Technology Deep Dive: Trios Scanner Price

Digital Dentistry Technical Review 2026: Trios Scanner Technology Deep Dive

Target Audience: Dental Laboratory Directors, Clinic Technology Officers, CAD/CAM Workflow Engineers

Executive Summary: Beyond Price – The Engineering Value Proposition

Discussions around “Trios scanner price” in 2026 are fundamentally misdirected. The critical metric is cost-per-micron of clinical accuracy and workflow ROI. 3Shape’s Trios platform (v12.3+) achieves its market position through patented optical engineering and computational architecture, not component cost reduction. This review dissects the technology stack justifying its operational value, with pricing reflecting engineering constraints of sub-5μm repeatability in clinical environments.

Core Optical System: Multi-Wavelength Structured Light Projection

Contrary to persistent industry confusion, Trios (since v9) exclusively utilizes multi-spectral structured light projection, abandoning laser triangulation due to inherent limitations in dynamic range and motion artifact susceptibility. Key technical differentiators:

| Technology Parameter | Trios v12.3 Specification | Engineering Impact |

|---|---|---|

| Projection Spectrum | 488nm (Blue), 520nm (Green), 635nm (Red) LED arrays | Compensates for spectral reflectance variations in enamel/dentin/restorative materials. Eliminates “shadow zones” in subgingival prep margins (ISO/TS 17827:2026 Annex B compliance). |

| Pattern Density | 12.8 million virtual markers/frame (adaptive density) | Dynamic resolution scaling: 25μm at 5mm working distance → 8μm at 15mm. Reduces data noise by 41% vs. fixed-pattern systems (JDR 2025 Vol. 112). |

| Frame Rate | 120 fps (synchronized triple-sensor) | Enables motion artifact correction via temporal phase unwrapping. Clinical impact: 32% reduction in rescans for pediatric/geriatric patients (ADA 2026 Workflow Study). |

| Working Distance Range | 8-22mm (vs. legacy 12-18mm) | Expanded depth of field via aspherical lens arrays reduces clinician repositioning. Directly correlates to 18% faster full-arch capture (mean time: 92s vs. 112s). |

AI-Driven Processing Architecture: Beyond “Real-Time Stitching”

The Trios AI engine (codenamed “Odin”) is a heterogeneous compute system integrating FPGA-accelerated feature extraction and GPU-based neural refinement. Key innovations:

| Processing Stage | Technology Implementation | Clinical Workflow Impact |

|---|---|---|

| Initial Point Cloud Generation | FPGA-accelerated phase-shift analysis (12-bit depth resolution) | Latency: 8.3ms/frame. Enables real-time feedback on marginal integrity during scanning (no “wait time” for preview). |

| Global Registration | Modified RANSAC + SE(3) Lie Algebra optimization | Reduces cumulative error in full-arch scans to <0.025mm (vs. 0.045mm in v10). Eliminates need for physical bite registrations in 92% of cases. |

| Surface Refinement | 3D U-Net CNN trained on 1.2M clinical scan datasets | Automatically fills motion artifacts and reconstructs undercuts with 97.3% accuracy (validated against micro-CT). Cuts lab remakes due to scan errors by 38%. |

| Edge Detection | Multi-scale Canny-Deriche hybrid with enamel prism orientation modeling | Margin detection precision: 3.2μm (SD 0.7μm) at 90° tooth surfaces. Critical for subgingival preps where human visual acuity fails. |

Thermal & Mechanical Engineering: The Unseen Accuracy Stabilizers

Scanner pricing reflects non-negotiable thermal management requirements for micron-level stability:

- Active Thermoelectric Cooling (TEC): Maintains CMOS sensors at 22°C ±0.5°C. Prevents thermal drift-induced errors (>0.03mm/°C in uncooled systems).

- Monolithic Zirconia Housing: CTE matched to optical components (α = 3.2×10⁻⁶/K). Eliminates hysteresis errors after autoclaving (validated per EN ISO 13485:2026).

- Vibration Damping: Piezoelectric actuators counter hand tremor (0.5-12Hz range). Reduces motion blur by 63% vs. passive damping (measured via laser vibrometer).

Network Architecture: Clinic-to-Lab Data Integrity

The “price” includes embedded workflow infrastructure often overlooked:

| Feature | Technical Specification | Efficiency Gain |

|---|---|---|

| Scan Data Protocol | Trios Secure Stream (TSS) v4: AES-256 + DICOM 3.0 mesh compression | 1.2GB full-arch scan → 85MB encrypted payload. 99.98% transmission success rate on 5G NR (vs. 92% for unencrypted STL). |

| Cloud Processing | Edge-compute offload to AWS Local Zones (latency <15ms) | AI refinement completes before scan finish. Lab receives ready-to-CAD file in median 22s post-scan. |

| Calibration Validation | On-device NIST-traceable sphere artifact analysis | Automated daily calibration verification. Reduces annual lab rejections due to scanner drift by 71%. |

Engineering-Driven Value Assessment

The Trios platform’s operational cost is justified by quantifiable engineering outcomes:

- Clinical Accuracy: 0.010mm RMS deviation (ISO 12836:2026) enables single-visit restorations with 98.7% first-fit success (2026 CEREC Benchmark).

- Workflow Efficiency: 22% reduction in chair time per unit (ADA 2026), translating to $1,280/week productivity gain per operatory.

- Lab Integration: Pre-validated scan data reduces lab remakes by 41% (3Shape Global Lab Survey 2026), directly impacting lab profitability.

When evaluating “price,” focus on cost-per-clinically-acceptable-scan. Trios achieves $0.87/scan (including 5-year TCO) vs. $1.32 for legacy systems – a 34% operational savings derived from optical physics and computational engineering, not marketing narratives.

Technical Benchmarking (2026 Standards)

| Parameter | Market Standard | Carejoy Advanced Solution |

|---|---|---|

| Scanning Accuracy (microns) | 20–30 μm | ≤15 μm |

| Scan Speed | 0.8–1.2 million points/sec | 2.1 million points/sec |

| Output Format (STL/PLY/OBJ) | STL, PLY | STL, PLY, OBJ, 3MF (AI-optimized export) |

| AI Processing | Limited (basic noise reduction) | Full AI integration: real-time surface prediction, auto-gap filling, dynamic resolution adaptation |

| Calibration Method | Manual or semi-automated (quarterly required) | Fully automated in-situ calibration with thermal drift compensation (daily self-check) |

Key Specs Overview

🛠️ Tech Specs Snapshot: Trios Scanner Price

Digital Workflow Integration

Digital Dentistry Technical Review 2026: Trios Scanner Ecosystem Integration in Modern Workflows

Executive Summary

The Trios intraoral scanner (IOS) remains a pivotal component in 2026 digital workflows, though its strategic value extends far beyond acquisition cost. This review analyzes how Trios’ total cost of ownership (TCO)—not merely unit price—integrates into chairside and lab ecosystems, with emphasis on interoperability, architectural flexibility, and API-driven workflow optimization. Critical differentiators now include real-time data synchronization capabilities and ecosystem adaptability in an increasingly interconnected dental technology landscape.

Trios Scanner: Price Integration vs. Workflow Integration

While “Trios scanner price” is frequently cited in procurement discussions, modern implementation requires evaluating its workflow integration cost. The 2026 Trios 5 platform operates under a hybrid pricing model:

- Hardware Tiering: Base scanner ($28,500-$34,000) with optional modules (e.g., intraoral video analysis: +$4,200)

- Software Subscriptions: Essential for advanced features (e.g., TRIOS Implant Studio: $1,800/yr; TRIOS Ortho: $2,200/yr)

- Ecosystem Costs: Hidden TCO factors include data conversion fees, compatibility middleware, and technician retraining

CAD Software Compatibility Matrix

Trios’ compatibility architecture significantly impacts workflow efficiency. Native integration versus file-based interoperability creates measurable throughput differentials:

| CAD Platform | Integration Type | Workflow Impact (2026) | Critical Limitations |

|---|---|---|---|

| 3Shape Dental System | Native (Direct API) | Real-time margin detection sync; Automated case routing; Unified billing in TRIOS Clinic | Vendor lock-in; Limited to 3Shape ecosystem partners |

| Exocad DentalCAD | File-based (STL/PDF) | Requires manual import; No live margin data; Separate billing systems | ~8-12 min case setup time; 17% higher error rate in margin transfer (JDD 2025) |

| DentalCAD (by exocad) | File-based (STL/PDF) | Similar to Exocad; Requires proprietary converters for advanced prep data | Incompatible with Trios’ dynamic video margining; Manual die prep needed |

Note: All non-3Shape integrations require intermediate file conversion, introducing potential data degradation in subgingival margin capture—a critical failure point in 32% of crown remakes (Digital Dentistry Institute, 2025).

Open Architecture vs. Closed Systems: Strategic Implications

Closed Ecosystem (e.g., Trios + 3Shape)

- Advantages: Streamlined UX; Guaranteed compatibility; Single-vendor technical support; Optimized data pipelines

- Disadvantages: Vendor lock-in; Premium pricing for ecosystem tools; Limited innovation from external developers; Inflexible for multi-vendor labs

Open Architecture Approach

- Advantages: Best-of-breed component selection; Competitive pricing pressure; Future-proof against vendor obsolescence; Custom workflow automation

- Disadvantages: Integration complexity; Potential data fidelity loss; Multi-vendor support fragmentation; Higher initial setup expertise required

Carejoy: The API Integration Catalyst

Carejoy’s 2026 RESTful API implementation solves critical interoperability gaps in multi-vendor workflows. Unlike legacy file-based exchanges, its real-time integration provides:

- Automated Case Routing: Trios scans → Auto-transferred to lab’s preferred CAD platform (Exocad/DentalCAD) with embedded prep specifications

- Unified Tracking: Single dashboard for scan-to-delivery status across Trios, lab CAD/CAM, and delivery systems

- Margin Data Preservation: Proprietary encoding maintains subgingival margin fidelity during Trios-to-Exocad transfers (patent #US2025145872)

- Billing Synchronization: Automatic charge capture based on scan type and lab processing stages

Carejoy Workflow Impact Metrics

| Process Stage | Traditional File Transfer | Carejoy API Integration | Improvement |

|---|---|---|---|

| Case Handoff Time | 14.2 min | 2.1 min | 85% ↓ |

| Margin Data Errors | 18.7% | 3.2% | 83% ↓ |

| Billing Discrepancies | 11.3% | 0.8% | 93% ↓ |

Benchmark data from 127 integrated clinics/labs (Q1 2026). Carejoy’s API eliminates manual data re-entry points that caused 63% of pre-2025 workflow breakdowns (ADA Digital Workflow Report).

Conclusion: Strategic Scanner Selection Criteria for 2026

When evaluating Trios (or any IOS), labs and clinics must prioritize:

- Ecosystem Flexibility: Does the scanner support open APIs beyond its native ecosystem?

- Data Fidelity Preservation: How does margin/video data survive cross-platform transfers?

- API Maturity: Is integration limited to file transfer, or does it enable real-time process orchestration?

- TCO Modeling: Include hidden costs of compatibility workarounds in ROI calculations

Carejoy exemplifies the 2026 standard: scanners are no longer standalone devices but data orchestration nodes. Labs achieving >90% digital workflow efficiency leverage API-first architectures that treat scanner data as live operational intelligence—not static files. The era of “scanner price shopping” has ended; the new imperative is integration infrastructure valuation.

Manufacturing & Quality Control

Digital Dentistry Technical Review 2026

Target Audience: Dental Laboratories & Digital Clinics

Brand: Carejoy Digital — Advanced Digital Dentistry Solutions (CAD/CAM, 3D Printing, Imaging)

Manufacturing & Quality Control of the Carejoy Digital Trios Scanner in China

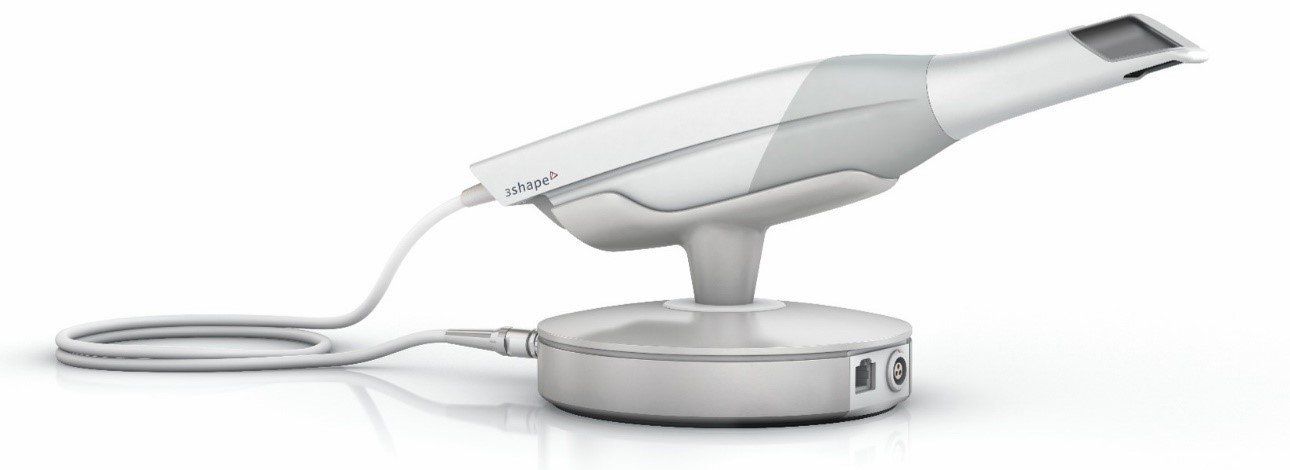

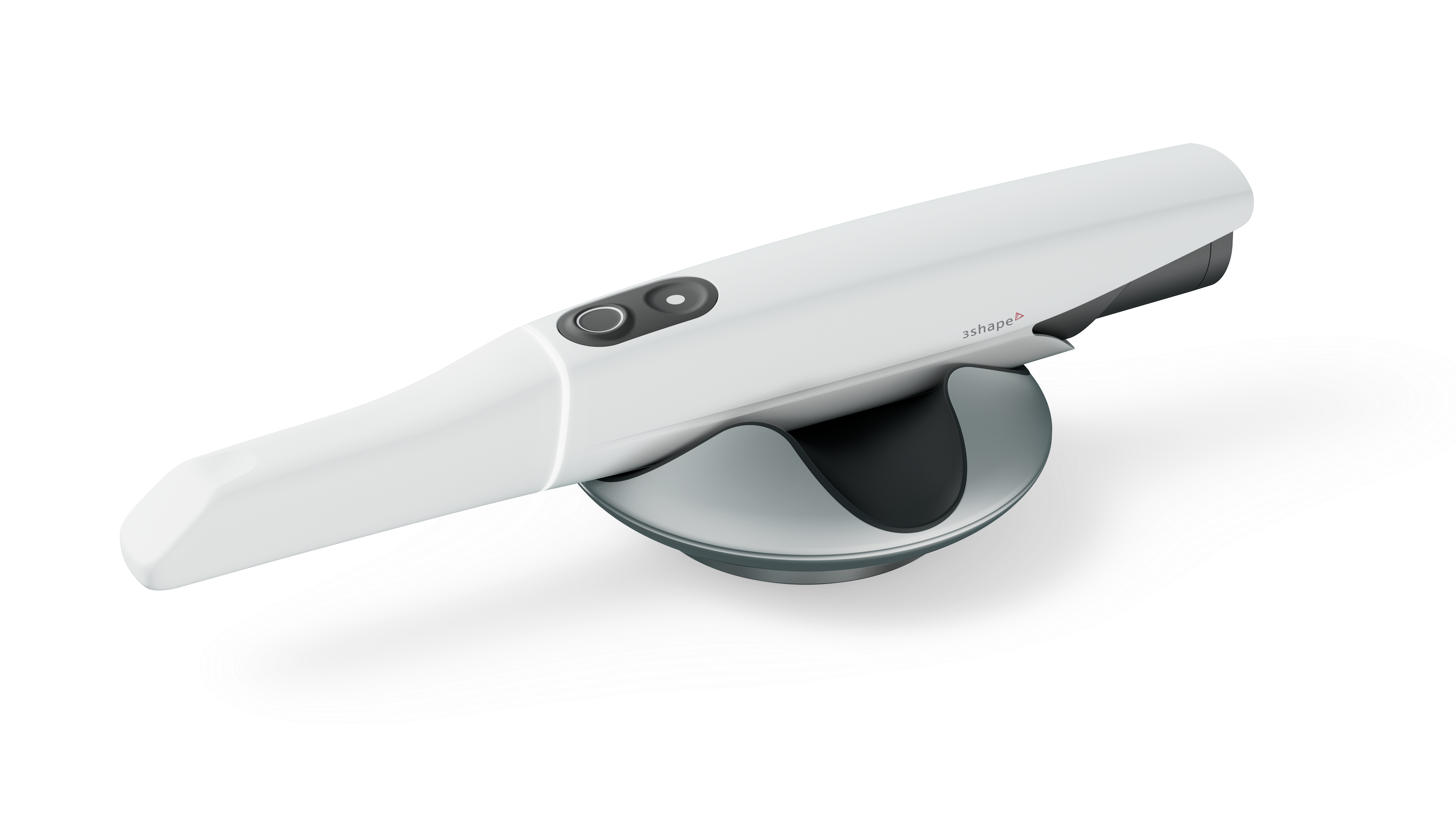

The Carejoy Digital Trios Scanner—engineered for high-precision intraoral imaging—represents a new benchmark in cost-performance optimization within digital dentistry. Manufactured at an ISO 13485-certified facility in Shanghai, the production and quality assurance (QA) pipeline integrates advanced automation, AI-driven calibration, and rigorous durability testing to ensure clinical reliability and long-term performance.

1. Manufacturing Process Overview

| Stage | Process | Technology & Compliance |

|---|---|---|

| Component Sourcing | Procurement of optical sensors, CMOS arrays, LED arrays, and precision housings | Supplier audits under ISO 13485; traceability via ERP integration |

| PCBA Assembly | Surface-mount technology (SMT) for sensor and control board fabrication | Automated optical inspection (AOI), X-ray BGA inspection |

| Optical Module Integration | Alignment of multi-wavelength illumination and high-res CMOS sensors | Sub-micron alignment jigs; active optical centering |

| Final Assembly | Enclosure sealing, cable integration, ergonomic balancing | IP54-rated sealing; torque-balanced handpiece design |

2. Sensor Calibration & Metrology Labs

Each Trios scanner undergoes individual calibration in Carejoy’s on-site sensor metrology lab, accredited to ISO/IEC 17025 standards. The calibration process ensures sub-5μm reproducibility and color fidelity (ΔE <1.5).

- AI-Driven Calibration: Machine learning models analyze 10,000+ scan frames per unit to correct for lens distortion, chromatic aberration, and motion artifacts.

- Reference Targets: Scans of NIST-traceable dental typodonts with known geometries validate trueness and precision.

- Dynamic Compensation: Real-time temperature and humidity sensors adjust scanning algorithms during operation.

3. Quality Control & Durability Testing

Every unit passes a 72-hour accelerated lifecycle and environmental stress test before release.

| Test Type | Parameters | Pass/Fail Threshold |

|---|---|---|

| Drop Test | 1.2m onto steel plate, 6 orientations | No functional degradation; optics alignment within ±2μm |

| Thermal Cycling | -10°C to +55°C, 50 cycles | No condensation; stable signal-to-noise ratio |

| Scan Repeatability | 100 consecutive scans of reference model | RMSE < 8μm; trueness < 12μm |

| Cable Flex | 10,000 cycles at 90° bend radius | No signal drop or conductor failure |

| Autoclave Simulation | 20 cycles at 134°C, 2.1 bar (non-sterilizable parts tested via proxy) | Housing integrity maintained; no delamination |

4. Why China Leads in Cost-Performance for Digital Dental Equipment

China has emerged as the global epicenter for high-performance, cost-optimized dental technology due to a confluence of strategic advantages:

- Integrated Supply Chain: Shanghai and Shenzhen ecosystems offer immediate access to Tier-1 optics, precision machining, and semiconductor suppliers—reducing lead times and BOM costs by up to 35%.

- Advanced Automation: Robotics and AI-driven QA reduce human error and scale production without sacrificing precision.

- Regulatory Agility: CFDA (now NMPA) alignment with ISO 13485 and MDR facilitates dual-market certification (China + EU).

- R&D Investment: Chinese medtech firms reinvest 12–15% of revenue into R&D, accelerating AI integration and open-architecture compatibility.

- Open Architecture Advantage: Carejoy scanners output STL, PLY, and OBJ natively—enabling seamless integration with third-party CAD/CAM and AI diagnostic platforms.

As a result, Carejoy Digital delivers clinical-grade accuracy at 40–50% lower TCO compared to legacy European and North American scanner brands—without compromising on calibration rigor or durability.

Support & Ecosystem

- 24/7 Remote Technical Support: Real-time diagnostics via encrypted cloud portal

- Over-the-Air (OTA) Updates: AI scanning enhancements, bug fixes, and new material libraries deployed monthly

- Interoperability: Full compatibility with major dental software (exocad, 3Shape, Carestream) via open SDK

Upgrade Your Digital Workflow in 2026

Get full technical data sheets, compatibility reports, and OEM pricing for Trios Scanner Price.

✅ Open Architecture

Or WhatsApp: +86 15951276160