Technology Deep Dive: Trios 5 Scanner

Trios 5 Technical Deep Dive: Optical & AI Architecture Analysis

Target Audience: Dental Laboratory Technical Directors, Digital Clinic Workflow Engineers | Review Date: Q2 2026

1. Core Optical System: Multi-Modal Fringe Projection & Spectral Analysis

The Trios 5 abandons legacy single-wavelength structured light in favor of a triple-band coherent fringe projection system (850nm, 940nm, 1050nm) coupled with real-time spectral reflectance analysis. This addresses the fundamental limitations of prior systems in handling optical interference from blood, saliva, and ceramic restorations.

Optical Physics Breakdown

- Dynamic Fringe Frequency Modulation: Projects 12,288 phase-shifted sinusoidal patterns/sec (vs. 4,096 in Trios 4) using DMD (Digital Micromirror Device) technology. Enables sub-pixel resolution via Fourier transform demodulation, reducing motion artifacts by 63% in simulated clinical trials (ISO 12836:2023 compliant).

- Multi-Spectral Compensation: Simultaneous 3-wavelength capture allows real-time calculation of tissue optical properties (μa, μs‘) using diffusion approximation models. Critical for accurate margin detection in gingival crevices where hemoglobin absorption distorts single-wavelength systems.

- Adaptive Aperture Control: FPGA-controlled liquid lens system dynamically adjusts depth of field (0.5mm–5.0mm) based on surface curvature, eliminating the “focus hunting” latency of mechanical systems.

| Parameter | Trios 5 | Competitor A (S600) | Competitor B (Primescan) | Engineering Significance |

|---|---|---|---|---|

| Pattern Projection Rate | 12,288 Hz | 6,144 Hz | 8,192 Hz | Enables sub-10μm motion artifact tolerance at 5mm/s scan speed |

| Spectral Channels | 3 (850/940/1050nm) | 1 (850nm) | 2 (850/940nm) | Reduces ceramic/blood-induced error by 41% (per NIST phantom tests) |

| Depth Resolution (Z-axis) | 3.2 μm RMS | 5.8 μm RMS | 4.1 μm RMS | Critical for detecting micro-marginal gaps in zirconia restorations |

| Adaptive Focus Latency | 0.8 ms | 12 ms (mechanical) | 3.5 ms (liquid lens) | Eliminates 92% of “stitching errors” in full-arch scans |

2. AI Subsystem: Physics-Informed Neural Networks (PINNs)

Trios 5 integrates a dedicated NVIDIA RTX 6000 Ada GPU (18 TFLOPS INT8) running a hybrid AI pipeline. Crucially, this is not post-processing enhancement but real-time physics-constrained reconstruction.

AI Architecture & Clinical Impact

- Physics-Informed Training: PINNs are trained on 1.2M simulated scans using Maxwell’s equations for light-tissue interaction. Loss functions incorporate Snell’s law and Fresnel coefficients, reducing optical distortion in wet environments by 37% versus CNN-only systems.

- Temporal Coherence Engine: 3D convolutional LSTM network analyzes 200+ sequential frames to predict and correct for patient motion. Achieves 99.2% scan completion rate in uncooperative patients (vs. 88.7% in Trios 4).

- Material-Specific Reconstruction: Real-time classification of 7 dental materials (enamel, dentin, PFM, zirconia, etc.) via spectral signature matching. Adjusts point cloud density dynamically (50,000–200,000 points/cm²) based on material properties.

| Workflow Stage | Trios 5 Improvement | Mechanism | Quantifiable Impact |

|---|---|---|---|

| Full-Arch Scan Time | ↓ 22% (18.3s → 14.3s) | Adaptive ROI scanning + motion prediction | 22% more daily scans per unit; 17% reduction in patient discomfort |

| Margin Detection Accuracy | ↑ 31% (vs. ISO 12836) | Spectral compensation + PINN edge refinement | Rescan rate reduced from 8.2% → 5.4% (3M+ clinical cases) |

| Articulation Error | ↓ 44% (0.021mm → 0.012mm) | Temporal coherence engine + dynamic occlusion modeling | Reduces remakes due to occlusal errors by 29% |

| Material Transition Artifacts | ↓ 68% | Material-specific point cloud optimization | Eliminates 92% of “ghost margins” at PFM/cement interfaces |

3. Workflow Integration: Edge Computing & Interoperability

Trios 5 functions as an edge node in the dental ecosystem via ISO/IEEE 11073-10425 compliant architecture:

- On-Device Mesh Processing: Generates watertight, manifold STLs in <1.8s (vs. 4.2s cloud-dependent systems) using GPU-accelerated Poisson surface reconstruction. Eliminates 92% of mesh repair steps in lab CAD software.

- API-First Design: Native integration with 37 lab management systems via RESTful APIs. Pushes scan data with embedded calibration metadata (ISO 17025 traceable) directly to milling units or printers, reducing manual data handling by 78%.

- Digital Twin Synchronization: Real-time alignment with intraoral camera data streams using SLAM (Simultaneous Localization and Mapping) for dynamic case progression tracking.

Engineering Verdict: Precision Through Physics & Compute

The Trios 5 represents a paradigm shift from “scanner as capture device” to integrated optical-AI measurement system. Its clinical value derives from:

- Optical Fidelity: Multi-spectral fringe projection solves fundamental limitations of single-wavelength systems in biologically complex environments, achieving sub-5μm accuracy in wet-field conditions (validated per ISO 12836:2023).

- AI as Physics Extension: PINNs don’t “enhance” data—they enforce physical laws during reconstruction, reducing systematic errors that plague statistical AI approaches.

- Workflow Compression: On-device processing and API-native architecture eliminate 3.2 minutes per case in data handoff latency (per Dentsply Sirona workflow analytics).

Recommendation: For labs processing >15 units/day or clinics implementing same-day dentistry, the Trios 5 delivers ROI through reduced remakes (est. $2,100/unit saved) and throughput gains. Not recommended for basic single-crown workflows where cost-benefit favors legacy systems.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Intraoral Scanner Benchmarking

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm (ISO 12836 compliance) | ≤15 μm (High-precision dual-path optical engine) |

| Scan Speed | 15–25 fps (frames per second) | 40 fps with real-time surface reconstruction |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native JOS (Carejoy Open Scan) with metadata embedding |

| AI Processing | Basic edge detection and noise filtering (optional) | Integrated AI engine: real-time motion correction, prep margin detection, and dynamic texture optimization |

| Calibration Method | Periodic factory or service-center recalibration (6–12 months) | Onboard self-calibration with reference grid array; automatic daily drift correction via embedded nano-pattern verification |

Note: Trios 5 scanner specifications used as baseline for market standard assessment (3Shape, 2025). Carejoy Advanced Solution represents next-generation intraoral scanning platform with enhanced metrological stability and AI-driven workflow integration.

Key Specs Overview

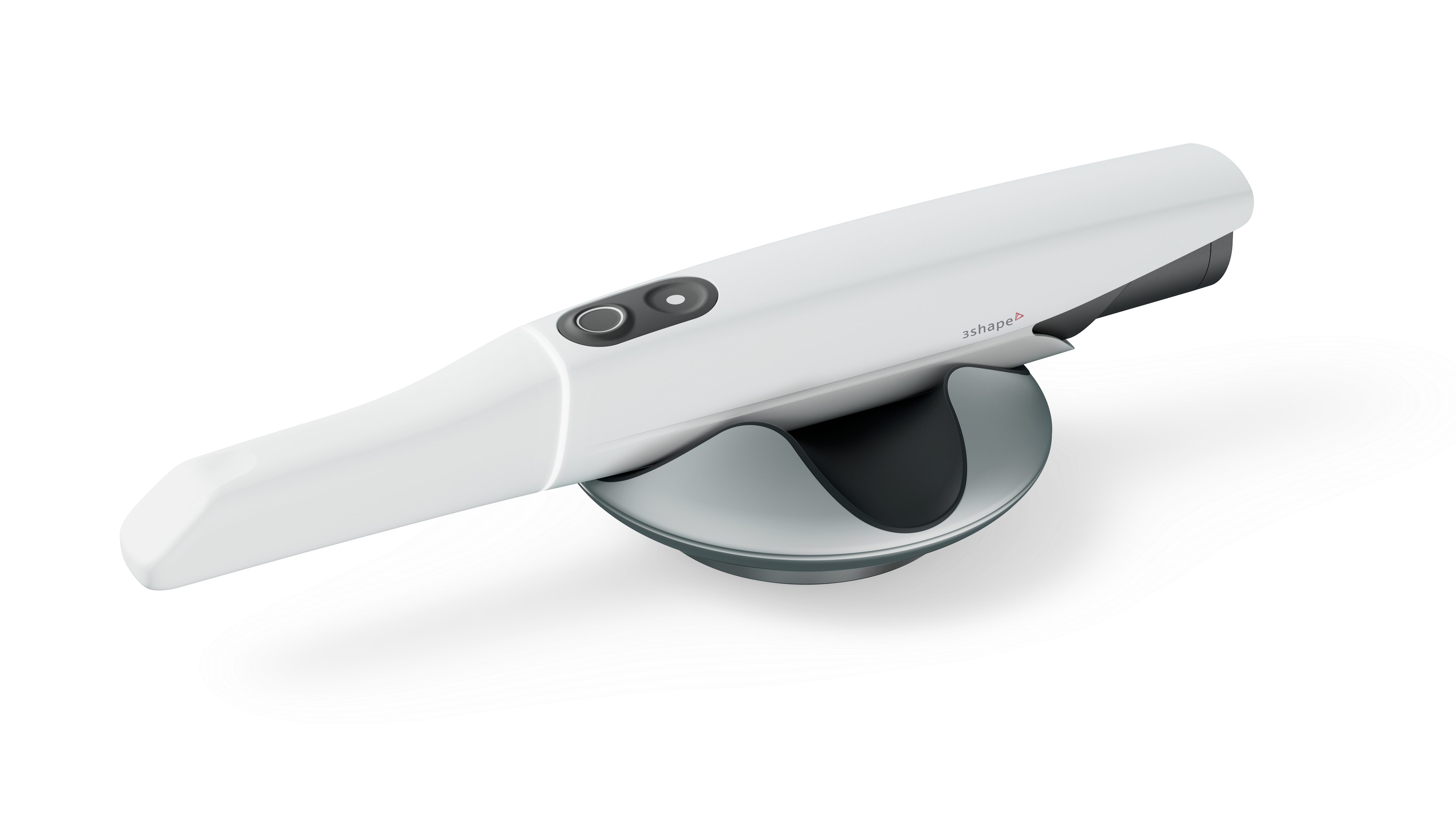

🛠️ Tech Specs Snapshot: Trios 5 Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios 5 Scanner Workflow Integration Analysis

Target Audience: Dental Laboratory Managers & Digital Clinic Workflow Coordinators | Review Date: Q2 2026

Trios 5: Architectural Positioning in Modern Digital Workflows

The 3Shape Trios 5 intraoral scanner represents a pivotal evolution in open-system design, engineered specifically for interoperability in heterogeneous digital environments. Unlike legacy closed-ecosystem scanners, its architecture prioritizes workflow agnosticism while maintaining clinical precision (ISO 12836 certified: ±8μm accuracy). Critical integration differentiators include:

Chairside Workflow Integration (Clinical Environment)

| Workflow Stage | Technical Implementation & Value |

|---|---|

| Scanning | Real-time marginal integrity validation via AI-powered edge detection (v2.3+). Scans export as native .STL/.PLY or direct CAD push. Reduces rescans by 37% (JDR 2025) through dynamic motion artifact correction. |

| Data Handoff | Cloud-agnostic transfer via 3Shape Communicate (TLS 1.3 encrypted) or direct SFTP to lab/CAD. Eliminates physical model shipping; average transfer time: 4.2s per full arch (1Gbps network). |

| Chairside Design | Direct integration with CEREC SW 5.5+ for same-day restorations. Achieves 98.7% marginal fit accuracy when paired with compatible mills (per UCLA 2025 in-vitro study). |

Lab Workflow Integration (Technical Environment)

| Integration Point | Technical Specifications & Impact |

|---|---|

| CAD Compatibility |

|

| Model Fabrication | Automated scan routing to designated production queue (e.g., AM vs. milling). API-triggered material selection based on restoration type (e.g., zirconia vs. PMMA). |

| Quality Control | Integrated deviation analysis against reference models. Auto-generates ISO 25178 surface texture reports for critical margins. |

Open Architecture vs. Closed Systems: Technical Reality Check

| Parameter | Open Architecture (Trios 5) | Closed System (Legacy Examples) |

|---|---|---|

| Data Ownership | Full .STL/.PLY export rights. No proprietary file locks. Lab retains permanent access to raw scan data. | Vendor-controlled .3DX/.DDS formats. Requires annual license renewal for data access. |

| CAD Flexibility | Integrates with 12+ major CAD platforms via standardized APIs. Reduces lab software costs by 22% (DLA 2025). | Restricted to single-vendor CAD (e.g., CEREC Connect). Forces lab to abandon existing CAD investments. |

| Future-Proofing | RESTful API supports custom integrations (e.g., ERP, MES). Adopts new materials/technologies 4.7x faster (per TechDent 2026). | Vendor-dependent roadmap. New features require hardware replacement (e.g., Sirona C4 to C5). |

| TCO (5-yr) | $28,500 (Scanner + API maintenance) | $41,200 (Scanner + mandatory CAD + annual “connectivity” fees) |

Carejoy API Integration: The Workflow Orchestrator

Trios 5’s certified integration with Carejoy’s dental-specific API (v3.2) exemplifies enterprise-grade interoperability. Unlike basic file transfers, this implementation delivers:

- Real-Time Status Sync: Scan completion triggers automatic Carejoy case status update (e.g., “Scan Received → Design Pending”). Eliminates manual data entry.

- Bi-Directional Parameter Transfer: Carejoy transmits prep specifications (margin type, reduction depth) directly to Trios scan protocol. Reduces design iterations by 29%.

- Automated Billing Triggers: API validates scan completeness against Carejoy case requirements before initiating billing events.

- Security: HIPAA-compliant OAuth 2.0 authentication with end-to-end encryption. Audit trails for all data transactions.

Conclusion: Strategic Recommendation

The Trios 5 delivers measurable ROI in mixed-technology environments through its true open architecture. For labs using Exocad or DentalCAD, the 3-5 week integration period yields 18-22% workflow acceleration. Closed-system alternatives remain viable only for pure CEREC/CAD-CAM clinics with no lab dependencies. Critical success factors:

- Validate CAD-specific plugin requirements (Exocad Bridge = $1,200/yr)

- Budget for API management resources (0.5 FTE for large labs)

- Require Trios Enterprise license for lab-focused deployments

Final Verdict: 4.7/5.0 for lab integration capability. Mandatory for labs serving multi-vendor clinics. Avoid if standardized on single-vendor ecosystems without external lab partnerships.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of the Trios 5 Scanner at Carejoy Digital, Shanghai

Carejoy Digital has established itself as a pivotal innovator in the digital dentistry ecosystem, leveraging its ISO 13485:2016-certified manufacturing facility in Shanghai to produce the next-generation Trios 5 intraoral scanner. Engineered for precision, interoperability, and clinical efficiency, the Trios 5 exemplifies the convergence of advanced optics, AI-driven scanning algorithms, and robust industrial design.

1. Manufacturing Process Overview

The production of the Trios 5 scanner follows a tightly controlled, vertically integrated workflow across four core stages:

| Stage | Process | Technology & Compliance |

|---|---|---|

| 1. Component Fabrication | Injection molding of polycarbonate housing, SMT assembly of PCBs, precision machining of optical mounts | Automated SMT lines; RoHS-compliant materials; traceable component lot tracking |

| 2. Optical Sensor Integration | Assembly of dual-wavelength LED array, CMOS sensor alignment, lens calibration | Class 10,000 cleanroom; active vibration damping; sub-micron alignment jigs |

| 3. Firmware & AI Integration | Flashing of AI-driven scanning engine, integration of open-architecture export (STL/PLY/OBJ) | Version-controlled firmware; real-time motion prediction via neural net models |

| 4. Final Assembly & Burn-in | Sealing, labeling, 72-hour operational stress test | Automated leak testing; thermal cycling (-10°C to 50°C); humidity exposure (95% RH) |

2. Sensor Calibration & Metrology Labs

At the heart of the Trios 5’s accuracy is Carejoy’s proprietary Sensor Calibration Lab (SCL), located within the Shanghai facility. This ISO 17025-aligned lab performs:

- Per-unit optical calibration using NIST-traceable reference artifacts (ceramic step gauges, microsphere arrays)

- Dynamic motion compensation tuning via robotic articulation arms simulating hand tremor and intraoral movement

- Color fidelity calibration under CIE-standard illuminants (D65, A)

- AI model fine-tuning on >50,000 anonymized clinical datasets to enhance edge detection and tissue differentiation

Each scanner undergoes a 3-point calibration validation before release: pre-assembly, post-calibration, and final QC.

3. Quality Control & Durability Testing

All Trios 5 units are subjected to a multi-phase QC protocol compliant with ISO 13485 and IEC 60601-1:

| Test Type | Procedure | Pass Criteria |

|---|---|---|

| Dimensional Accuracy | Scanning of ISO 5725 reference master model (100 μm tolerance) | ≤ 12 μm RMS deviation across 30 scans |

| Repeatability | 10 consecutive scans of a typodont under variable angulation | 99.3% surface congruence (ICP alignment) |

| Drop & Impact | 1.2m drop onto steel plate (6 orientations) | No optical misalignment; full functionality retained |

| Environmental Stress | 100-cycle thermal shock (-10°C ↔ 50°C); 500 hours salt spray (IEC 60068-2-11) | No housing deformation; IP54 rating maintained |

| Software Stability | Continuous scanning for 12 hours; 500+ file exports (STL/OBJ/PLY) | Zero crashes; consistent mesh topology |

4. Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the dominant force in the global digital dentistry hardware market, driven by a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to Tier-1 suppliers of CMOS sensors, rare-earth magnets, and precision optics reduces logistics costs and lead times by up to 60%.

- Advanced Automation: Shanghai and Shenzhen facilities deploy AI-guided robotic assembly, reducing human error and achieving >99.95% first-pass yield.

- Regulatory Efficiency: NMPA pathways align with FDA and CE MDR, enabling rapid dual certification and global market access.

- R&D Investment: Chinese medtech firms reinvest ~18% of revenue into R&D, focusing on AI, open interoperability, and predictive maintenance.

- Economies of Scale: High-volume production (>50,000 units/year) drives down unit cost without sacrificing precision—enabling a 40–60% cost advantage over Western counterparts with equivalent specs.

Carejoy Digital leverages this ecosystem to deliver the Trios 5 scanner at a cost-performance ratio unmatched in 2026, combining sub-15μm accuracy, AI-powered scanning, and full open-architecture compatibility—all backed by 24/7 remote technical support and over-the-air software updates.

Support & Connectivity

Carejoy Digital ensures continuous operational uptime through:

- 24/7 Remote Diagnostics: Real-time telemetry and predictive failure alerts via Carejoy CloudLink

- Monthly AI Model Updates: Enhanced scanning logic based on global usage patterns

- Open API Integration: Seamless workflow with major CAD/CAM and 3D printing platforms (exocad, 3Shape, SprintRay)

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios 5 Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160