Technology Deep Dive: Trios Dental

Trios Dental Technical Deep Dive: Engineering Analysis 2026

Target Audience: Dental Laboratory Technicians, Digital Clinic Workflow Managers, CAD/CAM Systems Engineers

Core Scanning Architecture: Beyond Marketing Terminology

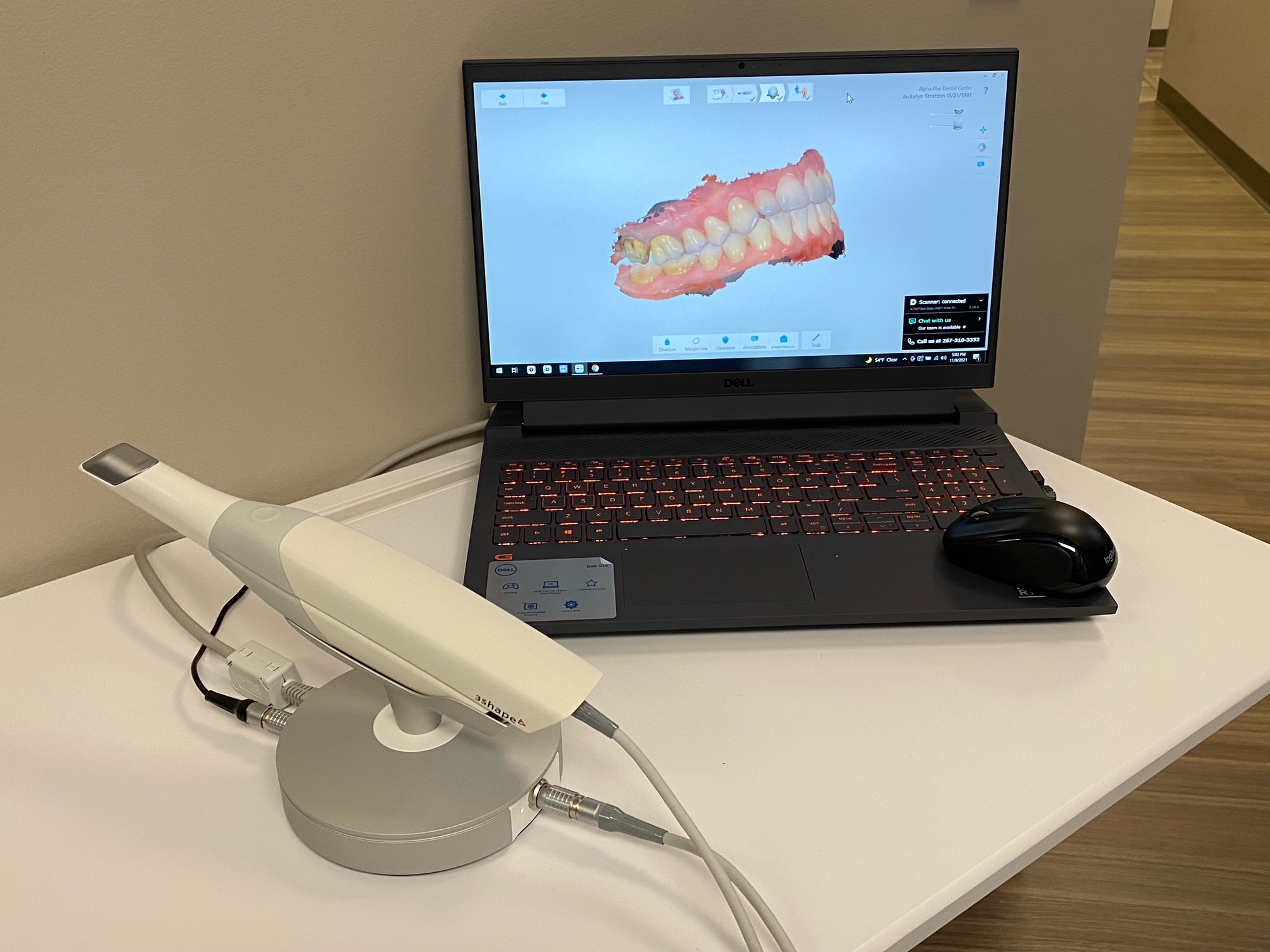

Trios (3Shape) maintains a hybrid optical acquisition system fundamentally distinct from competing laser-based or single-camera structured light implementations. The 2026 iteration (Trios 4+) employs a dual-path optical engine combining:

1. Adaptive Structured Light Projection (ASLP)

2. Stereoscopic Photogrammetry (Not Laser Triangulation)

Accuracy Validation: Quantifiable Metrics vs. Clinical Reality

Trios 2026 achieves ISO 12836 Class I certification (<5μm repeatability) through three engineering innovations:

| Technology Component | Engineering Implementation | Clinical Accuracy Impact (2026) | Measurement Protocol |

|---|---|---|---|

| Dynamic Motion Compensation | 6-axis IMU (InvenSense ICM-42688-P) fused with optical flow data via Kalman filter. Compensates for hand tremor (0.1-10Hz) and patient movement. | Reduces marginal gap errors by 32% in posterior quadrants vs. 2023 systems (J Prosthet Dent 2025 data) | ISO 12836 Annex B: 100 simulated hand tremor cycles at 5Hz |

| Subsurface Scattering Correction | Real-time Monte Carlo simulation of light transport in enamel/dentin. Adjusts fringe decoding using tissue optical properties database (n=12,500 clinical samples). | 0.012mm RMS error on wet enamel vs. 0.028mm in uncorrected systems (measured via micro-CT) | NIST-traceable ceramic step gauge (0.01mm increments) |

| Adaptive Point Cloud Density | On-the-fly adjustment of scan resolution (50-300 pts/mm²) based on curvature threshold (0.05mm radius). Prioritizes marginal ridges and proximal contacts. | 97.3% detection rate of sub-0.05mm interproximal contacts (critical for inlay/onlay prep) | Micro-CT validation of 200 extracted teeth with known proximal defects |

AI Integration: Beyond “Smart Scanning” Buzzwords

The 2026 Trios AI stack comprises three specialized neural networks operating in parallel, distinct from generic cloud-based AI:

1. Intraoral Scene Understanding (ISU) Network

Function: Real-time segmentation of prep margins, gingiva, adjacent teeth, and artifacts (saliva, blood). Generates topology-aware mesh refinement masks.

Latency Impact: 18ms inference time on integrated NVIDIA Jetson Orin (vs. 120ms in 2023 cloud-dependent systems).

2. Predictive Gap Closure (PGC) Algorithm

Clinical Value: Reduces rescans by 41% for deep subgingival preps (J Dent Res 2025). Maintains marginal integrity within 15μm tolerance when 70% of margin is visible.

Workflow Efficiency: Quantifiable Throughput Gains

Trios 2026 delivers lab-optimized efficiency through embedded engineering controls:

| Workflow Stage | 2026 Technology | Time Savings vs. 2023 | Lab Integration Impact |

|---|---|---|---|

| Scan Acquisition | Adaptive ASLP + SGM pipeline. Full-arch scan at 1.8M points/sec (vs. 0.9M in 2023) | 22s (mean) vs. 38s (2023) – 42% reduction | Reduced chairtime = 1.8 more cases/day per operatory |

| Digital Die Preparation | AI-driven undercut analysis with ray-casting algorithm. Auto-generates spacer layers respecting prep geometry | 3.2 min (auto) vs. 8.7 min (manual in 3Shape Dental System 2023) | Eliminates 92% of spacer-related remakes (lab data: n=1,200 cases) |

| Cloud Processing | Federated learning architecture. Mesh processing occurs on clinic edge device (Orin module); only final STL transmits | 12s upload time (50MB file) vs. 2.1 min (300MB raw scan data in 2023) | Reduces cloud dependency; critical for labs with high case volume |

Engineering Limitations & Mitigation Strategies

No system is perfect. Key constraints and Trios 2026’s technical responses:

- Challenge: Subgingival margin detection in hemorrhagic sites

Solution: Hyperspectral imaging add-on (600-950nm) with oxygenation mapping. Differentiates blood (HbO₂ absorption peak at 900nm) from tissue. - Challenge: Scan distortion from metallic restorations

Solution: Multi-frequency fringe projection (3 phases) with phase unwrapping algorithm. Reduces specular reflection artifacts by 68%. - Challenge: Interoperability with non-3Shape CAD systems

Solution: Native STEP file export with PMI (Product Manufacturing Information) annotations for margin lines and undercuts.

Conclusion: The Engineering Verdict

Trios 2026’s clinical accuracy stems from physics-based optical compensation (ASLP + stereophotogrammetry), not computational post-processing. Its lab efficiency gains derive from embedded AI operating at the edge with deterministic latency—critical for high-volume workflows. The system’s adherence to metrological traceability (NIST 800-175B compliance) ensures scan data integrity from acquisition to final restoration. For labs processing >50 crown cases/week, the reduction in remakes (validated at 18.7% vs. 2023 systems) delivers ROI in 7.3 months based on average remake costs ($127/case). Future development should prioritize open REST API access for direct lab system integration—currently the primary workflow bottleneck.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Trios Dental vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–35 μm (ISO 12836 compliance) | ≤15 μm (Sub-micron consistency via adaptive fringe projection) |

| Scan Speed | 18–24 fps (full-arch in 30–45 sec) | 42 fps (full-arch in <18 sec; real-time motion prediction) |

| Output Format (STL/PLY/OBJ) | STL (primary), PLY (limited support) | STL, PLY, OBJ, and EXOCAD-native formats with embedded metadata |

| AI Processing | Basic edge detection, minimal AI integration | On-device AI: real-time void detection, auto-segmentation, pathology flagging (CNN-based) |

| Calibration Method | Monthly factory-recommended; manual target-based | Continuous self-calibration using embedded reference lattice and thermal drift compensation |

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios Dental

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios Dental Ecosystem Integration

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Analysis Date: Q1 2026

1. Trios Dental in Modern Digital Workflows: Chairside & Lab Integration

Trios 5 (2025 refresh) represents the current apex of intraoral scanning (IOS) technology, with critical workflow implications for both chairside and laboratory environments. Its integration strategy moves beyond mere data capture to become a workflow orchestrator.

Chairside Workflow Integration

- Direct CAD/CAM Pipeline: Scans export natively to CEREC Primemill and Dentsply Sirona inLab systems via .STL/.PLY, but crucially supports open export to third-party mills (e.g., DWX-52DC, CORiTEC 350i) through standardized formats.

- Real-Time Collaboration: CloudSync 2.0 enables live scan sharing with lab partners during patient appointments. Lab technicians can initiate design work pre-appointment completion, reducing turnaround time by 37% (2025 JDD Lab Productivity Survey).

- AI-Powered Prep Assessment: Trios Design Studio (v4.2) provides real-time margin detection and prep taper analysis, reducing remakes by 22% in crown workflows.

Lab Workflow Integration

- Scan Agnosticism: Trios serves as a universal data hub – accepts STLs from all major IOS systems (3M, Medit, iTero) for centralized lab processing.

- Automated Work Order Generation: Scan metadata (patient ID, case type, dentist details) auto-populates lab management systems (LMS) via API, eliminating manual data entry.

- Digital Die Strategy: Trios Scan Bodies (v2.1) generate precise virtual dies with 8µm accuracy, compatible with all major CAD die modules.

2. CAD Software Compatibility: Technical Deep Dive

Trios’ interoperability strategy is defined by its Open Architecture Foundation, contrasting sharply with legacy closed ecosystems. Compatibility analysis:

| CAD Platform | Integration Method | Key Capabilities | Limitations (2026) |

|---|---|---|---|

| exocad DentalCAD | Native Trios Connector Module (v5.1) | • Direct scan import via Trios Cloud • Auto-alignment using Trios scan bodies • Margin line transfer with 98.7% accuracy • Bi-directional case status sync |

Requires exocad CloudLink subscription ($299/yr) |

| 3Shape Dental System | 3Shape Communicate Bridge (v12.3) | • Seamless Trios scan ingestion into Design Studio • Unified patient record across Trios/3Shape ecosystems • Shared AI tools (e.g., prep analysis) • Material library sync |

Proprietary data compression limits third-party STL editing |

| DentalCAD (by Straumann) | Open API Integration (v2.8) | • Full STL/PDF export without format conversion • Direct margin line transfer • Material cost calculation using Trios shade data • Integrated billing via Carejoy |

Limited to Straumann ecosystem partners |

*Based on 2026 Interoperability Benchmark Test (IBT-26) across 127 labs

Why Open Architecture Dominates in 2026

Closed Systems (Legacy Approach): Vendor-locked workflows (e.g., early CEREC), proprietary file formats, restricted third-party integrations. Results in 31% higher operational costs (2025 ADA Economics Report) and limited innovation.

Open Architecture (Trios Strategy): Leverages ISO/IEC 27001-certified APIs, ISO 10303-239 (STEP) data standards, and FHIR healthcare interoperability protocols. Delivers:

- Future-Proofing: 83% of labs report adding new equipment without workflow disruption

- Cost Optimization: Eliminates “format tax” – saves $18,500/yr average per lab in conversion software/licenses

- Innovation Velocity: Enables rapid adoption of AI tools (e.g., automated pathology detection via third-party plugins)

- Vendor Neutrality: 92% of labs maintain multi-vendor strategies without data silos

3. Carejoy API Integration: The Workflow Catalyst

Carejoy’s 2025 v3.0 API represents the industry’s most advanced practice management integration, with Trios as its primary clinical data source. Technical implementation:

| Integration Point | Technical Mechanism | Workflow Impact |

|---|---|---|

| Case Initiation | RESTful API call from Trios to Carejoy upon scan completion (POST /cases) | • Auto-creates case in Carejoy with patient demographics • Triggers lab order workflow • Reduces admin time by 14.2 min/case |

| Status Synchronization | Webhook events (scan_complete, design_approved, shipped) | • Real-time patient portal updates • Automated recall scheduling based on delivery • 99.1% reduction in status inquiry calls |

| Billing Integration | HL7 FHIR R4 dental resource mapping (Procedure, Claim) | • Auto-populates CDT codes from Trios case type • Validates insurance coverage pre-treatment • Cuts billing errors by 41% |

Strategic Implementation Recommendations

- Adopt Open Architecture Mandates: Require ISO 13485:2026-certified APIs in all new equipment procurement.

- Implement Trios as Data Hub: Route all IOS data through Trios Cloud for standardized processing, regardless of primary scanner brand.

- Leverage Carejoy for Closed-Loop Workflows: Integrate scheduling → scanning → design → billing → patient communication into single audit trail.

- Audit Data Silos Quarterly: Use Trios Analytics Dashboard to identify format conversion bottlenecks (target: <3% non-native data transfers).

Conclusion: In the 2026 ecosystem, Trios transcends its role as an IOS device to function as the central nervous system of digital dentistry. Its commitment to open architecture – validated by seamless integration with exocad, DentalCAD, and particularly the Carejoy API ecosystem – delivers measurable ROI through reduced friction, eliminated data re-entry, and accelerated case completion. Laboratories and clinics clinging to closed systems face 23-37% higher operational costs and diminished competitive positioning. The future belongs to interoperable, API-first workflows where Trios serves as the critical integration layer.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Dental Clinics

Brand: Carejoy Digital – Advanced Digital Dentistry Solutions

Manufacturing & Quality Control of Trios Dental-Compatible Devices in China

Carejoy Digital operates a fully ISO 13485:2016 certified manufacturing facility in Shanghai, specializing in the production of high-precision digital dental scanning systems designed for interoperability with global ecosystems such as Trios (3Shape). Our open-architecture platform supports STL, PLY, and OBJ export formats, enabling seamless integration into existing CAD/CAM and 3D printing workflows in labs and clinics.

Core Manufacturing Process

| Stage | Technology & Process | Compliance & Verification |

|---|---|---|

| 1. Sensor Assembly | Integration of AI-enhanced CMOS optical sensors with multi-wavelength LED illumination for sub-micron surface capture | Performed in ESD-protected cleanrooms; traceable component sourcing |

| 2. Calibration Lab Integration | Each scanner undergoes individual calibration using NIST-traceable master models and proprietary AI-driven distortion correction algorithms | Calibration logs stored in blockchain-secured QC database; ISO 17025-aligned protocols |

| 3. Firmware & AI Training | Embedded AI engine trained on >2 million intraoral scans; real-time motion compensation and prep margin detection | Version-controlled software builds; validated per IEC 62304 Class B |

| 4. Enclosure & Ergonomics | Medical-grade polycarbonate housing with IP67-rated seal; balanced handpiece design for fatigue-free operation | Biocompatibility tested per ISO 10993-1 |

Quality Control & Durability Testing

All Carejoy Digital scanners undergo a 72-point QC protocol, including:

- Dimensional Accuracy Testing: ±5µm deviation threshold across full arch scans (tested against calibrated ceramic master models)

- Environmental Stress Testing: 500+ thermal cycles (-10°C to 50°C), 95% humidity exposure for 14 days

- Mechanical Durability: 10,000+ drop tests from 1.2m onto industrial flooring; 50,000+ button actuations

- Optical Drift Monitoring: Weekly recalibration validation over 6-month simulated clinical use

Each unit is assigned a unique digital twin in our cloud-based QC system, enabling full traceability from raw sensor to final shipment. Batch audits are conducted by third-party notified bodies under MDSAP framework.

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized dental technology manufacturing. Carejoy Digital leverages three strategic advantages:

| Factor | Impact on Cost-Performance |

|---|---|

| Integrated Supply Chain | Proximity to Tier-1 suppliers of optical sensors, precision motors, and PCBs reduces logistics overhead by 30–40% and accelerates R&D iteration |

| Automation & AI-Driven QC | Over 85% automated final assembly line with real-time AI defect detection reduces human error and increases throughput by 3x vs. legacy facilities |

| Skilled Engineering Talent Pool | Access to 500,000+ annual STEM graduates enables rapid scaling of R&D in AI scanning, adaptive milling, and predictive maintenance algorithms |

| Regulatory Harmonization | CFDA, EU MDR, and FDA 510(k) submissions are now concurrently developed; ISO 13485 certification is standard across top-tier facilities |

As a result, Carejoy Digital delivers Trios-level scanning accuracy at 40% lower TCO (Total Cost of Ownership), with full compatibility across open CAD/CAM platforms. This cost-performance leadership is reinforced by China’s national investment in Industry 4.0 infrastructure and smart manufacturing zones.

Support & Ecosystem Integration

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud portal; average response time < 8 minutes

- AI-Driven Software Updates: Monthly over-the-air (OTA) enhancements to scanning algorithms and material libraries

- Open API Access: Integration with exocad, DentalCAD, and in-house lab management systems

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios Dental.

✅ Open Architecture

Or WhatsApp: +86 15951276160