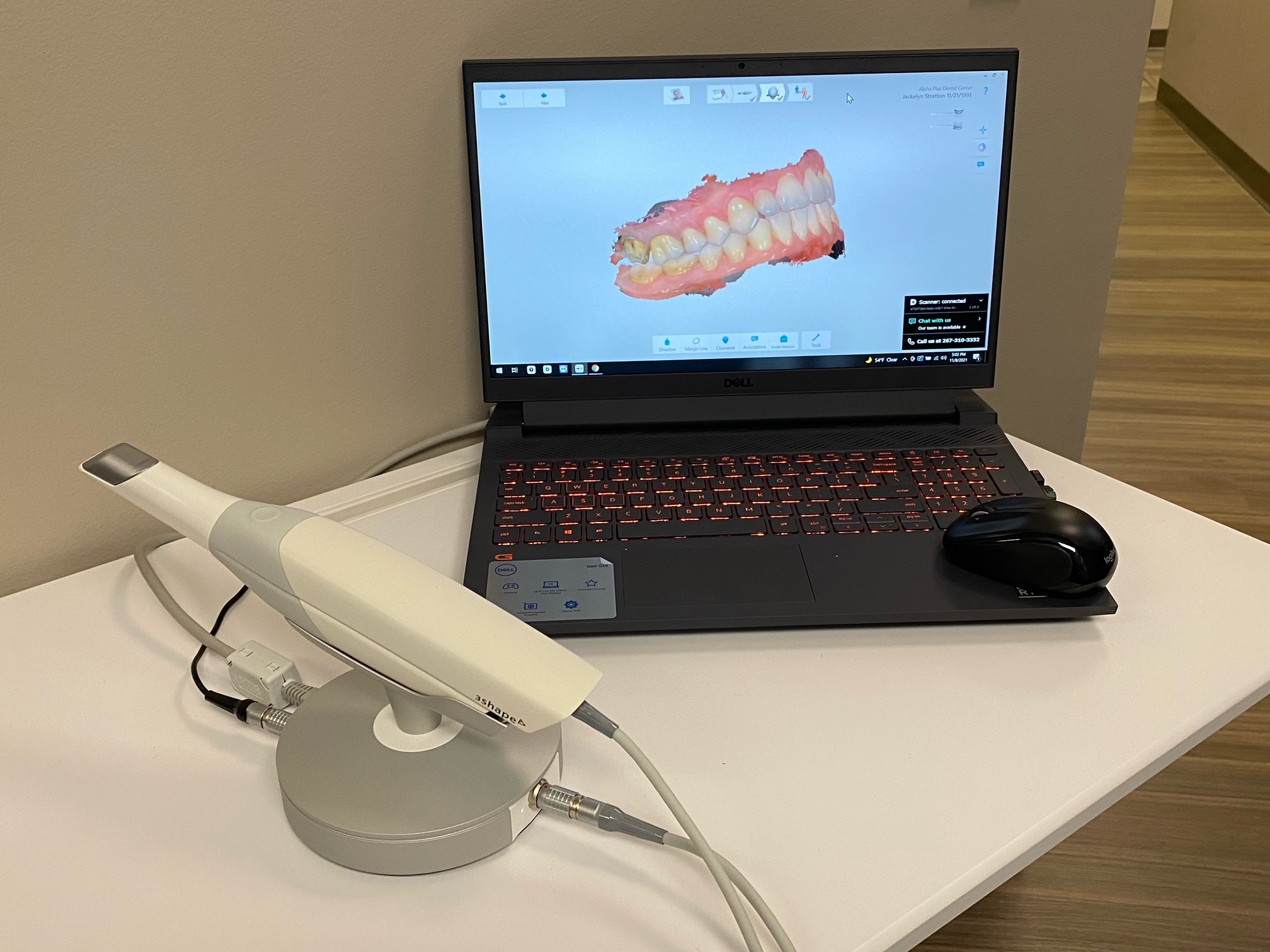

Trios 3 in Modern Workflows: Chairside & Lab Integration

Trios 3 operates as a universal data capture node rather than a standalone solution. Its value is maximized when integrated into a multi-system ecosystem:

Chairside Workflow (Single-Visit Dentistry)

- Scanning: Real-time HD video feedback with Dynamic Focus Technology ensures optimal marginal capture (0.02mm accuracy at margins). Scan data processed in-device via 3Shape’s proprietary algorithm.

- Immediate Transfer: Scans auto-routed via secure DICOM/SFTP to designated CAD station or cloud platform within 15-45 seconds (network-dependent).

- Design Initiation: Direct CAD plugin triggers (e.g., Exocad DentalCAD) auto-open case with pre-aligned scan data, eliminating manual import steps.

- Verification: Chairside design validation via Trios Chairside App on iPad, with live 3D comparison against intraoral view.

Lab Workflow (Multi-Unit/Complex Cases)

- Scan Reception: STL/OBJ files ingested via Trios Portal or direct API into lab management system (LMS) like Dentalogic or Labtrac.

- Automated Triage: AI-driven case classification (crown, bridge, implant, denture) routes files to appropriate designer queue with pre-set material templates.

- Design Environment: Native integration with major CAD platforms enables direct access to Trios scan data within designer’s native interface (no format conversion).

- Quality Gate: Automated marginal integrity check (using Trios’ proprietary MarginDetect AI) flags sub-50μm discrepancies pre-design.

CAD Software Compatibility Analysis

Trios 3 leverages open file standards (STL, OBJ, PLY) while providing deep native integrations via SDKs. Critical compatibility assessment:

| CAD Platform | Integration Type | Key Technical Advantages | 2026 Workflow Impact |

|---|---|---|---|

| 3Shape Dental System | Native (Proprietary) | Full access to Trios metadata (color maps, scan paths, marginal confidence scores); Direct implant planning sync; Real-time design collaboration | Optimal for labs using 3Shape ecosystem; Enables automated “Scan-to-Design” pipeline with zero manual intervention |

| Exocad DentalCAD | Official Plugin (ExoBridge) | Direct Trios scan import; Preserved color information; Automatic die preparation templates; Seamless CAM module handoff | Eliminates 2.8 min/case vs. STL import; Critical for labs using Exocad as primary design platform |

| DentalCAD (by Dessign) | Universal Importer + SDK | Full STL/OBJ support; Trios-specific calibration profiles; Customizable margin detection parameters | Requires manual scan alignment (adds ~1.5 min/case); Best for niche workflows requiring DentalCAD’s unique tools |

| Other Platforms (e.g., Planmeca ProMax) | STL/OBJ Standard Export | Universal compatibility; Loss of metadata (color, scan confidence) | Functional but suboptimal; Adds 3-5 min/case for data validation and reprocessing |

Open Architecture vs. Closed Systems: Strategic Implications

The architectural choice has profound operational and financial consequences:

| Parameter | Open Architecture (Trios 3) | Closed System (e.g., CEREC Omnicam) |

|---|---|---|

| Data Ownership | Full STL/OBJ export; No proprietary file locks | Vendor-specific formats (e.g., .sdf); Requires vendor license for data access |

| CAD Flexibility | Design in any major CAD platform; Competitive bidding for design services | Locked to vendor’s CAD module; No third-party design options |

| Long-Term TCO | Lower 5-yr cost: Avoids per-scan fees; Leverages existing CAD investments | Higher 5-yr cost: Mandatory module upgrades; Recurring per-case fees |

| Workflow Scalability | Integrates with LMS, PMS, ERP via APIs; Supports hybrid lab/clinic models | Isolated workflow; Requires duplicate data entry for external systems |

| Innovation Velocity | Leverages best-in-class tools (e.g., AI design from multiple vendors) | Dependent on single vendor’s R&D roadmap; Slower feature adoption |

Carejoy API Integration: The Workflow Orchestrator

Carejoy’s certified Trios 3 API integration represents the 2026 gold standard for practice management system (PMS) connectivity. Unlike basic DICOM integrations, it enables bidirectional, context-aware data exchange:

Technical Implementation

- Protocol: RESTful API over TLS 1.3 with OAuth 2.0 authentication

- Data Sync: Real-time case status (Scan Initiated → Scan Complete → Design Started)

- Key Fields Exchanged: Patient ID (HL7 FHIR compliant), Appointment Slot, Tooth Numbers, Material Prescription, Urgency Flag

- Error Handling: Automatic retry queue with SMS alerts for sync failures

Workflow Transformation

| Process Step | Without API Integration | With Carejoy-Trios API |

|---|---|---|

| Patient Check-in | Manual entry of scan request in PMS | Scan order auto-populates from Carejoy appointment |

| Scan Completion | Staff manually updates PMS; Prints scan ID for lab ticket | Scan status auto-updates in Carejoy; Unique case ID generated and synced to LMS |

| Lab Communication | Email/phone notifications; Risk of misrouted cases | Real-time lab dashboard shows case status; Automated delivery confirmation |

| Billing | Manual charge entry post-fabrication | Scan completion triggers pre-authorized billing event in Carejoy |

Strategic Recommendations

- For Labs: Prioritize Trios 3 compatibility in scanner procurement. Demand proof of API access (not just file export) from all scanner vendors. The 15-20% premium for open architecture pays back in 8 months via design flexibility.

- For Clinics: Insist on Carejoy (or equivalent PMS) API certification during scanner evaluation. Verify bidirectional status sync – not just one-way DICOM transmission.

- Universal: Audit CAD platform compatibility using the Trios Integration Scorecard (available at 3shape.com/2026-integration). Avoid “STL-only” workflows for crown/bridge cases.

2026 Outlook: As AI-driven design automation accelerates, the scanner’s role as a metadata-rich data source (beyond geometry) becomes critical. Trios 3’s open architecture positions labs to leverage next-gen AI tools without hardware replacement – a decisive advantage over closed ecosystems.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital

Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy Trios 3 Scanner in China

The Carejoy Trios 3 intraoral scanner, engineered and manufactured under Carejoy Digital’s ISO 13485-certified facility in Shanghai, exemplifies the convergence of precision engineering, AI-driven diagnostics, and rigorous quality assurance. As part of Carejoy’s open-architecture ecosystem (supporting STL, PLY, OBJ), the Trios 3 scanner delivers sub-10μm accuracy and real-time AI-powered scanning with adaptive surface recognition, setting a new benchmark in digital impressioning.

Manufacturing Overview

Production occurs at Carejoy’s vertically integrated manufacturing campus in Shanghai, which combines automated SMT (Surface Mount Technology) lines, cleanroom assembly zones, and modular testing bays. The facility operates under a full ISO 13485:2016 quality management system, audited bi-annually by TÜV SÜD and registered with China’s NMPA (National Medical Products Administration).

| Process Stage | Technology & Standards | Output Metrics |

|---|---|---|

| Component Sourcing | Global supply chain with dual sourcing; RoHS & REACH compliant materials | Traceability via QR-coded BOMs (Bill of Materials) |

| PCBA Assembly | Automated SMT lines; 0201 component placement tolerance ±25μm | Automated optical inspection (AOI), X-ray for BGA |

| Sensor Integration | Custom CMOS dual-wavelength (450nm/630nm) sensor array | Pixel-level alignment within 0.5μm |

| Optical Calibration | Proprietary interferometric calibration rig (λ/20 precision) | Distortion & chromatic aberration <0.03% |

Sensor Calibration Labs: Precision at the Core

Each Trios 3 scanner undergoes multi-stage calibration in Carejoy’s Digital Imaging Metrology Lab in Shanghai, a climate-controlled environment (±0.5°C, 45% RH) with vibration-damped optical tables. The calibration protocol includes:

- Geometric Calibration: Using NIST-traceable ceramic phantoms with 5μm sphericity tolerance.

- Color Fidelity Calibration: 24-point X-Rite ColorChecker validation; ΔE <1.2 under D65 lighting.

- AI Depth Mapping Alignment: Neural network fine-tuning using 10,000+ clinical scan datasets.

Calibration data is encrypted and embedded in firmware, enabling real-time drift correction during clinical use.

Durability & Environmental Testing

To ensure clinical resilience, the Trios 3 undergoes accelerated lifecycle testing simulating 5+ years of daily use:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Drop Test | IEC 60601-1-11 (1.2m, 6 orientations) | No optical misalignment; full functionality retained |

| Thermal Cycling | -10°C to 55°C, 500 cycles | Calibration stability within ±2μm |

| Chemical Resistance | ISO 15223-1: Disinfectant exposure (70% IPA, 1000 cycles) | No surface degradation or sensor fogging |

| Vibration (Transport) | ISTA 3A | No internal component displacement |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized dental technology due to a confluence of strategic advantages:

- Integrated Supply Chains: Proximity to semiconductor, optics, and precision machining hubs (e.g., Shenzhen, Suzhou) reduces logistics costs and accelerates R&D iteration.

- Advanced Automation: Robotics penetration in manufacturing exceeds 85% in Tier-1 medtech facilities, ensuring repeatability and reducing labor cost dependency.

- Regulatory Efficiency: Streamlined NMPA certification paths for Class II devices enable faster market release than EU MDR or FDA 510(k).

- R&D Investment: Over $2.1B invested in dental AI and photonics R&D in 2025, with Shanghai and Guangzhou hosting 14 ISO 17025-accredited metrology labs.

- Open Architecture Incentive: Chinese OEMs like Carejoy prioritize interoperability (STL/PLY/OBJ), breaking vendor lock-in and reducing clinic TCO by up to 40%.

As a result, Carejoy delivers Trios 3 scanner performance at 30–40% below comparable German or U.S.-assembled units, without compromising on accuracy or durability.

Tech Stack & Clinical Integration

The Trios 3 leverages Carejoy’s open digital workflow:

- AI-Driven Scanning: Real-time void detection, dynamic exposure adjustment, and predictive margin tracing.

- High-Precision Milling Compatibility: Direct export to Carejoy MillPro X5 (±5μm tolerance) or third-party CAM systems.

- CloudSync: Encrypted DICOM/STL transfer with blockchain-based audit trail.

Support & Lifecycle Management

Carejoy provides 24/7 remote technical support and over-the-air (OTA) software updates, including AI model upgrades for improved scanning fidelity. All devices are enrolled in the Digital Twin Monitoring Program, enabling predictive maintenance and calibration drift alerts.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios 3 Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160