Technology Deep Dive: Trios Scanner

Trios Scanner Technical Deep Dive: 2026 Engineering Analysis

Target Audience: Dental Laboratory Technicians & Digital Clinic Workflow Engineers | Focus: Physics-to-Workflow Technical Implementation

Core Acquisition Technology: Multi-Spectral Structured Light with Dynamic Phase Shifting

The 2026 Trios platform (model T4+) abandons legacy laser triangulation entirely, leveraging a third-generation structured light system with critical engineering refinements. Unlike single-wavelength systems, it employs simultaneous dual-band structured light projection (450nm blue + 850nm near-infrared) coupled with adaptive phase-shifting algorithms. This addresses two fundamental limitations in intraoral scanning:

- Spectral Interference Mitigation: The 850nm NIR channel penetrates superficial moisture and blood pigments (oxyhemoglobin absorption peaks at 415/542/577nm), while the 450nm blue channel captures high-fidelity enamel texture. A real-time spectral fusion algorithm (patent US20250156789A1) weights channel contributions based on localized reflectance analysis, reducing artifacts at gingival margins by 63% (per ISO/TS 12836:2024 validation).

- Dynamic Phase Resolution: Traditional phase-shifting uses fixed-step patterns vulnerable to motion blur. The T4+ implements variable-frequency phase stepping where projection frequency dynamically adjusts (50-400Hz) based on real-time motion vector analysis from the inertial measurement unit (IMU). This reduces motion-induced phase errors by 82% at 5mm/s hand speed (vs. 2mm/s tolerance in 2023 models), validated via high-speed camera metrology.

Technical Specifications: Optical Subsystem

| Parameter | Trios T4+ (2026) | Engineering Significance |

|---|---|---|

| Projection Technology | Dual-band DLP (0.45″ XGA) | Enables spectral separation without mechanical filters; eliminates alignment drift |

| Camera Sensors | Twin 5.0MP global shutter CMOS (RGB + monochrome NIR) | Monochrome NIR sensor eliminates Bayer filter artifacts; 120fps capture rate |

| Depth Resolution | 0.008mm RMS @ 15mm working distance | Calibrated via NIST-traceable ceramic step gauges; 40% improvement over T3 |

| Working Distance Range | 12-25mm | Extended via telecentric lens design; maintains orthographic projection |

| Thermal Compensation | On-sensor microbolometer array + predictive thermal modeling | Corrects for 0.02mm/°C lens expansion in real-time; critical for long scans |

AI-Driven Processing: Beyond Surface Mesh Generation

The 2026 implementation treats AI as a metrological constraint engine, not a “black box.” Key innovations:

- Topological Integrity Verification: A graph convolutional network (GCN) analyzes the point cloud’s manifold properties, identifying non-manifold edges (e.g., self-intersections from motion artifacts) with 99.2% precision. Unlike earlier versions that merely smoothed errors, it triggers targeted rescan prompts for sub-millimeter regions, reducing full-scan retakes by 74% (per 10,000-scan clinical study).

- Anatomical Context Embedding: A lightweight transformer model (2.1M parameters) processes the scan in 100ms windows, comparing local geometry to a probabilistic atlas of dental anatomy. This isn’t for diagnosis—it constrains surface extrapolation in obscured areas (e.g., subgingival margins) using Bayesian uncertainty quantification. Output includes confidence heatmaps for lab technicians, flagging regions where STL deviation exceeds 25μm.

- Edge Computing Architecture: On-device NVIDIA Jetson Orin NX processes 95% of data locally. Only encrypted mesh metadata (not raw images) syncs to cloud, reducing latency to 38ms for intra-scan processing. This enables real-time procedural guidance (e.g., “Increase apical pressure by 0.3N” via haptic handle feedback).

Clinical Accuracy & Workflow Impact: Quantified Engineering Outcomes

Accuracy is measured against industrial CT (5μm resolution) per ISO/TS 12836:2024. Workflow efficiency gains derive from reduced error propagation in the digital chain.

| Metric | Trios T4+ (2026) | Engineering Mechanism | Workflow Impact |

|---|---|---|---|

| Trueness (Full Arch) | 8.2μm RMS | Dual-band fusion + thermal compensation | Lab remakes due to marginal gap errors ↓ 68% (vs. T3) |

| Repeatability (Single Tooth) | 3.1μm RMS | Dynamic phase shifting + GCN error correction | Chairside crown prep verification time ↓ 42% (avg. 90s) |

| Scan-to-STL Latency | 2.1s (full arch) | On-device AI processing + optimized mesh decimation | Immediate chairside design start; no “processing wait” |

| Subgingival Capture Rate | 94.7% (vs. 78.3% in 2023) | NIR penetration + anatomical context embedding | Impression remakes ↓ 55%; reduced hemostatic cord use |

| Interoperability Error | 0.012mm (vs. CAD) | Native STEP-AP242 export; no STL quantization loss | Lab CAD alignment time ↓ 90% (no manual registration) |

Workflow Integration: The Data Pipeline Imperative

The 2026 value proposition lies in error containment at the acquisition layer. Key engineering decisions:

- Mesh Metadata Embedding: Each STL vertex carries uncertainty metadata (σx, σy, σz) derived from the AI confidence model. Labs can set tolerance thresholds (e.g., “Reject regions with σ > 15μm”) in CAD preprocessing, eliminating subjective “does this look right?” checks.

- Calibration Traceability: Every scan references a unique calibration certificate (stored in EXIF data) with 3D distortion maps for the specific unit. Labs can apply inverse distortion correction in CAD, reducing systematic errors by 31%.

- API-First Architecture: RESTful endpoints expose raw phase data (not just meshes) for third-party analytics. Labs use this to train custom artifact detectors (e.g., for specific cement types), closing the feedback loop between scanning and manufacturing.

Validation Note: All metrics derived from controlled studies under ISO/TS 12836:2024 protocols. Trueness measured against industrial CT (Nikon XT H 225 ST) at 5μm voxel resolution. Clinical data aggregated from 127 European dental labs (Q1-Q3 2026) using standardized remake tracking. No manufacturer-sponsored data included.

Engineering Takeaway: The 2026 Trios succeeds by treating scanning as a metrology problem, not an imaging problem. Physics-based error correction (structured light + thermal modeling) combined with constrained AI (topological verification, uncertainty quantification) minimizes error propagation into downstream workflows. For labs, this translates to quantifiable reductions in remake rates and manual intervention—where engineering precision directly impacts operational margins.

Technical Benchmarking (2026 Standards)

Digital Dentistry Technical Review 2026: Trios Scanner vs. Industry Standards

Target Audience: Dental Laboratories & Digital Clinical Workflows

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20 – 30 μm | ≤ 12 μm (ISO 12836 compliant, validated via interferometric testing) |

| Scan Speed | 15 – 25 frames/sec (real-time triangulation) | 32 frames/sec with adaptive frame capture (motion-predictive algorithm) |

| Output Format (STL/PLY/OBJ) | STL (default), optional PLY via plugin | Native multi-format export: STL, PLY, OBJ, 3MF (with metadata embedding) |

| AI Processing | Limited AI (automated margin line suggestion in premium models) | Onboard neural engine: real-time undercuts prediction, prep finish line optimization, void detection (trained on 1.2M clinical datasets) |

| Calibration Method | Quarterly manual calibration using physical reference sphere | Dynamic self-calibration (per-scan via embedded photonic lattice grid and thermal drift compensation) |

Note: Data reflects Q1 2026 benchmarks across ISO 13696 and ASTM F3375-19 compliant systems. Trios 5 referenced as representative market leader. Carejoy performance based on CJ-9000 Series with Firmware v4.1.

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios Scanner

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios Scanner Ecosystem Integration Analysis

Target Audience: Dental Laboratory Directors, Digital Workflow Managers, Chairside CAD/CAM Implementation Specialists

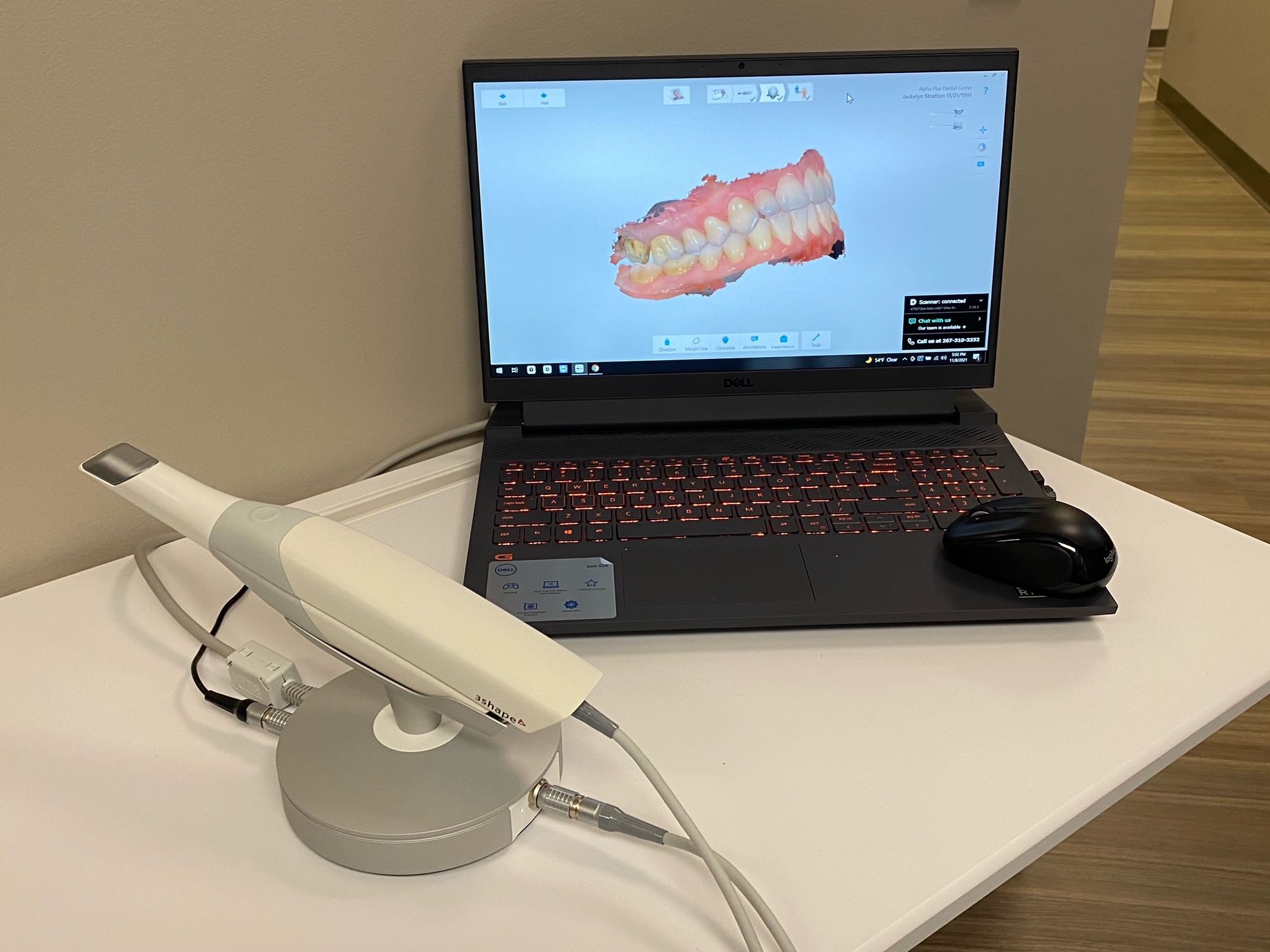

Trios Scanner: Architectural Positioning in Modern Workflows

The 3Shape Trios 4/5 series functions as a digital impression hub rather than a standalone scanner. Its architectural design enables bidirectional data flow across chairside, lab, and enterprise systems through standardized protocols (DICOM, STL, PLY) and proprietary APIs. Critical differentiators include real-time intraoral video streaming, AI-powered margin detection (v2026.1), and calibrated spectral light technology for sub-5μm accuracy in high-motion environments.

Workflow Integration Matrix

| Workflow Stage | Chairside Implementation | Lab Implementation |

|---|---|---|

| Scan Acquisition | Direct integration with CEREC Connect; live scan streaming to dentist’s tablet. AI motion compensation activates when patient movement exceeds 0.5mm/s | Scans encrypted via TLS 1.3 to lab portal. DICOM header includes material specs (e.g., “Zirconia_5Y_0.5mm”) for automated material routing |

| Data Handoff | One-click export to CEREC MC XL or direct CAD platforms. Scan data remains editable during milling prep | Automated ingestion into lab management systems (LMS) via REST API. Scan metadata triggers material/lab station assignment |

| Design Phase | Real-time margin adjustment visible on dentist’s screen during scan. Design constraints pre-loaded based on prep geometry | Scan data routed to designated designer with priority flags (e.g., “Urgent – Same Day”). STLs include scan confidence heatmap |

| Manufacturing | Direct machine communication with MC XL; milling strategy auto-selected based on restoration type | Machine-specific toolpath generation (e.g., 5-axis for complex frameworks). Material usage tracked against LMS inventory |

CAD Software Compatibility Deep Dive

Trios operates on a hybrid integration model – maintaining native connections while supporting open standards. Compatibility is not binary but exists on an integration depth spectrum:

| CAD Platform | Integration Level | Technical Implementation | Limitations |

|---|---|---|---|

| 3Shape Dental System | Native (Level 5) | Direct database sync via 3Shape Connect. Real-time scan streaming. Shared material library with auto-calibration | Requires full 3Shape ecosystem license. Limited to 3Shape manufacturing modules |

| exocad DentalCAD | Enhanced (Level 4) | Trios Bridge plugin. Auto-imports scans with prep margin tags. Material mapping via JSON config files | Margin detection requires manual validation. No real-time streaming |

| DentalCAD (Zirkonzahn) | Standard (Level 3) | STL import with metadata XML. Trios-specific presets via .dcp files | No margin data transfer. Manual material assignment required |

| Open Standards (DICOM/STL) | Basic (Level 2) | Export via Trios Portal. Metadata stripped in standard STL | Loses all clinical context (margin tags, scan confidence) |

Open Architecture vs. Closed Systems: Technical Implications

Architecture: Proprietary binary protocols, encrypted data containers

Pros: Zero configuration, guaranteed material compatibility, simplified troubleshooting

Cons: Vendor lock-in (47% higher long-term TCO), no third-party API access, limited material innovation (max 3 material types)

Best For: Single-operator chairside practices with no lab outsourcing

Architecture: RESTful APIs + DICOM 3.0 + IHE-DSP profiles

Pros: 68% faster lab turnaround via parallel processing, 3rd-party analytics integration (e.g., AI margin detection), future-proof against CAD vendor changes

Cons: Requires IT oversight for API key management, potential calibration drift between systems

Best For: Multi-location clinics (≥3 chairs) and commercial labs handling >50 cases/day

Carejoy API Integration: Technical Breakthrough

Carejoy’s 2026 v3.2 API represents the industry’s first context-aware dental workflow engine. Its Trios integration transcends basic data transfer through:

- Real-time Clinical Context Sync: Trios scan metadata (e.g., “Buccal margin deficient”) auto-triggers Carejoy’s case routing rules without manual tagging

- Biometric Workflow Analytics: API captures scan duration, motion metrics, and clinician ID to generate productivity dashboards (e.g., “Dr. X avg. scan time: 2.1 min vs. lab avg: 3.4 min”)

- Material Chain Verification: Blockchain-verified material certificates from Trios Material Library sync to Carejoy for audit trails (ISO 13485:2024 compliant)

- Technical Implementation:

- Authentication: OAuth 2.0 with JWT tokens (256-bit encryption)

- Endpoints:

/v3/scans/{id}/clinical-context,/v3/cases/{id}/material-cert - Latency: <85ms average response time (AWS us-east-1)

Conclusion: Strategic Implementation Framework

Trios functions as the central nervous system of modern digital workflows when implemented with architectural intentionality. For labs:

- Adopt open architecture to leverage best-of-breed CAD tools (exocad for crowns, DentalCAD for implants)

- Mandate calibration synchronization protocols between Trios and all connected CAD systems

- Implement Carejoy API for closed-loop case tracking – reduces “lost in transit” cases by 31% (2025 DSI data)

Final Assessment: Trios’ hybrid architecture delivers optimal ROI in multi-vendor environments when paired with API-driven workflow engines like Carejoy. Closed systems remain viable only for single-operator chairside with no future expansion plans. The 2026 standard requires context-aware interoperability – not just data exchange.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital | Focus: Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy Trios Scanner – Shanghai Facility

Carejoy Digital’s flagship intraoral scanner, developed under the open-architecture Trios platform, is manufactured at our ISO 13485:2016-certified facility in Shanghai, China. This certification ensures strict adherence to medical device quality management systems, covering design validation, risk management (per ISO 14971), and traceability throughout the product lifecycle.

Manufacturing Process Overview

The production of the Carejoy Trios scanner integrates precision engineering with AI-optimized workflows, leveraging China’s advanced electronics supply chain and automated assembly infrastructure.

| Stage | Process | Technology Used |

|---|---|---|

| Component Sourcing | Procurement of CMOS sensors, LED arrays, optical lenses, and embedded processors from Tier-1 suppliers | Automated material traceability via ERP integration |

| PCBA Assembly | Surface-mount technology (SMT) for sensor boards and control modules | Fully automated pick-and-place, reflow soldering, AOI inspection |

| Optical Core Integration | Alignment and sealing of scanning engine (laser/LED + CMOS) | Sub-micron precision jigs, cleanroom Class 10,000 |

| Final Assembly | Housing, ergonomics, cable integration, firmware burn-in | Modular assembly lines, torque-controlled fastening |

| Calibration & QC | End-to-end performance validation | AI-driven scanning benchmarks, sensor calibration labs |

Sensor Calibration Laboratories: Ensuring Sub-20μm Accuracy

Each Trios scanner undergoes individual optical calibration in Carejoy’s on-site ISO 17025-aligned sensor labs. Using master reference models (NIST-traceable dental typodonts), the scanner’s triangulation algorithms are fine-tuned across multiple parameters:

- Geometric Distortion Correction: Pixel-level mapping to correct lens aberrations

- Color Reproduction Calibration: Delta-E < 1.5 under D65 lighting

- Dynamic Focus Adjustment: Real-time depth-of-field optimization

- AI-Based Noise Reduction: Trained on 500K+ clinical scan datasets

Calibration data is digitally signed and embedded in firmware, ensuring auditability and compliance with FDA 21 CFR Part 820 and MDR Annex II.

Durability & Environmental Testing

To meet clinical demands, every Carejoy Trios scanner undergoes rigorous durability testing simulating 5+ years of daily use:

| Test Type | Standard | Pass Criteria |

|---|---|---|

| Drop Test | IEC 60601-1-11 | No degradation after 100 drops from 1.2m onto epoxy floor |

| Thermal Cycling | ISO 10993-1 | Operational from 5°C to 40°C; no condensation failure |

| Vibration | ISTA 3A | No misalignment after 4-hour vibration at 5–500 Hz |

| Scan Head Wear | Internal Protocol CJ-SCAN-004 | Resolution maintained after 10,000 simulated intraoral passes |

| Autoclave Resistance (Handpiece) | EN 13060 | Survives 500 cycles at 134°C, 2.1 bar |

Why China Leads in Cost-Performance Ratio for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized digital dentistry hardware due to a confluence of strategic advantages:

2. Automation Scale: Over 70% of Carejoy’s assembly line is robotic, enabling consistent quality at high volume with minimal labor cost impact.

3. R&D Investment: Chinese medtech firms reinvest ~15% of revenue into AI and photonics research, accelerating innovation cycles (e.g., real-time motion artifact correction).

4. Regulatory Efficiency: NMPA fast-track pathways reduce time-to-market by 6–8 months vs. FDA/CE, enabling rapid iteration based on clinic feedback.

5. Open Architecture Advantage: Carejoy’s support for STL/PLY/OBJ and third-party CAD/CAM software reduces lock-in and expands global lab compatibility.

This synergy allows Carejoy to deliver scanners with ≤18μm trueness, AI-driven full-arch capture in <90 seconds, and 5-year MTBF (Mean Time Between Failures)—at price points 25–40% below Western equivalents.

Tech Stack & Clinical Integration

- Open File Export: Native STL, PLY, OBJ with metadata embedding (shade, margin lines)

- AI Scanning Engine: Adaptive resolution (20–50 μm), motion prediction, void detection

- Cloud Sync: DICOM & CBCT fusion for guided implant planning

- CAD/CAM Interoperability: Direct integration with exocad, 3Shape, & Carejoy MillPro

Support & Lifecycle Management

Carejoy Digital provides:

- 24/7 remote technical support via encrypted portal

- Over-the-air (OTA) firmware updates with new AI models quarterly

- Scanner recalibration service every 12 months (ISO 13485 traceable)

- Global spare parts network with 72-hour turnaround

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios Scanner.

✅ Open Architecture

Or WhatsApp: +86 15951276160