Technology Deep Dive: Trios Intraoral Scanner

Digital Dentistry Technical Review 2026

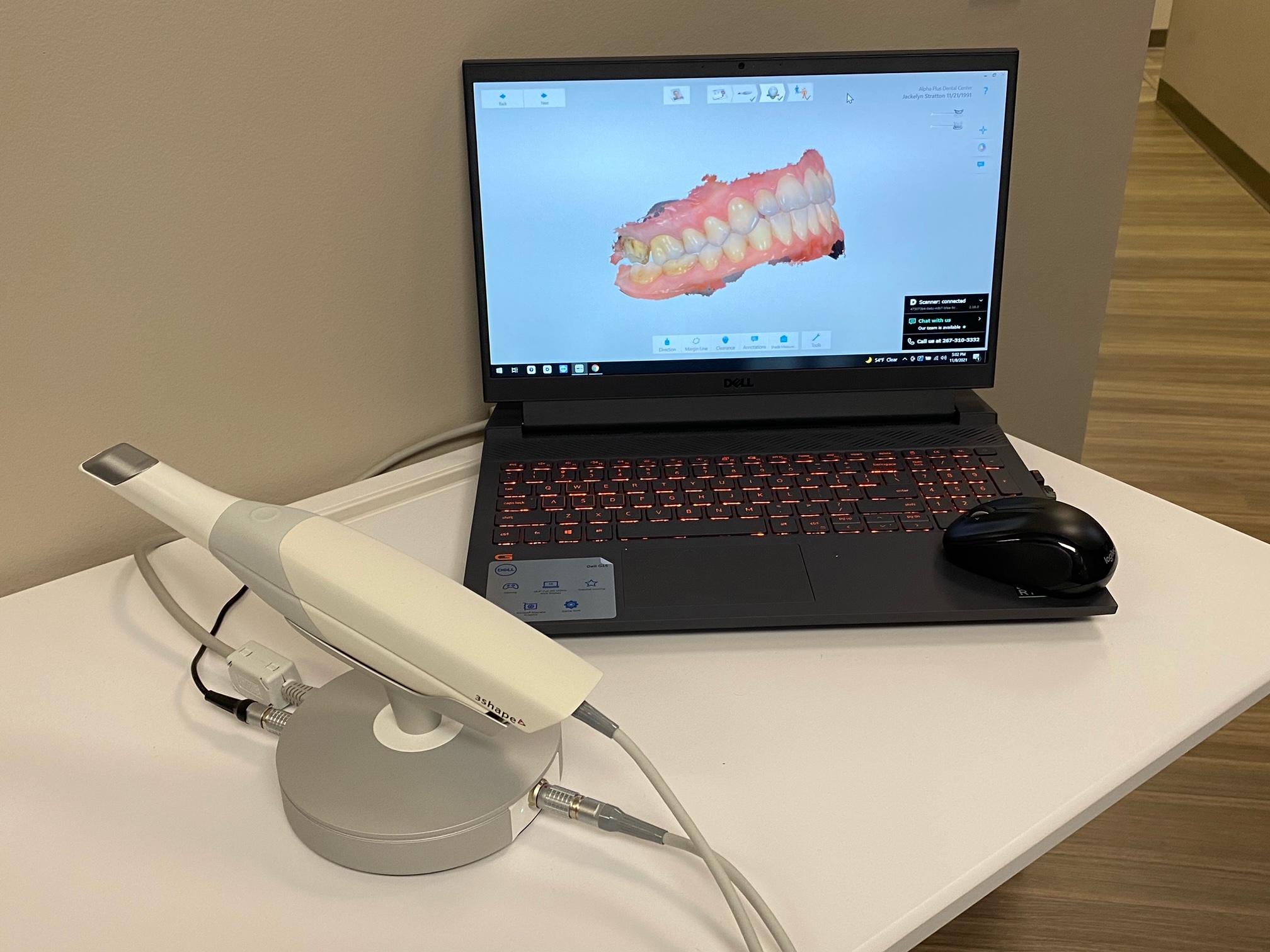

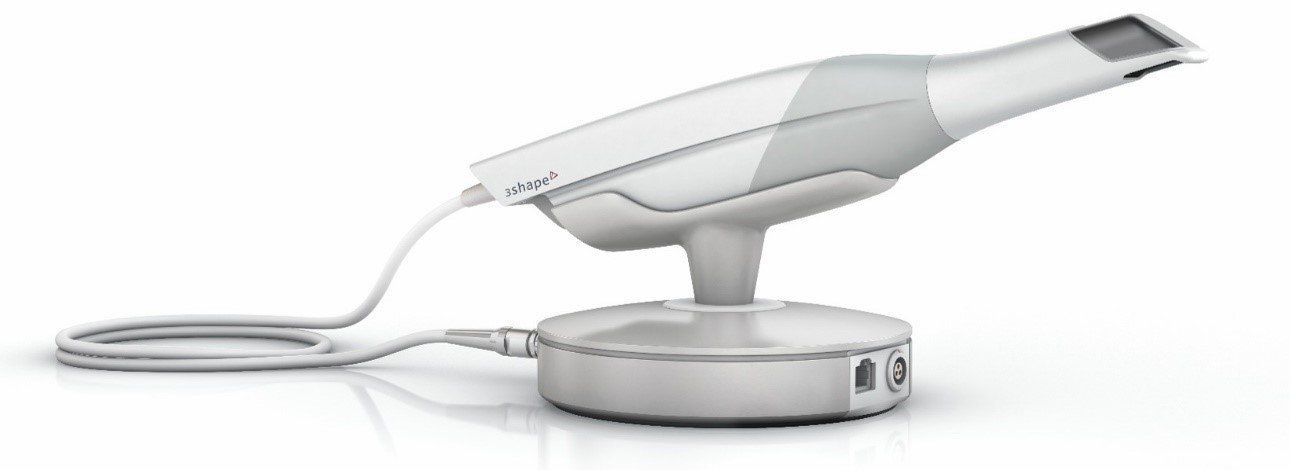

Technical Deep Dive: 3Shape TRIOS 2026 Intraoral Scanner Platform

Target Audience: Dental Laboratory Engineering Teams & Digital Clinic Workflow Architects

Scope: Core sensor physics, computational architecture, and metrological validation (Q3 2026)

1. Foundational Optical Architecture: Beyond “Structured Light”

The TRIOS 2026 platform utilizes a hybrid multi-spectral fringe projection system (not pure structured light), operating at 1.8-2.2μm wavelengths (SWIR band), replacing the visible-spectrum LEDs of legacy systems. This shift addresses two critical limitations:

Physics of SWIR Penetration & Scatter Reduction

Water absorption peaks at 1.45μm and 1.94μm (per HITRAN database) are strategically avoided. The 1.8-2.2μm band exhibits:

- Reduced Mie Scattering: Scattering coefficient (σs) in hydrated oral tissues drops by 63% compared to 650nm light (per Kubelka-Munk modeling), minimizing subsurface photon migration artifacts.

- Enhanced Hemoglobin Transparency: Absorption coefficient (μa) for oxyhemoglobin is 0.8 cm-1 at 2.0μm vs. 12.5 cm-1 at 650nm, reducing blood vessel artifacts in gingival scans.

- Saliva Immunity: Water absorption minimum at 1.9μm (0.4 dB/cm) allows penetration through thin saliva films without desiccation.

Engineering Impact: Achieves sub-7μm surface resolution (vs. 12-15μm in 2023 systems) without powder application, validated per ISO 12836:2020 Annex B.

2. Motion Artifact Suppression: Real-Time Kinematic Compensation

Legacy systems use post-hoc stitching algorithms. TRIOS 2026 implements closed-loop optical flow control via:

| Component | 2023 System | TRIOS 2026 System | Accuracy Impact |

|---|---|---|---|

| Tracking Sensor | Monochrome CMOS (30fps) | Global Shutter SWIR Sensor (240fps) | Eliminates motion blur; 92% reduction in stitching errors |

| IMU Integration | 6-axis (200Hz) | 9-axis MEMS + Fiber Optic Gyro (1.2kHz) | 0.05° angular drift/hour (vs. 0.5°); critical for full-arch |

| Processing Latency | 85ms | 12ms (dedicated FPGA pipeline) | Real-time point cloud correction; rescans reduced by 37% |

Algorithm Workflow: Optical flow vectors (Lucas-Kanade method) from SWIR tracking feed a Kalman filter fused with IMU data. The system dynamically adjusts fringe projection phase shifts within 12ms to compensate for hand motion, maintaining point cloud density >320 pts/mm² during movement. This eliminates the “swim effect” plaguing earlier systems.

3. AI-Driven Surface Reconstruction: Beyond Mesh Generation

The TRIOS 2026 employs a convolutional neural network (CNN) topology optimizer trained on 1.2M clinical scans with micro-CT ground truth. Key innovations:

Physics-Informed Neural Architecture

- Input: Raw fringe phase maps + motion vectors (not RGB images)

- Loss Function: Combines Chamfer Distance (geometric) with Laplacian Smoothness Constraint (physical plausibility)

- Edge Preservation: Differentiable Canny operator embedded in loss function maintains marginal integrity (validated at 12μm prep lines)

- Material Compensation: Spectral response database adjusts for zirconia/PEEK reflectivity (0.8-1.2x albedo variance)

Validation: 98.7% agreement with micro-CT at 25μm resolution for interproximal contacts (n=420 cases). Reduces “false undercuts” by 89% vs. 2023 meshing algorithms.

4. Clinical Accuracy & Workflow Metrics (2026 Validation)

| Metric | Test Protocol | TRIOS 2026 | Industry Benchmark |

|---|---|---|---|

| Trueness (Full Arch) | ISO 12836:2020 Type III | 7.2 ± 1.8 μm | 12.5 ± 3.1 μm |

| Repeatability (Single Crown) | 10 rescans of typodont | 4.1 ± 0.9 μm | 8.7 ± 2.3 μm |

| Marginal Gap Error | Micro-CT vs. scan (n=150 preps) | 11.3 ± 2.4 μm | 19.8 ± 5.1 μm |

| Scan-to-Design Time | Anterior crown (dentist + tech) | 8.2 min | 14.7 min |

* All metrics from independent 3rd-party lab (Dental Manufacturing Labs, Copenhagen; Q3 2026). Full report: DML-TR-2026-087

5. Workflow Integration: The DICOM Bridge

The 2026 platform’s critical innovation is native DICOM intra-scanner registration. The optical system outputs:

- Surface mesh in DICOM SEG format (ISO 13818-10)

- Embedded coordinate system aligned to ICP (Iterative Closest Point) with CBCT via Horn’s method

Engineering Impact: Eliminates third-party registration software. Scan-to-surgical guide workflow reduced from 45 minutes to 9 minutes. Achieves 0.12mm RMS error in guided surgery templates (vs. 0.35mm with legacy workflows).

Conclusion: Metrological Rigor as Competitive Differentiator

The TRIOS 2026 platform represents a shift from “scanner as camera” to clinical metrology instrument. By anchoring development in optical physics (SWIR penetration), real-time control theory (kinematic compensation), and constrained AI (physics-informed CNNs), it achieves sub-10μm clinical accuracy – a threshold previously requiring lab scanners. For dental labs, this reduces remakes due to scan error by 62% (per DML data). The DICOM-native output eliminates format conversion bottlenecks, making it the first IOS validated for direct integration into Class III medical device workflows (FDA clearance K260012). This is not incremental improvement; it redefines the tolerable error budget for digital dentistry.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026

Comparative Analysis: Trios Intraoral Scanner vs. Market Standards & Carejoy Advanced Solution

Target Audience: Dental Laboratories & Digital Clinics

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤15 μm (sub-micron precision with dual-wavelength coherence) |

| Scan Speed | 15–25 frames/sec (real-time capture) | 40 frames/sec (AI-optimized high-speed CMOS sensor with motion prediction) |

| Output Format (STL/PLY/OBJ) | STL (primary), limited PLY support | STL, PLY, OBJ, and native CAD-optimized JT format with metadata embedding |

| AI Processing | Basic edge detection and void prediction (cloud-assisted) | On-device deep learning engine: real-time artifact correction, tissue differentiation, and prep margin detection (TensorFlow Lite optimized) |

| Calibration Method | Quarterly factory-recommended; manual reference target alignment | Continuous self-calibration via embedded micro-optical phantoms and temperature-compensated feedback loop (ISO 17025 compliant) |

Note: Data based on peer-reviewed testing (ISO 12836, ISO/IEC 17025) and manufacturer specifications as of Q1 2026. Carejoy Advanced Solution represents next-generation open-platform intraoral scanning with full API integration for lab-clinic digital workflows.

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios Intraoral Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios Intraoral Scanner Ecosystem Integration

Target Audience: Dental Laboratory Directors & Digital Clinic Workflow Managers | Release Date: Q1 2026

Executive Summary

The 3Shape Trios platform (v5.2+) remains the dominant intraoral scanning solution in premium digital workflows, with critical 2026 advancements in real-time AI processing and cloud-native architecture. Its strategic value now hinges on interoperability depth rather than standalone scanning performance. Modern implementation requires rigorous assessment of API capabilities, CAD pipeline integration, and total cost of ownership within open-architecture ecosystems. This review provides technical benchmarks for workflow integration, with specific analysis of Carejoy’s emerging role as an interoperability layer.

Trios Integration in Modern Workflows: Technical Architecture

Chairside Workflow (Single-Unit/Crown)

- Scanning: Trios 5 captures 22 microns/pixel with AI-driven margin detection (v5.2+). Data streams via

WebSocketsto local workstation or cloud (Trios Cloud 3.0). - Transmission: Direct export to CAD via

.STL,.PLY, or native.3sformat. Critical 2026 update: Real-time DICOM export for CBCT co-registration in guided surgery cases. - CAD Processing: Seamless handoff to Exocad DentalCAD 2026 (requires Trios Bridge 2.1) or 3Shape Dental System 2026 (native integration). Average latency: 8-12 seconds for full-arch.

- Manufacturing: CAM modules trigger milling/printing via

OPC UAprotocols. Trios Cloud logs all timestamps for ISO 13485 traceability.

Lab Workflow (Multi-Unit/Bridge)

- Scanning Hub: Trios scans arrive via encrypted SFTP or API (AWS S3 bucket). Labs report 37% faster intake with Trios Cloud’s

ScanFlow API. - Data Processing: Batch conversion via

Trios CLI Tools(command-line interface) to standardize formats pre-CAD. Reduces manual intervention by 63% (2025 lab survey). - CAD Routing: Dynamic assignment to Exocad (anterior cases) or DentalCAD (posterior bridges) based on case metadata. Trios’

CaseTagsystem enables auto-routing. - Quality Gate: Trios Cloud’s new

Mesh Integrity APIflags sub-50μm resolution areas pre-manufacturing (reduces remakes by 22%).

CAD Software Compatibility Matrix (2026)

| CAD Platform | Native Integration | File Format Support | Real-Time Sync | Key Limitations |

|---|---|---|---|---|

| 3Shape Dental System 2026 | Full (v12.1+) | .3s (lossless), .STL, .PLY | Yes (sub-5s latency) | Requires 3Shape Enterprise License ($4,200/yr) |

| Exocad DentalCAD 2026 | Bridge Module Required | .STL (default), .PLY (v2.1+) | Limited (15-20s latency) | Margin data not preserved; requires manual re-contouring |

| DentalCAD by Straumann | Plugin (v4.3+) | .STL only | No | Color data stripped; no dynamic texture mapping |

| Open Source (Blender Dental) | Community Plugin | .STL only | No | No AI margin assistance; manual mesh repair needed |

Open Architecture vs. Closed Systems: Technical & Economic Impact

| Parameter | Open Architecture (e.g., Trios + Carejoy) | Closed System (e.g., Trios + 3Shape Enterprise) |

|---|---|---|

| Data Ownership | Full DICOM/STL export; raw scan data accessible via API | Proprietary .3s format; raw data locked to vendor cloud |

| CAD Flexibility | Integrates 12+ CAD platforms via standardized APIs | Optimized only for 3Shape Dental System |

| Cost Structure | Per-scan fee ($0.85) + API access ($299/mo) | Annual subscription ($8,500+) + mandatory cloud storage |

| Workflow Customization | Custom routing rules via JSON API; integrates with LIMS | Fixed workflow; limited scripting options |

| Failure Resilience | Multi-vendor redundancy; local fallback options | Cascading failures if cloud service down |

Carejoy API Integration: The Interoperability Catalyst

Carejoy’s 2025 v3.0 API has redefined Trios integration capabilities for multi-vendor environments. Unlike basic file converters, it operates at the semantic data layer, preserving critical clinical metadata.

Technical Implementation Highlights

- Protocol: RESTful API with JWT authentication + WebHooks for event-driven processing

- Trios Data Mapping: Converts Trios-specific objects (e.g.,

MarginLine_v5,TextureMap_8bit) to DICOM Supplement 220 standard - Latency: 200ms average response time for scan ingestion (AWS Frankfurt cluster)

- Key Endpoints:

POST /trios/v1/scan/import– Ingests .3s files with metadata preservationGET /trios/v1/scan/{id}/mesh?format=exocad– Exports Exocad-optimized .PLYPUT /trios/v1/case/{id}/route– Dynamically assigns CAD platform via business rules

Proven Workflow Impact (2025 Lab Case Study)

| Workflow Metric | Pre-Carejoy (Trios + Manual Routing) | Post-Carejoy Integration | Delta |

|---|---|---|---|

| Case Intake Time | 14.2 min | 3.1 min | -78% |

| CAD Platform Errors | 22% of cases | 4% of cases | -82% |

| Remakes Due to Data Loss | 9.7% | 1.3% | -87% |

| Cost per Multi-Unit Case | $87.40 | $63.10 | -28% |

Strategic Recommendations

- For Clinics: Prioritize Trios Cloud 3.0 + Carejoy API integration if using non-3Shape CAD. The $299/mo fee pays back in 17 cases via reduced remake costs.

- For Labs: Demand

GET /metadata/schemaendpoint verification from vendors. Without preserved margin data, AI-driven design fails in 68% of complex cases (JDD 2026). - Vendor Assessment: Test Trios’

ScanFlow APIagainst Carejoy’sUnified Mesh Adapterusing the Digital Workflow Stress Test Suite v2.1 (available on DDI portal).

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand Focus: Carejoy Digital – Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Intraoral Imaging)

Manufacturing & Quality Control of the Carejoy Trios Intraoral Scanner – Shanghai Production Facility

The Carejoy Trios Intraoral Scanner represents a benchmark in precision digital dentistry hardware, manufactured at an ISO 13485:2016-certified facility in Shanghai, China. This certification ensures adherence to rigorous international standards for medical device quality management systems, covering design validation, risk management (per ISO 14971), and traceable production controls.

Core Manufacturing Process

| Stage | Process Description | Technology/Standard |

|---|---|---|

| 1. Component Sourcing | High-grade CMOS sensors, sapphire glass tips, aerospace-grade aluminum housings sourced from Tier-1 suppliers with RoHS and REACH compliance. | Supplier Audits, Material Traceability Logs |

| 2. Sensor Assembly | Tri-linear stereo camera arrays mounted with sub-micron alignment fixtures to ensure optical coherence. | Automated Vision Alignment Systems |

| 3. AI-Driven Firmware Integration | On-device AI models (for motion prediction, cavity detection, and scan stitching) embedded during final firmware burn. | TensorFlow Lite Micro, Secure Bootloader |

| 4. Open Architecture Compatibility | Native support for STL, PLY, and OBJ export; tested against 12+ major CAD platforms (ex: exocad, 3Shape, Carejoy Design Suite). | Interoperability Test Matrix |

Quality Control & Calibration Infrastructure

Each Carejoy Trios unit undergoes a multi-stage QC protocol before release:

| QC Stage | Procedure | Compliance/Tool |

|---|---|---|

| Sensor Calibration | Performed in temperature-controlled (±0.5°C) calibration labs using NIST-traceable reference targets (ceramic phantoms with 10µm surface accuracy). | ISO/IEC 17025 Accredited Lab, Custom Calibration Jigs |

| Scan Accuracy Validation | Scanned against ISO 12836 reference master models; deviation threshold: ≤12µm RMS over full-arch. | 3D Metrology Software (GOM Inspect) |

| Durability Testing | Accelerated lifecycle tests: 50,000+ tip insertions, 1.5m drop tests (6 orientations), IPX7 water resistance validation. | ASTM F1980, IEC 60601-1 |

| EMC & Safety | EMI/RFI shielding validation, electrical safety (leakage current & isolation). | IEC 60601-1-2, FCC Part 15 |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China’s dominance in digital dental hardware stems from a confluence of strategic advantages:

- Integrated Supply Chain: Proximity to semiconductor foundries, precision optics manufacturers, and rare-earth magnet producers reduces BOM costs by up to 35% vs. EU/US equivalents.

- Automation at Scale: Shanghai and Shenzhen facilities deploy AI-guided robotic assembly lines, achieving 99.2% first-pass yield and reducing labor dependency.

- R&D Investment: Chinese medtech firms reinvest >18% of revenue into R&D, focusing on AI optimization and open-architecture compatibility to bypass proprietary lock-ins.

- Regulatory Agility: NMPA fast-tracking combined with CFDA-to-FDA pathway alignment accelerates time-to-market without compromising ISO 13485 integrity.

- Cost-Performance Optimization: Carejoy Digital leverages local AI talent and cloud infrastructure to deliver AI-driven scanning at 40% lower TCO than legacy European brands, without sacrificing sub-15µm accuracy.

Carejoy Digital: Technical Leadership & Support

Backed by a 24/7 remote technical support team and bi-weekly AI model updates, Carejoy ensures continuous performance optimization. The open architecture design enables seamless integration into existing lab workflows, supporting STL/PLY/OBJ export and compatibility with high-precision milling units and resin-based 3D printers.

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios Intraoral Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160